ASTM D3217-07

(Test Method)Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

SIGNIFICANCE AND USE

Both the loop breaking tenacity and the knot breaking tenacity, calculated from the breaking force measured under the conditions specified herein and the linear density of the fiber, are fundamental properties that are used to establish limitations on fiber-processing and upon their end-use applications. Physical properties, such as brittleness, not well defined by tests for breaking force and elongation can be estimated from the ratio of breaking tenacity measured in loop or knot tests, or both, and the normal tenacity as measured by Test Method D 3822.

This test method is not recommended for acceptance testing of commercial shipments in the absence of reliable information on between-laboratory precision (see Note 3). In some cases the purchaser and the supplier may have to test a commercial shipment of one or more specific materials by the best available method, even though the method has not been recommended for acceptance testing of commercial shipments. In such a case, if there is a disagreement arising from differences in values reported by the purchaser and the supplier when using this test method for acceptance testing, the statistical bias, if any, between the laboratory of the purchaser and the laboratory of the supplier should be determined with each comparison being based on testing specimens randomly drawn from one sample of material of the type being evaluated.

SCOPE

1.1 These test methods cover the measurement of the breaking tenacity of manufactured textile fibers taken from filament yarns, staple, or tow fiber, either crimped or uncrimped, and tested in either a double loop or as a strand formed into a single overhand knot.

1.2 Methods for measuring the breaking tenacity of conditioned and wet (immersed) fibers in loop and knot form are included.

1.3 Elongation in loop or knot tests has no known significance, and is usually not recorded.

1.4 The basic distinction between the procedures described in these test methods and those included in Test Methods D 2101 is the configuration of the specimen, that is, either as a double loop or in the configuration of a single overhand knot.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3217 −07

StandardTest Methods for

Breaking Tenacity of Manufactured Textile Fibers in Loop or

1

Knot Configurations

This standard is issued under the fixed designation D3217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2258 Practice for Sampling Yarn for Testing

D3333 Practice for Sampling Manufactured Staple Fibers,

1.1 These test methods cover the measurement of the

Sliver, or Tow for Testing

breaking tenacity of manufactured textile fibers taken from

D3822 Test Method for Tensile Properties of Single Textile

filament yarns, staple, or tow fiber, either crimped or

Fibers

uncrimped, and tested in either a double loop or as a strand

D4849 Terminology Related to Yarns and Fibers

formed into a single overhand knot.

1.2 Methods for measuring the breaking tenacity of condi-

3. Terminology

tioned and wet (immersed) fibers in loop and knot form are

3.1 For all terminology relating to D13.58, Yarns and

included.

Fibers, refer to Terminology D4849.

1.3 Elongation in loop or knot tests has no known

3.1.1 The following terms are relevant to this standard:

significance, and is usually not recorded.

breaking force, breaking tenacity, linear density for fiber and

1.4 The basic distinction between the procedures described

yarn, manufactured staple fiber, tenacity.

in these test methods and those included in Test Methods

3.2 For all other terminology related to textiles, refer to

D2101 is the configuration of the specimen, that is, either as a

Terminology D123.

double loop or in the configuration of a single overhand knot.

1.5 This standard does not purport to address all of the

4. Summary of Test Methods

safety concerns, if any, associated with its use. It is the

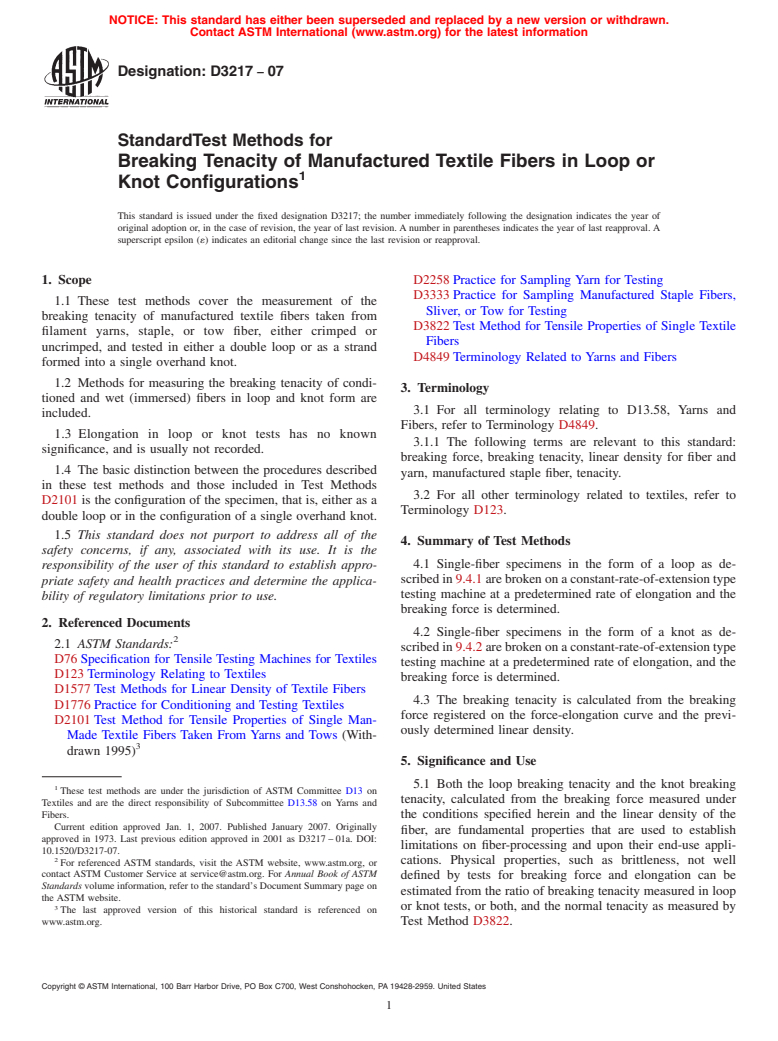

4.1 Single-fiber specimens in the form of a loop as de-

responsibility of the user of this standard to establish appro-

scribedin9.4.1arebrokenonaconstant-rate-of-extensiontype

priate safety and health practices and determine the applica-

testing machine at a predetermined rate of elongation and the

bility of regulatory limitations prior to use.

breaking force is determined.

2. Referenced Documents

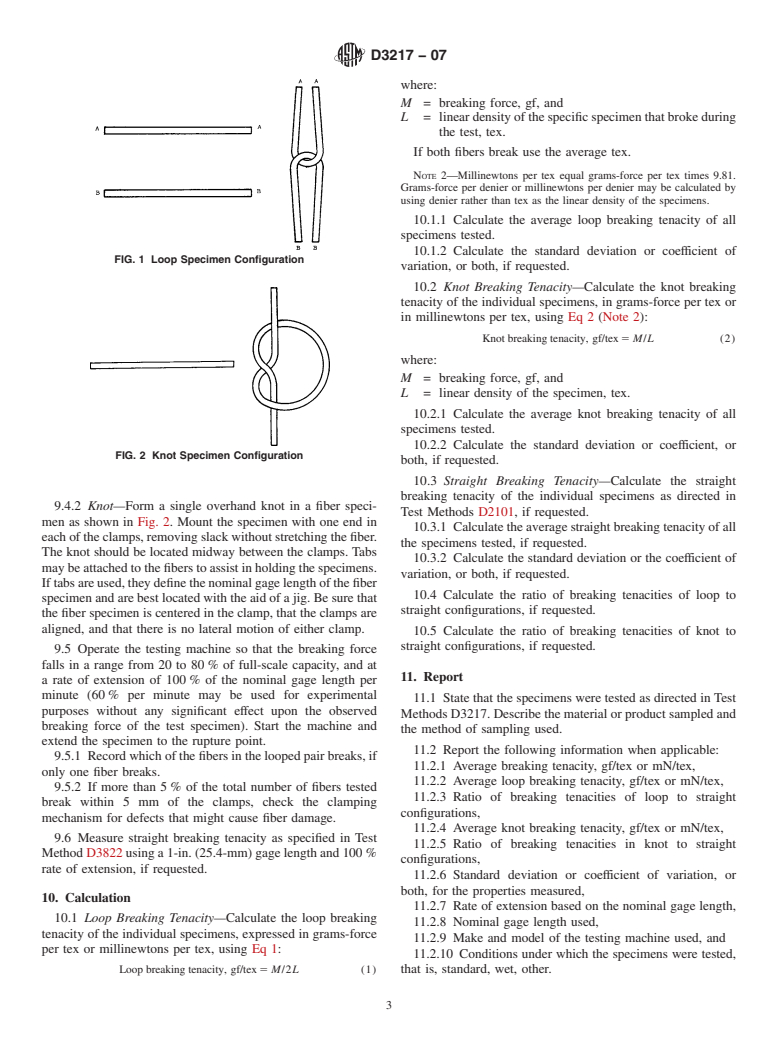

4.2 Single-fiber specimens in the form of a knot as de-

2

2.1 ASTM Standards:

scribedin9.4.2arebrokenonaconstant-rate-of-extensiontype

D76 Specification for Tensile Testing Machines for Textiles

testing machine at a predetermined rate of elongation, and the

D123 Terminology Relating to Textiles

breaking force is determined.

D1577 Test Methods for Linear Density of Textile Fibers

4.3 The breaking tenacity is calculated from the breaking

D1776 Practice for Conditioning and Testing Textiles

force registered on the force-elongation curve and the previ-

D2101 Test Method for Tensile Properties of Single Man-

ously determined linear density.

Made Textile Fibers Taken From Yarns and Tows (With-

3

drawn 1995)

5. Significance and Use

5.1 Both the loop breaking tenacity and the knot breaking

1

These test methods are under the jurisdiction of ASTM Committee D13 on

tenacity, calculated from the breaking force measured under

Textiles and are the direct responsibility of Subcommittee D13.58 on Yarns and

Fibers.

the conditions specified herein and the linear density of the

Current edition approved Jan. 1, 2007. Published January 2007. Originally

fiber, are fundamental properties that are used to establish

approved in 1973. Last previous edition approved in 2001 as D3217 – 01a. DOI:

limitations on fiber-processing and upon their end-use appli-

10.1520/D3217-07.

2

cations. Physical properties, such as brittleness, not well

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

defined by tests for breaking force and elongation can be

Standards volume information, refer to the standard’s Document Summary page on

estimated from the ratio of breaking tenacity measured in loop

the ASTM website.

3

or knot tests, or both, and the normal tenacity as measured by

The last approved version of this historical standard is referenced on

www.astm.org. Test Method D3822.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3217−07

5.2 This test method is not recommended for acceptance random which shipping containers are to have each number of

testing of commercial shipments in the absence of reliable laboratory units drawn.

information on between-laboratory precision (see Note 3). In 7.2.1 For Staple Fiber—Take 50-g samples from laboratory

some cases the purchaser and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.