ASTM D3217-01a

(Test Method)Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

Standard Test Methods for Breaking Tenacity of Manufactured Textile Fibers in Loop or Knot Configurations

SCOPE

1.1 These test methods cover the measurement of the breaking tenacity of manufactured textile fibers taken from filament yarns, staple, or tow fiber, either crimped or uncrimped, and tested in either a double loop or as a strand formed into a single overhand knot.

1.2 Methods for measuring the breaking tenacity of conditioned and wet (immersed) fibers in loop and knot form are included.

1.3 Elongation in loop or knot tests has no known significance, and is usually not recorded.

1.4 The basic distinction between the procedures described in these test methods and those included in Test Methods D2101 is the configuration of the specimen, that is, either as a double loop or in the configuration of a single overhand knot.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3217 – 01a

Standard Test Methods for

Breaking Tenacity of Manufactured Textile Fibers in Loop or

1

Knot Configurations

This standard is issued under the fixed designation D 3217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3822 Test Method forTensile Properties of SingleTextile

3

Fibers

1.1 These test methods cover the measurement of the

D 4848 Terminology of Force, Deformation, and Related

breaking tenacity of manufactured textile fibers taken from

3

Properties of Textiles

filament yarns, staple, or tow fiber, either crimped or un-

crimped, and tested in either a double loop or as a strand

3. Terminology

formed into a single overhand knot.

3.1 Definitions:

1.2 Methods for measuring the breaking tenacity of condi-

3.1.1 breaking force, n—the maximum force applied to a

tioned and wet (immersed) fibers in loop and knot form are

material carried to rupture.

included.

3.1.1.1 Discussion—Force is commonly expressed in

1.3 Elongation in loop or knot tests has no known signifi-

grams-force (gf ), kilograms-force (kgf ), pounds-force (lbf),

cance, and is usually not recorded.

newtons (N), or millinewtons (mN).

1.4 The basic distinction between the procedures described

3.1.2 breaking tenacity, n—the tenacity at the breaking

in these test methods and those included in Test Methods

force.

D 2101 is the configuration of the specimen, that is, either as a

3.1.2.1 Discussion—Breaking tenacity is commonly ex-

double loop or in the configuration of a single overhand knot.

pressed as grams-force per tex (gf/tex), grams-force per denier

1.5 This standard does not purport to address all of the

(gf/den), millinewtons per tex (mN/tex), or grams-force per

safety concerns, if any, associated with its use. It is the

denier (gf/den). Millinewtons are numerically equal to grams-

responsibility of the user of this standard to establish appro-

force times 9.81.

priate safety and health practices and determine the applica-

3.1.2.2 Discussion—The breaking tenacity is calculated

bility of regulatory limitations prior to use.

from the breaking force and the linear density of the unstrained

2. Referenced Documents specimen, or obtained directly from tensile testing machines

which can be suitably adjusted to indicate tenacity instead of

2.1 ASTM Standards:

breaking force, for specimens of known linear density.

D 76 Specification for Tensile Testing Machines for Tex-

2

3.1.3 linear density, nfor fiber and yarn,—mass per unit

tiles

2 length.

D 123 Terminology Relating to Textiles

2

3.1.3.1 Discussion—The preferred units of measurement

D 1577 Test Methods for Linear Density of Textile Fibers

2 are grams and metres, or multiples or submultiples of these.

D 1776 Practice for Conditioning and Testing Textiles

2

The tex unit, grams per kilometre, is recommended for yarns.

D 2258 Practice for Sampling Yarn for Testing

3.1.4 manufactured staple fiber, n—fiber of spinnable

D 3333 Practice for Sampling Manufactured Staple Fibers,

3

length manufactured directly or by cutting filaments.

Sliver, or Tow for Testing

3.1.4.1 Discussion—Man-made staple fiber does not in-

clude cut waste.

3.1.5 tenacity, n—in a tensile test, the force exerted on the

1

These test methods are under the jurisdiction of ASTM Committee D13 on

specimenbasedonthelineardensityoftheunstrainedmaterial.

Textiles and are the direct responsibility of Subcommittee D13.58 onYarn and Fiber

Test Methods.

3.1.5.1 Discussion—Tenacity is commonly expressed as

Current edition approved September 10, 2001. Published November 2001.

grams-force per tex (gf/tex), grams-force per denier (gf/den),

Originally published as D 3217 – 73 T. Last previous edition D 3217 – 01.

2 millinewtons per tex (mN/tex), or grams-force per denier

Annual Book of ASTM Standards, Vol 07.01.

3

Annual Book of ASTM Standards, Vol 07.02. (gf/den).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 3217 – 01a

3.1.6 For definitions of other textile terms used in these test 6.4 Jig, to aid in accurately mounting specimens on tabs at

methods, refer to Terminology D 123. For definitions of other the specified gage length.

terms related to force and deformation in textiles, refer to

7. Sampling

Terminology D 4848.

7.1 Lot Sampling—As a lot sample for acceptance testing,

4. Summary of Test Methods

take at random the number of shipping containers directed in

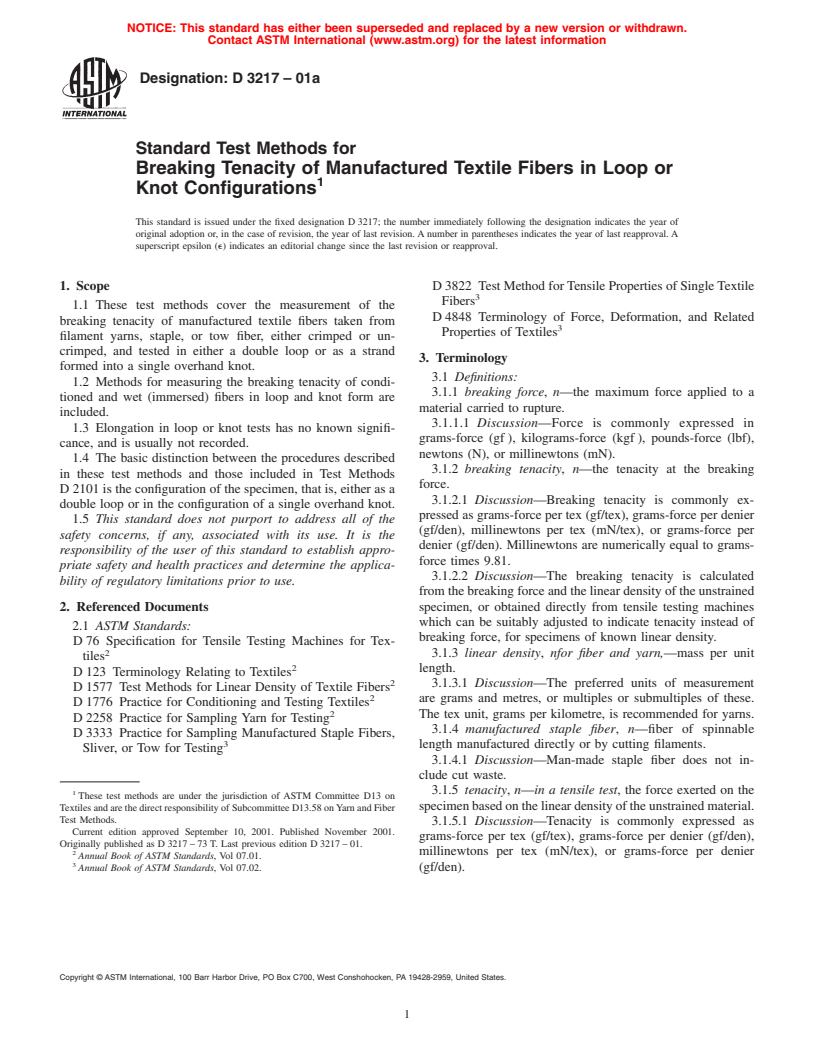

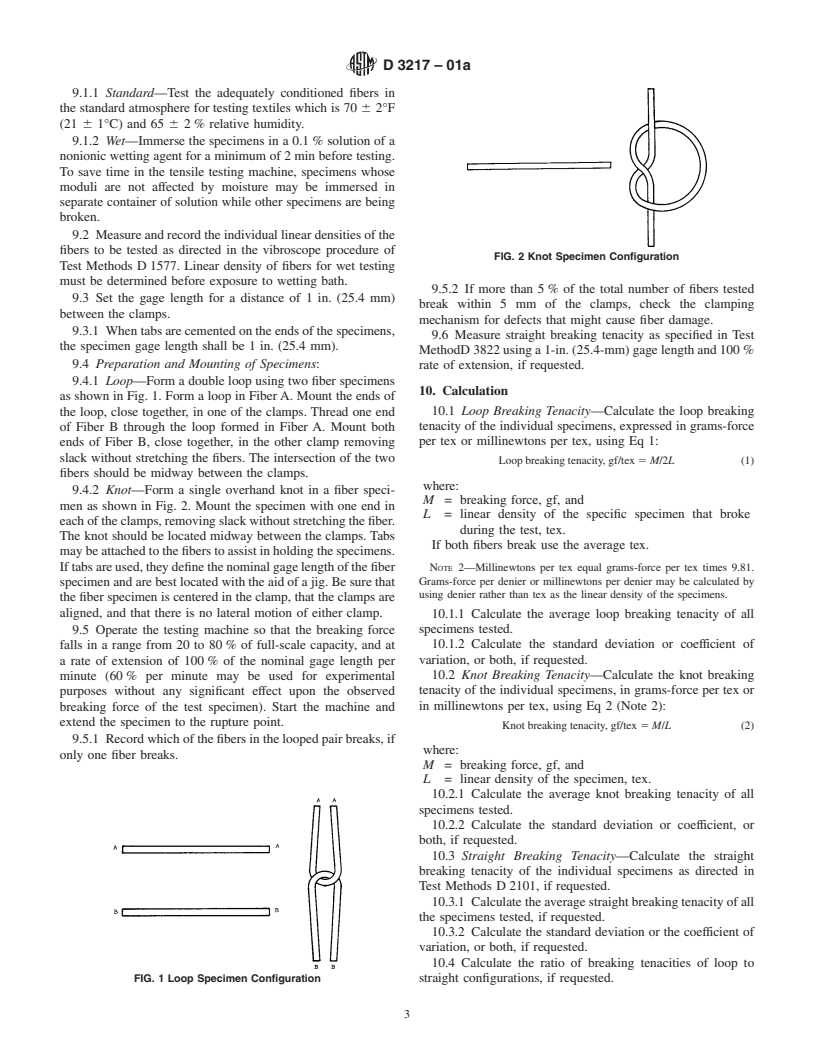

4.1 Single-fiber specimens in the form of a loop as de- the applicable material specification or other agreement be-

scribedin9.4.1arebr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.