ASTM C793-05

(Test Method)Standard Test Method for Effects of Laboratory Accelerated Weathering on Elastomeric Joint Sealants

Standard Test Method for Effects of Laboratory Accelerated Weathering on Elastomeric Joint Sealants

SIGNIFICANCE AND USE

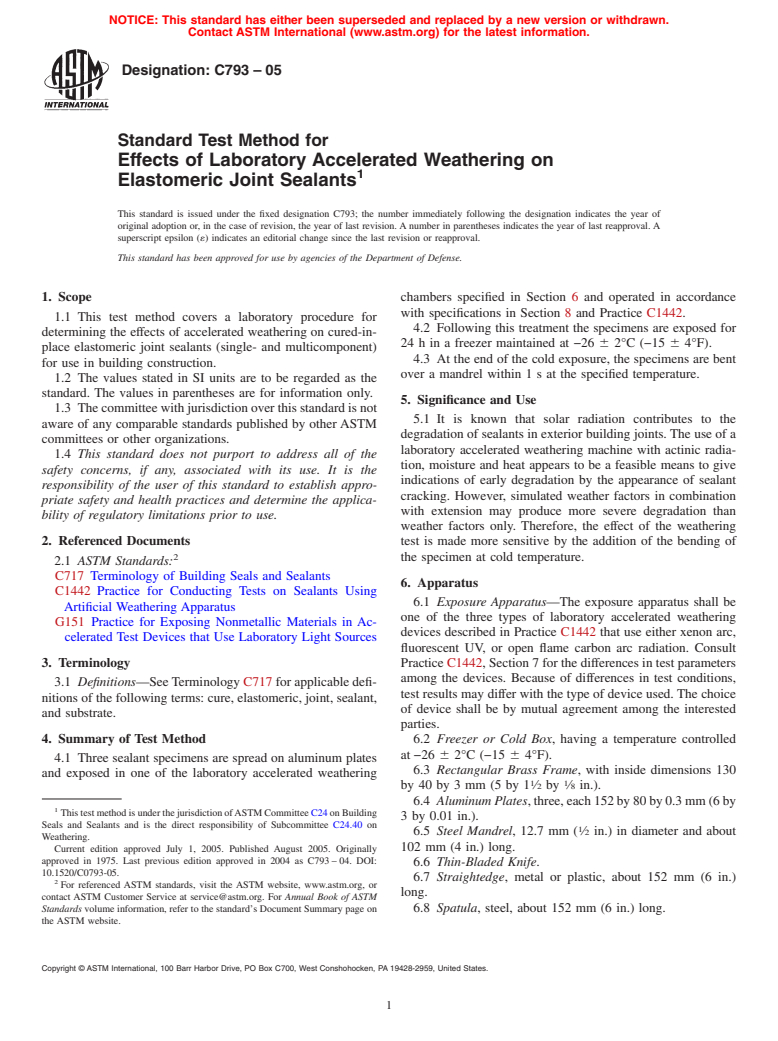

It is known that solar radiation contributes to the degradation of sealants in exterior building joints. The use of a laboratory accelerated weathering machine with actinic radiation, moisture and heat appears to be a feasible means to give indications of early degradation by the appearance of sealant cracking. However, simulated weather factors in combination with extension may produce more severe degradation than weather factors only. Therefore, the effect of the weathering test is made more sensitive by the addition of the bending of the specimen at cold temperature.

SCOPE

1.1 This test method covers a laboratory procedure for determining the effects of accelerated weathering on cured-in-place elastomeric joint sealants (single- and multicomponent) for use in building construction.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 The committee with jurisdiction over this standard is not aware of any comparable standards published by other ASTM committees or other organizations.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C793–05

Standard Test Method for

Effects of Laboratory Accelerated Weathering on

1

Elastomeric Joint Sealants

This standard is issued under the fixed designation C793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope chambers specified in Section 6 and operated in accordance

with specifications in Section 8 and Practice C1442.

1.1 This test method covers a laboratory procedure for

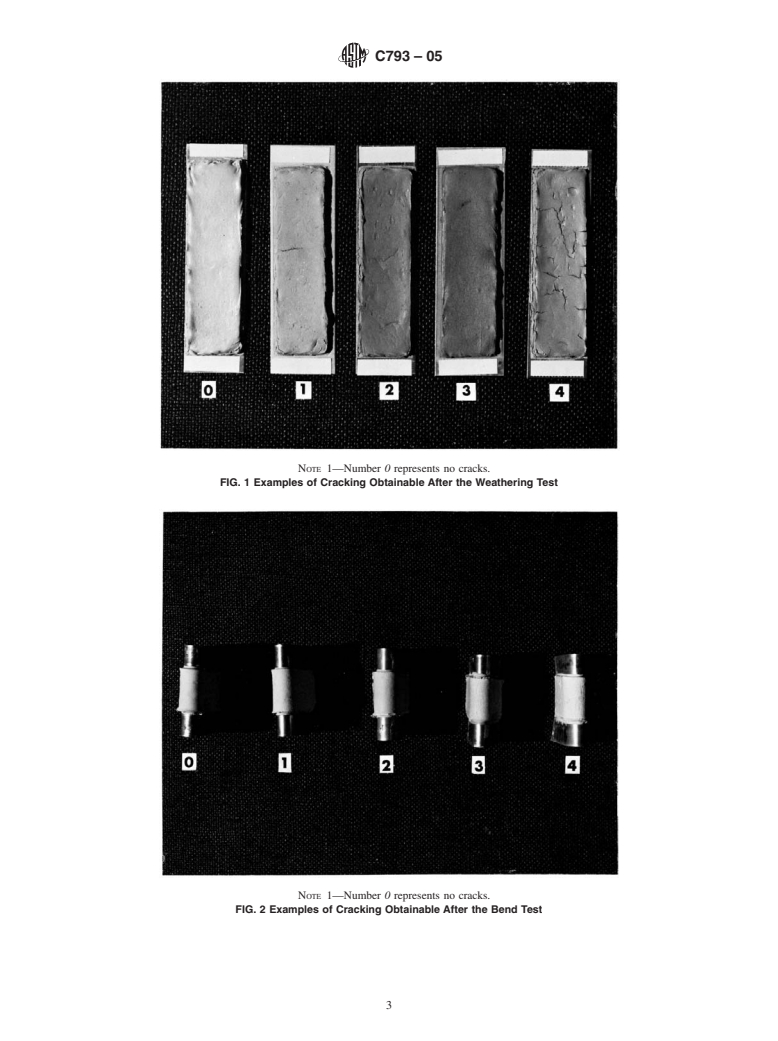

4.2 Following this treatment the specimens are exposed for

determining the effects of accelerated weathering on cured-in-

24 h in a freezer maintained at −26 6 2°C (−15 6 4°F).

place elastomeric joint sealants (single- and multicomponent)

4.3 At the end of the cold exposure, the specimens are bent

for use in building construction.

over a mandrel within1satthe specified temperature.

1.2 The values stated in SI units are to be regarded as the

standard. The values in parentheses are for information only.

5. Significance and Use

1.3 Thecommitteewithjurisdictionoverthisstandardisnot

5.1 It is known that solar radiation contributes to the

aware of any comparable standards published by otherASTM

degradation of sealants in exterior building joints.The use of a

committees or other organizations.

laboratory accelerated weathering machine with actinic radia-

1.4 This standard does not purport to address all of the

tion, moisture and heat appears to be a feasible means to give

safety concerns, if any, associated with its use. It is the

indications of early degradation by the appearance of sealant

responsibility of the user of this standard to establish appro-

cracking. However, simulated weather factors in combination

priate safety and health practices and determine the applica-

with extension may produce more severe degradation than

bility of regulatory limitations prior to use.

weather factors only. Therefore, the effect of the weathering

2. Referenced Documents test is made more sensitive by the addition of the bending of

2

the specimen at cold temperature.

2.1 ASTM Standards:

C717 Terminology of Building Seals and Sealants

6. Apparatus

C1442 Practice for Conducting Tests on Sealants Using

6.1 Exposure Apparatus—The exposure apparatus shall be

Artificial Weathering Apparatus

one of the three types of laboratory accelerated weathering

G151 Practice for Exposing Nonmetallic Materials in Ac-

devices described in Practice C1442 that use either xenon arc,

celerated Test Devices that Use Laboratory Light Sources

fluorescent UV, or open flame carbon arc radiation. Consult

3. Terminology PracticeC1442,Section7forthedifferencesintestparameters

among the devices. Because of differences in test conditions,

3.1 Definitions—SeeTerminologyC717forapplicabledefi-

test results may differ with the type of device used.The choice

nitions of the following terms: cure, elastomeric, joint, sealant,

of device shall be by mutual agreement among the interested

and substrate.

parties.

4. Summary of Test Method

6.2 Freezer or Cold Box, having a temperature controlled

at−26 6 2°C (−15 6 4°F).

4.1 Three sealant specimens are spread on aluminum plates

6.3 Rectangular Brass Frame, with inside dimensions 130

and exposed in one of the laboratory accelerated weathering

1 1

by40by3mm(5by1 ⁄2 by ⁄8 in.).

6.4 Aluminum Plates,three,each152by80by0.3mm(6by

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

3 by 0.01 in.).

Seals and Sealants and is the direct responsibility of Subcommittee C24.40 on

1

6.5 Steel Mandrel, 12.7 mm ( ⁄2 in.) in diameter and about

Weathering.

102 mm (4 in.) long.

Current edition approved July 1, 2005. Published August 2005. Originally

approved in 1975. Last previous edition approved in 2004 as C793–04. DOI:

6.6 Thin-Bladed Knife.

10.1520/C0793-05.

6.7 Straightedge, metal or plastic, about 152 mm (6 in.)

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

long.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 6.8 Spatula, steel, about 152 mm (6 in.) long.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C793–05

arc exposure time required to obtain the same radiant exposure at other

7. Standard Test Conditions

irradiance levels.

7.1 Unless otherwise specified by those authorizing the test,

8.1.4 At the end of exposure, remove the specimens from

standardconditionsshallbeasde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.