ASTM C1656-13

(Guide)Standard Guide for Measuring the Reactivity of Hydraulic Refractory Castables using Exothermic Profile

Standard Guide for Measuring the Reactivity of Hydraulic Refractory Castables using Exothermic Profile

SIGNIFICANCE AND USE

4.1 The heat of hydration of a calcium aluminate based castable is liberated over a short period of time (as compared to Portland cement). This makes it easy to measure the heat profile using off-the-shelf thermocouple equipment.

4.2 The heat profile can be used to make inferences about the setting and strength gain behavior of a castable and sometimes the working time of a castable.

4.3 Factors that should be controlled when comparing two castables include: size, shape and mass of cast object, start temperature of the mix, temperature of environment, and the thermal conductivity of the environment. If these factors are held constant, then the two castables heat profiles can be compared.

4.4 The temperature increase created by the castable exothermic reaction shall be at least 2.0°C more than the normal fluctuation of the laboratory temperature so that the time of this increase is easily discernible to the user.

4.5 Varying the amount of cement in the castable, the amount of water, the type and quantity of admixtures, and so forth, will change the shape, maximum temperature and time to maximum temperature of the curve.

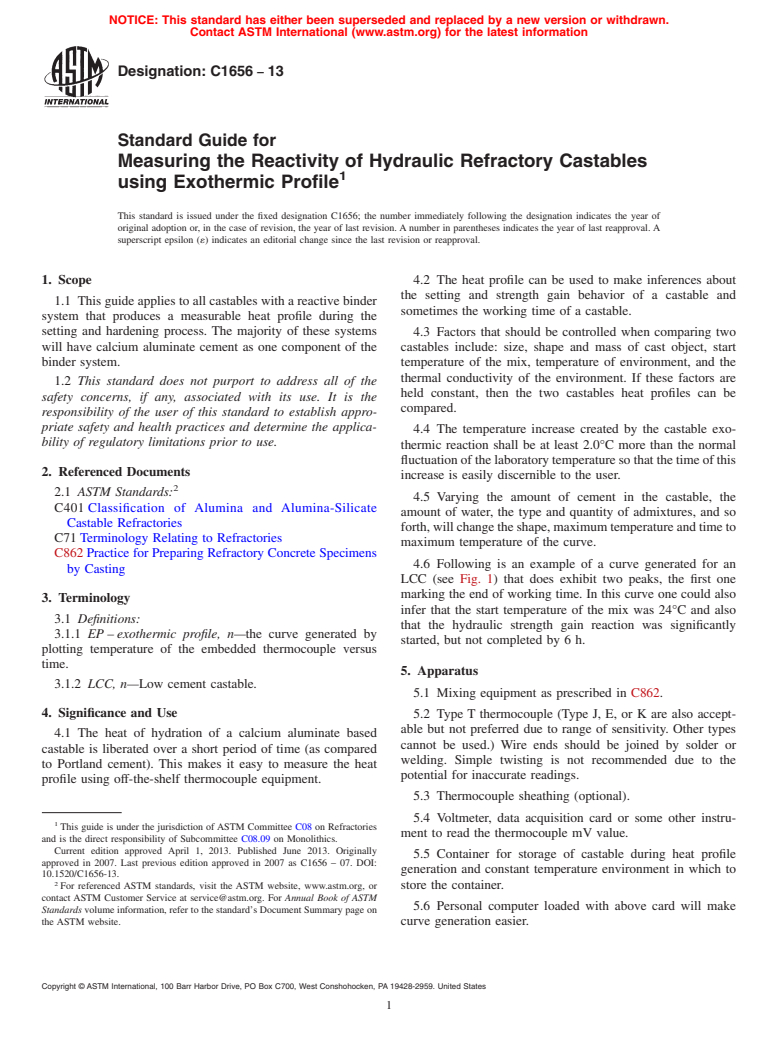

4.6 Following is an example of a curve generated for an LCC (see Fig. 1) that does exhibit two peaks, the first one marking the end of working time. In this curve one could also infer that the start temperature of the mix was 24°C and also that the hydraulic strength gain reaction was significantly started, but not completed by 6 h.

SCOPE

1.1 This guide applies to all castables with a reactive binder system that produces a measurable heat profile during the setting and hardening process. The majority of these systems will have calcium aluminate cement as one component of the binder system.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use .

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1656 −13

Standard Guide for

Measuring the Reactivity of Hydraulic Refractory Castables

1

using Exothermic Profile

This standard is issued under the fixed designation C1656; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 The heat profile can be used to make inferences about

the setting and strength gain behavior of a castable and

1.1 This guide applies to all castables with a reactive binder

sometimes the working time of a castable.

system that produces a measurable heat profile during the

setting and hardening process. The majority of these systems

4.3 Factors that should be controlled when comparing two

will have calcium aluminate cement as one component of the castables include: size, shape and mass of cast object, start

binder system.

temperature of the mix, temperature of environment, and the

thermal conductivity of the environment. If these factors are

1.2 This standard does not purport to address all of the

held constant, then the two castables heat profiles can be

safety concerns, if any, associated with its use. It is the

compared.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.4 The temperature increase created by the castable exo-

bility of regulatory limitations prior to use.

thermic reaction shall be at least 2.0°C more than the normal

fluctuation of the laboratory temperature so that the time of this

2. Referenced Documents

increase is easily discernible to the user.

2

2.1 ASTM Standards:

4.5 Varying the amount of cement in the castable, the

C401 Classification of Alumina and Alumina-Silicate

amount of water, the type and quantity of admixtures, and so

Castable Refractories

forth,willchangetheshape,maximumtemperatureandtimeto

C71 Terminology Relating to Refractories

maximum temperature of the curve.

C862 Practice for Preparing Refractory Concrete Specimens

4.6 Following is an example of a curve generated for an

by Casting

LCC (see Fig. 1) that does exhibit two peaks, the first one

marking the end of working time. In this curve one could also

3. Terminology

infer that the start temperature of the mix was 24°C and also

3.1 Definitions:

that the hydraulic strength gain reaction was significantly

3.1.1 EP – exothermic profile, n—the curve generated by

started, but not completed by 6 h.

plotting temperature of the embedded thermocouple versus

time.

5. Apparatus

3.1.2 LCC, n—Low cement castable.

5.1 Mixing equipment as prescribed in C862.

4. Significance and Use

5.2 Type T thermocouple (Type J, E, or K are also accept-

able but not preferred due to range of sensitivity. Other types

4.1 The heat of hydration of a calcium aluminate based

cannot be used.) Wire ends should be joined by solder or

castable is liberated over a short period of time (as compared

welding. Simple twisting is not recommended due to the

to Portland cement). This makes it easy to measure the heat

potential for inaccurate readings.

profile using off-the-shelf thermocouple equipment.

5.3 Thermocouple sheathing (optional).

5.4 Voltmeter, data acquisition card or some other instru-

1

This guide is under the jurisdiction of ASTM Committee C08 on Refractories

ment to read the thermocouple mV value.

and is the direct responsibility of Subcommittee C08.09 on Monolithics.

Current edition approved April 1, 2013. Published June 2013. Originally

5.5 Container for storage of castable during heat profile

approved in 2007. Last previous edition approved in 2007 as C1656 – 07. DOI:

generation and constant temperature environment in which to

10.1520/C1656-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or store the container.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.6 Personal computer loaded with above card will make

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. curve generation easier.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1656−13

FIG. 1Example of LCC Exo Profile

6. Hazards ally at desired time intervals (note the mV (or temperature)

reading readjusting your time 0 from the water addition point

6.1 Therearenoknownhazardsassociatedwiththemethod.

or automatically with a PC) by using a strip recorder or

Safe practice should be used when mixing the castable.

automatically gathering the information with a PC outfitted

Castable MSDS should be consulted to determine if any

with the correct hardware to re

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1656 − 07 C1656 − 13

Standard Guide for

Measuring the Reactivity of Hydraulic Refractory Castables

1

using Exothermic Profile

This standard is issued under the fixed designation C1656; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide applies to all castables with a reactive binder system that produces a measurable heat profile during the setting

and hardening process. The majority of these systems will have calcium aluminate cement as one component of the binder system.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory

limitations prior to use .

2. Referenced Documents

2

2.1 ASTM Standards:

C401 Classification of Alumina and Alumina-Silicate Castable Refractories

C71 Terminology Relating to Refractories

C862 Practice for Preparing Refractory Concrete Specimens by Casting

3. Terminology

3.1 Definitions:

3.1.1 EP – exothermic profile, n— the curve generated by plotting temperature of the embedded thermocouple versus time.

3.1.2 LCC, n—Low cement castable

4. Significance and Use

4.1 The heat of hydration of a calcium aluminate based castable is liberated over a short period of time (as compared to Portland

cement). This makes it easy to measure the heat profile using off-the-shelf thermocouple equipment.

4.2 The heat profile can be used to make inferences about the setting and strength gain behavior of a castable and sometimes

the working time of a castable.

4.3 Factors that should be controlled when comparing two castables include: size, shape and mass of cast object, start

temperature of the mix, temperature of environment, and the thermal conductivity of the environment. If these factors are held

constant, then the two castables heat profiles can be compared.

4.4 The amount of heat rise temperature increase created by the castable shall be a minimum of 5°F. If this is not achieved, then

either a larger sample or better insulation (or both) should be used to increase the measurable heat release.exothermic reaction shall

be at least 2.0°C more than the normal fluctuation of the laboratory temperature so that the time of this increase is easily discernible

to the user.

4.5 Varying the amount of cement in the castable, the amount of water, the type and quantity of admixtures, and so forth, will

change the shape, maximum temperature and time to maximum temperature of the curve.

4.6 Following is an example of a curve generated for an LCC (see Fig. 1) that does exhibit two peaks, the first one marking

the end of working time. In this curve one could also infer that the start temperature of the mix was 24°C and also that the hydraulic

strength gain reaction was significantly started, but not completed by 6 h.

1

This guide is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.09 on Monolithics.

Current edition approved March 1, 2007April 1, 2013. Published April 2007June 2013. Originally approved in 2007. Last previous edition approved in 2007 as C1656-07.

DOI: 10.1520/C1656-07.10.1520/C1656-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1656 − 13

FIG. 1 Example of LCC Exo Profile

5. Apparatus

5.1 Mixing equipment as prescribed in C862.

5.2 Type T thermocouple (Type J, E, or K are also acceptable but not preferred due to range of sensitivity. Other types cannot

be used.) Wire ends should be joined by solder or welding. Simple twisting is not recommended due to the potential for inaccurate

readings.

5.3 Thermocouple sheathing (optional)

5.4 Voltmeter, data acquisition card or some other instrument to read the thermocouple mV value.

5.5 Container for storage of castable during heat profile generation and constant temperature environment in which to store the

container.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.