ASTM D6159-17

(Test Method)Standard Test Method for Determination of Hydrocarbon Impurities in Ethylene by Gas Chromatography

Standard Test Method for Determination of Hydrocarbon Impurities in Ethylene by Gas Chromatography

SIGNIFICANCE AND USE

4.1 High-purity ethylene is required as a feedstock for some manufacturing processes and the presence of trace amounts of certain hydrocarbon impurities can have deleterious effects. This test method is suitable for setting specifications, for use as an internal quality control tool, and for use in development or research work.

4.2 This test method does not detect such impurities as H2O, CO, CO2, and alcohols that may be present in the sample. Hydrocarbons higher than n-decane cannot be analyzed by this test method, if present in the sample. Test Method D2504 addresses the analysis of noncondensable gases and Test Method D2505 addresses the analysis of CO2. Guide D5234 describes all potential impurities present in ethylene. These standards should be consulted when determining the total concentration of impurities in ethylene.

SCOPE

1.1 This test method covers the determination of methane, ethane, propane, propene, acetylene, iso-butane, propadiene, butane, trans-2-butene, butene-1, isobutene, cis-2-butene, methyl acetylene and 1,3-butadiene in high-purity ethylene. The purity of the ethylene can be calculated by subtracting the total percentage of all impurities from 100.00 %. Since this test method does not determine all possible impurities such as CO, CO2, H2O, alcohols, nitrogen oxides, and carbonyl sulfide, as well as hydrocarbons higher than decane, additional tests may be necessary to fully characterize the ethylene sample.

1.2 Data are reported in this test method as ppmV (parts per million by gaseous volume) and ppmMol (parts per million Mol). This test method was evaluated in an interlaboratory cooperative study in the concentration range of 4 ppmV to 340 ppmV (2 mg/kg to 204 mg/kg). The participants in the interlaboratory cooperative study reported the data in non-SI units. Wherever possible, SI units are included.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6159 − 17

Standard Test Method for

Determination of Hydrocarbon Impurities in Ethylene by Gas

1

Chromatography

This standard is issued under the fixed designation D6159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

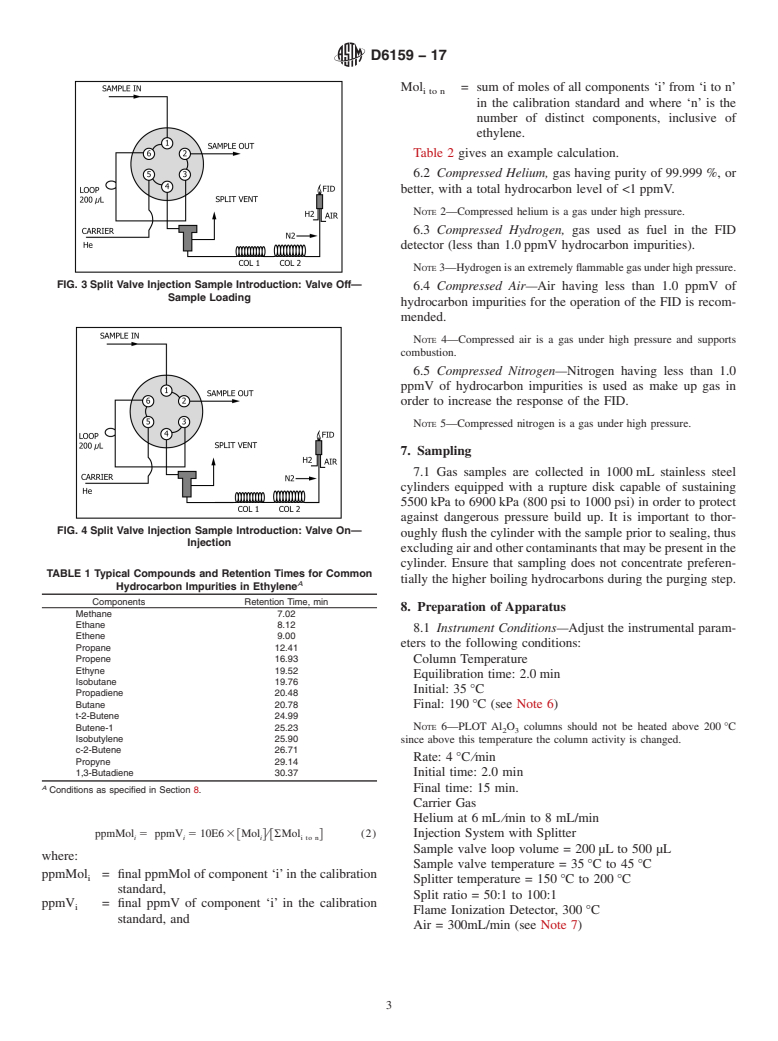

1. Scope* 3. Summary of Test Method

1.1 This test method covers the determination of methane, 3.1 A gaseous ethylene sample is analyzed as received. The

ethane, propane, propene, acetylene, iso-butane, propadiene, gaseous sample is injected into a capillary gas chromatograph.

butane, trans-2-butene, butene-1, isobutene, cis-2-butene, Sample may be introduced by direct valve injection or by split

methyl acetylene and 1,3-butadiene in high-purity ethylene. valve injection. The gas chromatograph is provided with a

The purity of the ethylene can be calculated by subtracting the 6-port sampling valve and two wide bore capillary columns

total percentage of all impurities from 100.00 %. Since this test connected in series. These columns are a dimethyl polysi-

method does not determine all possible impurities such as CO, loxane column and a porous layer open tubular column (PLOT)

CO , H O, alcohols, nitrogen oxides, and carbonyl sulfide, as Al O /KCl column. (See Note 1.) A flame ionization detector is

2 2 2 3

well as hydrocarbons higher than decane, additional tests may used for detection. The integrated detector signal (peak areas)

be necessary to fully characterize the ethylene sample. are corrected for detector response. The hydrocarbon impuri-

ties are determined and the total impurities are used to

1.2 Data are reported in this test method as ppmV (parts per

determine the ethylene content.

million by gaseous volume) and ppmMol (parts per million

Mol). This test method was evaluated in an interlaboratory

NOTE 1—This column is supplied by major column manufacturers.

cooperative study in the concentration range of 4 ppmV to

4. Significance and Use

340 ppmV (2 mg ⁄kg to 204 mg ⁄kg). The participants in the

interlaboratory cooperative study reported the data in non-SI

4.1 High-purity ethylene is required as a feedstock for some

units. Wherever possible, SI units are included.

manufacturing processes and the presence of trace amounts of

1.3 This standard does not purport to address all of the certain hydrocarbon impurities can have deleterious effects.

safety concerns, if any, associated with its use. It is the

This test method is suitable for setting specifications, for use as

responsibility of the user of this standard to establish appro- an internal quality control tool, and for use in development or

priate safety and health practices and determine the applica-

research work.

bility of regulatory limitations prior to use.

4.2 This test method does not detect such impurities as H O,

2

CO, CO , and alcohols that may be present in the sample.

2

2. Referenced Documents

Hydrocarbons higher than n-decane cannot be analyzed by this

2

2.1 ASTM Standards:

test method, if present in the sample. Test Method D2504

D2504 Test Method for Noncondensable Gases in C and

2 addresses the analysis of noncondensable gases and Test

Lighter Hydrocarbon Products by Gas Chromatography

Method D2505 addresses the analysis of CO . Guide D5234

2

D2505 Test Method for Ethylene, Other Hydrocarbons, and

describes all potential impurities present in ethylene. These

Carbon Dioxide in High-Purity Ethylene by Gas Chroma-

standards should be consulted when determining the total

tography

concentration of impurities in ethylene.

D5234 Guide for Analysis of Ethylene Product

5. Apparatus

5.1 Gas Chromatograph (GC), a gas chromatographic in-

1

This test method is under the jurisdiction of ASTM Committee D02 on

strument provided with a temperature programmable column

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.D0.02 on Ethylene.

oven and a flame ionization detector (FID). Carrier gas is

Current edition approved Jan. 1, 2017. Published February 2017. Originally

regulated by pressure control.

approved in 1997. Last previous edition approved in 2012 as D6159 – 97 (2012).

DOI: 10.1520/D6159-17.

5.2 Detector—A flame ionization detector (FID) having a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

sensitivity of approximately 2.0 ppmV (1.2 mg ⁄kg) or less for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the compounds listed in 1.1. An FID was exclusively used in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the interlaboratory cooperative study.

*A Summary of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6159 − 97 (Reapproved 2012) D6159 − 17

Standard Test Method for

Determination of Hydrocarbon Impurities in Ethylene by Gas

1

Chromatography

This standard is issued under the fixed designation D6159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of methane, ethane, propane, propene, acetylene, iso-butane, propadiene, butane,

trans-2-butene, butene-1, isobutene, cis-2-butene, methyl acetylene and 1,3-butadiene in high-purity ethylene. The purity of the

ethylene can be calculated by subtracting the total percentage of all impurities from 100.00 %. 100.00 %. Since this test method

does not determine all possible impurities such as CO, CO , H O, alcohols, nitrogen oxides, and carbonyl sulfide, as well as

2 2

hydrocarbons higher than decane, additional tests may be necessary to fully characterize the ethylene sample.

1.2 Data are reported in this test method as ppmV (parts per million by volume). gaseous volume) and ppmMol (parts per

million Mol). This test method was evaluated in an interlaboratory cooperative study in the concentration range of 44 ppmV to 340

ppmV340 ppmV (2 mg (2 ⁄kg to 204204 mg mg/kg). ⁄kg). The participants in the interlaboratory cooperative study reported the

data in non-SI units. Wherever possible, SI units are included.

1.3 This standard dosedoes not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2504 Test Method for Noncondensable Gases in C and Lighter Hydrocarbon Products by Gas Chromatography

2

D2505 Test Method for Ethylene, Other Hydrocarbons, and Carbon Dioxide in High-Purity Ethylene by Gas Chromatography

D5234 Guide for Analysis of Ethylene Product

3. Summary of Test Method

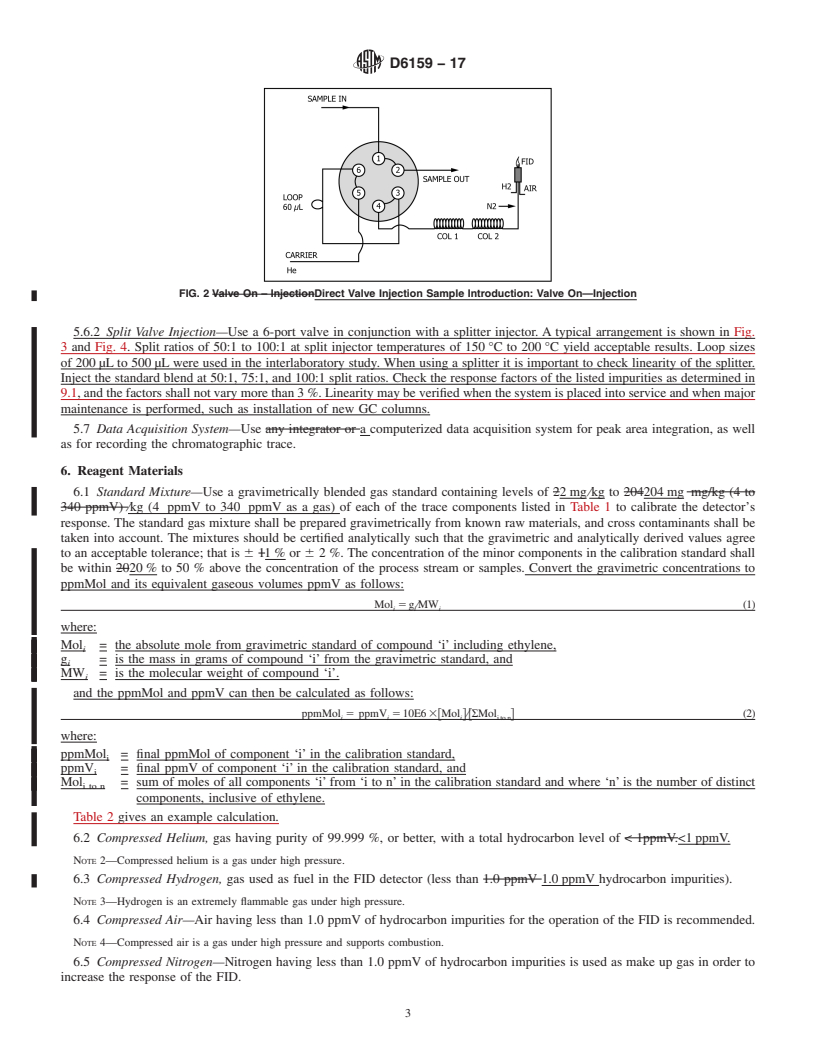

3.1 A gaseous ethylene sample is analyzed as received. The gaseous sample is injected into a capillary gas chromatograph. A

split-injector may or may not be used.Sample may be introduced by direct valve injection or by split valve injection. The gas

chromatograph is provided with a 6–port6-port sampling valve and two wide bore capillary columns connected in series. These

columns are a dimethyl siliconepolysiloxane column and a (porousporous layer open tubular column (PLOT) Al O /KCl column.

2 3

(See Note 1.) A flame ionization detector is used for detection. The integrated detector signal (peak areas) are corrected for detector

response. The hydrocarbon impurities are determined and the total impurities are used to determine the ethylene content.

NOTE 1—This column is supplied by major column manufacturers.

4. Significance and Use

4.1 High-purity ethylene is required as a feedstock for some manufacturing processes and the presence of trace amounts of

certain hydrocarbon impurities can have deleterious effects. This test method is suitable for setting specifications, for use as an

internal quality control tool, and for use in development or research work.

4.2 This test method does not detect such impurities as H O, CO, CO , and alcohols that may be present in the sample.

2 2

Hydrocarbons higher than n-decane cannot be analyzed by this test method, if present in the sample. Test Method D2504 addresses

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.D0.02 on Ethylene.

Current edition approved Dec. 1, 2012Jan. 1, 2017. Published December 2012February 2017. Originally approved in 1997. Last previous edition approved in 20072012

as D6159–97(2007).D6159 – 97 (2012). DOI: 10.1520/D6159-97R12.10.1520/D6159-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.