ASTM F364-96

(Specification)Standard Specification for Molybdenum Flattened Wire for Electron Tubes

Standard Specification for Molybdenum Flattened Wire for Electron Tubes

SCOPE

1.1 This specification covers two types of molybdenum flattened wire up to 0.050 in. (1.27 mm) thick and up to 0.375 in. (9.52 mm) wide, specifically for use in electron tubes. The two grades have UNS numbers R03604 and R03603.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the test method described in this specification (see 10.2). This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 364 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Molybdenum Flattened Wire for Electron Tubes

This standard is issued under the fixed designation F 364; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

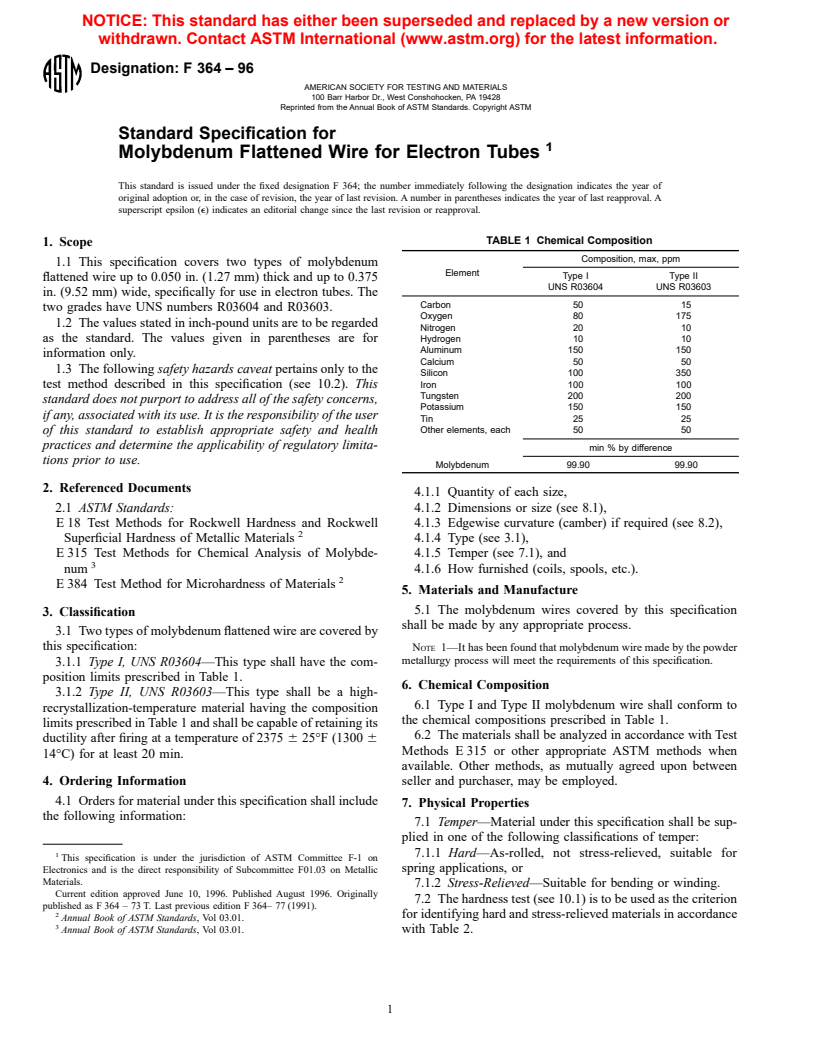

TABLE 1 Chemical Composition

1. Scope

Composition, max, ppm

1.1 This specification covers two types of molybdenum

Element

Type I Type II

flattened wire up to 0.050 in. (1.27 mm) thick and up to 0.375

UNS R03604 UNS R03603

in. (9.52 mm) wide, specifically for use in electron tubes. The

Carbon 50 15

two grades have UNS numbers R03604 and R03603.

Oxygen 80 175

1.2 The values stated in inch-pound units are to be regarded

Nitrogen 20 10

as the standard. The values given in parentheses are for Hydrogen 10 10

Aluminum 150 150

information only.

Calcium 50 50

1.3 The following safety hazards caveat pertains only to the

Silicon 100 350

test method described in this specification (see 10.2). This Iron 100 100

Tungsten 200 200

standard does not purport to address all of the safety concerns,

Potassium 150 150

if any, associated with its use. It is the responsibility of the user

Tin 25 25

Other elements, each 50 50

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

min % by difference

tions prior to use.

Molybdenum 99.90 99.90

2. Referenced Documents

4.1.1 Quantity of each size,

2.1 ASTM Standards: 4.1.2 Dimensions or size (see 8.1),

E 18 Test Methods for Rockwell Hardness and Rockwell 4.1.3 Edgewise curvature (camber) if required (see 8.2),

2

Superficial Hardness of Metallic Materials 4.1.4 Type (see 3.1),

E 315 Test Methods for Chemical Analysis of Molybde- 4.1.5 Temper (see 7.1), and

3

num 4.1.6 How furnished (coils, spools, etc.).

2

E 384 Test Method for Microhardness of Materials

5. Materials and Manufacture

5.1 The molybdenum wires covered by this specification

3. Classification

shall be made by any appropriate process.

3.1 Two types of molybdenum flattened wire are covered by

this specification:

NOTE 1—It has been found that molybdenum wire made by the powder

metallurgy process will meet the requirements of this specification.

3.1.1 Type I, UNS R03604—This type shall have the com-

position limits prescribed in Table 1.

6. Chemical Composition

3.1.2 Type II, UNS R03603—This type shall be a high-

6.1 Type I and Type II molybdenum wire shall conform to

recrystallization-temperature material having the composition

the chemical compositions prescribed in Table 1.

limits prescribed in Table 1 and shall be capable of retaining its

6.2 The materials shall be analyzed in accordance with Test

ductility after firing at a temperature of 2375 6 25°F (1300 6

Methods E 315 or other appropriate ASTM methods when

14°C) for at least 20 min.

available. Other methods, as mutually agreed upon between

seller and purchaser, may be employed.

4. Ordering Information

4.1 Orders for material under this specification shall include

7. Physical Properties

the following information:

7.1 Temper—Material under this specification shall be sup-

plied in one of the following classifications of temper:

1 7.1.1 Hard—As-rolled, not stress-relieved, suitable for

This specification is under the jurisdiction of ASTM Committee F-1 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic spring applications, or

Materials.

7.1.2 Stress-Relieved—Suitable for bending or winding.

Current edition approved June 10, 1996. Published August 1996. Originally

7.2 The hardness test (see 10.1) is to be used as the criterion

published as F 364 – 73 T. Last previous edition F 364– 77 (1991).

2

for identifying hard and stress-relieved materials in accordance

Annual Book of ASTM Standards, Vol 03.01.

3

Annual Book of ASTM Standards, Vol 03.01. with Table 2.

1

---------------------- Page: 1 ----------------------

F 364

TABLE 2 Hardness Ranges TABLE 4 Dimensional Tolerances

Diamond Pyramid Tolerance

Rockwell Super- Specified Thickness,

Hardness (HDP) plus and mi-

Temper ficial Hardness in. (mm)

or Vickers Hard- nus, in. (mm)

A

30T-Scale

ness (HV)

Up to 0.0050 (0.127), incl 0.0002 (0.005)

Hard 300 and over 85 and over

Over 0.0050 to 0.0100 (0.127 to 0.254), 0.0003 (0.008)

Stress-relieved up to 300, excl up to 85, excl

incl

A

3

Rockwell 30T for material ⁄16 in. (4.8 mm) wide and over only.

Over 0.0100 to 0.0200 (0.254 to 0.508), 0.0004 (0.010)

incl

Over 0.0200 to 0.0300 (0.508 to 0.762), 0.0005 (0.013)

7.2.1 When determining mic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.