ASTM D2663-95a(2000)e1

(Test Method)Standard Test Methods for Carbon Black-Dispersion in Rubber

Standard Test Methods for Carbon Black-Dispersion in Rubber

SCOPE

1.1 These test methods determine the degree of dispersion of carbon black in rubber. Three test methods are described as follows: SectionsTest Method A-Visual InspectionTest Method B-Agglomerate CountTest Method C-Microroughness Measurement

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D2663–95a (Reapproved 2000)

Standard Test Methods for

Carbon Black—Dispersion in Rubber

This standard is issued under the fixed designation D2663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Adjunct references were corrected editorially in April 2006.

1. Scope Carbon Black Dispersion Chart

1.1 These test methods determine the degree of dispersion

TEST METHOD A—VISUAL INSPECTION

of carbon black in rubber. Three test methods are described as

follows:

3. Scope

Sections

3.1 Test Method A is a qualitative visual test method.

Test Method A—Visual Inspection 3-11

Ratings are made against a set of standard photographs (Fig.

Test Method B—Agglomerate Count 12-23

Test Method C—Microroughness Measurement 24-34 1), andtheresultsareexpressedonanumericalscale.Thistest

methodcannotbeusedforcompoundsthatcontainfillersother

1.2 The values stated in SI units are to be regarded as the

than carbon black.

standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 The compound rubber is torn or cut to expose a fresh

responsibility of the user of this standard to establish appro-

surface for examination by the eye, aided preferably by a hand

priate safety and health practices and determine the applica-

lens or a low-power binocular microscope. The dispersion

bility of regulatory limitations prior to use.

level of the carbon black is compared against a series of five

photographic standards and then rated numerically from 1

2. Referenced Documents

(very low) to 5 (high) (see Fig. 1).

2.1 ASTM Standards:

D1765 Classification System for Carbon Blacks Used in

5. Significance and Use

Rubber Products

5.1 Visual dispersion ratings correlate with certain impor-

D3051 Recommended Practice for Carbon Black—Stating

3 tant physical properties of the compound. A rating of 5

the Precision of ASTM Test Methods

indicates a state of dispersion developing near maximum

D3182 Practice for Rubber—Materials, Equipment, and

properties, while a rating of 1 would indicate a state of

Procedures for Mixing Standard Compounds and Prepar-

dispersion developing considerably depressed properties. Nor-

ing Standard Vulcanized Sheets

mally, the visual dispersion ratings indicate the following

D 3396 Recommended Practice for Carbon Black—

levels of compound quality:

Measuring the Precision of ASTM Test Methods

Visual Dispersion Rating Classification

2.2 ASTM Adjuncts:

Carbon Black Dispersion Standards

4to5 High

3 to 4 Intermediate

2to3 Low

1 to 2 Very low

These test methods are under the jurisdiction of ASTM Committee D24 on

Carbon Black and are the direct responsibility of Subcommittee D24.71 on Carbon

6. Apparatus

Black Testing in Rubber.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

6.1 Sharp Knife or Razor Blade.

published as D2663–67T. Last previous edition D2663–95.

6.2 Hand Lens (103)orbinocularmicroscope(10to203).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.3 Illuminator, microscopical-type.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Withdrawn.

4 5

Available from ASTM International Headquarters. Order Adjunct No. Available from ASTM International Headquarters. Order Adjunct No.

ADJD266302. Original adjunct produced in 1967. ADJD266301. Original adjunct produced in 1967.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D2663–95a (2000)

FIG. 1 Carbon Black Dispersion Standards—Visual Analysis of Torn Vulcanizates

6.4 Knife Heater.

6.5 Series of Photographic Standards, rating 1 to 5. These

standards give the following percent dispersion ratings by the 7. Test Specimen

Agglomerate Count Method:

7.1 Vulcanized Compounds—Use a slab of rubber about 2

Visual Rating Black Dispersed, %

mm in thickness.Tear it so that a fresh surface is exposed.The

280 tear may be initiated by a small cut. The most nearly flat part

of the tear is used for rating.

e1

D2663–95a (2000)

7.2 Unvulcanized Compounds—Unvulcanized rubber may small deviations from what is considered the norm for a

be examined as follows: specific type of compound. Prepare a fresh surface on the

7.2.1 Ifthespecimencontainscuringagents,sheetitoutand control as often as necessary to ensure cleanliness.

cure in a press to form a vulcanized slab about 2 mm in

10. Report

thickness. Mill and cure in accordance with Practice D3182.

Then proceed as in 7.1.

10.1 Ratings:

7.2.2 If the specimen contains no curatives, add the appro-

10.1.1 List all ratings, including those on any control

priate materials with a minimum of mixing. Then cure and

compound, on the basis of the 1 to 5 scale defined by the

proceed as above.

standard photographs. Use fractional ratings when necessary.

7.2.3 If the specimen contains no curatives and a dispersion

10.1.2 Average the ratings on different specimens of the

evaluation with no further mixing is required, the compound

same compound as well as the ratings of different operators.

must first be compressed to remove most of the air holes. To

Report the final average values.

accomplish this, press the rubber into a slab between thin

10.2 Compound Identification:

sheets of plastic in a mold at a pressure of about 1.03 kPa for

10.2.1 Formulation—Wheneverpossiblelistthefollowing:

5 min at 105°C. Care should be taken to avoid excessive flow

10.2.1.1 Carbon black, type and loading,

during this step. The surface to be examined is formed with a

10.2.1.2 Other fillers, type and loading,

smooth cutting stroke using a sharp, hot knife (a standard type

10.2.1.3 Polymer type, and

knife heater may be employed). The most nearly smooth and

10.2.1.4 Extender oil, type and loading.

flat part of the cut surface is used for rating.

10.2.2 Mixing—Describe the mixing of the compound in

terms of one or more of the following:

8. Number of Tests

10.2.2.1 Standard mixing procedure,

8.1 Preferably more than one test (on different tears) should

10.2.2.2 Type of equipment,

be made for each specimen. If convenient, more than one

10.2.2.3 Masterbatch,

operator should rate the samples.

10.2.2.4 Finished compound (vulcanized), and

10.2.2.5 Finished compound (unvulcanized).

9. Procedure

9.1 Examine the prepared specimens under a hand lens or

11. Precision and Bias

binocular microscope (the latter being preferred), with oblique

11.1 No statement is made about either the precision or the

illumination to accentuate surface detail. Keep the magnifica-

bias of Test Method A since the result is qualitative and not

tion and lighting conditions constant for all specimens.

applicable to statistical treatment.

9.2 Comparethesizeandfrequencyofcarbonagglomerates

inthespecimens(showingupassurfacebumpsordepressions)

TEST METHOD B—AGGLOMERATE COUNT

to the photographic standards. Then assign the most closely

matched numerical rating to each compound being rated. In

12. Scope

borderlinecases,usefractionalratings,forexample,3 ⁄2would

12.1 TestMethodBisaquantitativetestmethod.Dispersion

indicate a rating between 3 and 4. In cases of dissimilarity in

is evaluated by measuring with a light microscope the percent-

thesizeandfrequencyoftheagglomeratesinthespecimenand

age area covered by black agglomerates in microtomed sec-

those of the standards, the operator shall assign the rating that

tions of the compound. Since this test method involves direct

in his judgment is most applicable. Certain compounds (for

measurement, it is quantitative and more accurate than the

example,NRandIR)areparticularlypronetoverysmallblack

visual test method. The test is applicable to the analysis of

agglomerations which are difficult to resolve by the Visual

carbonblackdispersionincompoundsthatcontainotherfillers.

Inspection Method. In instances of high agglomerate fre-

quency, the surface of stocks of this type may show a general

13. Summary of Test Method

roughness or fine pebbled appearance. Differences are best

13.1 The compounded rubber is microtomed into sections

resolvedatsomewhathighermagnification(forexample,203,

sufficiently thin to permit observation of the carbon agglom-

binocular microscope). If at all possible, examine compounds

erates by transmitted light, with the aid of a light microscope.

ofthistypealsobytheagglomeratecountmethod,atleastuntil

The total cross-sectional area of all agglomerates 5 µm or

sufficient experience is gained to recognize dispersion differ-

larger is counted, and from the known content of carbon black

ences with the Visual Inspection Method.

in the stock, the percentage of carbon black below the 5-µm

9.3 In comparing a series of different compounds, it is also

size is calculated and expressed as “Percentage of Carbon

desirable to rate the specimens side by side rather than one at

Black Dispersed.”

a time. This use of a control compound is also advisable. This

is best prepared by individual operators, since dispersion

14. Significance and Use

requirements may vary greatly for different types of com-

pounds. The control sample should represent a minimum 14.1 Certain important physical properties of the compound

acceptable dispersion level for the type of compound being are influenced significantly by the degree of carbon black

rated. Because it can be observed side by side with unknown dispersion within the compound (for example, tensile strength

samples under identical conditions, a control compound is and abrasion resistance). The correlation of these properties

more accurate than the photographic standards in discerning with the percentage dispersion determined by theAgglomerate

e1

D2663–95a (2000)

Count Method approximates the following pattern for many 15.6 Glass Pliers and Cutter—Wide-face glazier pliers and

types of black loaded rubber compounds: a wheel-type glass cutter are recommended for preparing glass

knives.

Dispersion, % Classification

15.7 Sample Die—Tempered steel die for cutting out 3 by

Above 99 Very high

8-mm specimens.

97 to 99 High

15.8 Sable Brushes (00).

95 to 97 Intermediate

92 to 95 Low

15.9 Dewar Flask, 2dm (2-L) size (wide-mouth).

Below 92 Very low

15.10 Glass Knives—Theknivesarepreparedfrom50-mm

wide strips of approximately 6-mm thick plate glass.

15. Apparatus

15.11 Microscope Slides and Cover Glasses.

15.1 Microtome—A sledge-type microtome equipped with

16. Reagents and Materials

specimen clamp and holder for glass knives. Steel knives may

also be employed, according to the preference of the operator.

16.1 Liquid Nitrogen.

16.2 Water-Soluble Mucilage.

15.2 Freezing Blocks, consisting of a brass screw which is

16.3 Naphtha,boilingpointrangefromabout113to144°C.

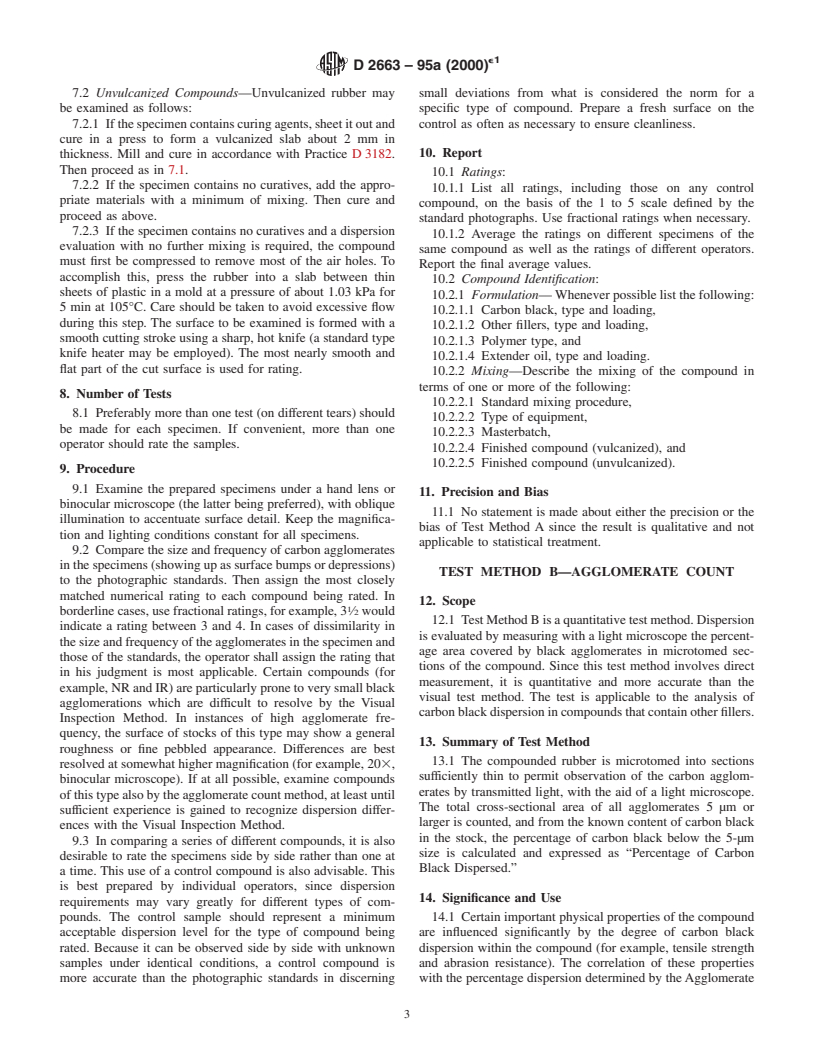

threadedintoaninsulatingblockofTFE-fluorocarbon(Fig.2).

16.4 Xylene, boiling point range from 135 to 145°C.

The TFE-fluorocarbon block shall be 28-mm square in cross

section and 40-mm high. The threaded part of the brass screw

17. Sampling

shall be 15 mm in diameter and shall extend into the center of

17.1 Vulcanizates— Specimens may be cut from standard

the TFE-fluorocarbon block to a depth of 34 mm. Coarse,

test sheets (about 2-mm thick) or from pieces of actual cured

expansion-type threads should be used to prevent splitting of

articles. Vulcanized samples must be employed because of the

the TFE-fluorocarbon when the mount is frozen. The head of

solvent used to uncurl the thin sections. If pieces other than

the brass screw shall be 18 mm in diameter and shall extend 3

2-mm sheets are used, they should first be cut down to a

mm above the TFE-fluorocarbon insulator. The top of the

thickness of about 2 to 3 mm.

screw head shall be cross-hatched with fine grooves to a depth

17.2 Unvulcanized Compounds—Forrubbersofhighunsat-

of about 1 mm.

uration (for example, OE-SBR, NR, and BR), dust small bits

15.3 Microscope—An optical microscope with binocular

(enoughsubsequentlytoformbuttonsabout10mmindiameter

viewing (trinocular type if photomicrographs are desired) is

and about 2 to 3-mm deep) thoroughly with dicumyl peroxide.

recommended. This should include a movable specimen stage

Cure in a button mold under high pressure at about 155°C.

and white light source with variable intensity. Lenses should

OE-SBR rubbers require about 30 to 60-min cure. BR requires

include two 103 wide field eyepieces and objectives in the

about 10 to 15-min cure. After cure, scrape off the excess

range from 6 to 103. Taking into account microscope tube

peroxide from the sample surface and proceed with sectioning

corrections, objectives should be selected so that magnifica-

inthestandardmanner,takingcarenottoparedownbelowthe

tions in the range from 75 to 1003 are available. (For

cured surface layer.

photomicrographsa43planeobjectiveanda103periplanatic

17.2.1 For IIR, satisfactory surface cures can be obtained

eyepiece are recommended.)

with a mixture of 1 part tetramethylthiuram disulfide (TMTD),

15.4 Microscope Accessories—A 103 wide field eyepiece

1partmercaptobenzothiazole(MBT),1partsulfur,and5parts

containing a graticule that is 1 cm in size and divided into

zinc oxide, with a cure of 1 h at 155°C. Other alternative

10000 small squares.

approaches for curing high unsaturation polymers without

15.5 Measuring Lens—A73 measuring magnifier cali-

actually mixing in curatives are (1) high-energy radiation and

brateddownto0.1mmformeasuringtheswellingfactorofthe

(2) chemical treatment with sulfur monochloride. However,

microtome sections. A mechanical vernier stage can also be

before using either of these latter methods, the stock should be

used for this purpose.

pressed out to eliminate most of the air holes. Cure in

accordance with Practice D3182.

18. Test Specimen

18.1 Cut out a rectangular specimen 8-mm long, 3-mm

wide, and approximately 2-mm deep. Use a cutting die, if

available. If a die is not used, the specimen length and width

should be recorded using a measuring magnifier.

18.2 Prepare one specimen block for each different com-

pound to be examined.

19. Preparation of Glass Knives

19.1 Standard types of plate glass are suitable for making

knives. Thickness should be preferably about 6 mm. A large

A special mold containing several circular cavities that are approximately 10

FIG. 2 Brass Sample Mount and TFE-Fluorocarbon Insulator mm in diameter and 3-mm de

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.