ASTM C1604/C1604M-05(2012)

(Test Method)Standard Test Method for Obtaining and Testing Drilled Cores of Shotcrete

Standard Test Method for Obtaining and Testing Drilled Cores of Shotcrete

SIGNIFICANCE AND USE

4.1 This test method provides standardized procedures for obtaining cored specimens to determine the compressive strength and splitting tensile strength of shotcrete during pre-construction, during construction, and from older shotcrete structures.

4.2 Generally, test specimens are obtained in situ when doubt exists about the in-place shotcrete quality due either to low strength test results during construction or signs of distress in the structure. Other uses of this method are to provide specimens for acceptance testing, construction control and to assess the condition, quality and uniformity of the shotcrete in accordance with Practice C823 (see Note 1).

4.3 Specimens obtained by this method are used to verify the thickness of shotcrete and aid in the visual assessment of the shotcrete quality, workmanship, defects, shotcrete-to-substrate bond and the condition of any reinforcement used in the shotcrete4.

4.4 Shotcrete strength is affected by the location of the shotcrete in a structure. Vertical, sub-horizontal and overhead elements of the shotcrete structure may show variability. Core strength is affected by core orientation relative to direction of shotcrete application. These factors shall be considered in planning the locations for obtaining shotcrete samples and in interpreting strength test results.

4.5 Shotcrete is applied in single or multiple layers, as plain shotcrete, reinforced shotcrete, or fiber-reinforced shotcrete. Core samples containing wire-mesh and reinforcing bars shall not be used for compressive strength testing.

4.6 The strength of shotcrete is affected by moisture content, the specified moisture conditioning procedure for cores is intended to provide test specimens with reproducible moisture contents that minimize within-laboratory and between-laboratory variations.

4.7 Sample acquisition may require a combination of core-drilling, sawing, and grinding that may have the potential to adversely affect the sample conditio...

SCOPE

1.1 This test method covers obtaining, preparing, and testing cores drilled from shotcrete for length, compressive strength, or splitting tensile strength determinations.

1.2 The values stated in either inch-pound units or SI units shall be regarded separately as standard. SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.4 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1604/C1604M − 05 (Reapproved 2012)

Standard Test Method for

Obtaining and Testing Drilled Cores of Shotcrete

This standard is issued under the fixed designation C1604/C1604M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

1.1 This test method covers obtaining, preparing, and test-

C823 Practice for Examination and Sampling of Hardened

ing cores drilled from shotcrete for length, compressive

Concrete in Constructions

strength, or splitting tensile strength determinations.

C1140 Practice for Preparing and Testing Specimens from

1.2 The values stated in either inch-pound units or SI units

Shotcrete Test Panels

shall be regarded separately as standard. SI units are shown in

C1231/C1231M Practice for Use of Unbonded Caps in

brackets. The values stated in each system may not be exact

DeterminationofCompressiveStrengthofHardenedCon-

equivalents; therefore, each system must be used indepen-

crete Cylinders

dently of the other. Combining values from the two systems

2.2 ACI Standards:

may result in nonconformance with the standard.

318 Building Code Requirements for Structural Concrete

1.3 The text of this standard references notes and footnotes

506.2 Specification for Shotcreting

that provide explanatory material. These notes and footnotes

506.4R Guide for the Evaluation of Shotcrete

(excluding those in tables and figures) shall not be considered

as requirements of the standard.

3. Terminology

1.4 This standard does not purport to address the safety

3.1 For definitions of terms used in this standard, refer to

concerns, if any, associated with its use. It is the responsibility

Terminology C125.

of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory

4. Significance and Use

limitations prior to use.

4.1 This test method provides standardized procedures for

obtaining cored specimens to determine the compressive

2. Referenced Documents

2 strength and splitting tensile strength of shotcrete during

2.1 ASTM Standards:

pre-construction, during construction, and from older shotcrete

C39/C39M Test Method for Compressive Strength of Cylin-

structures.

drical Concrete Specimens

C42/C42M Test Method for Obtaining and Testing Drilled 4.2 Generally, test specimens are obtained in situ when

Cores and Sawed Beams of Concrete doubt exists about the in-place shotcrete quality due either to

C125 Terminology Relating to Concrete and Concrete Ag- low strength test results during construction or signs of distress

gregates in the structure. Other uses of this method are to provide

C174/C174M Test Method for MeasuringThickness of Con- specimens for acceptance testing, construction control and to

crete Elements Using Drilled Concrete Cores assess the condition, quality and uniformity of the shotcrete in

C496/C496M Test Method for Splitting Tensile Strength of accordance with Practice C823 (see Note 1).

Cylindrical Concrete Specimens

4.3 Specimens obtained by this method are used to verify

C617 Practice for Capping Cylindrical Concrete Specimens

the thickness of shotcrete and aid in the visual assessment of

the shotcrete quality, workmanship, defects, shotcrete-to-

substrate bond and the condition of any reinforcement used in

This test method is under the jurisdiction of ASTM Committee C09 on

the shotcrete.

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

C09.46 on Shotcrete.

Current edition approved April 1, 2012. Published November 2012. Originally

approved in 2005. Last previous edition approved in 2005 as C1604/C1604M–05.

DOI: 10.1520/C1604_C1604M-05R12. Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Hills, MI 48333-9094, http://www.concrete.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Bartlett, F. M., and MacGregor, J. G., “Effect of Core Diameter on Concrete

Standards volume information, refer to the standard’s Document Summary page on Core Strengths,” ACI Materials Journal, Vol 91, No. 5, September–October 1994,

the ASTM website. pp. 460–470.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1604/C1604M − 05 (2012)

4.4 Shotcrete strength is affected by the location of the 6.1.1 Sampling shall be planned in accordance with the

shotcrete in a structure. Vertical, sub-horizontal and overhead applicable provisions of Practice C823. The number of

elements of the shotcrete structure may show variability. Core samples, sample locations and sampling procedures shall be

strength is affected by core orientation relative to direction of established in the plan.

shotcrete application. These factors shall be considered in 6.1.2 Shotcretesamplesobtainedfromtestpanelsshallbein

planning the locations for obtaining shotcrete samples and in accordance with the applicable provisions of Practice C1140.

interpreting strength test results. 6.1.3 Samples of hardened shotcrete for use in the prepara-

tion of strength test specimens shall not be taken until the

4.5 Shotcrete is applied in single or multiple layers, as plain

shotcrete is strong enough to permit sample removal without

shotcrete, reinforced shotcrete, or fiber-reinforced shotcrete.

disturbing the bond between the mortar, coarse aggregate (see

Core samples containing wire-mesh and reinforcing bars shall

Note 3) and fiber-reinforcement. When preparing strength test

not be used for compressive strength testing.

specimens from samples of hardened shotcrete, samples that

4.6 Thestrengthofshotcreteisaffectedbymoisturecontent,

havebeendamagedintheprocessofremovalshallnotbeused.

the specified moisture conditioning procedure for cores is

Specimens of defective shotcrete that cannot be tested shall be

intended to provide test specimens with reproducible moisture

reported as such if the defects are representative of the in-place

contents that minimize within-laboratory and between-

condition of the shotcrete (see ACI 506.4R).

laboratory variations.

NOTE 3—It is not possible to specify a minimum age when shotcrete is

4.7 Sample acquisition may require a combination of core-

strong enough to withstand damage during removal, because the strength

drilling, sawing, and grinding that may have the potential to at any age depends on the strength grade and curing of the shotcrete. If

accelerating admixtures are used during shotcrete application, core speci-

adverselyaffectthesampleconditionifcareisnottakenduring

mens may be obtained for testing at approximately 6 h. If this is not

sampling and testing.

practical, removal of shotcrete can proceed if cored or cut surfaces do not

display erosion of the mortar and the exposed coarse aggregate particles

4.8 A sampling plan shall be established that indicates the

are embedded firmly in the mortar. Nondestructive test methods may be

number of samples and their locations (see Note 1). The

usedtoestimatelevelofin-placestrengthdevelopmentpriortoattempting

acceptance criteria for shotcrete core strengths shall be estab-

removal of shotcrete core samples (see ACI 506.4R).

lished by the specifier of tests (see Note 2).

6.1.4 Specimens containing embedded reinforcement shall

NOTE 1—Practice C823 provides guidance on the development of a

not be used for determining compressive or splitting tensile

sampling plan for concrete in constructions. A number of methods that

strength.

supplement the examination of hardened shotcrete by means of represen-

tative core samples and testing are discussed in ACI 506.4R.

6.2 Core Drilling—Drill core specimens perpendicular to

NOTE 2—The core strength acceptance criteria cited in ACI 318 are

the surface and avoid drilling near formed joints or edge

based on a comparison of molded cylinder specimens and cores. Shotcrete

placement. Record the approximate angle between the drilled

strengths are always based on core specimens, therefore the 85 % factor

core axis and the plane of the shotcrete as placed.

used in core to cylinder comparisons is not relevant to the evaluation of

shotcrete core strengths. A typical shotcrete specification reflecting stan-

7. Measuring the Length of Drilled Cores

dard industry practice is contained in ACI 506.2.

7.1 Cores for determining the thickness of shotcrete layers

5. Apparatus

or other structural elements shall have a diameter of at least 3.0

in. [75 mm] when the lengths of such cores are to be measured

5.1 Core Drill, for obtaining cylindrical core specimens

in accordance with Test Method C174/C174M.

with diamond impregnated bits attached to a core barrel. The

core drill shall have a rigid mounting base and be capable of

7.2 Forcoresthatarenotintendedfordeterminingstructural

being operated in any orientation normal to the shotcrete

dimensions,measurethelongestandshortestlengthsonthecut

structurethatisbeingsampled.Thecoredrillshallbefreefrom

surface along lines parallel to the core axis. Record the average

excessive vibration when in operation and shall have sufficient length to the nearest ⁄4 in. [5 mm].

torque and consistent rotational speed to sustain uniform rates

8. Cores for Compressive Strength

of penetration of the core drill. The core barrel shall be cooled

and core cuttings flushed with water during operation. 8.1 Diameter—The diameter of core specimens for the

determination of compressive strength in load bearing struc-

5.2 Saw, for cutting core specimens to size for compressive

tural members shall be at least 3.0 in. [75 mm] (see Note 4).

strength. The saw shall have a diamond or silicon carbide

Core diameters less than 3.0 in. [75 mm] shall be permitted as

cutting edge and shall be capable of cutting plain and rein-

directed by the specifier of the tests.

forced specimens in a single pass that conform with the

prescribed dimensions, without excessive heating or shock. NOTE4—Thecompressivestrengthsof2-in[50-mm]diametercoresare

known to be somewhat lower and more variable than those of 3-in.

5.3 Grinding wheel, to trim and clean plain and fiber-

[75-mm] diameter cores. In addition, smaller diameter cores appear to be

reinforced shotcrete specimens that conform to prescribed

more sensitive to the effect of the length-diameter ratio .

tolerances without significantly disturbing the aggregates, ma-

8.2 Length—The preferred length of the capped or ground

trix or fiber-reinforcement.

specimen is nominally two times the diameter.

8.2.1 If the ratio of the length to the diameter (L/D) of the

6. Sampling

core exceeds 2.1, reduce the length of the core so that the ratio

6.1 General: of the capped or ground specimen is between 1.9 and 2.1. Core

C1604/C1604M − 05 (2012)

NOTE 6—This limitation is intended to avoid cap thicknesses that

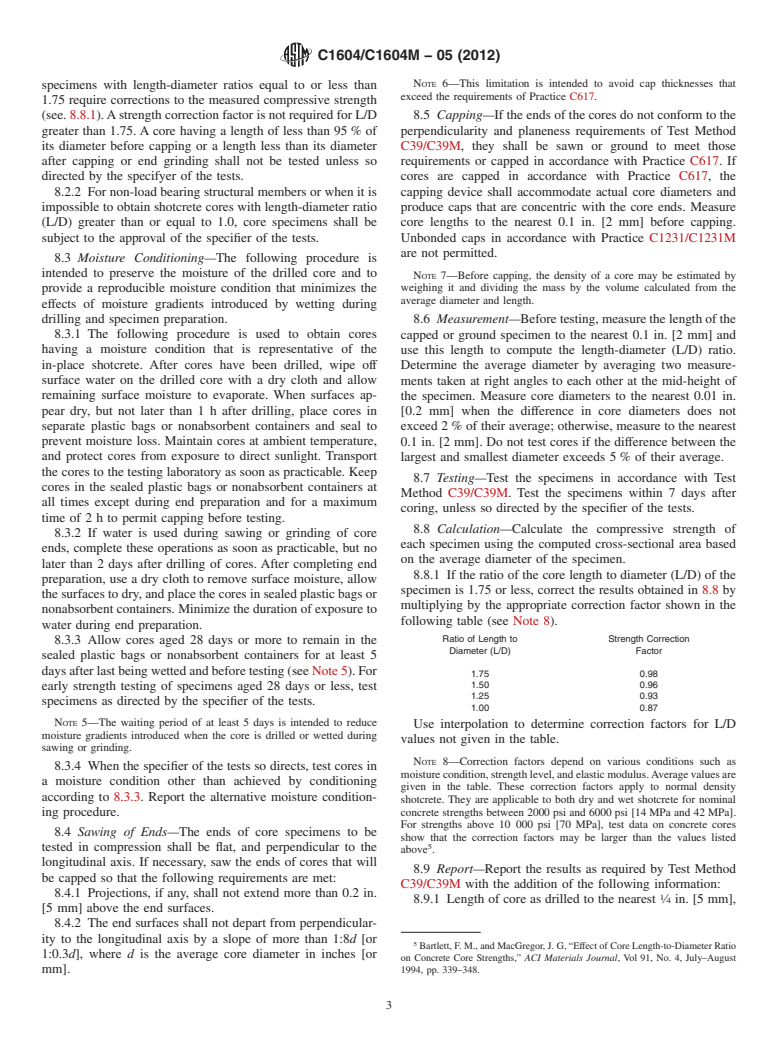

specimens with length-diameter ratios equal to or less than

exceed the requirements of Practice C617.

1.75 require corrections to the measured compressive strength

(see. 8.8.1).Astrength correction factor is not required for L/D 8.5 Capping—If the ends of the cores do not conform to the

greater than 1.75. A core having a length of less than 95 % of perpendicularity and planeness requirements of Test Method

its diameter before capping or a length less than its diameter C39/C39M, they shall be sawn or ground to meet those

after capping or end grinding shall not be tested unless so requirements or capped in accordance with Practice C617.If

directed by the specifyer of the tests. cores are capped in accordance with Practice C617, the

8.2.2 For non-load bearing structural members or when it is capping device shall accommodate actual core diameters and

impossible to obtain shotcrete cores with length-diameter ratio produce caps that are concentric with the core ends. Measure

(L/D) greater than or equal to 1.0, core specimens shall be core lengths to the nearest 0.1 in. [2 mm] before capping.

subject to the approval of the specifier of the tests. Unbonded caps in accordance with Practice C1231/C1231M

are not permitted.

8.3 Moisture Conditioning—The following procedure is

intended to preserve the moisture of the drilled core and to

NOTE 7—Before capping, the density of a core may be estimated by

provide a reproducible moisture condition that minimizes the weighing it and dividing the mass by the volume calculated from the

average diameter and length.

effects of moisture gradients introduced by wetting during

drilling and specimen preparation. 8.6 Measurement—Before testing, measure the length of the

8.3.1 The following procedure is used to obtain cores capped or ground specimen to the nearest 0.1 in. [2 mm] and

having a moisture condition that is representative of the use this length to compute the length-diameter (L/D) ratio.

in-place shotcrete. After cores have been drilled, wipe off

Determine the average diameter by averaging two measure-

surface water on the drilled core with a dry cloth and allow ments taken at right angles to each other at the mid-height of

remaining surface moisture to evaporate. When surfaces ap-

the specimen. Measure core diameters to the nearest 0.01 in.

pear dry, but not later than 1 h after drilling, place cores in [0.2 mm] when the difference in core diameters does not

separate plastic bags or nonabsorbent containers and seal to

exceed 2 % of their average; otherwise, measure to the nearest

prevent moisture loss. Maintain cores at ambient temperature, 0.1 in. [2 mm]. Do not test cores if the difference between the

and protect cores from exposure to direct sunlight. Transport

largest and smallest diameter exceeds 5 % of their average.

the cores to the testing laboratory as soon as practicable. Keep

8.7 Testing—Test the specimens in accordance with Test

cores in the sealed plastic bags or nonabsorbent containers at

Method C39/C39M. Test the specimens within 7 days after

all times except during end preparation and for a maximum

coring, unless so directed by the specifier of the tests.

time of2hto permit capping before testing.

8.8 Calculation—Calculate the compressive strength of

8.3.2 If water is used during sawing or grinding of core

each specimen using the computed cross-sectional area based

ends, complete these operations as soon as practicable, but no

on the average diameter of the specimen.

later than 2 days after drilling of cores. After completing end

8.8.1 If the ratio of the core length to diameter (L/D) of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.