ASTM F2949-12

(Specification)Standard Specification for Pole Vault Box Collars

Standard Specification for Pole Vault Box Collars

ABSTRACT

This specification covers minimum requirements of size, physical characteristics of materials, standard testing procedures, labeling and identification of pole vault box collars. With the required minimum dimensions, maximum thickness, maximum dimensions of box collar cutout, minimum dimensions of box collar cutout a pole vault box collars shall be tested under ambient conditions that match those of intended use. The pole vault box collar shall be tested using the impact testing procedures for Installed Surface Performance Test (Field Test) of ASTM F1292.

SCOPE

1.1 This specification covers minimum requirements of size, physical characteristics of materials, standard testing procedures, labeling and identification of pole vault box collars.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2949 −12

StandardSpecification for

Pole Vault Box Collars

This standard is issued under the fixed designation F2949; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 box collar wing, n—the part of the box collar arm that

extends down the inner sidewall of the pole vault box. The box

1.1 This specification covers minimum requirements of

collar wings provide protection and help to hold the box collar

size, physical characteristics of materials, standard testing

in place.

procedures, labeling and identification of pole vault box

collars. 3.1.5 front buns, n—the parts of the pole vault landing

system that pad the areas between the standard bases and

1.2 Units—The values stated in either SI units or inch-

around the pole vault box.

pound units are to be regarded separately as standard. The

values stated in each system may not be exact equivalents; 3.1.6 front opening, n—the opening at the front of the pole

vault box nearest the approach runway.

therefore, each system shall be used independently of the other.

Combining values from the two systems may result in non-

3.1.7 pole bend cavity, n—the rearmost portion of the pole

conformance with the standard.

vault box and box collar cutout in front of the strike plate

1.3 This standard does not purport to address all of the where the pole bends and rotates. The cavity is formed by the

safety concerns, if any, associated with its use. It is the sidewalls and strike plate of the pole vault box, the rearmost

responsibility of the user of this standard to establish appro- part of the pole slide, and inside edges of the box collar cutout

priate safety and health practices and determine the applica- over the deepest part of the box where the pole slide meets the

bility of regulatory limitations prior to use. strike plate.

3.1.8 pole slide, n—the floor of the pole vault box that slants

2. Referenced Documents

downward from its front boundary with the runway to its rear

2.1 ASTM Standards: boundary with the back of the box. The tip of the vaulting pole

F1292 Specification for Impact Attenuation of Surfacing

slides on the pole slide to the strike plate.

Materials Within the Use Zone of Playground Equipment

3.1.9 pole slide opening, n—the space between the ends of

the box collar arms at the front of the pole vault box collar and

3. Terminology

above the intersection of the runway with the pole slide.

3.1 Definitions:

3.1.10 pole vault box, n—the trough at the end of the pole

3.1.1 box collar arms, n—the two parts of the pole vault box

vault runway. It has four sides: a downward sloping floor or

collar to the left and right of the pole vault box. If the box

pole slide, two sidewalls, and a strike plate. A vaulter directs

collar has box collar wings, the wings are part of the box collar

the lower end of the vaulting pole into the pole vault box. The

arms.

backwallofpolevaultboxstopstheforwardmotionoftheend

3.1.2 box collar body, n—the part of the pole vault box

of the pole while allowing the pole to rotate about its end as the

collar that pads the horizontal surfaces around the rim of the

vaulter leaves the ground and completes a vault.

pole vault box and under the front buns.

3.1.11 pole vault box collar, n—a device used to offer

3.1.3 box collar cutout, n—the opening in the pole vault box

impact protection to pole vaulters in and around a pole vault

collar above the pole vault box.

box.

3.1.12 sidewalls, n—the left and right walls of the pole vault

box.

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment and Facilities and is the direct responsibility of Subcommittee F08.67 on

3.1.13 strike plate, n—the back wall of the pole vault box;

Pole Vault.

the stopboard.

Current edition approved Sept. 1, 2012. Published October 2012. DOI: 10.1520/

F2949-12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4. Performance Requirements

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 The average peak acceleration calculated from the last

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. two of a series of three impact tests for each impact test

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2949−12

location on the pole vault box collar shall not exceed 200 g rear edge of the box collar cutout shall be at least 38 cm (15

when impact tested in accordance with Section 9. in.). At its uppermost surface, the box collar shall cover the

upper edges of each sidewall of the box from the front of the

4.2 The average HIC score calculated from the last two of a

box where the pole slide meets the runway to a point on the top

series of three impact tests for each impact test location on the

edge of the sidewall no less than 20 cm (8 in.) forward of the

pole vault box collar shall not exceed 1150 when impact tested

topofthestrikeplate.Theboxcollararmsshallextendforward

in accordance with Section 9.

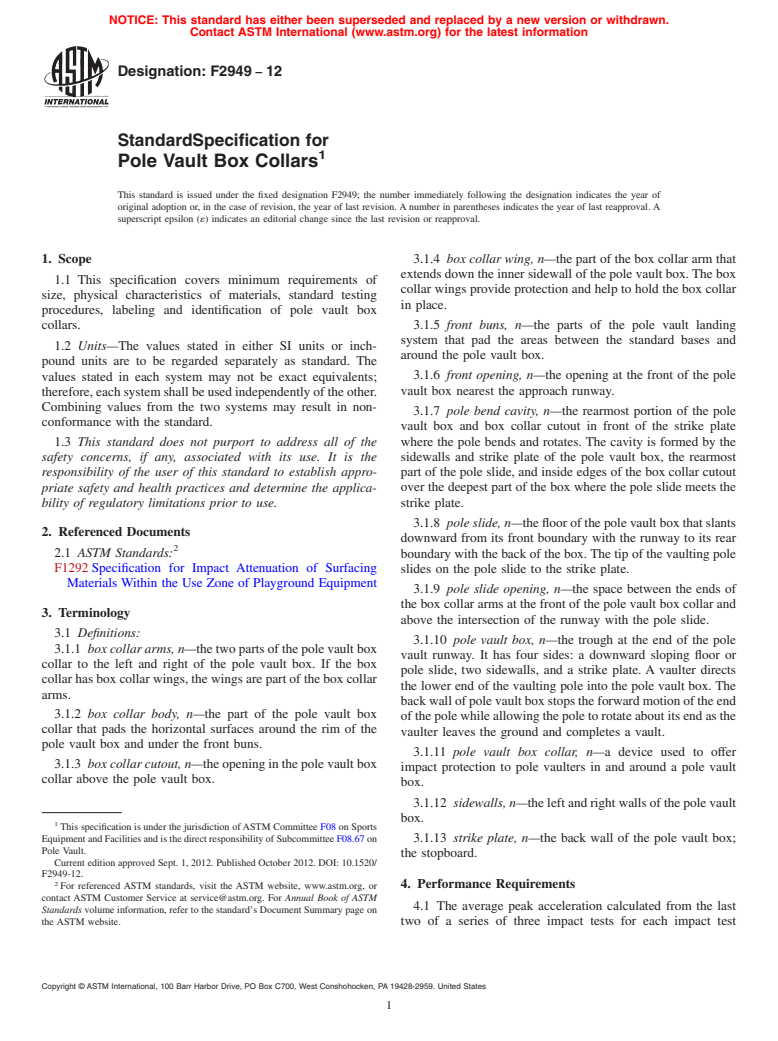

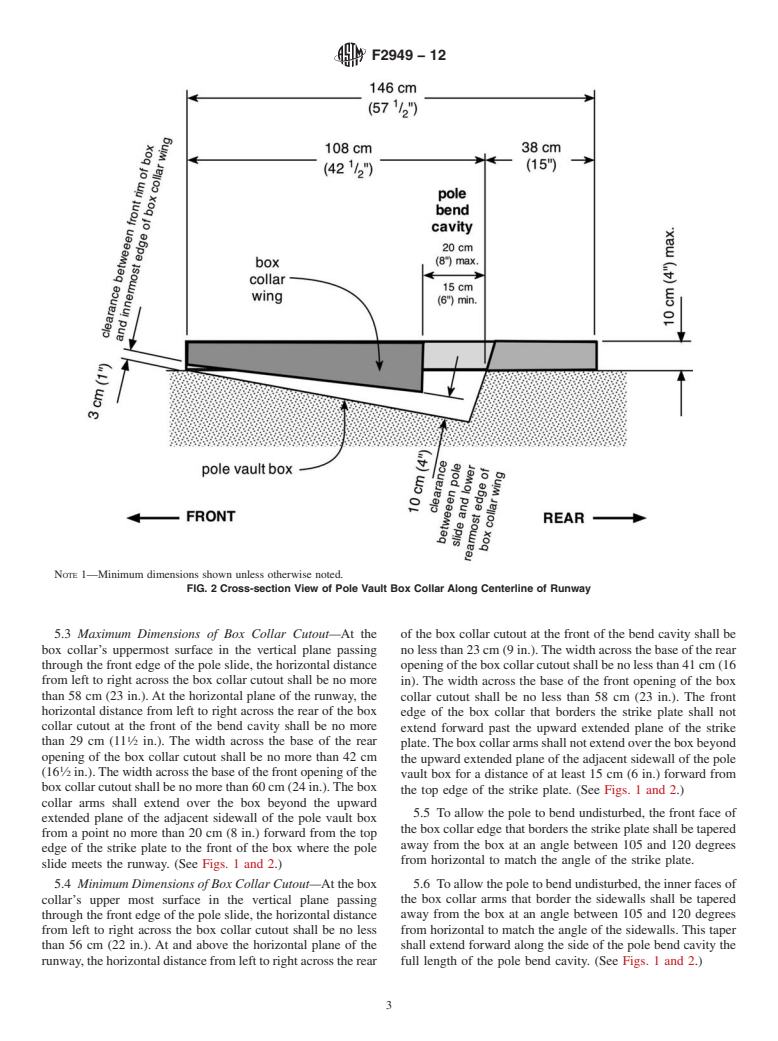

at least 108 cm (42 ⁄2 in.) from the base of the rear edge of the

5. Dimensions

box collar cutout. (See Figs. 1 and 2.)

5.1 Minimum Dimensions—A pole vault box collar shall be

5.2 Maximum Thickness—A pole vault box collar shall be

at least 122 cm (48 in.) wide and 146 cm (57 ⁄2 in.) long. The

no more than 10 cm (4 in.) thick.

distance from the rear edge of the box collar at its base to the

NOTE 1—Minimum dimensions shown unless otherwise noted.

FIG. 1Plan View of Pole Vault Box Collar

F2949−12

NOTE 1—Minimum dimensions shown unless otherwise noted.

FIG. 2Cross-section View of Pole Vault Box Collar Along Centerline of Runway

5.3 Maximum Dimensions of Box Collar Cutout—At the of the box collar cutout at the front of the bend cavity shall be

box collar’s uppermost surface in the vertical plane passing

no less than 23 cm (9 in.).The width across the base of the rear

through the front edge of the pole slide, the horizontal distance opening of the box collar cutout shall be no less than 41 cm (16

from left to right across the box collar cutout shall be no more

in). The width across the base of the front opening of the box

than 58 cm (23 in.). At the horizontal plane of the runway, the

collar cutout shall be no less than 58 cm (23 in.). The front

horizontal distance from left to right across the rear of the box

edge of the box collar that borders the strike plate shall not

collar cutout at the front of the bend cavity shall be no more

extend forward past the upward extended plane of the strike

than 29 cm (11 ⁄2 in.). The width across the base of the rear

plate.Theboxcollararmsshallnotextendovertheboxbeyond

opening of the box collar cutout shall be no more than 42 cm

the upward extended plane of the adjacent sidewall of the pole

(16 ⁄2 in.).The width across the base of the front opening of the

vault box for a distance of at least 15 cm (6 in.) forward from

box collar cutout shall be no more than 60 cm (24 in.).The box

the top edge of the strike plate. (See Figs. 1 and 2.)

collar arms shall extend over the box beyond the upward

5.5 To allow the pole to bend undisturbed, the front face of

extended plane of the adjacent sidewall of the pole vault box

the box collar edge that borders the strike plate shall be tapered

from a point no more than 20 cm (8 in.) forward from the top

away from the box at an angle between 105 and 120 degrees

edge of the strike plate to the front of the box where the pole

from horizontal to match the angle of the strike plate.

slide meets the runway. (See Figs. 1 and 2.)

5.4 Minimum Dimensions of Box Collar Cutout—At the box 5.6 To allow the pole to bend undisturbed, the inner faces of

the box collar arms that border the sidewalls shall be tapered

collar’s upper most surface in the vertical plane passing

through the front edge of the pole slide, the horizontal distance away from the box at an angle between 105 and 120 degrees

from left to right across the box collar cutout shall be no less from horizontal to match the angle of the sidewalls. This taper

than 56 cm (22 in.). At and above the horizontal plane of the shall extend forward along the side of the pole bend cavity the

runway,thehorizontaldistancefromlefttorightacrosstherear full length of the pole bend cavity. (See Figs. 1 and 2.)

F2949−12

5.7 The body of the box collar shall extend rearward at least 7.2 Missile—The missile used is described in section 8.2.1

30 cm (12 in.) under the front buns of the pole vault landing ofASTM F1292 Standard Specification for ImpactAt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.