ASTM E1300-00

(Practice)Standard Practice for Determining Load Resistance of Glass in Buildings

Standard Practice for Determining Load Resistance of Glass in Buildings

SCOPE

1.1 This practice covers a procedure to determine the load resistance of specified glass types, including combinations of glass types used in a sealed insulating glass unit, exposed to a uniform lateral load of short or long duration, for a specified probability of breakage.

1.2 This practice is applicable to common architectural designs only for which the specified design loads are less than or equal to 10 kPa (210 psf).

1.3 This practice can only be applied to monolithic, laminated, or insulating glass of rectangular shape with continuous lateral support of all four edges. This practice assumes that the edges of the glass are simply supported and free to slip in plane.

1.4 This practice is applicable to annealed, heat strengthened, fully tempered, laminated, and insulating glass units as defined in 3.2.4. This practice is not applicable to any form of wired, patterned, etched, sandblasted, or types of glass with surface treatments that reduce the glass strength.

1.5 This practice only addresses the determination of the resistance of glass to uniform lateral loads. The final thickness and type of glass selected also depends upon a variety of other factors (see 5.3).

1.6 Two procedures are presented which allow the approximate center of glass lateral deflection to be calculated (see Appendix X1 and Appendix X2 ). A procedure is also presented to calculate the probability of breakage of any annealed lite or ply (see Appendix X3 ), for short or long duration loads.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. For conversion of quantities in various systems of measurements to SI units refer to Practice E380.

1.8 Appendix X4 lists the key variables used in calculating the mandatory type factors in and comments on their conservative values.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: E 1300 – 00

Standard Practice for

Determining Load Resistance of Glass in Buildings

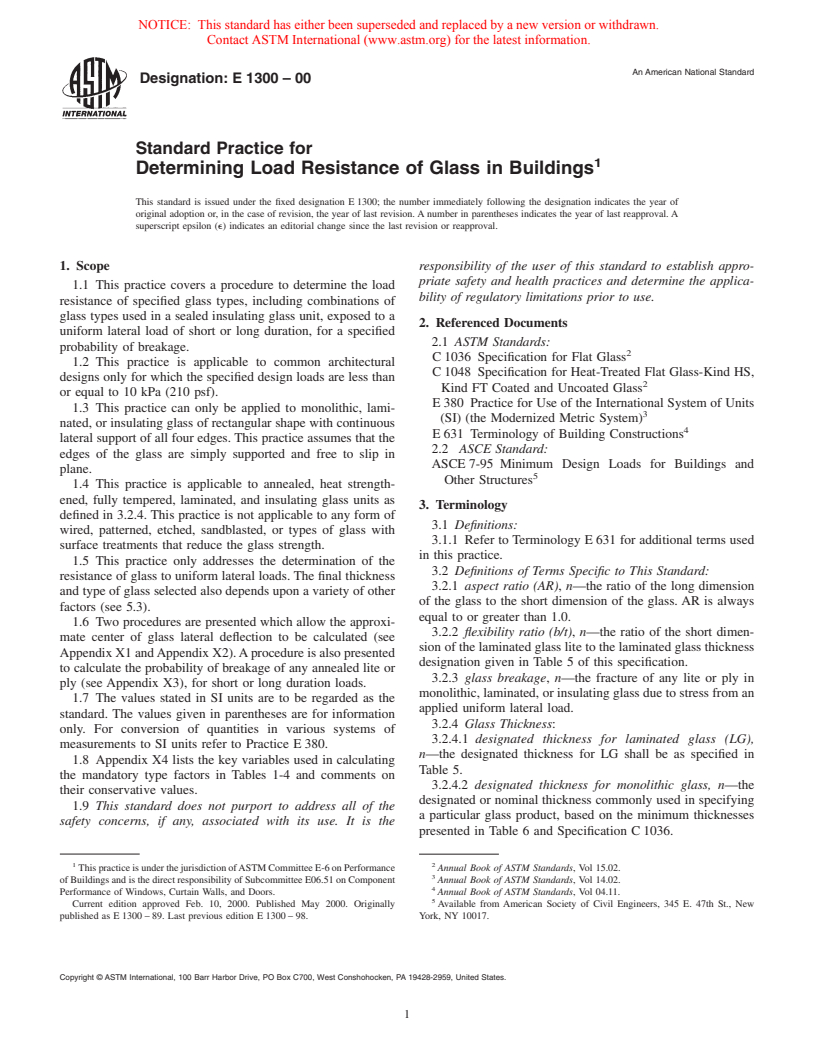

This standard is issued under the fixed designation E1300; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 This practice covers a procedure to determine the load

bility of regulatory limitations prior to use.

resistance of specified glass types, including combinations of

glass types used in a sealed insulating glass unit, exposed to a

2. Referenced Documents

uniform lateral load of short or long duration, for a specified

2.1 ASTM Standards:

probability of breakage.

C1036 Specification for Flat Glass

1.2 This practice is applicable to common architectural

C1048 Specification for Heat-Treated Flat Glass-Kind HS,

designs only for which the specified design loads are less than

Kind FT Coated and Uncoated Glass

or equal to 10 kPa (210 psf).

E380 Practice for Use of the International System of Units

1.3 This practice can only be applied to monolithic, lami-

(SI) (the Modernized Metric System)

nated, or insulating glass of rectangular shape with continuous

E631 Terminology of Building Constructions

lateral support of all four edges.This practice assumes that the

2.2 ASCE Standard:

edges of the glass are simply supported and free to slip in

ASCE7-95 Minimum Design Loads for Buildings and

plane.

Other Structures

1.4 This practice is applicable to annealed, heat strength-

ened, fully tempered, laminated, and insulating glass units as

3. Terminology

defined in 3.2.4. This practice is not applicable to any form of

3.1 Definitions:

wired, patterned, etched, sandblasted, or types of glass with

3.1.1 Refer to Terminology E631 for additional terms used

surface treatments that reduce the glass strength.

in this practice.

1.5 This practice only addresses the determination of the

3.2 Definitions of Terms Specific to This Standard:

resistance of glass to uniform lateral loads. The final thickness

3.2.1 aspect ratio (AR), n—the ratio of the long dimension

and type of glass selected also depends upon a variety of other

of the glass to the short dimension of the glass. AR is always

factors (see 5.3).

equal to or greater than 1.0.

1.6 Two procedures are presented which allow the approxi-

3.2.2 flexibility ratio (b/t), n—the ratio of the short dimen-

mate center of glass lateral deflection to be calculated (see

sion of the laminated glass lite to the laminated glass thickness

AppendixX1andAppendixX2).Aprocedureisalsopresented

designation given in Table 5 of this specification.

to calculate the probability of breakage of any annealed lite or

3.2.3 glass breakage, n—the fracture of any lite or ply in

ply (see Appendix X3), for short or long duration loads.

monolithic,laminated,orinsulatingglassduetostressfroman

1.7 The values stated in SI units are to be regarded as the

applied uniform lateral load.

standard. The values given in parentheses are for information

3.2.4 Glass Thickness:

only. For conversion of quantities in various systems of

3.2.4.1 designated thickness for laminated glass (LG),

measurements to SI units refer to Practice E380.

n—the designated thickness for LG shall be as specified in

1.8 Appendix X4 lists the key variables used in calculating

Table 5.

the mandatory type factors in Tables 1-4 and comments on

3.2.4.2 designated thickness for monolithic glass, n—the

their conservative values.

designated or nominal thickness commonly used in specifying

1.9 This standard does not purport to address all of the

a particular glass product, based on the minimum thicknesses

safety concerns, if any, associated with its use. It is the

presented in Table 6 and Specification C1036.

1 2

ThispracticeisunderthejurisdictionofASTMCommitteeE-6onPerformance Annual Book of ASTM Standards, Vol 15.02.

ofBuildingsandisthedirectresponsibilityofSubcommitteeE06.51onComponent Annual Book of ASTM Standards, Vol 14.02.

Performance of Windows, Curtain Walls, and Doors. Annual Book of ASTM Standards, Vol 04.11.

Current edition approved Feb. 10, 2000. Published May 2000. Originally Available from American Society of Civil Engineers, 345 E. 47th St., New

published as E1300–89. Last previous edition E1300–98. York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1300–00

TABLE 1 Glass Type (GT) Factors for a Single Lite of Monolithic

or sealed IG unit of a specified type, can carry for a given

or Laminated Glass for Short Duration Load

probability of breakage.

Short Duration Load

(a) Discussion—Multiplying the non-factored load from

Laminated

figures in Annex A1, by the relevant GT and LS factors gives

Monolithic AR# 2.0 AR>2.0

the load resistance for 8 in 1000 breakage probability.

and b/t > 150 or b/t# 150

AN 1.0 0.90 0.75

3.2.8.3 long duration load, n—any load lasting approxi-

HS 2.0 1.8 1.5

mately 30 days.

FT 4.0 3.6 3.0

3.2.8.4 non-factored load (NFL), n—sixty second duration

uniform load associated with a probability of breakage of 8

lites per thousand for monolithic annealed glass as determined

TABLE 2 Glass Type (GT) Factors for a Single Lite of Monolithic

or Laminated Glass for Long Duration Load

from the figures in Annex A1.

Long Duration Load 3.2.8.5 short duration load, n—anyloadlasting60sorless.

Laminated

3.2.9 load share (LS) factor, n—a multiplying factor de-

Monolithic

AR#2.5 AR>2.5

rived from the load sharing between the two lites, of equal or

AN 0.6 0.45 0.30

HS 1.6 1.2 0.80 different thicknesses and types (including the layered behavior

FT 3.6 2.7 1.8

of laminated glass under long duration loads), in a sealed IG

unit.

3.2.9.1 Discussion—The LS factor is used along with the

3.2.4.3 minimum thickness of monolithic glass, n—themini-

glass type factor (GT) and the value (NFL) from the non-

mum allowable thickness associated with a nominal or desig-

factored load charts to give the load resistance of the IG unit,

nated glass thickness as given in Table 6 and Specification

based on the resistance to breakage of one specific lite only.

C1036.

3.2.10 probability of breakage (P ), n—the theoretical frac-

b

3.2.4.4 monolithic glass thickness, n—the thickness of

tion of glass lites or plies that would break at the first

monolithic glass determined through measurement.

occurrence of the resistance load, typically expressed in lites

3.2.5 Glass Types:

per thousand.

3.2.5.1 annealed (AN) glass, n—a flat, monolithic, glass

3.2.11 specifying authority, n—the designer responsible for

plate of uniform thickness; it is formed by a process whereby

interpretinglocal,state,andfederalbuildingcodesandrespon-

the magnitudes of the residual stresses are nearly zero.

sible for considering appropriate site specific factors on behalf

3.2.5.2 fully tempered (FT) glass, n—a flat, monolithic,

of an architect, engineer or owner, in order to determine the

glass plate of uniform thickness.

appropriate values to be used to calculate the specified design

(a) Discussion—Fully tempered glass has been subjected to

load and for furnishing all other information required to

a special heat treatment process whereby the residual surface

perform this practice.

compression is not less than 69 MPa (10000 psi) or the edge

4. Summary of Practice

compression not less than 67 MPa (9700 psi) as defined in

Specification C1048.

4.1 The specifying authority shall provide the specified

3.2.5.3 heat strengthened (HS) glass, n—a flat, monolithic,

design load (shall be not more than 10 kPa, or 210 psf), the

glass plate of uniform thickness.

rectangular glass dimensions, the type of glass required, and a

(a) Discussion—Heatstrengthenedglasshasbeensubjected

statement, or details, showing that the framing system is stiff

toaspecialheattreatmentprocesswherebytheresidualsurface

enough to meet the requirements of this practice (see 5.2.4).

compression is not less than 24 MPa (3500 psi) or greater than

4.2 The procedure specified in this practice is used to

69 MPa (10000 psi), or the edge compression is not less than

determine the uniform lateral load resistance of a glazing

38 MPa (5500 psi) as defined in Specification C1048.

assembly. If the load resistance is less than the specified load,

3.2.5.4 insulating glass (IG) unit, n—consists of any com-

then other glass types and thicknesses can be evaluated to find

bination of two glass lites, as defined herein, that enclose a

asuitableassemblywhoseloadresistanceexceedsthespecified

sealed space filled with air or other gas.

load.

3.2.5.5 laminated glass (LG), n—a flat-plate of uniform

4.3 Two procedures that can be used to determine the

thickness that is fabricated by bonding two monolithic glass

approximate center of glass lateral deflection for a specified

plates or plies of equal thickness, as defined herein, together

load are presented in Appendix X1 and Appendix X2.

with a polyvinyl butyral (PVB) interlayer.

4.4 Anoptionalprocedurefordeterminingtheprobabilityof

3.2.6 glass type (GT) factor, n—a multiplying factor for

breakage at a given load is presented in Appendix X3.

annealed,heatstrengthened,fullytemperedorlaminatedglass,

5. Significance and Use

used with the non-factored load charts.

3.2.7 lateral, adj—perpendicular to the glass surface. 5.1 This practice can be used to determine the load resis-

3.2.8 load, n—a uniformly distributed lateral pressure. tance of specified glass types, including combinations of glass

3.2.8.1 specified design load, n—the magnitude in kPa types used in sealed insulating glass units, exposed to uniform

(psf), type (for example, wind or snow) and duration of the lateral loads, of short or long duration.

load given by the specifying authority. 5.2 Use of this practice assumes:

3.2.8.2 load resistance (LR), or resistance load, n—the 5.2.1 The glass is free of edge damage and is properly

uniform lateral load that a single glass lite of a specified type glazed,

E1300–00

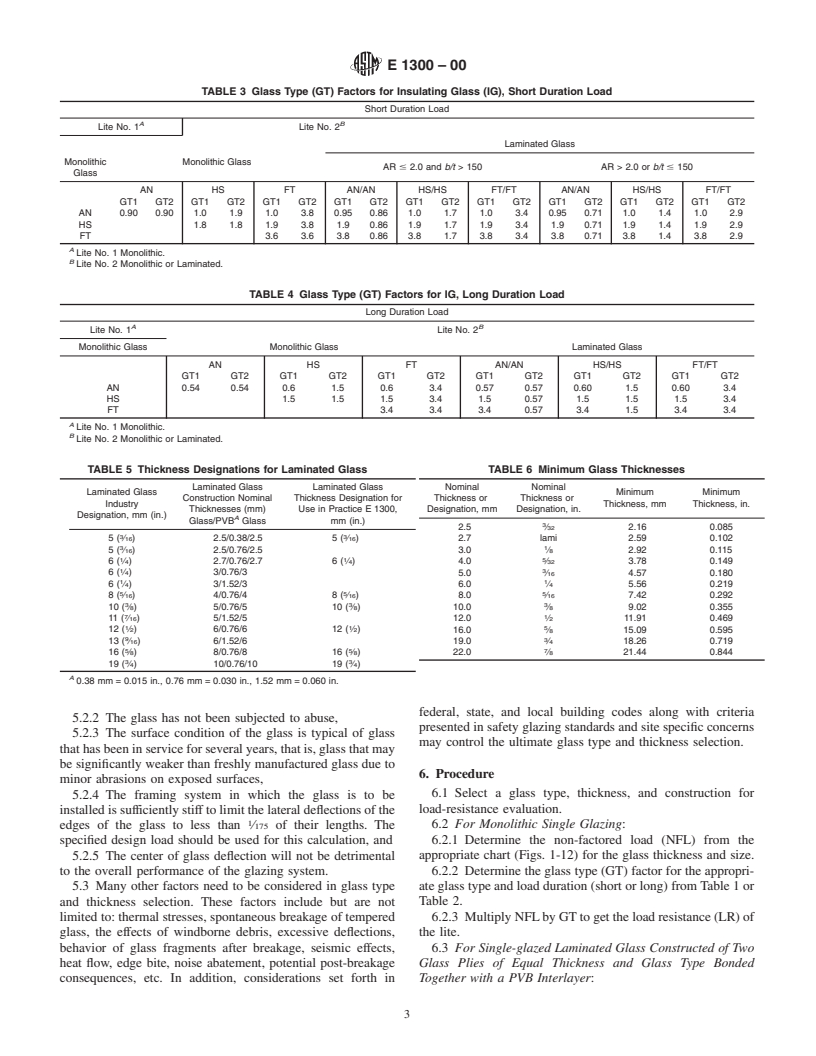

TABLE 3 Glass Type (GT) Factors for Insulating Glass (IG), Short Duration Load

Short Duration Load

A B

Lite No. 1 Lite No. 2

Laminated Glass

Monolithic Monolithic Glass

AR# 2.0 and b/t > 150 AR > 2.0 or b/t# 150

Glass

AN HS FT AN/AN HS/HS FT/FT AN/AN HS/HS FT/FT

GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2

AN 0.90 0.90 1.0 1.9 1.0 3.8 0.95 0.86 1.0 1.7 1.0 3.4 0.95 0.71 1.0 1.4 1.0 2.9

HS 1.8 1.8 1.9 3.8 1.9 0.86 1.9 1.7 1.9 3.4 1.9 0.71 1.9 1.4 1.9 2.9

FT 3.6 3.6 3.8 0.86 3.8 1.7 3.8 3.4 3.8 0.71 3.8 1.4 3.8 2.9

A

Lite No. 1 Monolithic.

B

Lite No. 2 Monolithic or Laminated.

TABLE 4 Glass Type (GT) Factors for IG, Long Duration Load

Long Duration Load

A B

Lite No. 1 Lite No. 2

Monolithic Glass Monolithic Glass Laminated Glass

AN HS FT AN/AN HS/HS FT/FT

GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2 GT1 GT2

AN 0.54 0.54 0.6 1.5 0.6 3.4 0.57 0.57 0.60 1.5 0.60 3.4

HS 1.5 1.5 1.5 3.4 1.5 0.57 1.5 1.5 1.5 3.4

FT 3.4 3.4 3.4 0.57 3.4 1.5 3.4 3.4

A

Lite No. 1 Monolithic.

B

Lite No. 2 Monolithic or Laminated.

TABLE 5 Thickness Designations for Laminated Glass TABLE 6 Minimum Glass Thicknesses

Laminated Glass Laminated Glass Nominal Nominal

Laminated Glass Minimum Minimum

Construction Nominal Thickness Designation for Thickness or Thickness or

Industry Thickness, mm Thickness, in.

Thicknesses (mm) Use in Practice E 1300, Designation, mm Designation, in.

Designation, mm (in.)

A

Glass/PVB Glass mm (in.)

2.5 ⁄32 2.16 0.085

3 3

5( ⁄16) 2.5/0.38/2.5 5 ( ⁄16) 2.7 lami 2.59 0.102

3 1

5( ⁄16) 2.5/0.76/2.5 3.0 ⁄8 2.92 0.115

1 1 5

6( ⁄4) 2.7/0.76/2.7 6 ( ⁄4)

4.0 ⁄32 3.78 0.149

1 3

6( ⁄4) 3/0.76/3 5.0 ⁄16 4.57 0.180

1 1

6( ⁄4) 3/1.52/3 6.0 ⁄4 5.56 0.219

5 5 5

8( ⁄16) 4/0.76/4 8 ( ⁄16) 8.0 ⁄16 7.42 0.292

3 3 3

10 ( ⁄8) 5/0.76/5 10 ( ⁄8) 10.0 ⁄8 9.02 0.355

11 ( ⁄16) 5/1.52/5 12.0 ⁄2 11.91 0.469

1 1 5

12 ( ⁄2) 6/0.76/6 12 ( ⁄2) 16.0 ⁄8 15.09 0.595

9 3

13 ( ⁄16) 6/1.52/6

19.0 ⁄4 18.26 0.719

5 5 7

16 ( ⁄8) 8/0.76/8 16 ( ⁄8) 22.0 ⁄8 21.44 0.844

3 3

19 ( ⁄4) 10/0.76/10 19 ( ⁄4)

A

0.38 mm = 0.015 in., 0.76 mm = 0.030 in., 1.52 mm = 0.060 in.

federal, state, and local building codes along with criteria

5.2.2 The glass has not been subjected to abuse,

presentedinsafetyglazingstandardsandsitespecificconcerns

5.2.3 The surface condition of the glass is typical of glass

may control the ultimate glass type and thickness selection.

thathasbeeninserviceforseveralyears,thatis,glassthatmay

be significantly weaker than freshly manufactured glass due to

6. Procedure

minor abrasions on exposed surfaces,

6.1 Select a glass type, thickness, and construction for

5.2.4 The framing system in which the glass is to be

load-resistance evaluation.

installedissufficientlystifftolimitthelateraldeflectionsofthe

edges of the glass to less than ⁄175 of their lengths. The 6.2 For Monolithic Single Glazing:

6.2.1 Determine the non-factored load (NFL) from the

specified design load should be used for this calculation, and

5.2.5 The center of glass deflection will not be detrimental appropriate chart (Figs. 1-12) for the glass thickness and size.

6.2.2 Determine the glass type (GT) factor for the appropri-

to the overall performance of the glazing system.

5.3 Many other factors need to be considered in glass type ateglasstypeandloadduration(shortorlong)fromTable1or

Table 2.

and thickness selection. These factors include but are not

limited to: thermal stresses, spontaneous breakage of tempered 6.2.3 MultiplyNFLbyGTtogettheloadresistance(LR)of

glass, the effects of windborne debris, excessive deflections, the lite.

behavior of glass fragments after breakage, seismic effects, 6.3 For Single-glazed Laminated Glass Constructed of Two

heat flow, edge bite, noise abatement, potential post-breakage Glass Plies of Equal Thickness and Glass Type Bonded

consequences, etc. In addition, considerations set forth in Together with a PVB Interlayer:

E1300–00

FIG. 1 Glass Thickness Selection Chart for 2.5 mm ( ⁄32 in.) Glass

FIG. 2 Glass Thickness Selection Chart for 2.7 mm Glass

E1300–00

FIG. 3 Glass Thickness Selection Chart for 3.0 mm ( ⁄8 in.) Glass

FIG. 4 Glass Thickness Selection Chart for 4.0 mm ( ⁄32 in.) Glass

E1300–00

FIG. 5 Glass Thickness Selection Chart for 5.0 mm ( ⁄16 in.) Glass

FIG. 6 Glass Thickness Selection Chart for 6.0 mm ( ⁄4 in.) Glass

E1300–00

FIG. 7 Glass Thickness Selection Chart for 8.0 mm ( ⁄16 in.) Glass

FIG. 8 Glass Thickness Selection Chart for 10.0 mm ( ⁄8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.