ASTM F3122-14(2022)

(Guide)Standard Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes

Standard Guide for Evaluating Mechanical Properties of Metal Materials Made via Additive Manufacturing Processes

SCOPE

1.1 This standard serves as a guide to existing standards or variations of existing standards that may be applicable to determine specific mechanical properties of materials made with an additive manufacturing process.

1.2 As noted in many of these referenced standards, there are several factors that may influence the reported properties, including material, material anisotropy, method of material preparation, porosity, method of specimen preparation, testing environment, specimen alignment and gripping, testing speed, and testing temperature. These factors should be recorded, to the extent that they are known, according to Practice F2971 and the guidelines of the referenced standards.

1.3 The following standards are not referred to directly in the guide but also have information that may be useful in the testing of metal test specimens made via additive manufacturing: A370, A1058, B211, B348, B557, B565, B724, B769, E3, E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

1

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

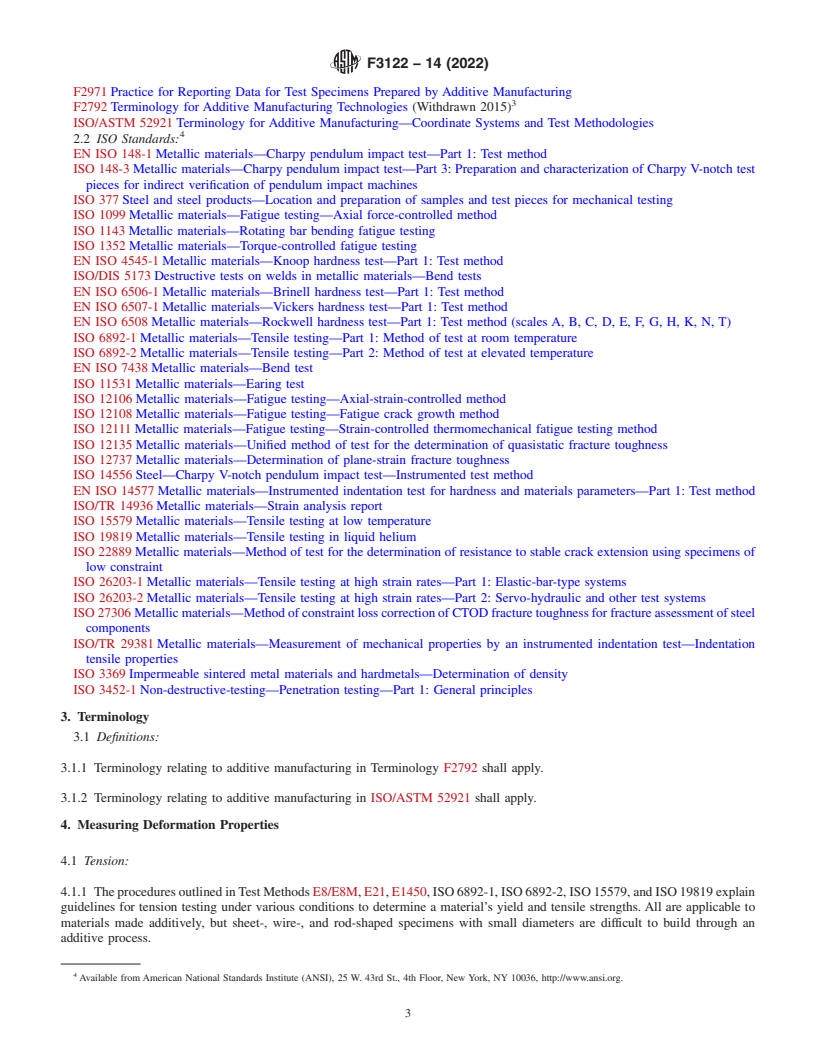

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This standard serves as a guide to existing standards or

variations of existing standards that may be applicable to A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

determine specific mechanical properties of materials made

with an additive manufacturing process. A1058 Test Methods for Mechanical Testing of Steel

Products—Metric

1.2 As noted in many of these referenced standards, there

B211 Specification for Aluminum and Aluminum-Alloy

are several factors that may influence the reported properties,

Rolled or Cold-Finished Bar, Rod, and Wire (Metric)

including material, material anisotropy, method of material

B0211_B0211M

preparation, porosity, method of specimen preparation, testing

B348 Specification for Titanium and Titanium Alloy Bars

environment, specimen alignment and gripping, testing speed,

and Billets

and testing temperature. These factors should be recorded, to

B557 Test Methods for Tension Testing Wrought and Cast

the extent that they are known, according to Practice F2971

Aluminum- and Magnesium-Alloy Products

and the guidelines of the referenced standards.

B565 Test Method for Shear Testing of Aluminum and

1.3 The following standards are not referred to directly in

Aluminum-Alloy Rivets and Cold-Heading Wire and

the guide but also have information that may be useful in the

Rods

testing of metal test specimens made via additive manufactur-

B645 Practice for Linear-Elastic Plane-Strain Fracture

ing: A370, A1058, B211, B348, B557, B565, B724, B769, E3,

Toughness Testing of Aluminum Alloys

E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

B646 Practice for Fracture Toughness Testing of Aluminum

Alloys

1.4 The values stated in SI units are to be regarded as

B647 Test Method for Indentation Hardness of Aluminum

standard. No other units of measurement are included in this

Alloys by Means of a Webster Hardness Gage

standard.

B648 Test Method for Indentation Hardness of Aluminum

1.5 This standard does not purport to address all of the

Alloys by Means of a Barcol Impressor

safety concerns, if any, associated with its use. It is the

B724 Test Method for Indentation Hardness of Aluminum

responsibility of the user of this standard to establish appro-

Alloys by Means of a Newage, Portable, Non-Caliper-

priate safety, health, and environmental practices and deter-

3

Type Instrument (Withdrawn 2013)

mine the applicability of regulatory limitations prior to use.

B769 Test Method for Shear Testing of Aluminum Alloys

1.6 This international standard was developed in accor-

B909 Guide for Plane Strain Fracture Toughness Testing of

dance with internationally recognized principles on standard-

Non-Stress Relieved Aluminum Products

ization established in the Decision on Principles for the

E3 Guide for Preparation of Metallographic Specimens

Development of International Standards, Guides and Recom-

E6 Terminology Relating to Methods of Mechanical Testing

mendations issued by the World Trade Organization Technical

E7 Terminology Relating to Metallography

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This guide is under the jurisdiction of ASTM Committee F42 on Additive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Manufacturing Technologies and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F42.01 on Test Methods. the ASTM website.

3

Current edition approved April 1, 2022. Published April 2022. Originally The last approved version of this historical standard is referenced on

approved in 2014 as F3122–14. DOI: 10.1520/F3122-14R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3122 − 14 (2022)

E8/E8M Test Methods for Tension Testing of Metallic Ma- E1450 Test Method for Tension Testing of StructuralAlloys

terials in Liquid Helium

E1457 Test Method for Measurement of Creep Crack

E9 Test Methods of Compress

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

1

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This standard serves as a guide to existing standards or 2.1 ASTM Standards:

variations of existing standards that may be applicable to A370 Test Methods and Definitions for Mechanical Testing

determine specific mechanical properties of materials made of Steel Products

with an additive manufacturing process. A1058 Test Methods for Mechanical Testing of Steel

Products—Metric

1.2 As noted in many of these referenced standards, there

B211 Specification for Aluminum and Aluminum-Alloy

are several factors that may influence the reported properties,

Rolled or Cold-Finished Bar, Rod, and Wire (Metric)

including material, material anisotropy, method of material

B0211_B0211M

preparation, porosity, method of specimen preparation, testing

B348 Specification for Titanium and Titanium Alloy Bars

environment, specimen alignment and gripping, testing speed,

and Billets

and testing temperature. These factors should be recorded, to

B557 Test Methods for Tension Testing Wrought and Cast

the extent that they are known, according to Practice F2971

Aluminum- and Magnesium-Alloy Products

and the guidelines of the referenced standards.

B565 Test Method for Shear Testing of Aluminum and

1.3 The following standards are not referred to directly in

Aluminum-Alloy Rivets and Cold-Heading Wire and

the guide but also have information that may be useful in the

Rods

testing of metal test specimens made via additive manufactur-

B645 Practice for Linear-Elastic Plane-Strain Fracture

ing: A370, A1058, B211, B348, B557, B565, B724, B769, E3,

Toughness Testing of Aluminum Alloys

E6, E7, E290, E467, E468, E837, E915, E1049,E1823, E1942.

B646 Practice for Fracture Toughness Testing of Aluminum

Alloys

1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this B647 Test Method for Indentation Hardness of Aluminum

Alloys by Means of a Webster Hardness Gage

standard.

B648 Test Method for Indentation Hardness of Aluminum

1.5 This standard does not purport to address all of the

Alloys by Means of a Barcol Impressor

safety concerns, if any, associated with its use. It is the

B724 Test Method for Indentation Hardness of Aluminum

responsibility of the user of this standard to establish appro-

Alloys by Means of a Newage, Portable, Non-Caliper-

priate safety, health, and environmental practices and deter-

3

Type Instrument (Withdrawn 2013)

mine the applicability of regulatory limitations prior to use.

B769 Test Method for Shear Testing of Aluminum Alloys

1.6 This international standard was developed in accor-

B909 Guide for Plane Strain Fracture Toughness Testing of

dance with internationally recognized principles on standard-

Non-Stress Relieved Aluminum Products

ization established in the Decision on Principles for the

E3 Guide for Preparation of Metallographic Specimens

Development of International Standards, Guides and Recom-

E6 Terminology Relating to Methods of Mechanical Testing

mendations issued by the World Trade Organization Technical

E7 Terminology Relating to Metallography

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This guide is under the jurisdiction of ASTM Committee F42 on Additive contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Manufacturing Technologies and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

F42.01 on Test Methods. the ASTM website.

3

Current edition approved April 1, 2022. Published April 2022. Originally The last approved version of this historical standard is referenced on

approved in 2014 as F3122–14. DOI: 10.1520/F3122-14R22. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3122 − 14 (2022)

E8/E8M Test Methods for Tension Testing of Metallic Ma- E1450 Test Method for Tension Testing of Structural Alloys

in Liquid Helium

terials

E1457 Test Method for Measurement of Creep Crack

E9 Test Methods of Compression Testing of Metallic Mate-

Growth Times in Metals

rials at Room Temperature

E1681 Test Method for Determining Threshold Stress Inten-

E10 Test Meth

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3122 − 14 F3122 − 14 (Reapproved 2022)

Standard Guide for

Evaluating Mechanical Properties of Metal Materials Made

1

via Additive Manufacturing Processes

This standard is issued under the fixed designation F3122; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard serves as a guide to existing standards or variations of existing standards that may be applicable to determine

specific mechanical properties of materials made with an additive manufacturing process.

1.2 As noted in many of these referenced standards, there are several factors that may influence the reported properties, including

material, material anisotropy, method of material preparation, porosity, method of specimen preparation, testing environment,

specimen alignment and gripping, testing speed, and testing temperature. These factors should be recorded, to the extent that they

are known, according to Practice F2971 and the guidelines of the referenced standards.

1.3 The following standards are not referred to directly in the guide but also have information that may be useful in the testing

of metal test specimens made via additive manufacturing: A370, A1058, B211, B348, B557, B565, B724, B769, E3, E6, E7, E290,

E467, E468, E837, E915, E1049,E1823, E1942.

1.4 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this

standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A1058 Test Methods for Mechanical Testing of Steel Products—Metric

B211 Specification for Aluminum and Aluminum-Alloy Rolled or Cold-Finished Bar, Rod, and Wire (Metric) B0211_B0211M

B348 Specification for Titanium and Titanium Alloy Bars and Billets

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

1

This test method guide is under the jurisdiction of ASTM Committee F42 on Additive Manufacturing Technologies and is the direct responsibility of Subcommittee

F42.01 on Test Methods.

Current edition approved Nov. 1, 2014April 1, 2022. Published December 2014April 2022. Originally approved in 2014 as F3122–14. DOI: 10.1520/F3122-14.10.1520/

F3122-14R22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3122 − 14 (2022)

B565 Test Method for Shear Testing of Aluminum and Aluminum-Alloy Rivets and Cold-Heading Wire and Rods

B645 Practice for Linear-Elastic Plane-Strain Fracture Toughness Testing of Aluminum Alloys

B646 Practice for Fracture Toughness Testing of Aluminum Alloys

B647 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Webster Hardness Gage

B648 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Barcol Impressor

B724 Test Method for Indentation Hardness of Aluminum Alloys by Means of a Newage, Portable, Non-Caliper-Type

3

Instrument (Withdrawn 2013)

B769 Test Method for Shear Testing of Aluminum Alloys

B909 Guide for Plane Strain Fracture Toughness Testing of Non-Stress Relieved Aluminum Products

E3 Guide for Preparation of Metallographic Specimens

E6 Terminology Relating to Methods of Mechanical Testing

E7 Terminology Relating to Metallography

E8/E8M Test Methods for Tension Testing of Metallic Materials

E9 Test Methods of Compression Testing of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.