ASTM D5148-97

(Test Method)Standard Test Method for Centrifuge Kerosine Equivalent

Standard Test Method for Centrifuge Kerosine Equivalent

SCOPE

1.1 This test method determines the centrifuge kerosine equivalent (CKE) of aggregate used in bituminous mixtures.

1.2 Units of Measure:

1.2.1 With regard to sieve sizes and size of aggregate as determined by the use of testing sieves, the values in inch-pound units are shown for the convenience of the user, but the standard sieve designation shown in parentheses is the standard value as stated in Specification E11.

1.2.2 With regard to other units of measure, the values shown in parentheses are for information purposes.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 7.1.

General Information

Relations

Standards Content (Sample)

Designation: D 5148 – 97

Standard Test Method for

1

Centrifuge Kerosine Equivalent

This standard is issued under the fixed designation D 5148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope sample which passes the ⁄8-in. (9.5-mm) sieve and is retained

on the No. 4 (4.75-mm) sieve.

1.1 This test method determines the centrifuge kerosine

3.1.2 F—fine aggregate fraction, that portion of the sample

equivalent (CKE) of aggregate used in bituminous mixtures.

which passes the No. 4 (4.75-mm) sieve.

1.2 Units of Measure:

2 2

3.1.3 SA—surface area. The sum, m /kg (ft /lb), obtained by

1.2.1 With regard to sieve sizes and size of aggregate as

adding the products of the percent passing each sieve and its

determined by the use of testing sieves, the values in inch-

corresponding factor, (see 11.1) and dividing by 100.

pound units are shown for the convenience of the user, but the

3.1.4 K factors—values determined as described in 3.1.5

standard sieve designation shown in parentheses is the standard

through 3.1.8 and identified as K , K,or K .

c f m

value as stated in Specification E 11.

3.1.5 K —determined from the percent of SAE No. 10 oil

1.2.2 With regard to other units of measure, the values c

retained, which represents the total effect of the aggregate’s

shown in parentheses are for information purposes.

absorptive properties and surface roughness of the aggregates

1.3 This standard does not purport to address all of the

coarse fraction.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

NOTE 1—Based on comparative testing in California, the same results

priate safety and health practices and determine the applica- can be obtained substituting Shell Tellus No. 100 oil for SAE No. 10 oil.

bility of regulatory limitations prior to use. For specific hazard

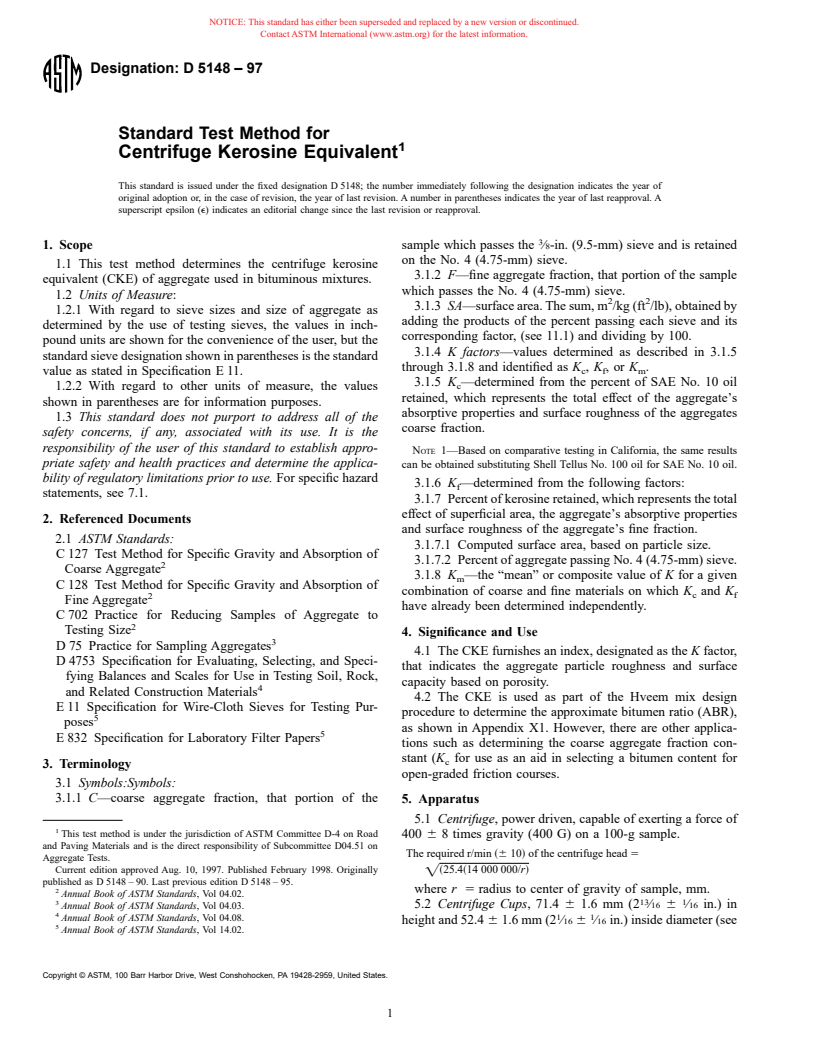

3.1.6 K —determined from the following factors:

f

statements, see 7.1.

3.1.7 Percent of kerosine retained, which represents the total

effect of superficial area, the aggregate’s absorptive properties

2. Referenced Documents

and surface roughness of the aggregate’s fine fraction.

2.1 ASTM Standards:

3.1.7.1 Computed surface area, based on particle size.

C 127 Test Method for Specific Gravity and Absorption of

3.1.7.2 Percent of aggregate passing No. 4 (4.75-mm) sieve.

2

Coarse Aggregate

3.1.8 K —the “mean” or composite value of K for a given

m

C 128 Test Method for Specific Gravity and Absorption of

combination of coarse and fine materials on which K and K

c f

2

Fine Aggregate

have already been determined independently.

C 702 Practice for Reducing Samples of Aggregate to

2

Testing Size

4. Significance and Use

3

D 75 Practice for Sampling Aggregates

4.1 The CKE furnishes an index, designated as the K factor,

D 4753 Specification for Evaluating, Selecting, and Speci-

that indicates the aggregate particle roughness and surface

fying Balances and Scales for Use in Testing Soil, Rock,

capacity based on porosity.

4

and Related Construction Materials

4.2 The CKE is used as part of the Hveem mix design

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

procedure to determine the approximate bitumen ratio (ABR),

5

poses

as shown in Appendix X1. However, there are other applica-

5

E 832 Specification for Laboratory Filter Papers

tions such as determining the coarse aggregate fraction con-

stant (K for use as an aid in selecting a bitumen content for

c

3. Terminology

open-graded friction courses.

3.1 Symbols:Symbols:

3.1.1 C—coarse aggregate fraction, that portion of the

5. Apparatus

5.1 Centrifuge, power driven, capable of exerting a force of

1

This test method is under the jurisdiction of ASTM Committee D-4 on Road

400 6 8 times gravity (400 G) on a 100-g sample.

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

The required r/min ~6 10! of the centrifuge head 5

Aggregate Tests.

Current edition approved Aug. 10, 1997. Published February 1998. Originally ~25.4~14 000 000/r!

=

published as D 5148 – 90. Last previous edition D 5148 – 95.

2 where r 5 radius to center of gravity of sample, mm.

Annual Book of ASTM Standards, Vol 04.02.

3 13 1

Annual Book of ASTM Standards, Vol 04.03. 5.2 Centrifuge Cups, 71.4 6 1.6 mm (2 ⁄16 6 ⁄16 in.) in

4

1 1

Annual Book of ASTM Standards, Vol 04.08.

height and 52.4 6 1.6 mm (2 ⁄16 6 ⁄16 in.) inside diameter (see

5

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5148

Fig. 1) complete with perforated brass plate 0.787 6 0.03 mm

(0.031 6 0.001 in.) thick with a minimum of 15 holes, 1.575

mm 6 0.03 mm (0.0626 0.001 in.) in diameter, per square

2

cen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.