ASTM D8534-23

(Test Method)Standard Test Method for Determination of Trace Peroxides in Liquid, Liquefied, and Reagents Soluble Hydrocarbon Streams using Flow Injection System with Ultraviolet/Visible Detector

Standard Test Method for Determination of Trace Peroxides in Liquid, Liquefied, and Reagents Soluble Hydrocarbon Streams using Flow Injection System with Ultraviolet/Visible Detector

SIGNIFICANCE AND USE

5.1 This test method is suitable for determining the quantity of hydrogen peroxide, organic hydroperoxides, and organic peroxides as total active oxygen in various hydrocarbon streams for both quality control and quality assurance of the product.

SCOPE

1.1 This test method covers the determination of trace peroxides in various hydrocarbon streams. A list of typical hydrocarbon streams can be found in Appendix X2.

1.2 This test method is applicable to the determination of peroxides in petroleum liquids including, but not limited to, 1,3-butadiene, styrene, methylcyclohexane, and alpha olefins in the range of 0.1 mg/kg to 100 mg/kg active oxygen. The limit of detection (LOD) is 0.03 mg/kg for active oxygen and the limit of quantitation (LOQ) is 0.11 mg/kg active oxygen. The upper limit has been determined by the calibration range.

Note 1: LOD and LOQ were calculated using data obtained during development of the method.

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 9.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8534 − 23

Standard Test Method for

Determination of Trace Peroxides in Liquid, Liquefied, and

Reagents Soluble Hydrocarbon Streams using Flow

1

Injection System with Ultraviolet/Visible Detector

This standard is issued under the fixed designation D8534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of trace

D1193 Specification for Reagent Water

peroxides in various hydrocarbon streams. A list of typical

D1265 Practice for Sampling Liquefied Petroleum (LP)

hydrocarbon streams can be found in Appendix X2.

Gases, Manual Method

1.2 This test method is applicable to the determination of

D3437 Practice for Sampling and Handling Liquid Cyclic

peroxides in petroleum liquids including, but not limited to,

Products

1,3-butadiene, styrene, methylcyclohexane, and alpha olefins

D3700 Practice for Obtaining LPG Samples Using a Float-

in the range of 0.1 mg ⁄kg to 100 mg ⁄kg active oxygen. The

ing Piston Cylinder

limit of detection (LOD) is 0.03 mg ⁄kg for active oxygen and

D4790 Terminology of Aromatic Hydrocarbons and Related

the limit of quantitation (LOQ) is 0.11 mg ⁄kg active oxygen.

Chemicals

The upper limit has been determined by the calibration range.

D6809 Guide for Quality Control and Quality Assurance

Procedures for Aromatic Hydrocarbons and Related Ma-

NOTE 1—LOD and LOQ were calculated using data obtained during

terials

development of the method.

E29 Practice for Using Significant Digits in Test Data to

1.3 In determining the conformance of the test results using

Determine Conformance with Specifications

this method to applicable specifications, results shall be

E691 Practice for Conducting an Interlaboratory Study to

rounded off in accordance with the rounding-off method of

Determine the Precision of a Test Method

Practice E29.

2.2 Other Documents:

1.4 Units—The values stated in SI units are to be regarded 29 CFR 1910.1000 OSHA Regulations, Toxic and Hazard-

3

as standard. No other units of measurement are included in this

ous Substances—Air Contaminants

standard. 29 CFR 1910.1200 OSHA Regulations, Toxic and Hazard-

3

ous Substances—Hazard Communication

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Acronyms:

priate safety, health, and environmental practices and deter-

3.1.1 DBP—dibenzoyl peroxide

mine the applicability of regulatory limitations prior to use.

3.1.2 DLP—dilauroyl peroxide

For specific hazard statements, see Section 9.

1.6 This international standard was developed in accor-

4. Summary of Test Method

dance with internationally recognized principles on standard-

4.1 This method uses a Flow Injection System (FIS) based

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- on High Performance Liquid Chromatography (HPLC) hard-

ware. A sample suspected of containing peroxides is injected in

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. a reagent stream of acidified iodide. Peroxides present in the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee D16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Aromatic, Industrial, Specialty and Related Chemicals and is the direct responsi- Standards volume information, refer to the standard’s Document Summary page on

bility of Subcommittee D16.04 on Instrumental Analysis. the ASTM website.

3

Current edition approved Nov. 15, 2023. Published November 2023. DOI: Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

10.1520/D8534-23. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8534 − 23

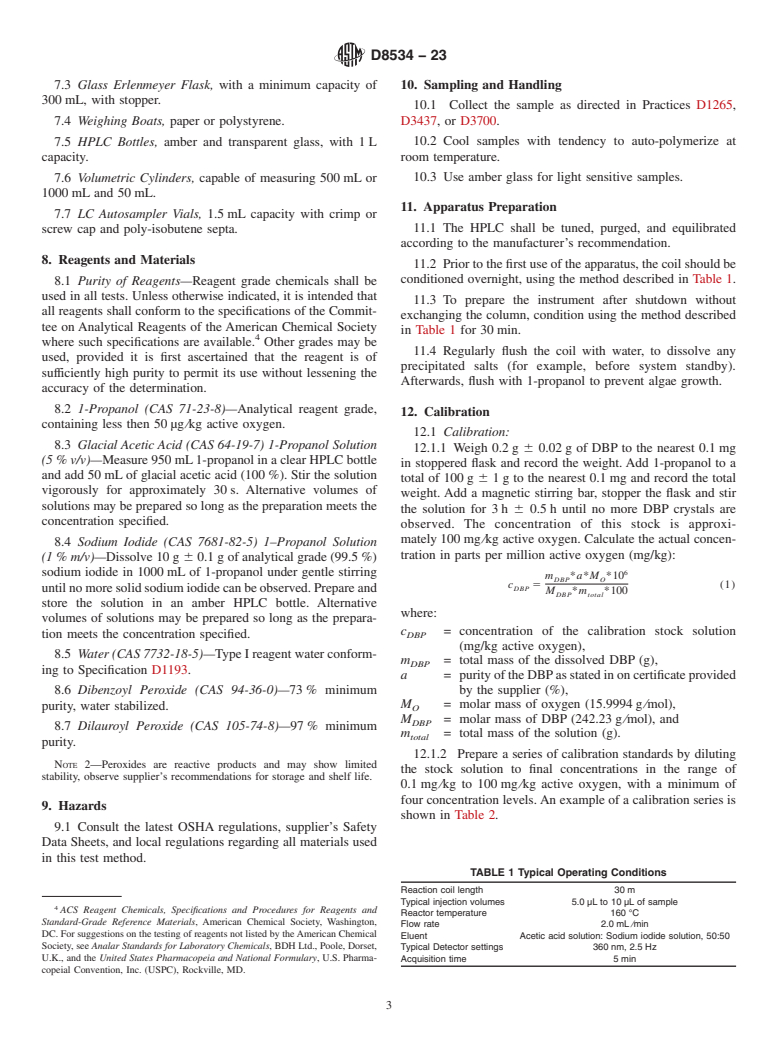

sample react with the iodide to form iodine. The formed iodine 7.1.1 HPLC System—Any high-performance liquid chro-

is detected using UV-Vis and is directly proportional to the matograph capable of delivering four liquids at flow rates

peroxide content. The concentration of peroxides in the hydro-

between 0.5 mL ⁄min and 3.0 mL ⁄min. A d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.