ASTM D5224-00(2006)

(Practice)Standard Practice for Compression Molding Test Specimens of Thermosetting Molding Compounds

Standard Practice for Compression Molding Test Specimens of Thermosetting Molding Compounds

SIGNIFICANCE AND USE

The conditions at which compounds are molded are known to influence the properties of the specimens. The degree of cure, elimination of knit-lines between particles, density of the part, and degradation of the polymer are among those factors which will be affected by the molding conditions. Thus it is important to hold to a standard set of conditions in order to have a valid comparison of properties between different compounds and different batches of the same compound.

If the molded specimens show evidence of low-density areas due to trapped gases, they should be discarded. A breathe step may be necessary to eliminate this situation. It is critical that the breathe step be as brief as possible to avoid precuring of the compound before full pressure is applied. This would lead to poorly “knitted” areas and lower strength in the molded specimen.

SCOPE

1.1 This practice covers the general principles to be followed when compression molding test specimens of thermosetting molding compounds, such as phenolics, aminoplastics, melamine phenolics, epoxies, and unsaturated polyesters.

Note 1—This standard is similar in content (but not technically equivalent) to ISO 295-1974 (E).

1.2 Molding conditions are given for amino, phenolic, and allyl molding compounds. Materials specification standards should always be consulted to determine whether the material to be molded has any special requirements.

1.3 The values stated in SI units are to be regarded as standard. The values in brackets are given for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5224–00 (Reapproved 2006)

Standard Practice for

Compression Molding Test Specimens of Thermosetting

1

Molding Compounds

This standard is issued under the fixed designation D5224; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers the general principles to be fol- 3.1 Definitions—For definitions of terms pertaining to plas-

lowed when compression molding test specimens of thermo- tics used in this practice, see Terminology D883.

setting molding compounds, such as phenolics, aminoplastics, 3.2 Definitions of Terms Specific to This Standard:

melamine phenolics, epoxies, and unsaturated polyesters. 3.2.1 breathe step, n—in plastics molding, the part of the

molding cycle in which the mold halves are opened momen-

NOTE 1—This standard is similar in content (but not technically

tarily, prior to curing, to release volatiles from the molded part.

equivalent) to ISO 295-1974 (E).

3.2.2 skin, n—in plastics molding, the thin resin-rich layer

1.2 Molding conditions are given for amino, phenolic, and

(skin) on the surface of the molded part.

allyl molding compounds. Materials specification standards

3.2.3 skin effect, n—in plastics testing, the positive or

should always be consulted to determine whether the material

negative effect the skin may have on the results of some

to be molded has any special requirements.

standard tests.

1.3 The values stated in SI units are to be regarded as

standard.Thevaluesinbracketsaregivenforinformationonly.

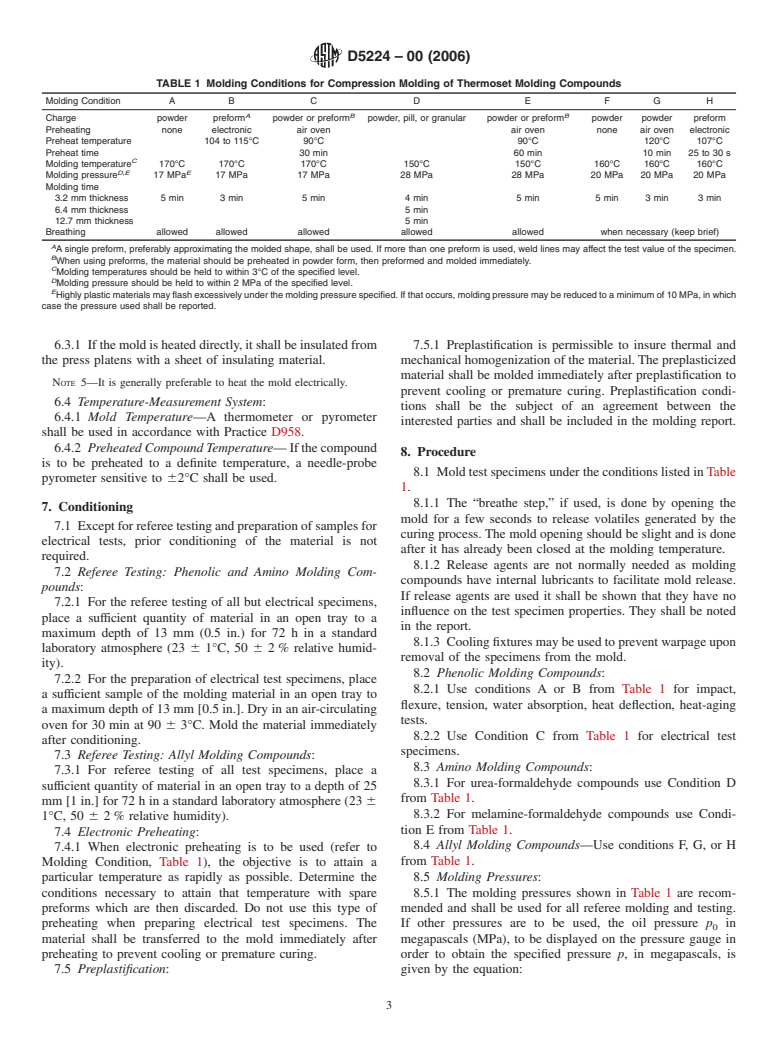

4. Summary of Practice

1.4 This standard does not purport to address all of the

4.1 Compression molded test specimens are produced by

safety concerns, if any, associated with its use. It is the

loading a mold cavity with some form of the molding material,

responsibility of the user of this standard to establish appro-

applying a specified pressure to the mating surface for a

priate safety and health practices and determine the applica-

specified time and at a specified temperature, and then remov-

bility of regulatory limitations prior to use.

ing the part from the cavity.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards:

5.1 The conditions at which compounds are molded are

D638 Test Method for Tensile Properties of Plastics

known to influence the properties of the specimens.The degree

D883 Terminology Relating to Plastics

of cure, elimination of knit-lines between particles, density of

D958 Practice for Determining Temperatures of Standard

the part, and degradation of the polymer are among those

3

ASTM Molds for Test Specimens of Plastics

factors which will be affected by the molding conditions. Thus

2.2 ISO Standard:

it is important to hold to a standard set of conditions in order

ISO 295 Plastics—Compression Molding Test Specimens

to have a valid comparison of properties between different

4

of Thermosetting Materials

compounds and different batches of the same compound.

4

ISO 3167 Plastics—Multipurpose—Test Specimens

5.2 If the molded specimens show evidence of low-density

areas due to trapped gases, they should be discarded.Abreathe

1

step may be necessary to eliminate this situation. It is critical

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

is the direct responsibility of Subcommittee D20.09 on Specimen Preparation. that the breathe step be as brief as possible to avoid precuring

Current edition approved March 15, 2006. Published March 2006. Originally

of the compound before full pressure is applied. This would

approved in 1992. Last previous edition approved in 2000 as D5224 - 00. DOI:

lead to poorly “knitted” areas and lower strength in the molded

10.1520/D5224-00R06.

2

specimen.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 6. Apparatus

the ASTM website.

3 6.1 Molds:

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. 6.1.1 The mold shall be made of steel, able to withstand the

4

ISO Standards Handbook 21, Vol 2, Plastics, 2nd Ed., 1990, available from

molding temperatures and pressures. The mold shall be de-

AmericanNationalStandardsInstitute(ANSI),25W.43rdSt.,4thFloor,NewYork,

signed such that the compressive mold force is transferred to

NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5224–00 (2006)

FIG. 1 Single-Cavity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.