ASTM D6646-03

(Test Method)Standard Test Method for Determination of the Accelerated Hydrogen Sulfide Breakthrough Capacity of Granular and Pelletized Activated Carbon

Standard Test Method for Determination of the Accelerated Hydrogen Sulfide Breakthrough Capacity of Granular and Pelletized Activated Carbon

SCOPE

1.1 This test method is intended to evaluate the performance of virgin, newly impregnated or in-service, granular or pelletized activated carbon for the removal of hydrogen sulfide from an air stream. A humidified air stream containing 1 % (by volume) hydrogen sulfide is passed through a carbon bed until 50 ppm breakthrough of H2S is observed. The H2S adsorption capacity of the carbon per unit volume at 99.5 % removal efficiency (g H2S/cm3 carbon) is then calculated. This test is not necessarily applicable to non-carbon adsorptive materials.

1.2 This standard as written is applicable only to granular and pelletized activated carbons with mean particle diameters (MPD) less than 2.5 mm. See paragraph 5.3 if activated carbons with larger MPDs are to be tested.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6646 – 03

Standard Test Method for

Determination of the Accelerated Hydrogen Sulfide

Breakthrough Capacity of Granular and Pelletized Activated

1

Carbon

This standard is issued under the fixed designation D 6646; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

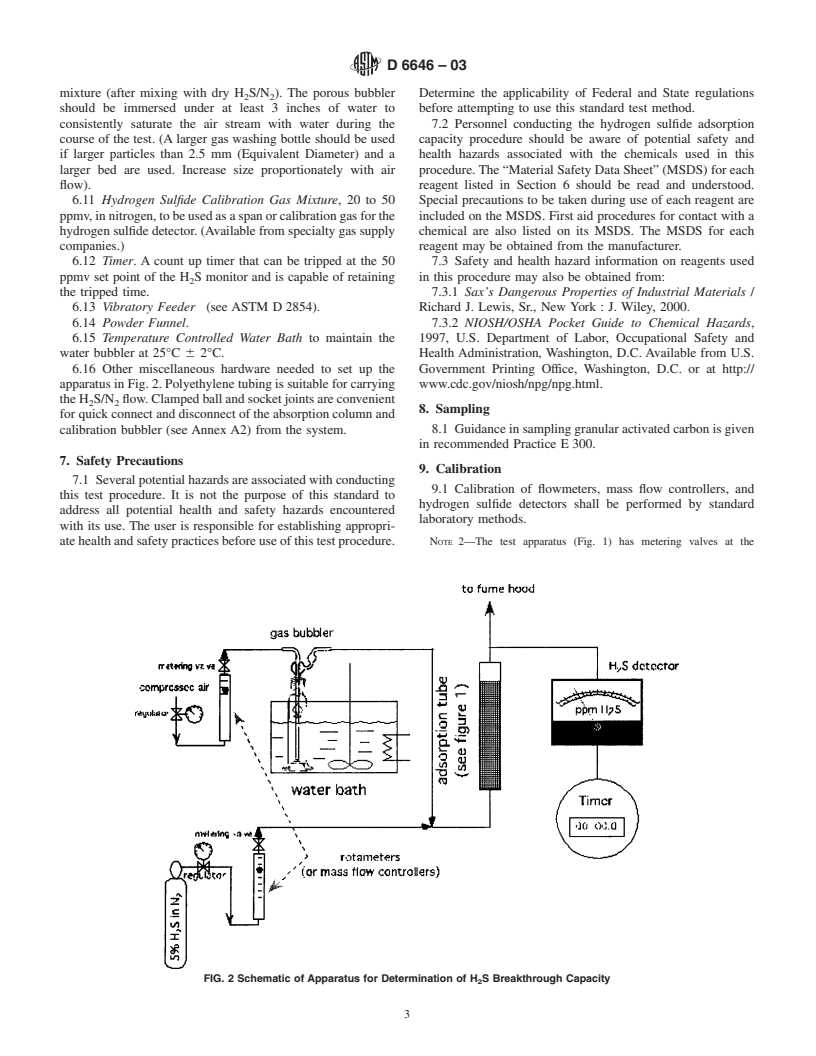

1.1 Thistestmethodisintendedtoevaluatetheperformance 4.1 Breakthrough capacity is determined by passing a

of virgin, newly impregnated or in-service, granular or pellet- stream of humidified air containing 1 volume % hydrogen

ized activated carbon for the removal of hydrogen sulfide from sulfide through a sample of granular or pelletized activated

an air stream, under the laboratory test conditions described carbon of known volume under specified conditions until the

herein. A humidified air stream containing 1 % (by volume) concentration of hydrogen sulfide in the effluent gas reaches 50

hydrogen sulfide is passed through a carbon bed until 50 ppm ppmv.

breakthrough of H S is observed. The H S adsorption capacity

2 2

5. Significance and Use

of the carbon per unit volume at 99.5 % removal efficiency (g

3

H S/cm carbon) is then calculated. This test is not necessarily 5.1 This method compares the performance of granular or

2

pelletized activated carbons used in odor control applications,

applicable to non-carbon adsorptive materials.

1.2 This standard as written is applicable only to granular such as sewage treatment plants, pump stations, etc. The

method determines the relative breakthrough performance of

and pelletized activated carbons with mean particle diameters

(MPD) less than 2.5 mm. See paragraph 5.3 if activated activatedcarbonforremovinghydrogensulfidefromahumidi-

fied gas stream. Other organic contaminants present in field

carbons with larger MPDs are to be tested.

1.3 This standard does not purport to address all of the operations may affect the H S breakthrough capacity of the

2

carbon; these are not addressed by this test. This test does not

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- simulate actual conditions encountered in an odor control

priate safety and health practices and determine the applica- application, and is therefore meant only to compare the

hydrogen sulfide breakthrough capacities of different carbons

bility of regulatory limitations prior to use.

under the conditions of the laboratory test.

2. Referenced Documents

5.2 This test does not duplicate conditions that an adsorber

2

2.1 ASTM Standards: would encounter in practical service.The mass transfer zone in

D 2652 Definition of Terms Relating to Activated Carbon the 23 cm column used in this test is proportionally much

D 2854 Determination of Apparent Density of Activated larger than that in the typical bed used in industrial applica-

Carbon tions. This difference favors a carbon that functions more

D 2867 Test For Moisture in Activated Carbon rapidly for removal of H S over a carbon with slower kinetics.

2

E 300 Practice for Sampling Industrial Chemicals Also, the 1 % H S challenge gas concentration used here

2

engendersasignificanttemperatureriseinthecarbonbed.This

3. Terminology

effect may also differentiate between carbons in a way that is

3.1 Terms relating to this standard are defined in D 2652.

not reflected in the conditions of practical service.

5.3 This standard as written is applicable only to granular

and pelletized activated carbons with mean particle diameters

1

This test method is under the jurisdiction of ASTM Committee D28 on

less than 2.5 mm. Application of this standard to activated

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

carbons with mean particle diameters (MPD) greater than 2.5

Phase Evaluation Tests.

mm will require a larger diameter adsorption column.The ratio

Current edition approved Oct. 1, 2003. Published November 2003. Originally

approved in 2001. Last previous version approved in 2001 as D 6646–01.

of column inside diameter to MPD should be greater than 10 in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

order to avoid wall effects. In these cases it is suggested that

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

bed superficial velocity and contact time be held invariant at

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the conditions specified in this standard (4.77 cm/sec and 4.8

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-295

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.