ASTM D5478-13

(Test Method)Standard Test Methods for Viscosity of Materials by a Falling Needle Viscometer

Standard Test Methods for Viscosity of Materials by a Falling Needle Viscometer

SIGNIFICANCE AND USE

5.1 These test methods are applicable for measuring the rheological properties of varnishes and paints. In particular, the low to moderate shear rate measurements provide information related to sag resistance, leveling, etc.

SCOPE

1.1 These test methods cover the measurement of the viscosity of Newtonian and non-Newtonian liquids. These test methods are applicable to liquids having viscosities in the range from 5 × 10−4 to 103 Pa·s (0.5 to 106 cP). The shear rate range is dependent upon the needle used and viscosity of the liquid and may vary from 10−4 to 103 s−1. With an extension bar and applied weight, a shear rate of 104 s–1 may be achieved.

1.2 The yield stress of liquids having this property may also be determined.

1.3 These test methods consist of determining liquid viscosities of Newtonian and non-Newtonian fluids (clear or opaque) by measuring the steady-state (constant) or terminal velocities of cylindrical needles as they fall through the test liquid under the influence of gravity. Yield stresses of non-Newtonian liquids may be measured using the same procedure.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5478 − 13

Standard Test Methods for

1

Viscosity of Materials by a Falling Needle Viscometer

This standard is issued under the fixed designation D5478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 dilatant or shear thickening fluid, n—fluid in which

the apparent viscosity increases with increasing shear rate.

1.1 These test methods cover the measurement of the

viscosity of Newtonian and non-Newtonian liquids. These test

3.1.2 Newtonian fluid, n—fluid in which the dynamic vis-

methods are applicable to liquids having viscosities in the

cosity does not vary with shear rate but only with the

−4 3 6

range from 5×10 to 10 Pa·s (0.5 to 10 cP). The shear rate

temperature and pressure.

range is dependent upon the needle used and viscosity of the

3.1.3 Non-Newtonian fluid, n—fluid in which the dynamic

−4 3 −1

liquid and may vary from 10 to 10 s . With an extension

viscosity varies with shear rate over at least some shear rate

4 –1

barandappliedweight,ashearrateof10 s maybeachieved.

range.

1.2 Theyieldstressofliquidshavingthispropertymayalso

3.1.3.1 Discussion—This viscosity is sometimes referred to

be determined.

as the “apparent viscosity” since it is not a true property of the

1.3 These test methods consist of determining liquid vis-

fluid but a variable depending on the shear rate. The viscosity

cosities of Newtonian and non-Newtonian fluids (clear or

of most non-Newtonian fluids fits a power law expression. A

opaque) by measuring the steady-state (constant) or terminal

power law fluid is defined by the following equation:

velocities of cylindrical needles as they fall through the test

n21

η 5 K dγ/dt (1)

~ !

a

liquid under the influence of gravity. Yield stresses of non-

where:

Newtonianliquidsmaybemeasuredusingthesameprocedure.

2

η = apparentviscosity,Pa·s(ordyne·s/cm =P),mPa·s=

a

1.4 The values stated in SI units are to be regarded as

cP,

standard. No other units of measurement are included in this

n n 2

K = fluid consistency, Pa·s (or dyne·s /cm ),

standard.

dγ/dt = shear rate or velocity gradient, 1/s, and

1.5 This standard does not purport to address all of the

n = flow behavior index, dimensionless.

safety concerns, if any, associated with its use. It is the

3.1.4 pseudoplastic or shear thinning fluid, n—fluid in

responsibility of the user of this standard to establish appro-

which the apparent viscosity decreases with increasing shear

priate safety and health practices and determine the applica-

rate.

bility of regulatory limitations prior to use.

3.1.5 viscosity, n—the ratio between an applied shear stress

2. Referenced Documents

to the resulting shear rate (velocity gradient) is defined as the

2

2.1 ASTM Standards:

dynamic viscosity. It is a measure of the resistance to flow of

E1Specification for ASTM Liquid-in-Glass Thermometers

a fluid.

E2251Specification for Liquid-in-Glass ASTM Thermom-

3.1.5.1 Discussion—In the SI unit system, the units of

eters with Low-Hazard Precision Liquids

viscosity are Pa·s. One mPa·s is equal to one centipoise (cP).

3. Terminology

3.1.6 yield stress, n—some fluids when subjected to a shear

3.1 Definitions:

stress behave as deformable solids until a certain critical shear

stress (yield stress or yield value) is reached after which they

1

These test methods are under the jurisdiction of ASTM Committee D01 on

behave as fluids.

Paint and Related Coatings, Materials, and Applications and are the direct

3.1.6.1 Discussion—Examples of such fluids include many

responsibility of Subcommittee D01.24 on Physical Properties of Liquid Paints and

paints and pigment pastes and certain food materials such as

Paint Materials.

Current edition approved Feb. 1, 2013. Published February 2013. Originally

ketchup.

approved in 1993. Last previous edition approved in 2009 as published as

D5478–09. DOI: 10.1520/D5478-13.

2 4. Summary of Test Methods

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.1 Test Method A consists of determining the viscosity of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Newtonian liquids.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5478 − 13

3,4,5

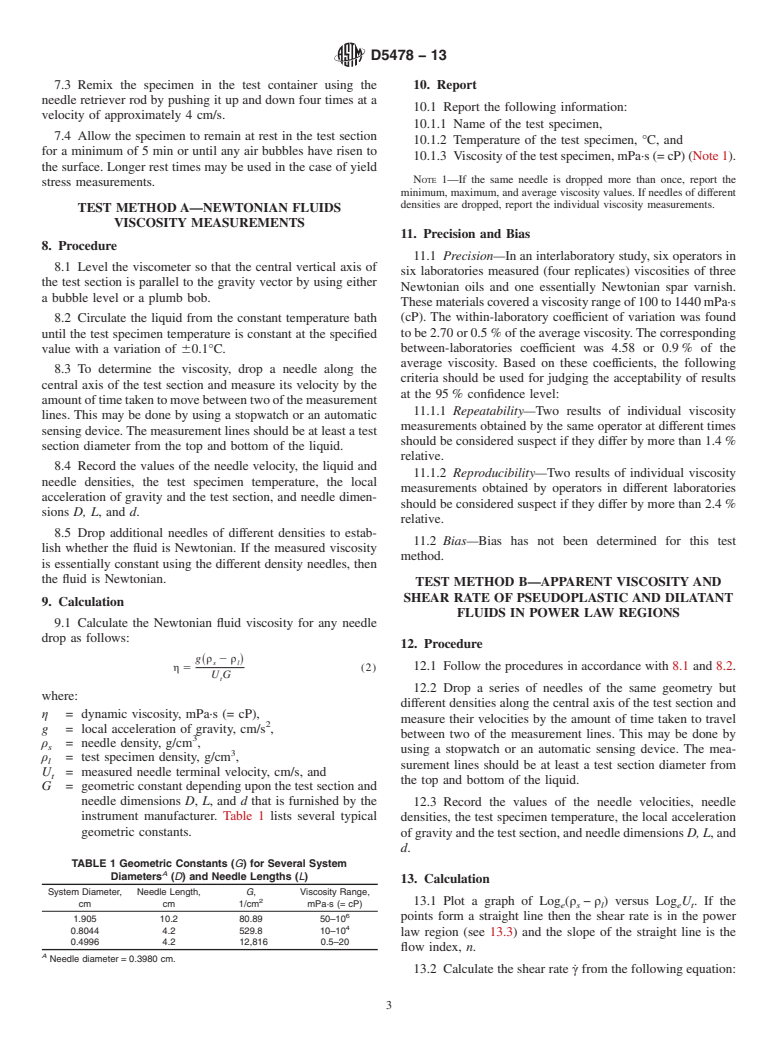

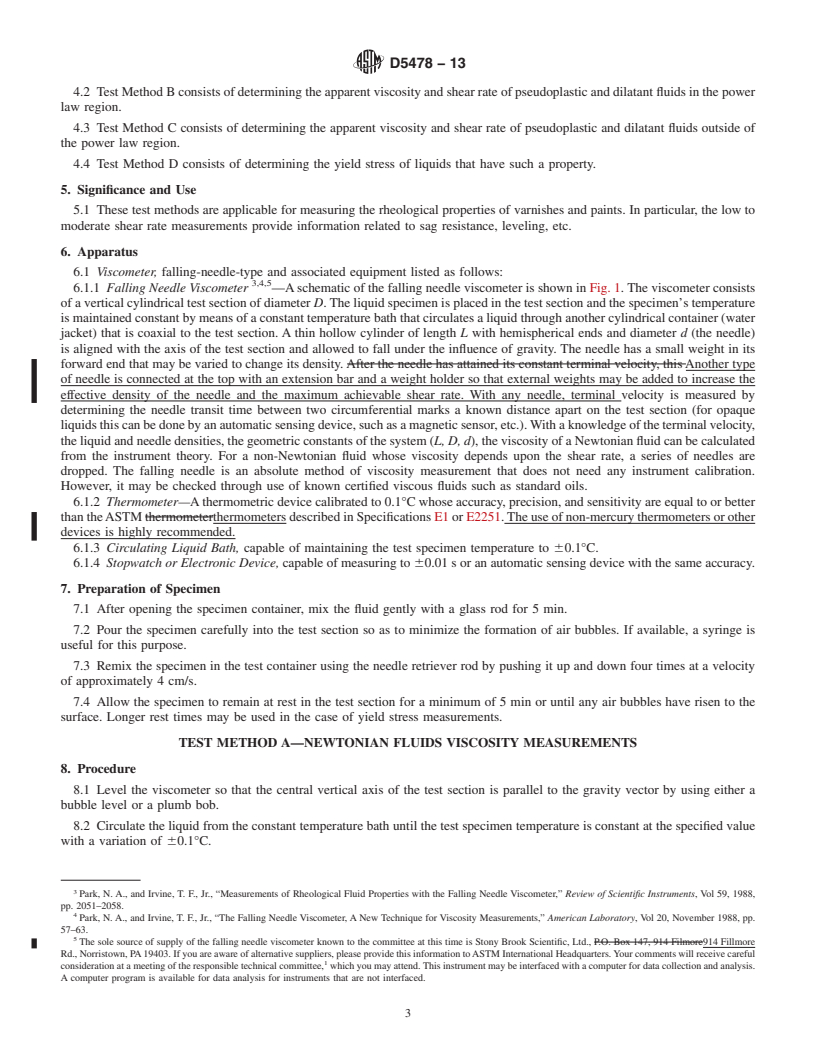

6.1.1 Falling Needle Viscometer —A schematic of the

falling needle viscometer is shown in Fig. 1. The viscometer

consistsofaverticalcylindricaltestsectionofdiameter D.The

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5478 − 09 D5478 − 13

Standard Test Methods for

1

Viscosity of Materials by a Falling Needle Viscometer

This standard is issued under the fixed designation D5478; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover the measurement of the viscosity of Newtonian and non-Newtonian liquids. These test methods

−4 3 6

are applicable to liquids having viscosities in the range from 5 × 10 to 10 Pa·s (0.5 to 10 cP). The shear rate range is dependent

−4 3 −1

upon the needle used and viscosity of the liquid and may vary from 10 to 10 s . With an extension bar and applied weight,

4 –1

a shear rate of 10 s may be achieved.

1.2 The yield stress of liquids having this property may also be determined.

1.3 These test methods consist of determining liquid viscosities of Newtonian and non-Newtonian fluids (clear or opaque) by

measuring the steady-state (constant) or terminal velocities of cylindrical needles as they fall through the test liquid under the

influence of gravity. Yield stresses of non-Newtonian liquids may be measured using the same procedure.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E1 Specification for ASTM Liquid-in-Glass Thermometers

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

3. Terminology

3.1 Definitions:

3.1.1 dilatant or shear thickening fluid, n—fluid in which the apparent viscosity increases with increasing shear rate.

3.1.2 Newtonian fluid, n—fluid in which the dynamic viscosity does not vary with shear rate but only with the temperature and

pressure.

3.1.3 Non-Newtonian fluid, n—fluid in which the dynamic viscosity varies with shear rate over at least some shear rate range.

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.24 on Physical Properties of Liquid Paints and Paint Materials.

Current edition approved Feb. 1, 2009Feb. 1, 2013. Published March 2009February 2013. Originally approved in 1993. Last previous edition approved in 20032009 as

published as D5478 – 98 (2003).D5478 – 09. DOI: 10.1520/D5478-09.10.1520/D5478-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.3.1 Discussion—

This viscosity is sometimes referred to as the “apparent viscosity” since it is not a true property of the fluid but a variable depending

on the shear rate. The viscosity of most non-Newtonian fluids fits a power law expression. A power law fluid is defined by the

following equation:

n21

η 5 K~dγ/dt! (1)

a

where:

2

η = apparent viscosity, Pa·s (or dyne·s/cm = P), mPa·s = cP,

a

n n 2

K = fluid consistency, Pa·s (or dyne·s /cm ),

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5478 − 13

dγ/dt = shear rate or velocity gradient, 1/s, and

n = flow behavior index, dimensionless.

3.1.4 pseudoplastic or shear thinning fluid, n—fluid in which the apparent viscosity decreases with increasing shear rate.

3.1.5 viscosity, n—the ratio between an applied shear stress to the resulting shear rate (velocity gradient) is defined as the

dynamic viscosity. It is a measure of the resistance to flow of a fluid.

3.1.5.1 Discussion—

In the SI unit system, the units of viscosity are Pa·s. One mPa·s is equal to one centipoise (cP).

3.1.6 yield stress, n—some fluids when subjected to a shear stress behave as deformable solids until a certain critical shear stress

(yield stress or yield value) is reached after which they behave as fluids.

3.1.6.1 Discussion—

Exam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.