ASTM F2096-11(2019)

(Test Method)Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)

Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)

SIGNIFICANCE AND USE

5.1 The internal pressurization test method provides a practical way to examine packages for gross leaks.

5.2 This test method is extremely useful in a test laboratory environment where no common package material/size exists.

5.3 This test method may apply to large or long packages that do not fit into any other package integrity test method apparatus.

5.4 This test method may be used as a means to evaluate package integrity. Package integrity is crucial to consumer safety since heat sealed packages are designed to provide a contamination free or sterile environment, or both, to the product.

5.5 This test method may be used to detect substrate holes and channels.

SCOPE

1.1 This test method covers the detection of gross leaks in packaging. Method sensitivity is down to 250 μm (0.010 in.) with an 81 % probability (see Section 11). This test method may be used for tray and pouch packages.

1.2 The sensitivity of this test method has not been evaluated for use with porous materials other than spunbonded polyolefin or with nonporous packaging.

1.3 This test method is destructive in that it requires entry into the package to supply an internal air pressure

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2096 − 11 (Reapproved 2019)

Standard Test Method for

Detecting Gross Leaks in Packaging by Internal

Pressurization (Bubble Test)

This standard is issued under the fixed designation F2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 breathing point pressure, n—pressure at which perme-

1.1 This test method covers the detection of gross leaks in

ation of air through the porous material begins.

packaging. Method sensitivity is down to 250 µm (0.010 in.)

with an 81 % probability (see Section 11). This test method

4. Summary of Test Method

may be used for tray and pouch packages.

4.1 The package is inflated underwater to a predetermined

1.2 The sensitivity of this test method has not been evalu-

pressure. The package is then observed for a steady stream of

ated for use with porous materials other than spunbonded

air bubbles indicating a failure area.

polyolefin or with nonporous packaging.

4.2 The sensitivity of this test method is dependent on the

1.3 This test method is destructive in that it requires entry

differential pressure and method of pressurization. Establish-

into the package to supply an internal air pressure

ment of a test pressure for each package material/size is critical

1.4 The values stated in SI units are to be regarded as the

for obtaining repeatable results (see Annex A1 for the proce-

standard. The values given in parentheses are for information

dure on establishing test pressure). Inadequate pressurization

only.

of the package can significantly reduce the sensitivity of this

test method. Higher differential pressures will increase the test

1.5 This standard does not purport to address all of the

sensitivity. However, excessive pressurization of the package

safety concerns, if any, associated with its use. It is the

may rupture seals or cause misinterpretation of bubble patterns

responsibility of the user of this standard to establish appro-

emanating from porous packaging. This may result in an

priate safety, health, and environmental practices and deter-

erroneous conclusion regarding the presence or absence of

mine the applicability of regulatory limitations prior to use.

package defects. While not required, use of a bleed-off control

1.6 This international standard was developed in accor-

valve in line with the pressure monitoring device, will aid in

dance with internationally recognized principles on standard-

stabilizing the test pressure, and help eliminate excessive

ization established in the Decision on Principles for the

pressurization of the package (see Fig. 1).

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.3 Two different test methods are presented for the testing

Barriers to Trade (TBT) Committee.

of porous and nonporous packaging. The key difference

between the test methods (as described in Annex A1)isin

2. Referenced Documents

allowing time for the water to saturate the porous material.

2.1 ASTM Standards:

F17 Terminology Relating to Primary Barrier Packaging

5. Significance and Use

5.1 The internal pressurization test method provides a prac-

3. Terminology

tical way to examine packages for gross leaks.

3.1 Definitions—General terms relating to barrier materials

5.2 This test method is extremely useful in a test laboratory

for medical packaging are found in Terminology F17.

environment where no common package material/size exists.

5.3 This test method may apply to large or long packages

This test method is under the jurisdiction ofASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on

that do not fit into any other package integrity test method

Package Integrity.

apparatus.

Current edition approved Nov. 1, 2019. Published December 2019. Originally

approved in 2001. Last previous edition approved in 2011 as F2096–11. DOI:

10.1520/F2096-11R19.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or All porous packaging by definition will permit the passage of air. At a given

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM internal pressure it will therefore exhibit an emanating stream of air bubbles

Standards volume information, refer to the standard’s Document Summary page on dependent on the pore size. A stream of bubbles identified at a lower internal

the ASTM website. pressure than the breathing pressure point may indicate a defect in the packaging.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2096 − 11 (2019)

FIG. 1 Sample Test Apparatus

5.4 This test method may be used as a means to evaluate 8. Conditioning

package integrity. Package integrity is crucial to consumer

8.1 No special conditioning of the specimen is required.

safety since heat sealed packages are designed to provide a

9. Procedure

contamination free or sterile environment, or both, to the

NOTE2—TheestablishmentofatestpressureinaccordancewithAnnex

product.

A1 must be performed prior to initiating the test procedure. It is

5.5 This test method may be used to detect substrate holes

recommended that a sample test set-up be provided.

and channels.

9.1 Test Method A—Procedure for Nonporous Packaging:

9.1.1 Create a hole in the package using a puncturing device

6. Apparatus

for inserting the air source and pressure monitor into the

6.1 Pressure Delivery System, with pressure monitoring

control sample. Create the hole wherever it is most efficient to

gage, and bleed-off control valve, capable of delivering air at a

observe defects without obscuring any pre-existing defects or

pressure of 0-50 mbar (0-20 in. H O).

creating defects in the inner package during the puncturing

process. The hole size should allow insertion of the air source

6.2 Device for Puncturing Package, device to allow inser-

and pressure monitor with minimal air leakage. Use tape or a

tion of air source and pressure monitoring device.

rubber disk as a septum over the puncture site to seal the

6.3 Water Container, adequate to cover the test specimen

insertion site if necessary.

with approximately 25.4 mm (1 in.) of water.

9.1.2 Insert the air source and pressure monitor into the test

NOTE 1—It may be beneficial for observation of the test specimen and

specimen. Submerge the package approximately 1 in. under

for interpretation of results to perform the testing in a water container that

water. Start airflow into the package.

has at least one transparent side.

NOTE 3—It may be helpful to use a fixture to keep the entire package

7. Sampling

submerged at the proper depth.

7.1 The number of test specimens shall be chosen to permit 9.1.3 Adjust the airflow and bleed-off valve as necessary to

an adequate determination of representative performance. slowlyinflatethepackagetoavalueequaltoorgreaterthanthe

F2096 − 11 (2019)

minimum test pressure as established in accordance with 9.2.6 Remove the package from the water and mark any

AnnexA1.Adjust the bleed-off valve and pressure regulator as observed area(s) of failure.

necessary to maintain constant pressure.

10. Report

9.1.4 Thoroughly inspect one side of the package facing

upwards for a constant stream of bubbles indicating a specific

10.1 Report the following information:

area of failure (seal channels, pinholes, cracks, tears, and so

10.1.1 Date and operator’s name or initials.

forth). Then repeat the process by rotating the package 180º so

10.1.2 Package type and any applicable traceable identifi-

the opposite side of the package is facing upwards. Inspection

cation numbers.

time will vary depending on package size.

10.1.3 Established defect size used to establish the test

9.1.5 Remove the package from water and mark any ob-

sensitivity, test pressure, and use of any blocking agent.

served area(s) of failure.

10.1.4 Number of test packages, number of packages that

passed, number of packages exhibiting leaks, and location of

9.2 Test Method B—Procedure for Porous Packaging:

each leak

9.2.1 Apply blocking agent to samples if required in accor-

10.1.5 Record the instrument used to create the opening of

dance with A1.1.2.4.

the package.

9.2.2 Create a hole in the package using a puncturing device

for inserting the air source and pressure monitor into the

11. Precision and Bias

control sample. Create the hole wherever it is most efficient to

observe defects without obscuring any pre-existing defects or

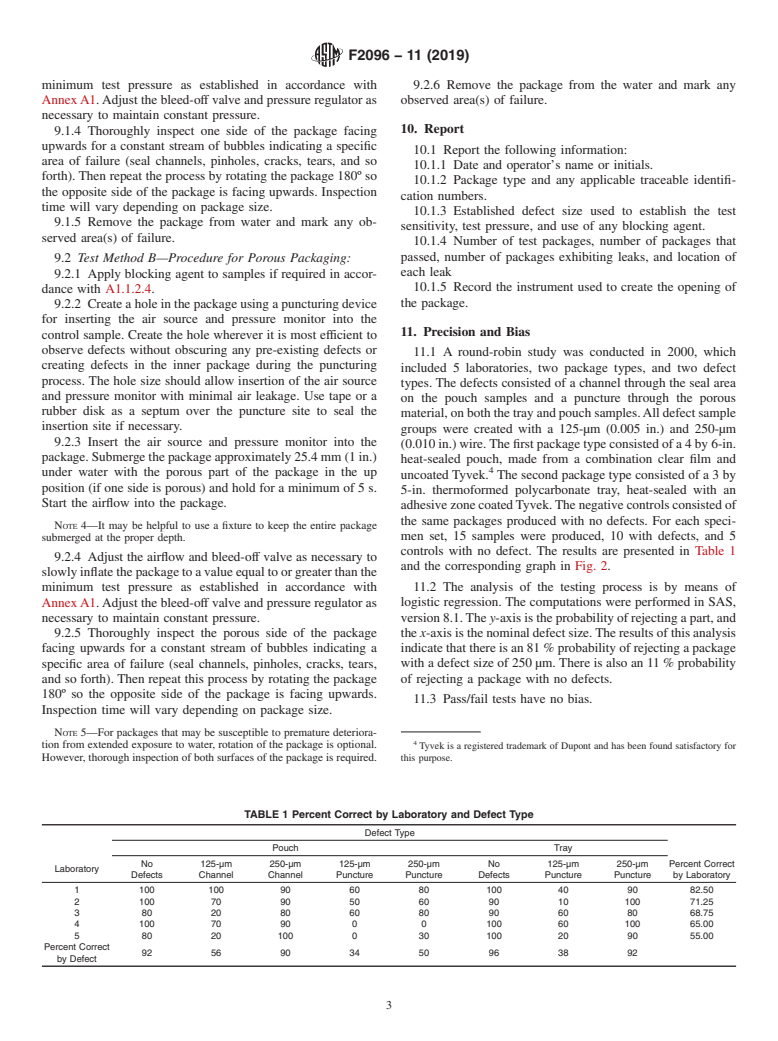

11.1 A round-robin study was conducted in 2000, which

creating defects in the inner package during the puncturing

included 5 laboratories, two package types, and two defect

process. The hole size should allow insertion of the air source

types. The defects consisted of a channel through the seal area

and pressure monitor with minimal air leakage. Use tape or a

on the pouch samples and a puncture through the porous

rubber disk as a septum over the puncture site to seal the

material,onboththetrayandpouchsamples.Alldefectsample

insertion site if necessary.

groups were created with a 125-µm (0.005 in.) and 250-µm

9.2.3 Insert the air source and pressure monitor into the

(0.010in.)wire.Thefirstpackagetypeconsistedofa4by6-in.

package.Submergethepackageapproximately25.4mm(1in.)

heat-sealed pouch, made from a combination clear film and

under water with the porous part of the package in the up

uncoated Tyvek. The second package type consisted ofa3by

position (if one side is porous) and hold for a minimum of 5 s.

5-in. thermoformed p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.