ASTM F2096-11

(Test Method)Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)

Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)

SIGNIFICANCE AND USE

The internal pressurization test method provides a practical way to examine packages for gross leaks.

This test method is extremely useful in a test laboratory environment where no common package material/size exists.

This test method may apply to large or long packages that do not fit into any other package integrity test method apparatus.

This test method may be used as a means to evaluate package integrity. Package integrity is crucial to consumer safety since heat sealed packages are designed to provide a contamination free or sterile environment, or both, to the product.

This test method may be used to detect substrate holes and channels.

SCOPE

1.1 This test method covers the detection of gross leaks in packaging. Method sensitivity is down to 250 μm (0.010 in.) with an 81 % probability (see Section 11). This test method may be used for tray and pouch packages.

1.2 The sensitivity of this test method has not been evaluated for use with porous materials other than spunbonded polyolefin or with nonporous packaging.

1.3 This test method is destructive in that it requires entry into the package to supply an internal air pressure

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2096 − 11

Standard Test Method for

Detecting Gross Leaks in Packaging by Internal

1

Pressurization (Bubble Test)

This standard is issued under the fixed designation F2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 breathing point pressure, n—pressure at which perme-

3

ation of air through the porous material begins.

1.1 This test method covers the detection of gross leaks in

packaging. Method sensitivity is down to 250 µm (0.010 in.)

4. Summary of Test Method

with an 81 % probability (see Section 11). This test method

4.1 The package is inflated underwater to a predetermined

may be used for tray and pouch packages.

pressure. The package is then observed for a steady stream of

1.2 The sensitivity of this test method has not been evalu-

air bubbles indicating a failure area.

ated for use with porous materials other than spunbonded

4.2 The sensitivity of this test method is dependent on the

polyolefin or with nonporous packaging.

differential pressure and method of pressurization. Establish-

1.3 This test method is destructive in that it requires entry ment of a test pressure for each package material/size is critical

into the package to supply an internal air pressure for obtaining repeatable results (see Annex A1 for the proce-

dure on establishing test pressure). Inadequate pressurization

1.4 The values stated in SI units are to be regarded as the

of the package can significantly reduce the sensitivity of this

standard. The values given in parentheses are for information

test method. Higher differential pressures will increase the test

only.

sensitivity. However, excessive pressurization of the package

1.5 This standard does not purport to address all of the

may rupture seals or cause misinterpretation of bubble patterns

safety concerns, if any, associated with its use. It is the

emanating from porous packaging. This may result in an

responsibility of the user of this standard to establish appro-

erroneous conclusion regarding the presence or absence of

priate safety and health practices and determine the applica-

package defects. While not required, use of a bleed-off control

bility of regulatory limitations prior to use.

valve in line with the pressure monitoring device, will aid in

stabilizing the test pressure, and help eliminate excessive

2. Referenced Documents

pressurization of the package (see Fig. 1).

2

2.1 ASTM Standards:

4.3 Two different test methods are presented for the testing

F17 Terminology Relating to Flexible Barrier Packaging

of porous and nonporous packaging. The key difference

between the test methods (as described in Annex A1)isin

3. Terminology

allowing time for the water to saturate the porous material.

3.1 Definitions—General terms relating to barrier materials

5. Significance and Use

for medical packaging are found in Terminology F17.

5.1 The internal pressurization test method provides a prac-

3.2 Definitions of Terms Specific to This Standard:

tical way to examine packages for gross leaks.

5.2 This test method is extremely useful in a test laboratory

environment where no common package material/size exists.

1

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

5.3 This test method may apply to large or long packages

Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on

Package Integrity.

that do not fit into any other package integrity test method

Current edition approved Dec. 15, 2011. Published February 2012. Originally

apparatus.

approved in 2001. Last previous edition approved in 2004 as F2096 – 04. DOI:

10.1520/F2096-11.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or All porous packaging by definition will permit the passage of air. At a given

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM internal pressure it will therefore exhibit an emanating stream of air bubbles

Standards volume information, refer to the standard’s Document Summary page on dependent on the pore size. A stream of bubbles identified at a lower internal

the ASTM website. pressure than the breathing pressure point may indicate a defect in the packaging.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

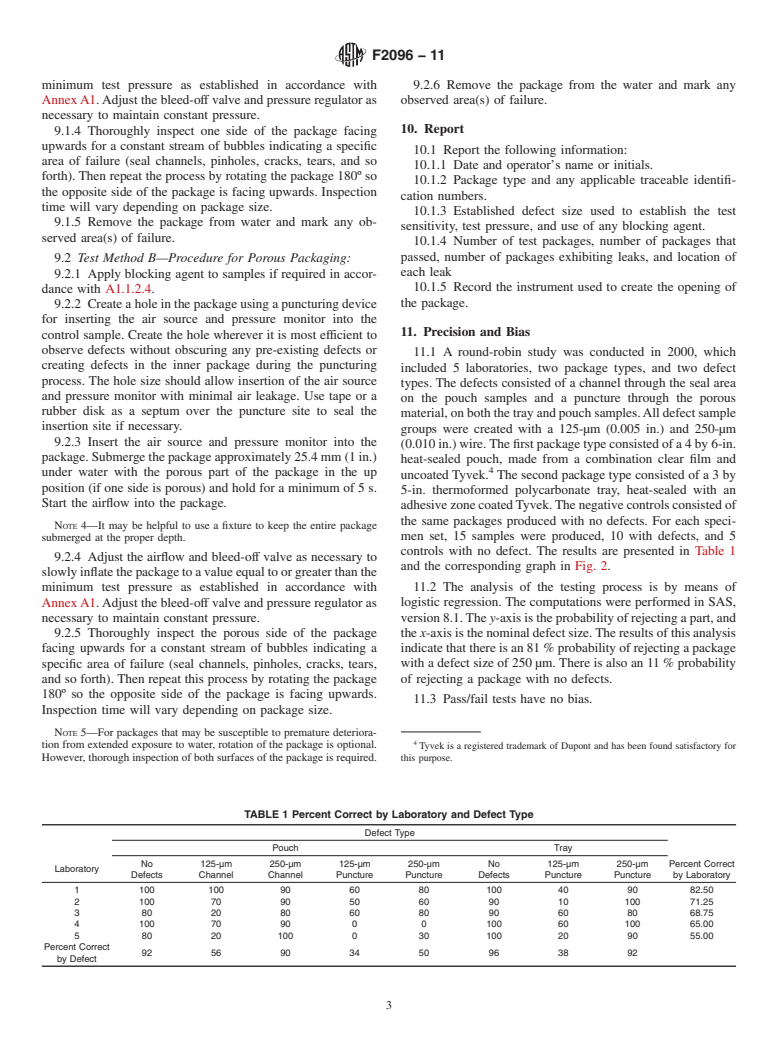

F2096 − 11

FIG. 1 Sample Test Apparatus

5.4 This test method may be used as a means to evaluate 8. Conditioning

package integrity. Package integrity is crucial to consumer

8.1 No special conditioning of the specimen is required.

safety since heat se

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F2096–04 Designation: F2096 – 11

Standard Test Method for

Detecting Gross Leaks in Medical Packaging by Internal

1

Pressurization (Bubble Test)

This standard is issued under the fixed designation F2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the detection of gross leaks in medical packaging. Method sensitivity is down to 250 µm (0.010

in.) with an 81 % probability (see Section 11). This test method may be used for tray and pouch packages.

1.2 The sensitivity of this test method has not been evaluated for use with porous materials other than spunbonded polyolefin

or with nonporous packaging.

1.3 This test method is destructive in that it requires entry into the package to supply an internal air pressure

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1898Practice for Sampling of Plastics

F1327TerminologyRelatingtoBarrierMaterialsforMedicalPackaging17 TerminologyRelatingtoFlexibleBarrierPackaging

3. Terminology

3.1 Definitions—General terms relating to barrier materials for medical packaging are found in Terminology F1327F17.

3.2 Definitions of Terms Specific to This Standard:

3

3.2.1 breathing point pressure, n—pressure at which permeation of air through the porous material begins.

4. Summary of Test Method

4.1 The package is inflated underwater to a predetermined pressure. The package is then observed for a steady stream of air

bubbles indicating a failure area.

4.2 The sensitivity of this test method is dependent on the differential pressure and method of pressurization. Establishment of

a test pressure for each package material/size is critical for obtaining repeatable results (see Annex A1 for the procedure on

establishing test pressure). Inadequate pressurization of the package can significantly reduce the sensitivity of this test method.

Higher differential pressures will increase the test sensitivity. However, excessive pressurization of the package may rupture seals

or cause misinterpretation of bubble patterns emanating from porous packaging. This may result in an erroneous conclusion

regarding the presence or absence of package defects. While not required, use of a bleed-off control valve in line with the pressure

monitoring device, will aid in stabilizing the test pressure, and help eliminate excessive pressurization of the package (see Fig. 1).

4.3 Two different test methods are presented for the testing of porous and nonporous packaging. The key difference between

the test methods (as described in Annex A1) is in allowing time for the water to saturate the porous material.

1

This test method is under the jurisdiction of ASTM Committee F02 on Flexible Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on Package

Integrity.

´1

CurrenteditionapprovedJan.3,2006.PublishedJune2004.Originallyapprovedin2001.Lastpreviouseditionapprovedin2002asF2096–02 .DOI:10.1520/F2096-04.

Current edition approved Dec. 15, 2011. Published February 2012. Originally approved in 2001. Last previous edition approved in 2004 as F2096 – 04. DOI:

10.1520/F2096-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

All porous packaging by definition will permit the passage of air.At a given internal pressure it will therefore exhibit an emanating stream of air bubbles dependent on

the pore size. A stream of bubbles identified at a lower internal pressure than the breathing pressure point may indicate a defect in the packaging.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F2096 – 11

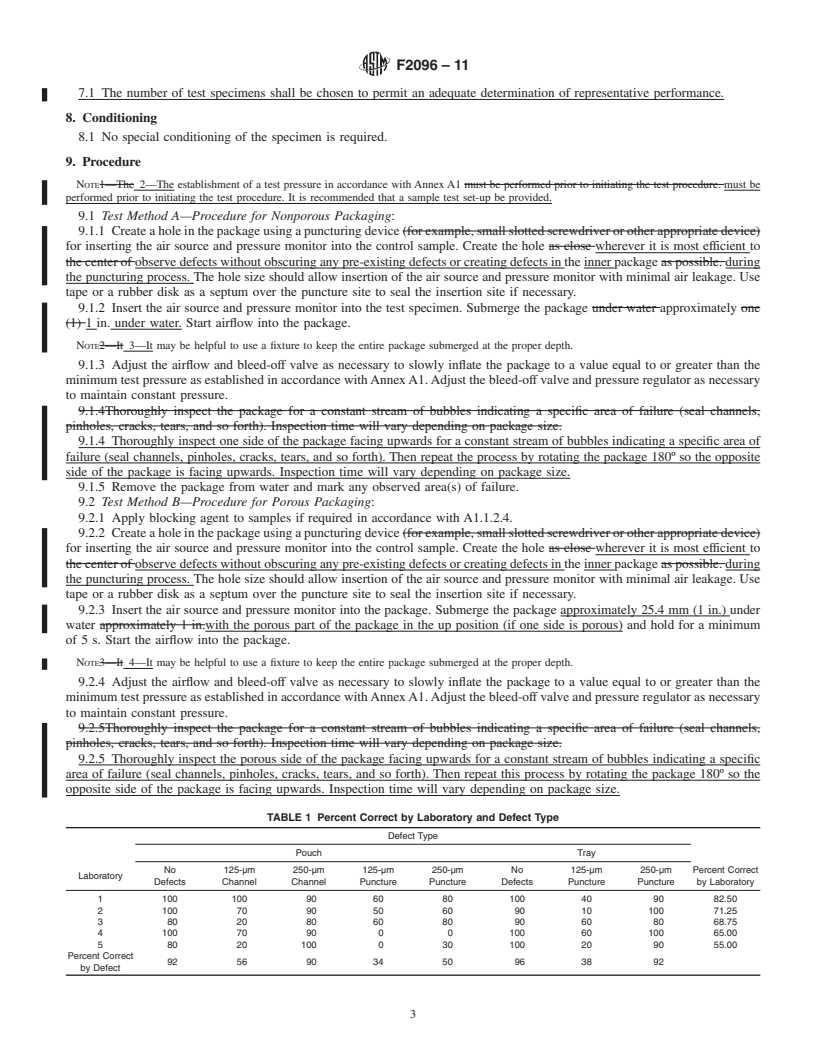

FIG. 1 Sample Test Apparatus

5. Significance and Use

5.1The internal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.