ASTM D4791-19

(Test Method)Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate

Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate

SIGNIFICANCE AND USE

5.1 The particles shape of course aggregates influences the properties of some construction materials and may affect their placement and consolidation.

5.2 This test method provides a means for checking compliance with specifications that limit such particles or to determine the relative shape characteristics of coarse aggregates.

SCOPE

1.1 This test method covers the determination of the percentages of flat particles, elongated particles, or flat and elongated particles in coarse aggregates. Two procedures, Method A and Method B, are presented in this standard. Method A is a reflection of the original procedure as developed prior to Superpave and is intended for all non-Superpave applications. Method B is a comparison of the maximum particle dimension to the minimum particle dimension and is intended for use with Superpave specifications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.2.1 Exception (regarding sieves, per Specification E11)—The values stated in SI units shall be considered standard for the dimensions of the wire cloth openings and the diameter of the wires used in the wire cloth. When sieve mesh sizes are referenced, the alternate inch-pound designations are provided for information purposes and enclosed in parenthesis.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4791 − 19

Standard Test Method for

Flat Particles, Elongated Particles, or Flat and Elongated

1

Particles in Coarse Aggregate

This standard is issued under the fixed designation D4791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of the per-

C136/C136M Test Method for Sieve Analysis of Fine and

centages of flat particles, elongated particles, or flat and

Coarse Aggregates

elongated particles in coarse aggregates. Two procedures,

C670 Practice for Preparing Precision and Bias Statements

Method A and Method B, are presented in this standard.

for Test Methods for Construction Materials

MethodAis a reflection of the original procedure as developed

C702/C702M Practice for Reducing Samples of Aggregate

prior to Superpave and is intended for all non-Superpave

to Testing Size

applications. Method B is a comparison of the maximum

D75/D75M Practice for Sampling Aggregates

particle dimension to the minimum particle dimension and is

E11 Specification for Woven Wire Test Sieve Cloth and Test

intended for use with Superpave specifications.

Sieves

1.2 The values stated in inch-pound units are to be regarded E177 Practice for Use of the Terms Precision and Bias in

as standard. The values given in parentheses are mathematical

ASTM Test Methods

conversions to SI units that are provided for information only E691 Practice for Conducting an Interlaboratory Study to

and are not considered standard. Determine the Precision of a Test Method

1.2.1 Exception (regarding sieves, per Specification E11)—

3. Terminology

The values stated in SI units shall be considered standard for

the dimensions of the wire cloth openings and the diameter of

3.1 Definitions:

the wires used in the wire cloth. When sieve mesh sizes are 3.1.1 elongated particles of aggregate—those particles of

referenced, the alternate inch-pound designations are provided aggregate having a ratio of length to width greater than a

specified value.

for information purposes and enclosed in parenthesis.

3.1.2 flat and elongated particles of aggregate—those par-

1.3 This standard does not purport to address all of the

ticles having a ratio of length to thickness greater than a

safety concerns, if any, associated with its use. It is the

specified value.

responsibility of the user of this standard to establish appro-

3.1.3 flat particles of aggregate—those particles of aggre-

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. gatehavingaratioofwidthtothicknessgreaterthanaspecified

value.

1.4 This international standard was developed in accor-

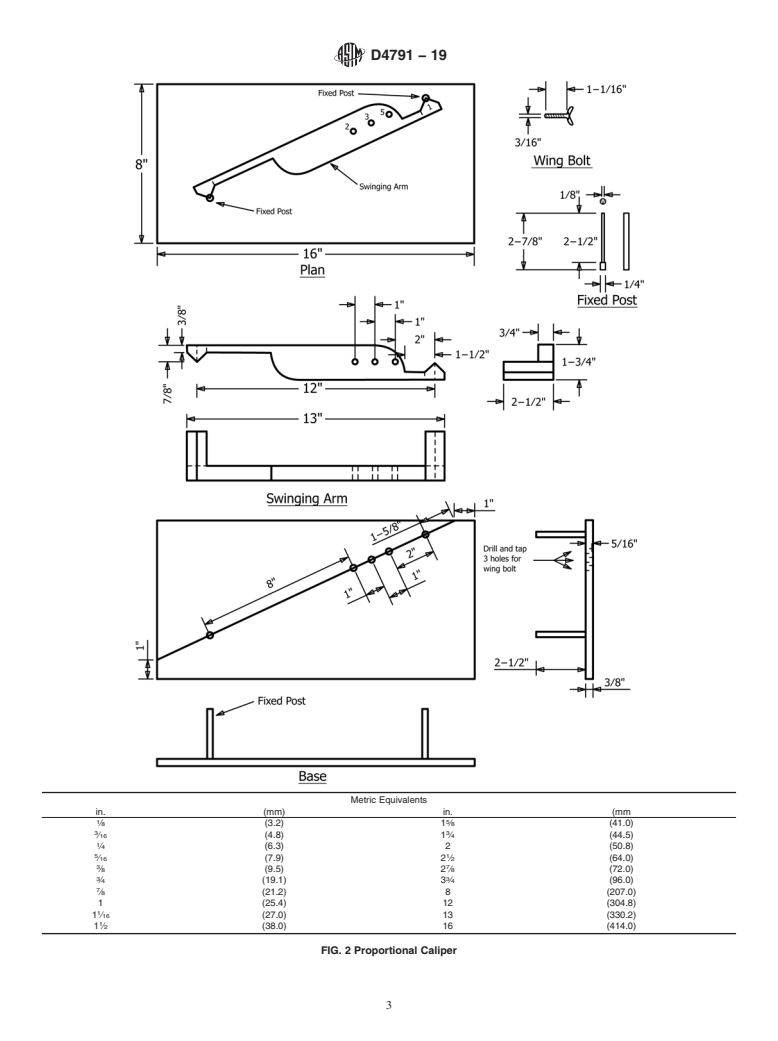

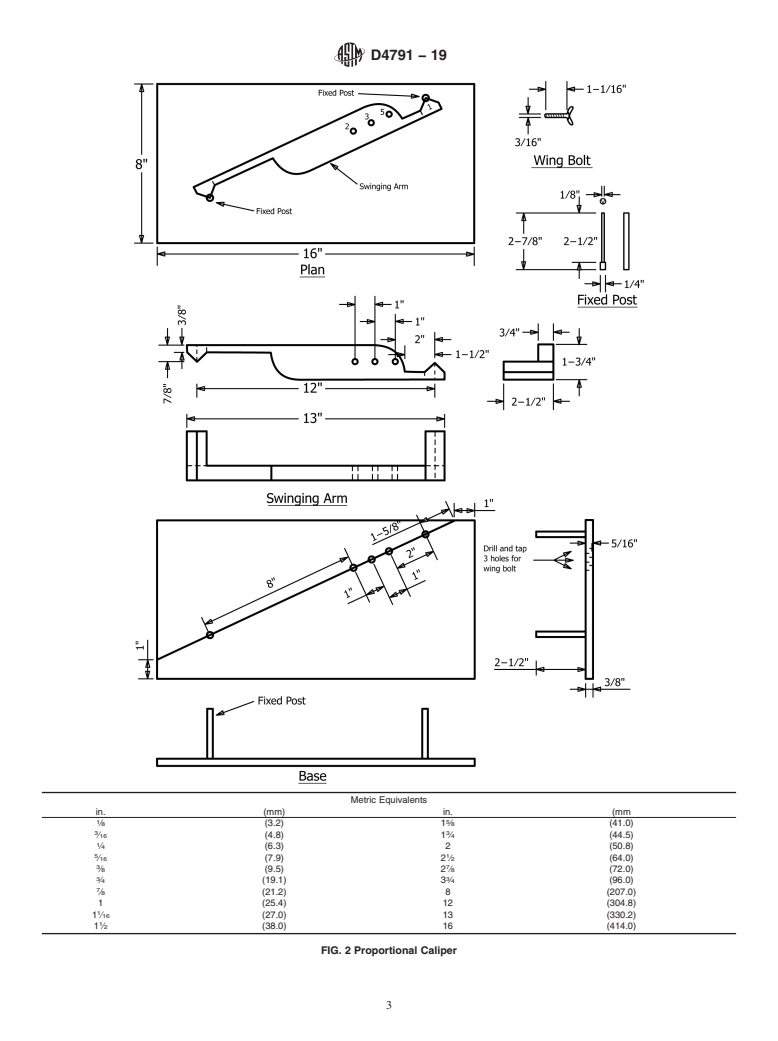

dance with internationally recognized principles on standard- 3.1.4 length—maximum dimension of the particle, as illus-

ization established in the Decision on Principles for the trated in Fig. 1.

Development of International Standards, Guides and Recom-

3.1.5 thickness—minimum dimension of particle. It is the

mendations issued by the World Trade Organization Technical

maximum dimension perpendicular to the length and width as

Barriers to Trade (TBT) Committee.

illustrated in Fig. 1.

3.1.6 width—intermediate dimension of the particle. It is the

maximum dimension in the plane perpendicular to the length

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

Aggregate Tests.

2

Current edition approved Nov. 1, 2019. Published November 2019. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1989. Last previous edition approved in 2010 as D4791 – 10, which contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

was withdrawn February 2019 and reinstated in November 2019. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D4791-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4791 − 19

FIG. 1 Particle Dimensions

and thickness.The width dimensions is greater than or equal to 7.2 Thoroughly mix the sample and reduce it to an amount

the thickness as illustrated in Fig. 1. suita

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4791 − 19

Standard Test Method for

Flat Particles, Elongated Particles, or Flat and Elongated

1

Particles in Coarse Aggregate

This standard is issued under the fixed designation D4791; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of the per-

C136/C136M Test Method for Sieve Analysis of Fine and

centages of flat particles, elongated particles, or flat and

Coarse Aggregates

elongated particles in coarse aggregates. Two procedures,

C670 Practice for Preparing Precision and Bias Statements

Method A and Method B, are presented in this standard.

for Test Methods for Construction Materials

Method A is a reflection of the original procedure as developed

C702/C702M Practice for Reducing Samples of Aggregate

prior to Superpave and is intended for all non-Superpave

to Testing Size

applications. Method B is a comparison of the maximum

D75/D75M Practice for Sampling Aggregates

particle dimension to the minimum particle dimension and is

E11 Specification for Woven Wire Test Sieve Cloth and Test

intended for use with Superpave specifications.

Sieves

1.2 The values stated in inch-pound units are to be regarded

E177 Practice for Use of the Terms Precision and Bias in

as standard. The values given in parentheses are mathematical ASTM Test Methods

conversions to SI units that are provided for information only E691 Practice for Conducting an Interlaboratory Study to

and are not considered standard. Determine the Precision of a Test Method

1.2.1 Exception (regarding sieves, per Specification E11)—

3. Terminology

The values stated in SI units shall be considered standard for

the dimensions of the wire cloth openings and the diameter of

3.1 Definitions:

the wires used in the wire cloth. When sieve mesh sizes are 3.1.1 elongated particles of aggregate—those particles of

referenced, the alternate inch-pound designations are provided aggregate having a ratio of length to width greater than a

for information purposes and enclosed in parenthesis. specified value.

3.1.2 flat and elongated particles of aggregate—those par-

1.3 This standard does not purport to address all of the

ticles having a ratio of length to thickness greater than a

safety concerns, if any, associated with its use. It is the

specified value.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.1.3 flat particles of aggregate—those particles of aggre-

gate having a ratio of width to thickness greater than a specified

mine the applicability of regulatory limitations prior to use.

value.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.1.4 length—maximum dimension of the particle, as illus-

ization established in the Decision on Principles for the trated in Fig. 1.

Development of International Standards, Guides and Recom-

3.1.5 thickness—minimum dimension of particle. It is the

mendations issued by the World Trade Organization Technical

maximum dimension perpendicular to the length and width as

Barriers to Trade (TBT) Committee.

illustrated in Fig. 1.

3.1.6 width—intermediate dimension of the particle. It is the

maximum dimension in the plane perpendicular to the length

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

Aggregate Tests.

2

Current edition approved Nov. 1, 2019. Published November 2019. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1989. Last previous edition approved in 2010 as D4791 – 10, which contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

was withdrawn February 2019 and reinstated in November 2019. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D4791-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4791 − 19

FIG. 1 Particle Dimensions

and thickness. The width dimensions is greater than or equal to 7.2 Thoroughly mix the sample and reduce it to an amount

the thickness as illustrated in Fig. 1. suitable for testing using the applicable procedures described in

Practice C702/C702M. The sample for test shall be approxi-

4. Summary

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.