ASTM D7109-04

(Test Method)Standard Test Method for Shear Stability of Polymer Containing Fluids Using a European Diesel Injector Apparatus at 30 and 90 Cycles

Standard Test Method for Shear Stability of Polymer Containing Fluids Using a European Diesel Injector Apparatus at 30 and 90 Cycles

SCOPE

1.1 This test method covers the evaluation of the shear stability of polymer-containing fluids. The test method measures the viscosity loss, in mm2/s and percent, at 100C of polymer-containing fluids when evaluated by a diesel injector apparatus procedure that uses European diesel injector test equipment. The viscosity loss reflects polymer degradation due to shear at the nozzle. Viscosity loss is evaluated after both 30 and 90 cycles of shearing.Note 1

This test method evaluates the shear stability of oils after both 30 and 90 cycles of shearing. In general, there is no correlation between results after 30 cycles and results after 90 cycles of shearing.Note 2

Test Method D 6278 uses essentially the same procedure with 30 cycles only instead of both 30 and 90 cycles. The correlation between results from this test method at 30 cycles and results from Test Method D 6278 has not been established.Note 3

Test Method D 2603 has been used for similar evaluation of shear stability; limitations are as indicated in the significance statement. No detailed attempt has been undertaken to correlate the results of this test method with those of the sonic shear test method.Note 4

This test method uses test apparatus as defined in CEC L-14-A-93. This test method differs from CEC-L-14-A-93 in the period of time required for calibration.Note 5

Test Method D 5275 also shears oils in a diesel injector apparatus but may give different results.Note 6

This test method has different calibration and operational requirements than Test Method D 3945.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7109–04

Standard Test Method for

Shear Stability of Polymer Containing Fluids Using a

European Diesel Injector Apparatus at 30 and 90 Cycles

This standard is issued under the fixed designation D 7109; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and the Calculation of Dynamic

1.1 This test method covers the evaluation of the shear

Viscosity)

stability of polymer-containing fluids. The test method mea-

D 2603 Test Method for Sonic Shear Stability of Polymer-

sures the viscosity loss, in mm /s and percent, at 100°C of

Containing Oils

polymer-containing fluids when evaluated by a diesel injector

D 3945 Test Method for Shear Stability of Polymer-

apparatus procedure that uses European diesel injector test

Containing Fluids Using a Diesel Injector Nozzle

equipment.The viscosity loss reflects polymer degradation due

D 5275 Test Method for Fuel Injector Shear Stability Test

to shear at the nozzle. Viscosity loss is evaluated after both 30

(FISST) for Polymer Containing Fluids

and 90 cycles of shearing.

D 6278 Test Method for Shear Stability of Polymer Con-

NOTE 1—Thistestmethodevaluatestheshearstabilityofoilsafterboth

taining Fluids Using a European Diesel InjectorApparatus

30 and 90 cycles of shearing. In general, there is no correlation between

D 6299 Practice for Applying Statistical Quality Assurance

results after 30 cycles and results after 90 cycles of shearing.

Techniques to Evaluate Analytical Measurement System

NOTE 2—Test Method D 6278 uses essentially the same procedure with

Performance

30 cycles only instead of both 30 and 90 cycles. The correlation between

results from this test method at 30 cycles and results from Test Method E 691 Practice for Conducting an Interlaboratory Study to

D 6278 has not been established.

Determine the Precision of a Test Method

NOTE 3—Test Method D 2603 has been used for similar evaluation of

2.2 Coordinated European Council (CEC) Standard:

shear stability; limitations are as indicated in the significance statement.

CEC L-14-A-93 Evaluation of the Mechanical Shear Sta-

Nodetailedattempthasbeenundertakentocorrelatetheresultsofthistest

bility of Lubricating Oils Containing Polymers

method with those of the sonic shear test method.

NOTE 4—This test method uses test apparatus as defined in CEC

3. Terminology

L-14-A-93.This test method differs from CEC-L-14-A-93 in the period of

time required for calibration. 3.1 Definitions:

NOTE 5—Test Method D 5275 also shears oils in a diesel injector

3.1.1 kinematic viscosity, n—a measure of the resistance to

apparatus but may give different results.

flow of a fluid under gravity.

NOTE 6—This test method has different calibration and operational

3.2 Definitions of Terms Specific to This Standard:

requirements than Test Method D 3945.

3.2.1 calibration pressure, n—the recorded gage pressure

1.2 This standard does not purport to address all of the

when calibration fluid RL34 undergoes a viscosity loss of 2.75

safety concerns, if any, associated with its use. It is the

to 2.85 mm /s when the recorded gage pressure is within the

responsibility of the user of this standard to establish appro-

range of 13.0 to 18.0 MPa (1885 to 2611 psi).

priate safety and health practices and determine the applica-

3.2.2 viscosity loss, n—the loss in viscosity determined

bility of regulatory limitations prior to use. Specific precau-

from the difference in kinematic viscosity at 100°C of pre-

tionary statements are given in Section 8.

sheared and post-sheared fluid.

3.2.3 percent viscosity loss, n—viscosity loss, as defined in

2. Referenced Documents

3.2.2, divided by the pre-sheared viscosity, and reported as a

2.1 ASTM Standards:

percent.

4. Summary of Test Method

4.1 A polymer-containing fluid is passed through a diesel

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee injector nozzle at a shear rate that may reduce its kinematic

D02.07 on Flow Properties.

Current edition approved Dec. 1, 2004. Published December 2004.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn.

Standards volume information, refer to the standard’s Document Summary page on Available from CEC Secretariat, Madou Plaza, 25th floor, Place Madou 1,

the ASTM website. B-1210 Brussels, Belgium.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7109–04

viscosity. The percent viscosity loss is a measure of the degradation of polymer by mechanical shearing, there may be

mechanical shear stability of the fluid. a correlation between the results from this test method and

results from the field.

NOTE 7—This test method may also be used for oils not containing

polymer. It might not be known whether an oil submitted for test contains

6. Apparatus

a polymer.

6.1 The apparatus consists of a fluid reservoir, a double-

plunger pump with an electric motor drive, an atomization

5. Significance and Use

chamber with a diesel injector spray nozzle, and a fluid cooling

5.1 This test method evaluates the percent viscosity loss of

vessel, installed in an area with an ambient temperature of 20

fluids resulting from physical degradation in the high shear

to25°C(68to77°F).Fig.1showstheschematicrepresentation

nozzle device. Thermal or oxidative effects are minimized.

of equipment.

5.2 This test method may be used for quality control

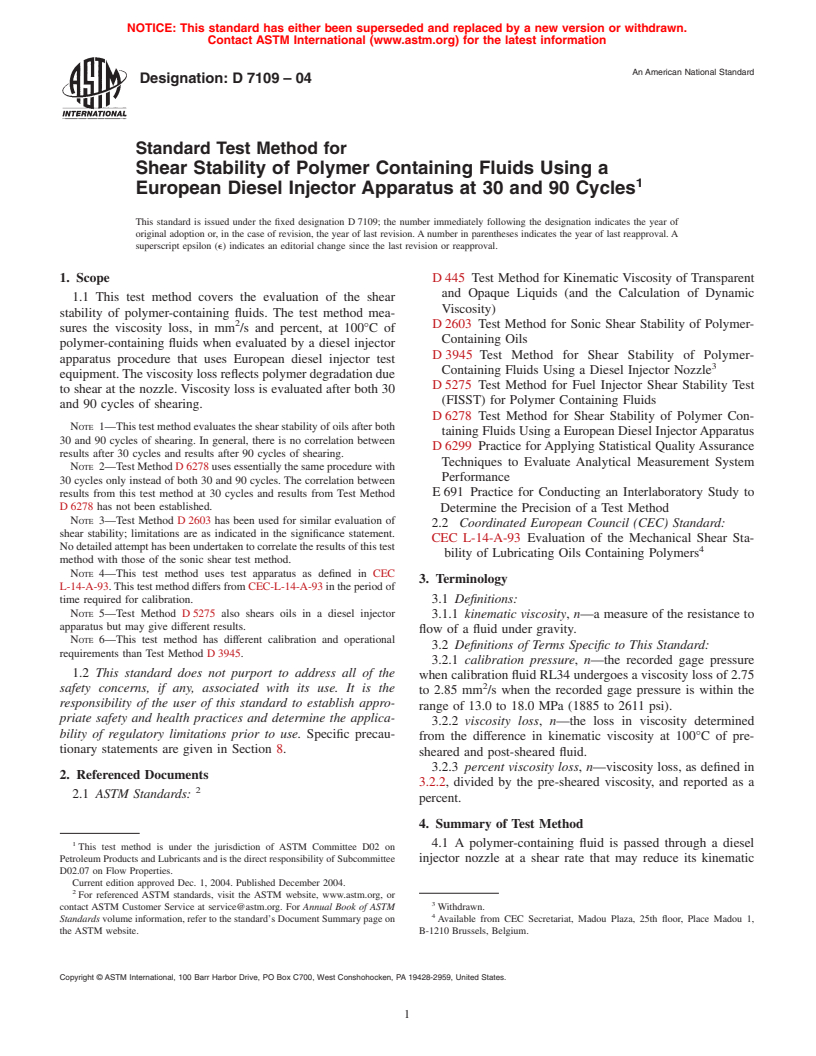

6.1.1 Fluid Reservoir—In Fig. 1, the fluid reservoir (7) is

purposes by manufacturers of polymeric lubricant additives

open on the top, has approximately a 250 mL capacity, has a

and their customers.

45-mm (1.772-in.) inner diameter, and is calibrated in units of

5.3 This test method is not intended to predict viscosity loss

volume. It is fitted with an internal fluid distributor as detailed

in field service in different field equipment under widely

in Fig. 2. A 40-mm (1.575-in.) diameter watch glass with

varying operating conditions, which may cause lubricant vis-

serratededgesisanacceptabledistributorplate.Thedistributor

cosity to change due to thermal and oxidative changes, as well

as by the mechanical shearing of polymer. However, when the

field service conditions, primarily or exclusively, result in the The number in parentheses refers to the legend in Fig. 1.

Note 1—Legend:

(1) Spray nozzle

(2) Atomization chamber

(3) Outlet of the atomization chamber

(4) Distributor plate

(5) Glass container fluid reservoir

(6) Three-way cock downstream of glass

(7) Glass container fluid reservoir

(8) Three-way cock downstream of glass container

(9) Support column

(10) Connection with pump-suction opening

(11) Double-plunger injection pump

(12) Pump setting screw

(13) Electric motor

(14) Venting screw/pump

(15) Stroke counter

(16) Pressure tubing from pump to injector

(17) Return line for overflowing liquid

(18) Pressure sensing device

FIG. 1 Apparatus for Shear Stability Testing

D7109–04

NOTE 1—Dimensions are given in millimetres.

FIG. 2 Distributor Plate

reduces the tendency of fluid channeling. Temperature is 60 Hz current. The 1100 rpm speed is not acceptable in this

measuredbyathermometersuspendedinthecenterofthefluid procedure. A suitable means shall be taken to ensure the

reservoir.Thebottomofthethermometerbulbshallbe10to15

prescribed 925 6 25 rpm speed to the injection pump. One

mm above the entrance to the drain tube opening. Other acceptable method is to usea6to5 speed reducer.

temperature-measuring equipment positioned at the same lo-

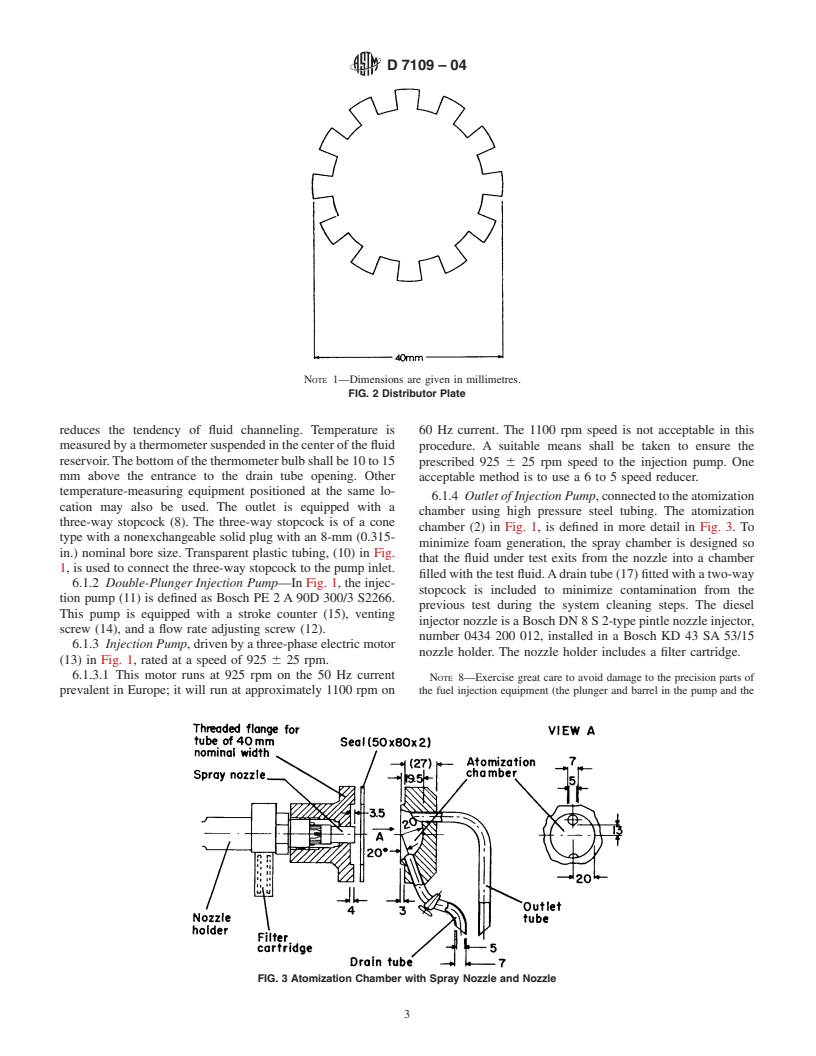

6.1.4 Outlet of Injection Pump,connectedtotheatomization

cation may also be used. The outlet is equipped with a

chamber using high pressure steel tubing. The atomization

three-way stopcock (8). The three-way stopcock is of a cone

chamber (2) in Fig. 1, is defined in more detail in Fig. 3.To

type with a nonexchangeable solid plug with an 8-mm (0.315-

minimize foam generation, the spray chamber is designed so

in.) nominal bore size. Transparent plastic tubing, (10) in Fig.

that the fluid under test exits from the nozzle into a chamber

1, is used to connect the three-way stopcock to the pump inlet.

filledwiththetestfluid.Adraintube(17)fittedwithatwo-way

6.1.2 Double-Plunger Injection Pump—In Fig. 1, the injec-

stopcock is included to minimize contamination from the

tion pump (11) is defined as Bosch PE 2 A 90D 300/3 S2266.

previous test during the system cleaning steps. The diesel

This pump is equipped with a stroke counter (15), venting

injector nozzle is a Bosch DN 8 S 2-type pintle nozzle injector,

screw (14), and a flow rate adjusting screw (12).

number 0434 200 012, installed in a Bosch KD 43 SA 53/15

6.1.3 Injection Pump, driven by a three-phase electric motor

nozzle holder. The nozzle holder includes a filter cartridge.

(13) in Fig. 1, rated at a speed of 925 6 25 rpm.

6.1.3.1 This motor runs at 925 rpm on the 50 Hz current

NOTE 8—Exercise great care to avoid damage to the precision parts of

prevalent in Europe; it will run at approximately 1100 rpm on the fuel injection equipment (the plunger and barrel in the pump and the

FIG. 3 Atomization Chamber with Spray Nozzle and Nozzle

D7109–04

nozzle valve assembly). Service work on the equipment should be

10. Calibration and Standardization

performedbyadieselfuelinjectorpumpspecialistorwithreferencetothe

10.1 Nozzle Adjustments—If the nozzle to be used is new or

manufacturer’s service manual.

has not been pre-calibrated, adjust the diesel injector nozzle

NOTE 9—An unusually rapid rise in gage pressure during testing may

signify filter blockage. When this occurs, the filter cartridge shall be

holder with the nozzle in place. Adjust the nozzle using diesel

replaced.

fuel and a nozzle tester so that the valve opening pressure is

13.0 MPa (1885 psi) under static conditions. If the nozzle has

6.1.5 Pressure Sensing Device (18), such as a glycerol-filled

been pre-calibrated with RL34 calibration oil, adjust the valve

pressure gage or electronic, digital display pressure indicator,

opening pressure to the calibration pressure prescribed, which

shall be installed and separated from the line by a pressure

must be between 13.0 MPa (1885 psi) and 18.0 MPa (2611

snubber or needle valve to suitably dampen pressure surges.

psi).

The pressure device shall be occasionally pressure tested to

ensure accuracy. 10.1.1 Install the nozzle and the nozzle holder in the test

6.1.6 Fluid Cooling Vessel, ((5) in Fig. 1), used to maintain apparatus. The pintle/spray nozzle shall be tightly fitted in the

the specified temperature of the test fluid, as indicated at the chamber to avoid leakage of oil around the external surface of

outletofthefluidreservoir.Thisvesselisaglasscontainerwith the spray nozzle.

exterior cooling jacket constructed so that the heat transfer

10.2 Measurement of Residual Undrained Volume, V :

res

surface of the jacket is spherical. The exterior jacket diameter,

10.2.1 The residual undrained oil volume of the system is

d , is approximately 50 mm (1.969 in.). The interior heat

the volume of the system between the three-way stopcock

transfer surface, d , is approximately 25 mm (0.984 in.) in

below the fluid reservoir (8) in Fig. 1, and the injector nozzle

diameter. The overall length, L, is approximately 180 mm

orifice (1). V does not include the atomization chamber

res

(7.087 in.). A distributor plate, similar in design to the

volume. When the residual undrained volume is known, go to

distributor plate in the fluid reservoir, is positioned in the upper

10.3.

portion of the fluid cooling vessel to ensure contact between

10.2.2 To determine residual undrained volume, first re-

the fluid and the cooling surface. The discharge from the fluid

move as much fluid as possible by briefly running the pump.

cooling vessel is through a three-way stopcock of the same

10.2.3 Remove the high-pressure lines (16) in Fig. 1, and

design used on the discharge of the fluid reservoir.The exterior

drain. Remove the plug at the end of the pump gallery to drain

cooling jacket shall be supplied with an adjustable volume of

the remaining oil in the pump. Drain atomization chamber (2).

cold water.

10.2.4 Reassemble the system and close all drains. The

7. Materials upper three-way stopcock (6) shall be open to the lower

reservoir (7) and the lower three-way cock (8) shall be open to

7.1 Diesel Fuel (No. 2),initiallyrequiredtoadjustthediesel

the pump suction (10).

injector nozzle valve opening pressure.

10.2.5 Add 170 mL of RL34 calibration oil to the lower

7.2 Calibration Fluid RL34, used to ensure that when the

reservoir (7) and observe the level. Start the pump and run for

apparatus is adjusted within a prescribed pressure range, the

several minutes until the oil is transparent and free of sus-

correct viscosity loss is obtained.

pended air.

8. Hazards

10.2.6 Stop the pump. Drain the fluid in the atomization

chamber into a beaker and then pour the fluid back into the

8.1 Warning—Use a safety shield between the high-

lower reservoir; draining to waste will result in an error in the

pressurecomponentsandtheoperatorduringuseofequipment.

measurement of V .Allow the system to drain for 20 min and

8.2 Warning—During operation, the line between the

res

free air trapped in the transparent connecting tube between the

pumpandnozzle,((16)inFig.1),isunderapressureofatleast

lower reservoir and pump.

13.0 MPa (130 bar or 1885 psi). Pressures above the upper

limit of 18.0 MPa (180 bar or 2611 psi) are possible if filter 10.2.7 Observe the difference in oil level in the lower

plugging occurs. Shut off the pump prior to tightening any

reservoir compared to that noted in 10.2.5. Record this differ-

fitting that is not properly sealed. ence as the residual volume, V .

res

NOTE 10—Undrained residual volumes of 15 to 30 mL have been

9. Sampling

reported by various users of this test. V measurements in excess of this

res

9.1 Approximately 650 mL of fluid is needed per test.

may occur when fluid in the atomization chamber is not poured back into

9.2 The test fluid shall be at room temperature, uniform in

the lower reservoir as in 10.2.6, or if the length of line (10) is excessive.

appearance, and free of any visible insoluble material prior to

10.2.8 Calculate the run volume, V , which is the differ-

run

placing it i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.