ASTM E2864-13

(Test Method)Standard Test Method for Measurement of Airborne Metal and Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers using Krypton Gas Adsorption

Standard Test Method for Measurement of Airborne Metal and Metal Oxide Nanoparticle Surface Area Concentration in Inhalation Exposure Chambers using Krypton Gas Adsorption

SIGNIFICANCE AND USE

5.1 A tiered strategy for characterization of nanoparticle properties is necessary to draw meaningful conclusions concerning dose-response relationships observed during inhalation toxicology experiments. This tiered strategy includes characterization of nanoparticles as produced (that is, measured as the bulk material sold by the supplier) and as administered (that is, measured at the point of delivery to a test subject) (Oberdorster et al., 2005) (6).

5.2 Test Methods B922 and C1274 and ISO Standards 9277 and 18757 exist for determination of the as produced surface area of bulk metal and metal oxide powders. During the delivery of metal and metal oxide nanoparticles in inhalation exposure chambers, the material properties may undergo change and therefore have properties that differ from the material as produced. This test method describes the determination of the as administered surface area of airborne metal and metal oxide nanoparticles in inhalation exposure chambers for inhalation toxicology studies.

SCOPE

1.1 This test method covers determination of surface area of airborne metal and metal oxide nanoparticles in inhalation exposure chambers for inhalation toxicology studies. Surface area may be measured by gas adsorption methods using adsorbates such as nitrogen, krypton, and argon (Brunauer et al., 1938; Anderson, 1975; Gregg and Sing, 1982) (1, 2, 3)2 or by ion attachment and mobility-based methods (Ku and Maynard, 2005) (4). This test method is specific to the measurement of surface area by gas adsorption by krypton gas adsorption. The test method permits the use of any modern commercial krypton adsorption instruments but strictly defines the sample collection, outgassing, and analysis procedures for metal and metal oxide nanoparticles. Use of krypton is required due to the low overall surface area of particle-laden samples and the need to accurately measure the background surface area of the filter used for sample collection. Instrument-reported values of surface area based on the multipoint Brunauer, Emmett and Teller (BET) equation (Brunauer et al., 1938; Anderson, 1975; Gregg and Sing, 1982) (1, 2, 3) are used to calculate surface area of airborne nanoparticles collected on a filter.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard. State all numerical values in terms of SI units unless specific instrumentation software reports surface area using alternate units.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2864 − 13

Standard Test Method for

Measurement of Airborne Metal and Metal Oxide

Nanoparticle Surface Area Concentration in Inhalation

1

Exposure Chambers using Krypton Gas Adsorption

This standard is issued under the fixed designation E2864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

2.1 ASTM Standards:

1.1 Thistestmethodcoversdeterminationofsurfaceareaof

B922Test Method for Metal Powder Specific Surface Area

airborne metal and metal oxide nanoparticles in inhalation

by Physical Adsorption

exposure chambers for inhalation toxicology studies. Surface

C1274Test Method forAdvanced Ceramic Specific Surface

area may be measured by gas adsorption methods using

Area by Physical Adsorption

adsorbates such as nitrogen, krypton, and argon (Brunauer et

2

E691Practice for Conducting an Interlaboratory Study to

al., 1938;Anderson, 1975; Gregg and Sing, 1982) (1, 2, 3) or

Determine the Precision of a Test Method

by ion attachment and mobility-based methods (Ku and

E2456Terminology Relating to Nanotechnology

Maynard, 2005) (4). This test method is specific to the

4

2.2 ISO Standards:

measurement of surface area by gas adsorption by krypton gas

ISO 9277Determination of the Specific Surface Area of

adsorption. The test method permits the use of any modern

Solids by Gas Adsorption using the BET Method

commercial krypton adsorption instruments but strictly defines

ISO 18757Fine Ceramics (Advanced Ceramics, Advanced

the sample collection, outgassing, and analysis procedures for

Technical Ceramics)—Determination of Specific surface

metalandmetaloxidenanoparticles.Useofkryptonisrequired

Area of Ceramic Powders by Gas Adsorption using the

due to the low overall surface area of particle-laden samples

BET Method

and the need to accurately measure the background surface

area of the filter used for sample collection. Instrument-

3. Terminology

reported values of surface area based on the multipoint

3.1 Definitions—For additional definitions related to

Brunauer, Emmett and Teller (BET) equation (Brunauer et al.,

nanotechnology, see Terminology E2456.

1938;Anderson,1975;GreggandSing,1982) (1, 2, 3)areused

3.1.1 nanoparticles, n—in nanotechnology, a sub-

to calculate surface area of airborne nanoparticles collected on

classification of ultrafine particle with lengths in two or three

a filter.

dimensions greater than 0.001 micrometre (1 nanometre) and

1.2 The values stated in SI units are to be regarded as

smallerthanabout0.1micrometre(100nanometres)andwhich

standard. No other units of measurement are included in this

may or may not exhibit a size-related intensive property.

standard. State all numerical values in terms of SI units unless

E2456

specific instrumentation software reports surface area using

3.1.2 adsorbate, n—material that has been retained by the

alternate units.

process of adsorption. B922

1.3 This standard does not purport to address all of the

3.1.3 adsorbent, n—any solid having the ability to concen-

safety concerns, if any, associated with its use. It is the

trate or collect significant quantities of other substances on its

responsibility of the user of this standard to establish appro-

surface. B922

priate safety and health practices and determine the applica-

3.1.4 adsorption, n—a process in which fluid molecules are

bility of regulatory limitations prior to use.

concentrated or collected on a surface by chemical or physical

forces, or both. B922

1

This test method is under the jurisdiction of ASTM Committee E56 on

3

Nanotechnology and is the direct responsibility of Subcommittee E56.02 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Physical and Chemical Characterization. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Sept. 1, 2013. Published October 2013. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2864-13. the ASTM website.

2 4

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

this standard. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

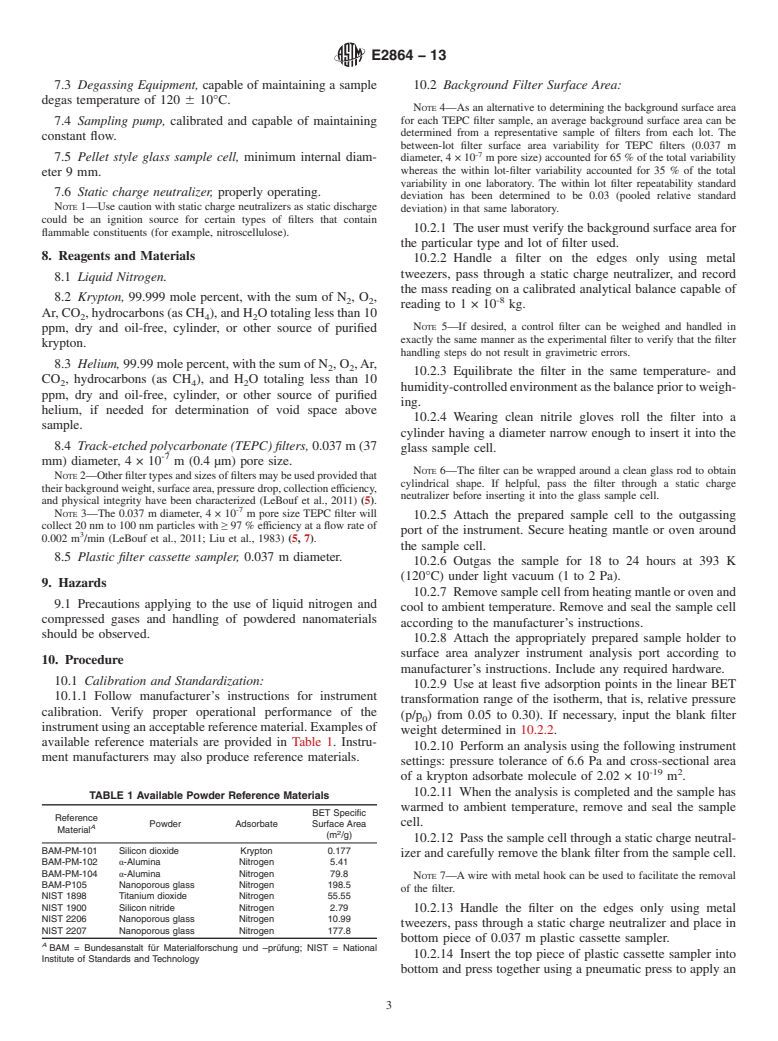

---------------------- Page: 1 ----------------------

E2864 − 13

3.1.5 BET-constant, n—an indication of the magnitude of instrument pressure tolerance (pressure range that must be

the adsorbent/adsorbate interactions in the first adsorbed layer. maintained within a sample cell to accept a va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.