ASTM D7348-07

(Test Method)Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues

Standard Test Methods for Loss on Ignition (LOI) of Solid Combustion Residues

SCOPE

1.1 These test methods cover the determination of the mass loss from solid combustion residues upon heating in an air or oxygen atmosphere to a prescribed temperature. The mass loss can be due to the loss of moisture, carbon, sulfur, and so forth, from the decomposition or combustion of the residue.

1.2 The values given in SI units are to be considered as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 7348 – 07

Standard Test Methods for

Loss on Ignition (LOI) of Solid Combustion Residues

This standard is issued under the fixed designation D 7348; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6357 Test Methods for Determination of Trace Elements

in Coal, Coke, and Combustion Residues from Coal

1.1 These test methods cover the determination of the mass

Utilization Processes by Inductively Coupled Plasma

loss from solid combustion residues upon heating in an air or

Atomic Emission Spectrometry, Inductively Coupled

oxygen atmosphere to a prescribed temperature. The mass loss

Plasma Mass Spectrometry, and Graphite Furnace Atomic

can be due to the loss of moisture, carbon, sulfur, and so forth,

Ab

from the decomposition or combustion of the residue.

1.2 The values given in SI units are to be considered as the

3. Terminology

standard.

3.1 Definitions—For definitions of terms used in these test

1.3 This standard does not purport to address all of the

methods, refer to Terminology D 121.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Loss on ignition (LOI) is determined by measuring the

bility of regulatory limitations prior to use.

loss in mass of the test specimen when heated under controlled

2. Referenced Documents conditions of temperature, time, atmosphere, specimen mass,

2 and equipment specifications. The LOI can be determined by

2.1 ASTM Standards:

measuring the mass loss in a single procedure or in a two-step

D 121 Terminology of Coal and Coke

procedure in which mass losses, equivalent to the moisture and

D 3174 TestMethodforAshintheAnalysisSampleofCoal

ash values of the test specimen, are determined.

and Coke from Coal

D 3180 Practice for Calculating Coal and Coke Analyses

5. Significance and Use

from As-Determined to Different Bases

5.1 LOI refers to the mass loss of a combustion residue

D 3682 Test Method for Major and Minor Elements in

when it is heated in an air or oxygen atmosphere to high

Combustion Residues from Coal Utilization Processes

temperatures. In the cement industry, use of the term LOI

D 3683 Test Method for Trace Elements in Coal and Coke

normally refers to a mass loss in a sample heated to 950°C. To

Ash by Atomic Absorption

combustion engineers, the term LOI normally refers to mass

D 4326 Test Method for Major and Minor Elements in Coal

losses in samples heated to temperatures normally less than

and Coke Ash By X-Ray Fluorescence

950°C. These test methods establish a procedure for determin-

D 5142 Test Methods for Proximate Analysis of the Analy-

ing LOI values for combustion residues heated to 950°C. LOI

sis Sample of Coal and Coke by Instrumental Procedures

values from these test methods can be used by industries that

D 6316 Test Method for Determination of Total, Combus-

utilize combustion residues in various processes and products.

tible and Carbonate Carbon in Solid Residues from Coal

5.2 If the solid combustion residue is heated to estimate the

and Coke

combustible or unburned carbon in the sample, it has been

D 6349 Test Method for Determination of Major and Minor

shown that LOI and estimation of unburned carbon do not

Elements in Coal, Coke, and Solid Residues from Com-

necessarily agree well with each other and that LOI should not

bustion of Coal and Coke by Inductively Coupled

be used as an estimate of unburned carbon in all combustion

Plasma—Atomic Emission Spectrometry

residues. . Direct determination of unburned (combustible)

carbon can be carried out using Test Method D 6316.

5.3 If the solid combustion residue is heated to prepare an

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD05onCoal

ash for the determination of the concentrations of major and

and Coke and is the direct responsibility of Subcommittee D05.29 on Major

Elements in Ash and Trace Elements of Coal.

Current edition approved May 1, 2007. Published May 2007.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service as service@astm.org. ForAnnual Book ofASTM S.C. Burris, D. Li, and J.T.Riley, “Comparison of Heating Losses and Macro

Standards volume information, refer to the standard’s Document Summary page on Thermogravimetric Analysis Procedures for Estimating Unburned Carbon in Com-

the ASTM website. bustion Residues,” Energy Fuels, Vol 19, 2005, pp. 1493-1502.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7348–07

minor elements, use the heating procedure described in Test 7.5 Operation of the instrumental system in its entirety shall

Methods D 3682, D 4326, and D 6349. be verified in accordance with the manufacturer’s operating

instructions.

5.4 If the solid combustion residue is heated to prepare an

ash for the determination of the concentrations of trace 7.6 Venting Equipment—Combustion and decomposition

gases evolved during the test procedures shall be vented from

elements, use the heating procedure described in Test Methods

D 3683 and D 6357. thelaboratoryandsuitableventingequipmentshallbeinstalled

in the vicinity of the apparatus.

NOTE 1—Combustion residues produced in furnace operations or other

combustion systems can differ from the ash yield, as determined in Test

8. Reagents and Materials

Methods D 3174 and D 5142, because combustion conditions influence

8.1 Drying Gases—Air dried to a moisture content of 1.9

the chemistry and amount of ash. Combustion causes an expulsion of all

water, the loss of carbon dioxide from carbonates, the conversion of metal mg/L or less (dew point –10°C or less). Nitrogen (99.5 %

sulfides into metal oxides, metal sulfates and sulfur oxides, and other

purity) is normally used with the macro TGA system. Argon

chemicalreactions.Likewise,the“ash”obtainedafterignitingcombustion

can also be used.

residues can differ in composition and amount from Test Methods D 3174

8.2 Oxidizing Gases—Oxygen (99.5 % purity) or air.

and D 5142 ash yields because of different heating procedures, combus-

tion of unburned carbon, and decomposition of materials in the residue.

9. Hazards

9.1 The user shall insure acceptable documented safety

6. Interferences

procedures are in place for the handling of all reagents and test

6.1 Therearenoknowninterferencesforthesetestmethods.

materials and for the operation of laboratory equipment speci-

fied for these test methods.

7. Apparatus

10. Sampling, Test Specimens, and Test Units

7.1 Furnace—The apparatus shall consist of a furnace with

a cavity large enough to accept multiple crucibles. The furnace

10.1 The sample used for analysis shall be thoroughly

shall be constructed so the cavity is surrounded by a suitable

mixed and of such fineness to pass through a 250-µm (No. 60)

refractoryandinsulatedsoastodevelopauniformtemperature

sieve. Pulverizing the sample to this fineness is required.

in all parts of the cavity but with a minimum free space. The

11. Preparation of Apparatus

furnace shall be capable of being heated rapidly (10°C/min or

faster) from ambient to 950°C. The temperature shall be

11.1 ForLOIdeterminationsusingamacroTGA,followthe

monitored and maintained at values specific to each of the

manufacturer’s recommended procedure for verifying system

determinations. Provisions shall be made to introduce drying

stability and for loading and taring the crucibles. Various

and oxidizing gases and to remove products of drying, decom-

modes of operation are possible depending on the instrument

position, and combustion. A recommended flow rate is one

used and the manner in which the determinations are com-

furnace volume change per minute, but higher flow rates (that

pleted.Theinstrumentcanbeprogrammedtoterminatethetest

is, two furnace volumes per minute as in some other standard

when the test specimens and crucibles have reached a constant

testmethodsforcoalandcoke)areacceptable.Thefurnacecan

weight. Typically, crucibles are weighed automatically at

be a stand alone muffle furnace or a computer-controlled

specified intervals, and the analysis is complete when two

macrothermogravimetric analyzer (macro TGA) system. In

successiveweighingsagreewithinaplateaudeviationspecified

macroTGA,asamplesizeof1g(orlarger)isused.Inatypical

for the instrument. Alternately, the instrument can be pro-

analysis, the temperature is ramped from ambient to a specific

grammed to allow for moisture determination by heating the

temperatureandheldatthattemperatureforaprescribedlength

test specimens for a specified time period (for example, 1 h) at

of time. In thermogravimetric analysis, the mass of a sample in

the prescribed temperature limits.

a controlled atmosphere is recorded repeatedly as a function of

11.2 When using a muffle furnace for LOI determinations,

temperature or time.

always start the test with the muffle furnace at ambient

7.2 Drying Oven—For determining the moisture in solid

temperature.

combustion residue samples, use a drying oven with openings

12. Conditioning

for drying gas circulation and capable of temperature regula-

tion between the limits of 104 and 110°C. A drying gas flow

12.1 Heat new crucibles for use in these test methods under

rate of approximately one volume change per minute is

the conditions of the test and cool before use.

recommended but higher flow rates, that is, two volume

13. Procedure

changes per minute as in some other standard test methods for

coal and coke, are acceptable. 13.1 For LOI of moisture and ash, in analyses of solid

7.3 Crucibles, use a crucible of a convenient form that

combustion residues using a macro TGA, the analyses are

allows extensive contact between the specimen and reactant normally complete when the sample reaches a constant weight

gas. The crucibles can be made of porcelain, fused silica, or

as defined in the instrumental operating parameters.

similar materials. The crucibles shall have the dimensions 13.2 For LOI determinations using a single-step procedure,

specified by the instrument manufacturer.

add approximately1gof solid combustion residue to each

7.4 Balance, sensitive to 0.1 mg. In the macro TGA, the successive crucible and weigh. Select oxygen or air as the

balance is an integral part of the system. For other systems, the furnace atmosphere and raise the temperature of the furnace at

balance is a separate piece of a

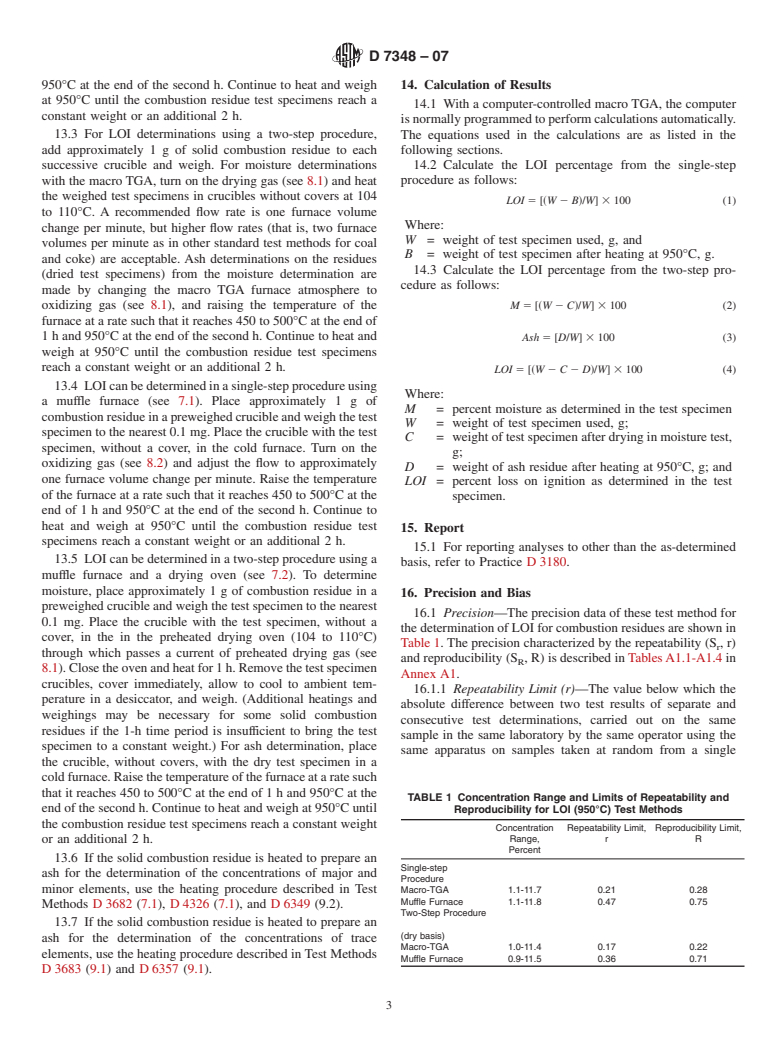

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.