ASTM D1894-14

(Test Method)Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting (Withdrawn 2023)

Standard Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting (Withdrawn 2023)

SIGNIFICANCE AND USE

4.1 Measurements of frictional properties may be made on a film or sheeting specimen when sliding over itself or over another substance. The coefficients of friction are related to the slip properties of plastic films that are of wide interest in packaging applications. These methods yield empirical data for control purposes in film production. Correlation of test results with actual performance can usually be established.

4.1.1 This test method includes testing at temperatures other than 23°C by heating only the plane while the sled is at ambient temperature.

4.2 Slip properties are generated by additives in some plastic films, for example, polyethylene. These additives have varying degrees of compatibility with the film matrix. Some of them bloom, or exude to the surface, lubricating it and making it more slippery. Because this blooming action may not always be uniform on all areas of the film surface, values from these tests may be limited in reproducibility.

4.3 The frictional properties of plastic film and sheeting may be dependent on the uniformity of the rate of motion between the two surfaces. Care should be exercised to ensure that the rate of motion of the equipment is as carefully controlled as possible.

4.4 Data obtained by these procedures may be extremely sensitive to the age of the film or sheet and the condition of the surfaces. The blooming action of many slip additives is time-dependent. For this reason, it is sometimes meaningless to compare slip and friction properties of films or sheets produced at different times, unless it is desired to study this effect.

4.5 Frictional and slip properties of plastic film and sheeting are based on measurements of surface phenomena. Where products have been made by different processes, or even on different machines by the same process, their surfaces may be dependent on the equipment or its running conditions. Such factors must be weighed in evaluating data from these methods.

4.6 The measure...

SCOPE

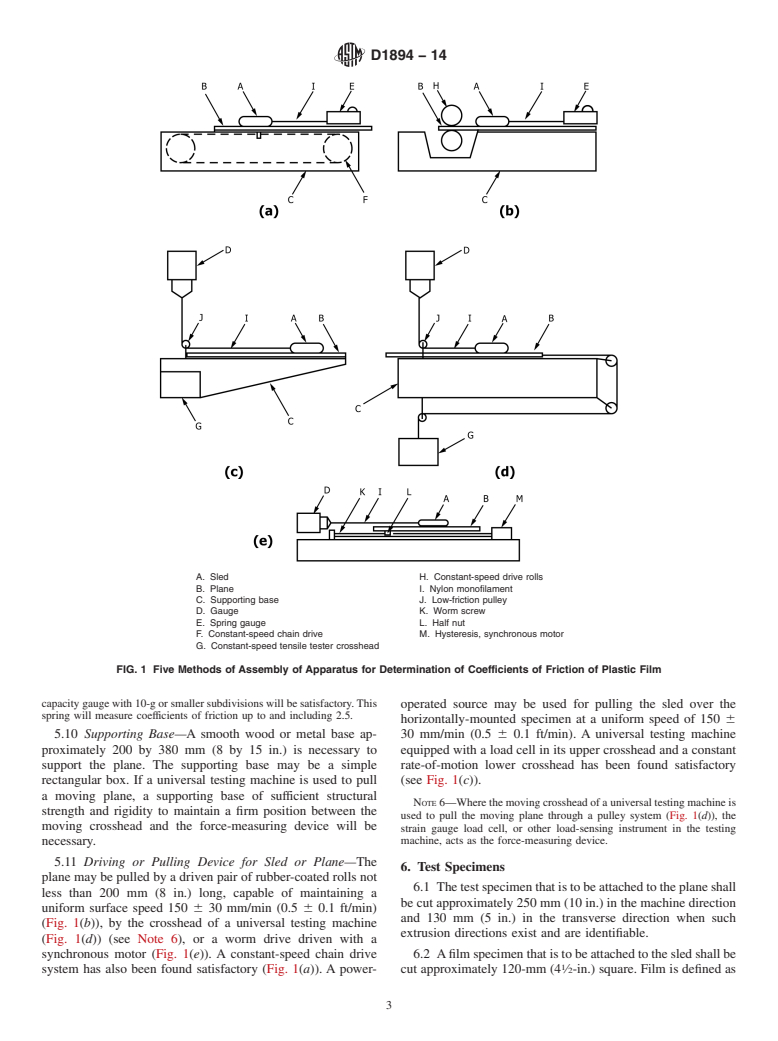

1.1 This test method covers determination of the coefficients of starting and sliding friction of plastic film and sheeting when sliding over itself or other substances at specified test conditions. The procedure permits the use of a stationary sled with a moving plane, or a moving sled with a stationary plane. Both procedures yield the same coefficients of friction values for a given sample. Note 1—For the frictional characteristics of plastic films partially wrapped around a cylinder, or capstan, see Test Method G143 under the jurisdiction of ASTM Subcommittee G02.50.

1.2 Test data obtained by this test method is relevant and appropriate for use in engineering design.

1.2.1 As an option to this test, coefficient of friction may be run at temperatures other than 23°C by heating only the plane while the sled is at ambient temperature.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see the end of 6.5.Note 2—This test method is not equivalent to ISO 8295–1995, and results cannot be directly compared between the two methods.

WITHDRAWN RATIONALE

This test method covers determination of the coefficients of starting and sliding friction of plastic film and sheeting when sliding over itself or other substances at specified test conditions. The procedure permits the use of a stationary sled with a moving plane, or a moving sled with a stationary plane. Both procedures yield the same coefficients of friction values for a given sample.

Formerly under the jurisdiction of Committee D20 on Plastics, this test method was ...

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1894 − 14

Standard Test Method for

Static and Kinetic Coefficients of Friction of Plastic Film and

1

Sheeting

This standard is issued under the fixed designation D1894; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D883 Terminology Relating to Plastics

D1894 Test Method for Static and Kinetic Coefficients of

1.1 This test method covers determination of the coefficients

Friction of Plastic Film and Sheeting

of starting and sliding friction of plastic film and sheeting when

D3574 Test Methods for Flexible Cellular Materials—Slab,

sliding over itself or other substances at specified test condi-

Bonded, and Molded Urethane Foams

tions. The procedure permits the use of a stationary sled with

D4000 Classification System for Specifying Plastic Materi-

a moving plane, or a moving sled with a stationary plane. Both

als

procedures yield the same coefficients of friction values for a

E177 Practice for Use of the Terms Precision and Bias in

given sample.

ASTM Test Methods

NOTE 1—For the frictional characteristics of plastic films partially

E691 Practice for Conducting an Interlaboratory Study to

wrapped around a cylinder, or capstan, see Test Method G143 under the

Determine the Precision of a Test Method

jurisdiction of ASTM Subcommittee G02.50.

G143 Test Method for Measurement of Web/Roller Friction

1.2 Test data obtained by this test method is relevant and

Characteristics

appropriate for use in engineering design.

2.2 ISO Standard:

3

1.2.1 As an option to this test, coefficient of friction may be

ISO 8295–1995

run at temperatures other than 23°C by heating only the plane

while the sled is at ambient temperature.

3. Terminology

1.3 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. The values given in parentheses are for information

3.1.1 friction, n—resistance to relative motion between two

only.

bodies in contact.

1.4 This standard does not purport to address all of the

3.1.1.1 coeffıcient of friction—the ratio of the force required

safety concerns, if any, associated with its use. It is the

to move one surface over another to the total force applied

responsibility of the user of this standard to establish appro-

normal to those surfaces.

priate safety and health practices and determine the applica-

3.1.1.2 kinetic coeffıcient of friction—the ratio of the force

bility of regulatory limitations prior to use. For a specific

required to move one surface over another to the total force

precautionary statement, see the end of 6.5.

applied normal to those surfaces, once that motion is in

progress.

NOTE 2—This test method is not equivalent to ISO 8295–1995, and

results cannot be directly compared between the two methods.

3.1.1.3 static coeffıcient of friction—the ratio of the force

required to move one surface over another to the total force

2. Referenced Documents

applied normal to those surfaces, at the instant motion starts.

2

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

D618 Practice for Conditioning Plastics for Testing

3.2.1 slip—in plastic films, lubricity of two surfaces sliding

in contact with each other.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.19 on Film, Sheeting, and

4. Significance and Use

Molded Products.

Current edition approved March 1, 2014. Published March 2014. Originally

4.1 Measurements of frictional properties may be made on a

ε1

approved in 1961. Last previous edition approved in 2011 as D1894 - 11 . DOI:

film or sheeting specimen when sliding over itself or over

10.1520/D1894-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1894 − 14

another substance. The coefficients of friction are related to the Density Test of Methods D3574. The pressure required to

slip properties of plastic films that are of wide interest in compress the foam 25 % shall be 85 6 15 kPa (12.5 6 2.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.