ASTM F2436-05

(Test Method)Standard Test Method for Measuring the Performance of Synthetic Rope Rescue Belay Systems Using a Drop Test

Standard Test Method for Measuring the Performance of Synthetic Rope Rescue Belay Systems Using a Drop Test

SIGNIFICANCE AND USE

The types of rope rescue systems to which this test method apply use a tensioned mainline and untensioned belay line. If a fall occurs because of a mainline system failure or misuse, considerable energy must be absorbed by the belay for a successful arrest. This drop test method simulates a “worst case” condition when systems are operated as designed, and is designed to help evaluate and compare the performance of various rope rescue belay systems under such conditions. (See Note 1.) The successful catching of a load does not imply that the tested system is suitable for any and all belaying. See X1.2.

Note 1—Higher forces may be encountered under some circumstances, such as the belay being operated with excessive slack.

SCOPE

1.1 This test method covers drop test procedures to measure rope rescue belay system performance. It applies only to belay systems consisting of an untensioned rope connecting the load to an anchored belay device. This test method does not address other types of belays, such as self-belays or belays for lead climbing, nor does it test the rescuer's belaying ability.

1.2 This test method may be used to help measure a rescue belay system's performance under controlled drop test conditions, but it will not necessarily provide guidance as to which belay method is most suited to a particular application. Other considerations, such as ease of handling, performance on different types and diameters of rope, portability, versatility, system safety factor, cost, and automatic operation that do not require the positive action of the belayer may influence the selection of a belay system and are not dealt with in this test method. See X1.1.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Additional precautions for this test method are given in 8.1 and 8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2436 – 05

Standard Test Method for

Measuring the Performance of Synthetic Rope Rescue Belay

Systems Using a Drop Test

This standard is issued under the fixed designation F2436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Document:

CI 1801-98 Low Stretch and Static Kernmantle Life Safety

1.1 This test method covers drop test procedures to measure

Rope

rope rescue belay system performance. It applies only to belay

systems consisting of an untensioned rope connecting the load

3. Terminology

to an anchored belay device.This test method does not address

3.1 Definitions:

other types of belays, such as self-belays or belays for lead

3.1.1 belay, n—a secondary system, or the system compo-

climbing, nor does it test the rescuer’s belaying ability.

nents, used to arrest the load in the event of a failure in the

1.2 This test method may be used to help measure a rescue

system.

belay system’s performance under controlled drop test condi-

3.1.2 belay, v—in rope rescue systems, to operate an unten-

tions, but it will not necessarily provide guidance as to which

sioned secondary rope (belay line) so that it may be taken in or

belay method is most suited to a particular application. Other

let out as the load is raised or lowered, and then hold the load

considerations, such as ease of handling, performance on

in case of failure of the lifting line (working line) system.

different types and diameters of rope, portability, versatility,

3.1.3 belay assembly, n—all elements of the belay system,

system safety factor, cost, and automatic operation that do not

but not including the belay line and the belay anchor.

require the positive action of the belayer may influence the

3.1.4 belay assembly extension, L, (cm), n—the increase in

selection of a belay system and are not dealt with in this test

length of the belay assembly, due to stretch or other extension,

method. See X1.1.

measured from the anchorage to the farthest gripping point of

1.3 The values stated in SI units are to be regarded as

the belay assembly while statically tensioned, post-drop, ex-

standard.

pressed in centimetres (cm).

1.4 This standard may involve hazardous materials, opera-

3.1.5 belay device, n—that element of the belay system

tions, and equipment. This standard does not purport to

providing a moveable connection point to the belay line, which

address all of the safety concerns associated with its use. It is

can secure the belay line when necessary.

the responsibility of whoever uses this standard to consult and

3.1.6 belay line, n—in rope rescue systems, a secondary

establish appropriate safety and health practices and deter-

line, generally untensioned, acting as a back-up to the lifting

mine the applicability of regulatory limitations prior to use.

line as distinguished from the lifting line (working line) that

Additionalprecautionsforthistestmethodaregivenin8.1and

actually raises, lowers, or transports the load.

8.2.

3.1.7 belay system, n—the belay assembly and the belay

2. Referenced Documents line, but for the purposes of this test method, not including the

2 belay anchor.

2.1 ASTM Standards:

3.1.8 belay system extension, L, (cm), n—the distance

D1776 Practice for Conditioning and Testing Textiles

below the zero line (this excludes drop height) reached at the

F2266 Specification for Masses Used in Testing Rescue

maximum extension during fall arrest, prior to rebound; also

Systems and Components

known as stopping distance, expressed in centimetres (cm).

3.1.9 belay system failure, n—when the test block hits the

This test method is under the jurisdiction ofASTM Committee F32 on Search

ground.

and Rescue and is the direct responsibility of Subcommittee F32.01 on Equipment,

3.1.10 drop height, L, (cm), n—the free-fall distance the

Testing, and Maintenance.

block falls before the belay system begins to arrest its fall.

Current edition approved July 1, 2005. Published July 2005. DOI: 10.1520/

F2436-05.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromCordageInstitute,994OldEagleSchoolRd.,Wayne,PA19087,

the ASTM website. http://www.ropecord.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2436 – 05

3.1.11 elongation classification, n—in rope rescue systems, 6.1.2 The use of a light cord between the test block and the

elongation of new rope as measured by CI 1801-98 at 10 % of hoist line, which is cut by a heated nichrome wire or stick

the manufacturer’s rated breaking strength: static <6 % elon- mounted knife, is also satisfactory.

gation, low-stretch >6 % and <10 % elongation 6.1.3 Any release buckle, latch, or device that might impart

3.1.12 extension, L, n—the change in length of a material,

a sideways force to the suspended mass shall not be used.

device, or system due to a change in an applied force, usually

6.1.4 Any restriction imposed on the test block, such as the

measured at some specified force, force rate, or duration of

use of guide rails to contain and control the block’s fall, or the

force, or combination thereof.

use of a linear motion transducer, shall be constructed and

3.1.13 final rope length, [L], (cm), n—the distance between

maintained so that the combined effect shall not reduce the

the inside of the bowline where it contacts the shackle of the

velocity of the mass more than 2 % from the velocity of a free

test block and the lowest gripping portion of the belay

falling block of similar mass. Velocity measurements shall be

assembly after the test block has rebounded and come to rest.

made and recorded at the beginning of each test day when

3.1.14 lifting line, n—the line that lifts the test block and

guide rail type test rigs are to be used.

from which a quick disconnection is made to drop the test

6.2 If the lifting line’s system uses a twisted cable, there

block (working line).

may be difficulties with the test block turning and twisting the

3.1.15 maximum arrest force, MAF, (N), n—the peak force

rope. This can be prevented by light “anti-twister” cords

measured during the fall arrest.

runningofftothesideoftheblockthatarereleasedatthesame

3.1.16 pre-grip slippage, L, (cm), n—rope movement

time as the lifting line connection.

through the belay device before gripping stops movement.

6.3 Inconsistency in the tightening of knots shall be

3.1.17 rope rescue system, n—a system using fiber ropes to

avoided.

raise, lower, or transport a load.

3.1.18 zero line, n—the level of the contact between the

7. Apparatus

inside of the bowline and test block shackle when it is 3 m

7.1 The test facility shall be a structure with less than 1 mm

below the lowest gripping portion of the belay assembly, prior

of immediate elastic deformation at a force of 50 kN at the

to the drop.

anchor point and having a natural frequency above 200 Hz.

7.1.1 Failing this, a distinct cautionary note should be made

4. Summary of Test Method

in all reports generated at the test facility regarding the anchor

4.1 Arigid test block of the correct mass simulates a rescue

rigidity or natural frequency.

load. A rope of given length connects the test block to a belay

7.2 The test block shall have an appropriate mass and, if

assembly that is in turn connected to a suitably rigid overhead

madefromacollectionofplates,bars,oringots,shallbejoined

anchor point. The test block is raised a given distance with a

in a fashion that prevents play or relative movement of parts

separate lifting system and is then released.After the block has

during the testing. It shall be provided with a shackle for the

free-fallen to its starting point, the belay system (the rope and

attachment of the belay line and the lifting line (through the

belay assembly) begins to arrest its fall. Among other things,

quick-disconnectfitting)fromwhichithangsinsymmetry.The

maximum arrest force and belay system extension are mea-

shackle shall have less than 1 mm of immediate elastic

sured. The belay system may or may not be successful in

deformation at a force of 50 kN.

stopping the falling test block.

7.2.1 The mass of the rigid test block shall be Type II (100

kg), Type IV (200 kg), or Type V (280 kg) 6 1 %, including

5. Significance and Use

attachment hardware, for the testing of equipment intended for

5.1 The types of rope rescue systems to which this test use with various rescue systems, in accordance with Specifi-

method apply use a tensioned mainline and untensioned belay

cationF2266.Theusershouldselectthemostappropriatemass

line. If a fall occurs because of a mainline system failure or to the intended application. Adequate attachment point, rigid-

misuse, considerable energy must be absorbed by the belay for

ity, and symmetry shall be maintained. The mass used shall be

a successful arrest. This drop test method simulates a “worst included in the report.

case” condition when systems are operated as designed, and is

7.3 The belay line shall be tied directly to the test block

designed to help evaluate and compare the performance of

using a bowline knot. Use of a setup where the rope is tied to

various rope rescue belay systems under such conditions. (See

a platen (catch plate) upon which the falling test block impacts

Note 1.) The successful catching of a load does not imply that

shall not be permitted.

the tested system is suitable for any and all belaying. See X1.2.

7.4 Thetestblockliftingsystemshallbeabletopositionthe

test block to a tolerance of 60.5 cm and when stopped, sustain

NOTE 1—Higherforcesmaybeencounteredundersomecircumstances,

thetestblockfora5minperiodatagivenheightwiththesame

such as the belay being operated with excessive slack.

tolerance.

6. Interferences

7.4.1 The lifting line shall pass not more than 10 cm

6.1 The method used to release the test block could affect horizontally in distance from the anchor point for the belay

assembly.

the results by imparting motion to the block, in addition to the

straight fall caused by gravity. 7.5 If a pit of loose material such as sand is used, care

6.1.1 Residual magnetism of an electromagnetic release shouldbetakensothatthetestblockdoesnotincreaseitsmass

shall be guarded against. by picking up material from the pit after impact.

F2436 – 05

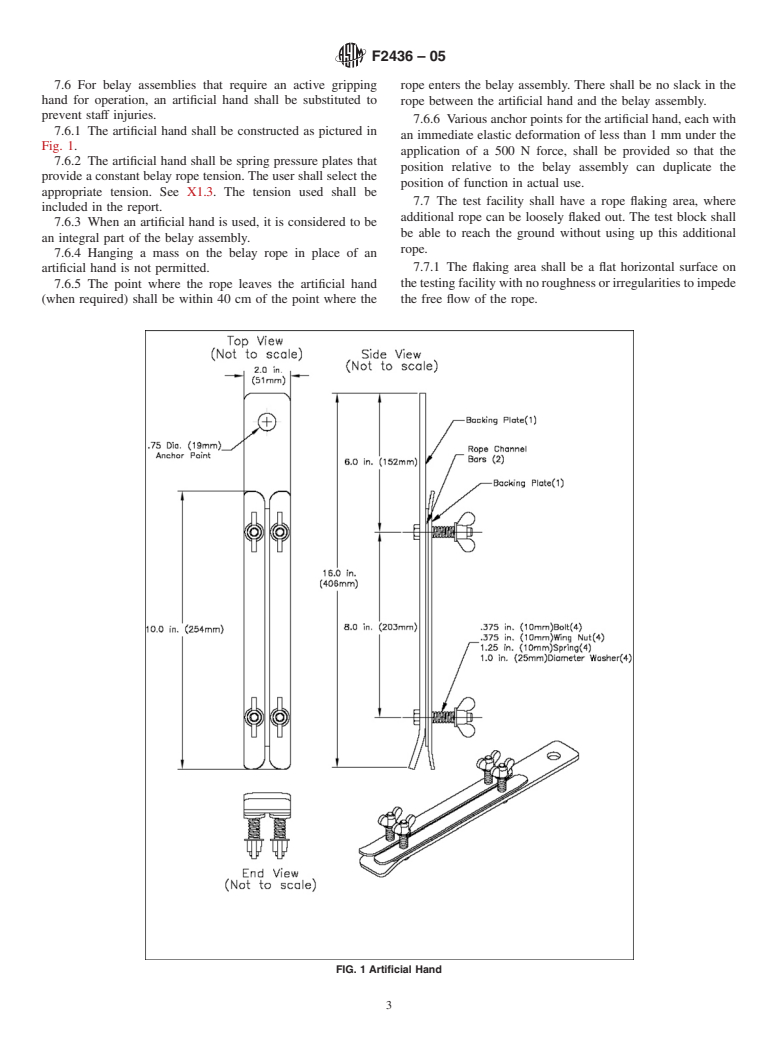

7.6 For belay assemblies that require an active gripping rope enters the belay assembly. There shall be no slack in the

hand for operation, an artificial hand shall be substituted to rope between the artificial hand and the belay assembly.

prevent staff injuries.

7.6.6 Various anchor points for the artificial hand, each with

7.6.1 The artificial hand shall be constructed as pictured in

an immediate elastic deformation of less than 1 mm under the

Fig. 1.

application of a 500 N force, shall be provided so that the

7.6.2 The artificial hand shall be spring pressure plates that

position relative to the belay assembly can duplicate the

provide a constant belay rope tension. The user shall select the

position of function in actual use.

appropriate tension. See X1.3. The tension used shall be

7.7 The test facility shall have a rope flaking area, where

included in the report.

additional rope can be loosely flaked out. The test block shall

7.6.3 When an artificial hand is used, it is considered to be

be able to reach the ground without using up this additional

an integral part of the belay assembly.

rope.

7.6.4 Hanging a mass on the belay rope in place of an

7.7.1 The flaking area shall be a flat horizontal surface on

artificial hand is not permitted.

thetestingfacilitywithnoroughnessorirregularitiestoimpede

7.6.5 The point where the rope leaves the artificial hand

(when required) shall be within 40 cm of the point where the the free flow of the rope.

FIG. 1 Artificial Hand

F2436 – 05

7.7.2 The rope (belay line) shall be flaked at an angle less 10.2 If conditioning is not an option, temperature and

than 15° of directly in line with the device’s intended manner humidityduringthetestsshallbethoseunderwhichequipment

of use for braking, and the flaking area shall be positioned to would normally be used. These conditions shall be noted in

provide1m(610cm)ofunsupportedropebetweentheflaking your test report.

area and the belay device being tested. 10.2.1 Storage conditions prior to the tests shall be those

7.8 The maximum arrest force (MAF) shall be measured by under which equipment would normally be stored prior to use.

a system, which is accurate to 61 % of the MAF, free from These conditions shall be noted in the test report.

artifact, and whose calibration is traceable to a recognized 10.3 A different piece of dry, new rope shall be used for

source. It is preferable that the recording device also be able to each test.

generate a force/time curve. 10.3.1 Altering rope conditions (used, wet, muddy, icy, and

7.8.1 MAF measurements are obtained by sampling of an so forth) will result in belay performance differences. The user

electronic load cell or other suitable device. Its physical ofthistestmethodmaywishtousethismethodtotestdifferent

characteristics and all associated electronics shall allow sam- rope conditions with a belay device; if so, the condition of the

pling at a minimum of 2000 times per second. The minimum rope shall be noted in the test report.

resonant frequency of the load cell shall be 4 kHz.

11. Procedure

7.9 To determine the belay extension, the lowest point

11.1 Procedural details will vary with the facility. Any

duringthedropshallbereadbyusingasuitabledevicecapable

deviationsfromtheitemslistedinthissectionshallbeincluded

of measuring to an accuracy of 61 cm. Care shall be exercised

in the report.

that extension measuring system causes no significant cush-

11.2 All rope, cord, and webbing samples shall be cut and

ioning or retarding effect on the test block. The total velocity

the ends finished by methods that preserve the integrity of

difference from a free falling mass and a mass with or without

construction, such as hot-cutting. All pre-drop measurements

guide rails and an extension measuring system shall be less

shall be made twice to 60.5 cm while under 10 N of tension.

than 2 %. The system used shall be clearly described and

Pertinent dimensions, masses, and so forth of each component

illustrated in the report.

of the system to be tested shall be recorde

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.