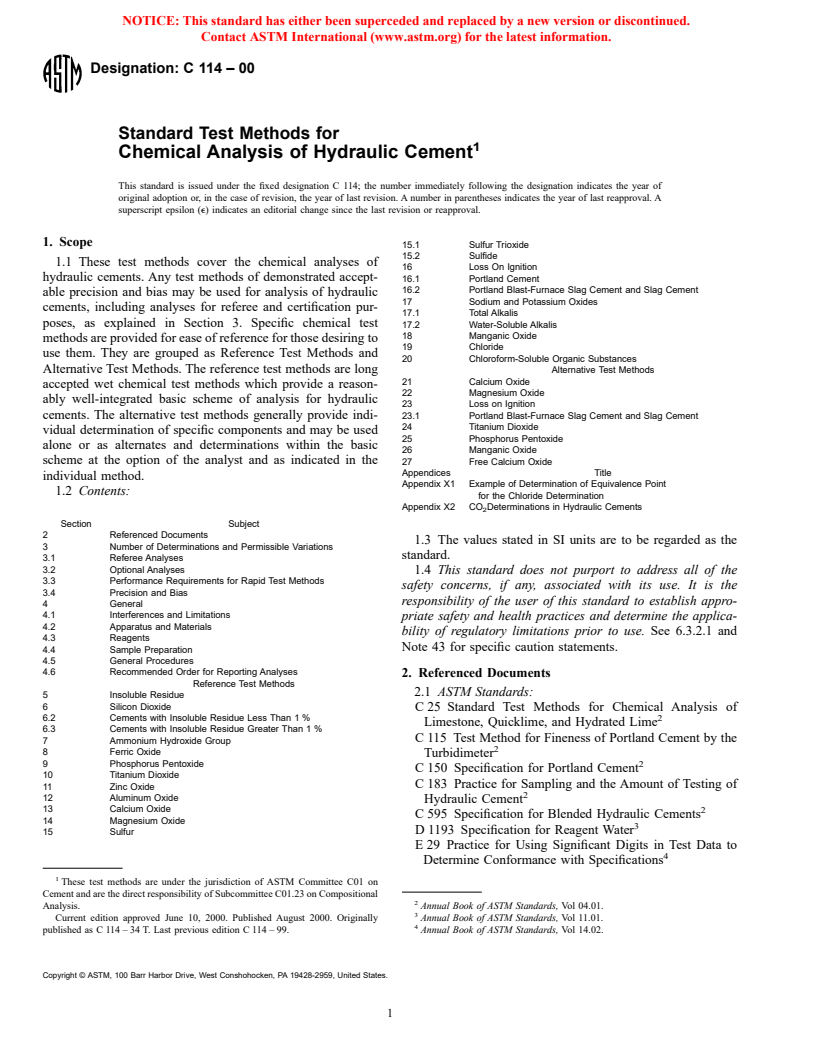

ASTM C114-00

(Test Method)Standard Test Methods for Chemical Analysis of Hydraulic Cement

Standard Test Methods for Chemical Analysis of Hydraulic Cement

SCOPE

1.1 These test methods cover the chemical analyses of hydraulic cements. Any test methods of demonstrated acceptable precision and bias may be used for analysis of hydraulic cements, including analyses for referee and certification purposes, as explained in Section 3. Specific chemical test methods are provided for ease of reference for those desiring to use them. They are grouped as Reference Test Methods and Alternative Test Methods. The reference test methods are long accepted wet chemical test methods which provide a reasonably well-integrated basic scheme of analysis for hydraulic cements. The alternative test methods generally provide individual determination of specific components and may be used alone or as alternates and determinations within the basic scheme at the option of the analyst and as indicated in the individual method. The individual analyst must demonstrate achievement of acceptable precision and bias, as explained in Section 3, when these test methods are used.

1.2 Contents: Section Subject 2 Referenced Documents 3 Number of Determinations and Permissible Variations 3.1 Referee Analyses 3.2 Optional Analyses 3.3 Performance Requirements for Rapid Test Methods 3.4 Precision and Bias 4 General 4.1 Interferences and Limitations 4.2 Apparatus and Materials 4.3 Reagents 4.4 Sample Preparation 4.5 General Procedures 4.6 Recommended Order for Reporting Analyses Reference Test Methods 5 Insoluble Residue 6 Silicon Dioxide 6.2 Cements with Insoluble Residue Less Than 1 % 6.3 Cements with Insoluble Residue Greater Than 1 % 7 Ammonium Hydroxide Group 8 Ferric Oxide 9 Phosphorus Pentoxide 10 Titanium Dioxide 11 Zinc Oxide 12 Aluminum Oxide 13 Calcium Oxide 14 Magnesium Oxide 15 Sulfur 15.1 Sulfur Trioxide 15.2 Sulfide 16 Loss On Ignition 16.1 Portland Cement 16.2 Portland Blast-Furnace Slag Cement and Slag Cement 17 Sodium and Potassium Oxides 17.1 Total Alkalis 17.2 Water-Soluble Alkalis 18 Manganic Oxide 19 Chloride 20 Chloroform-Soluble Organic Substances Alternative Test Methods 21 Calcium Oxide 22 Magnesium Oxide 23 Loss on Ignition 23.1 Portland Blast-Furnace Slag Cement and Slag Cement 24 Titanium Dioxide 25 Phosphorus Pentoxide 26 Manganic Oxide 27 Free Calcium Oxide

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 6.3.2.1 and Note 43 for specific caution statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 114 – 00

Standard Test Methods for

Chemical Analysis of Hydraulic Cement

This standard is issued under the fixed designation C 114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

15.1 Sulfur Trioxide

15.2 Sulfide

1.1 These test methods cover the chemical analyses of

16 Loss On Ignition

hydraulic cements. Any test methods of demonstrated accept-

16.1 Portland Cement

16.2 Portland Blast-Furnace Slag Cement and Slag Cement

able precision and bias may be used for analysis of hydraulic

17 Sodium and Potassium Oxides

cements, including analyses for referee and certification pur-

17.1 Total Alkalis

poses, as explained in Section 3. Specific chemical test 17.2 Water-Soluble Alkalis

18 Manganic Oxide

methods are provided for ease of reference for those desiring to

19 Chloride

use them. They are grouped as Reference Test Methods and

20 Chloroform-Soluble Organic Substances

Alternative Test Methods. The reference test methods are long Alternative Test Methods

21 Calcium Oxide

accepted wet chemical test methods which provide a reason-

22 Magnesium Oxide

ably well-integrated basic scheme of analysis for hydraulic

23 Loss on Ignition

cements. The alternative test methods generally provide indi-

23.1 Portland Blast-Furnace Slag Cement and Slag Cement

24 Titanium Dioxide

vidual determination of specific components and may be used

25 Phosphorus Pentoxide

alone or as alternates and determinations within the basic

26 Manganic Oxide

scheme at the option of the analyst and as indicated in the 27 Free Calcium Oxide

Appendices Title

individual method.

Appendix X1 Example of Determination of Equivalence Point

1.2 Contents:

for the Chloride Determination

Appendix X2 CO Determinations in Hydraulic Cements

Section Subject

2 Referenced Documents

1.3 The values stated in SI units are to be regarded as the

3 Number of Determinations and Permissible Variations

standard.

3.1 Referee Analyses

3.2 Optional Analyses

1.4 This standard does not purport to address all of the

3.3 Performance Requirements for Rapid Test Methods

safety concerns, if any, associated with its use. It is the

3.4 Precision and Bias

responsibility of the user of this standard to establish appro-

4 General

4.1 Interferences and Limitations

priate safety and health practices and determine the applica-

4.2 Apparatus and Materials

bility of regulatory limitations prior to use. See 6.3.2.1 and

4.3 Reagents

Note 43 for specific caution statements.

4.4 Sample Preparation

4.5 General Procedures

4.6 Recommended Order for Reporting Analyses

2. Referenced Documents

Reference Test Methods

2.1 ASTM Standards:

5 Insoluble Residue

6 Silicon Dioxide

C 25 Standard Test Methods for Chemical Analysis of

6.2 Cements with Insoluble Residue Less Than 1 %

Limestone, Quicklime, and Hydrated Lime

6.3 Cements with Insoluble Residue Greater Than 1 %

C 115 Test Method for Fineness of Portland Cement by the

7 Ammonium Hydroxide Group

8 Ferric Oxide

Turbidimeter

9 Phosphorus Pentoxide 2

C 150 Specification for Portland Cement

10 Titanium Dioxide

C 183 Practice for Sampling and the Amount of Testing of

11 Zinc Oxide

12 Aluminum Oxide

Hydraulic Cement

13 Calcium Oxide 2

C 595 Specification for Blended Hydraulic Cements

14 Magnesium Oxide

D 1193 Specification for Reagent Water

15 Sulfur

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

These test methods are under the jurisdiction of ASTM Committee C01 on

Cement and are the direct responsibility of Subcommittee C01.23 on Compositional

Analysis. Annual Book of ASTM Standards, Vol 04.01.

Current edition approved June 10, 2000. Published August 2000. Originally Annual Book of ASTM Standards, Vol 11.01.

published as C 114 – 34 T. Last previous edition C 114 – 99. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C114

A

TABLE 1 Maximum Permissible Variations in Results

E 275 Practice for Describing and Measuring Performance

of Ultraviolet, Visible, and Near Infrared Spectrophotom- (Column 3)

5 Maximum

eters

(Column 2) Difference of the

(Column 1)

E 350 Test Methods for Chemical Analysis of Carbon Steel,

Maximum Difference Average of

Component

B

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Between Duplicates Duplicates from

6 SRM Certificate

Wrought Iron

C,D,B

Values

E 617 Specification for Laboratory Weights and Precision

SiO (silicon dioxide) 0.16 60.2

4 2

Mass Standards

Al O (aluminum oxide) 0.20 60.2

2 3

E 832 Specification for Laboratory Filter Papers

Fe O (ferric oxide) 0.10 60.10

2 3

CaO (calcium oxide) 0.20 60.3

MgO (magnesium oxide) 0.16 60.2

3. Number of Determinations and Permissible Variations

SO (sulfur trioxide) 0.10 60.1

3.1 Referee Analyses— The reference test methods that LOI (loss on ignition) 0.10 60.10

Na O (sodium oxide) 0.03 60.05

follow in Sections 5-20, or other test methods qualified

K O (potassium oxide) 0.03 60.05

according to 3.3, are required for referee analysis in those cases

TiO (titanium dioxide) 0.02 60.03

P O (phosphorus pentoxide) 0.03 60.03

where conformance to chemical specification requirements are

2 5

ZnO (zinc oxide) 0.03 60.03

questioned. In these cases, a cement shall not be rejected for

Mn O (manganic oxide) 0.03 60.03

2 3

E

failure to conform to chemical requirements unless all deter-

S (sulfide sulfur) 0.01

E

minations of constituents involved and all necessary separa- Cl (chloride) 0.02

E

IR (insoluble residue) 0.10

tions prior to the determination of any one constituent are made

E

Cx (free calcium oxide) 0.20

entirely by reference test methods prescribed in the appropriate E F

CO (carbon dioxide) 0.12 ,

G E

Alk (water-soluble alkali) 0.75/w

sections of this test method or by other qualified test methods, sol

E

Chl (chloroform-soluble organic substances) 0.004

sol

except when specific test methods are prescribed in the

A

When seven SRM cements are required, as for demonstrating the perfor-

standard specification for the cement in question. The test

mance of rapid test methods, at least six of the seven shall be within the prescribed

methods actually used for the analysis shall be designated.

limits and the seventh shall differ by no more than twice that value. When more

3.1.1 Referee analyses, when there is a question regarding

than seven SRM’s are used, as for demonstrating the performance of rapid test

methods, at least 77 % shall be within the prescribed limits, and the remainder by

acceptance, shall be made in duplicate and the analyses shall be

no more than twice the value. When a lesser number of SRM cements are

made on different days. If the two results do not agree within

required, all of the values shall be within the prescribed limits.

B

the permissible variation given in Table 1, the determination Where no value appears in Column 3, SRM certificate values do not exist. In

such cases, only the requirement for differences between duplicates shall apply.

shall be repeated until two or three results agree within the

C

Interelement corrections may be used for any oxide standardization provided

permissible variation. When two or three results do agree

improved accuracy can be demonstrated when the correction is applied to all

within the permissible variation, their average shall be ac- seven SRM cements.

D

Where an SRM certificate value includes a subscript number, that subscript

cepted as the correct value. When an average of either two or

number shall be treated as a valid significant figure.

E

three results can be calculated, the calculation shall be based on

Not applicable. No certificate value given.

F

Demonstrate performance by analysis, in duplicate, of at least one Portland

the three results. For the purpose of comparing analyses and

cement. Prepare three standards, each in duplicate: Standard A shall be selected

calculating the average of acceptable results, the percentages

Portland cement; Standard B shall be Standard A containing 2.00 % Certified

shall be calculated to the nearest 0.01 (or 0.001 in the case of

CaCO (such as NIST 915a); Standard C shall be Standard A containing 5.00 %

Certified CaCO . Weigh and prepare two separate specimens of each standard.

chloroform-soluble organic substances), although some of the 3

Assign the CO content of Standard A as the average of the two values

average values are reported to 0.1 as indicated in the test

determined, provided they agree within the required limit of Column 2. Assign CO

methods. When a blank determination is specified, one shall be

values to Standards B and C as follows: Multiply the Certified CaCO value (Y) for

CO (from the certificate value) by the mass fraction of Certified CaCO added to

2 3

made with each individual analysis or with each group of two

that standard (percentage added divided by 100); multiply the value determined for

or more samples analyzed on the same day for a given

Standard A by the mass fraction of Standard A in each of the other standards (that

component. is, 0.98 and 0.95 for Standards B and C, respectively); add the two values for

Standard A and for Standard B, respectively; call these values B and C.

3.1.2 Referee analyses or analyses intended for use as a

Example:

basis for acceptance or rejection of a cement or for manufac-

B 5 0.98A + 0.02Y.

turer’s certification shall be made only after demonstration of C 5 0.95A + 0.05Y.

Where for Certified CaCO ,if Y 5 39.9 %

precise and accurate analyses by the test methods in use by

B 5 0.98A + 0.80 % by mass.

meeting the requirements of 3.1.3, except when demonstrated

C 5 0.95A + 2.00 % by mass.

under 3.3.2.1. Such demonstration may be made concurrently Maximum difference between the duplicate CO values for Standards B and C,

respectively, shall be 0.17 and 0.24 % by mass. Averages of the duplicate values

with analysis of the cement being tested and must have been

for Standards B and C shall differ from their assigned values (B and C) by no more

made within the preceding two years. The demonstration is

than 10 % of those respective assigned values.

G

w 5 weight, in grams, of samples used for the test.

required only for those constituents being used as a basis for

acceptance, rejection, or certification of a cement, but may be

made for any constituent of cement for which a standard exists.

least one NIST SRM cement (Note 1) no matter what test

3.1.3 Initial qualification of the operator/analyst shall be

method is used (for example, gravimetric, instrumental). Du-

demonstrated by analysis of each constituent of concern in at

plicate samples shall be run on different days. The same test

methods to be used for analysis of cement being tested shall be

used for analysis of the NIST SRM cement. If the duplicate

Annual Book of ASTM Standards, Vol 03.06.

Annual Book of ASTM Standards, Vol 03.05. results do not agree within the permissible variation given in

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C114

Table 1, the determinations shall be repeated, following iden- 3.3.1.1 If more than one instrument, even though substan-

tification and correction of problems or errors, until a set of tially identical, is used in a specific laboratory for the same

duplicate results do agree within the permissible variation. analyses, use of each instrument shall constitute a separate test

method and each must be qualified separately.

NOTE 1—The term SRM samples refers to NIST Portland-Cement

3.3.2 Qualification of a Test Method—Prior to use for

Chemical Standard Reference Materials.

analysis of hydraulic cement, each test method (see 3.3.1) must

3.1.4 The average of the results of acceptable duplicate

be qualified individually for such analysis. Qualification data,

determinations for each constituent may differ from the SRM

or if applicable, requalification data, shall be made available

certificate value by no more than the value shown in column 2

pursuant to the Manufacturer’s Certification Section of the

of Table 1 after correction for minor components when needed.

appropriate hydraulic cement specification.

When no SRM certificate value is given, a generally accepted

3.3.2.1 Using the test method chosen, make single determi-

accuracy standard for that constituent does not exist. In such

nations for each oxide under consideration on at least any

cases, only the differences between duplicate values as speci-

seven of the SRM samples (Note 1). Complete two rounds of

fied in 3.1.3 shall apply.

tests on different days repeating all steps of sample prepara-

3.1.5 Data demonstrating that precise and accurate results

tions. Calculate the differences between values and averages of

were obtained with NIST SRM cements by the same analyst

the values from the two rounds of tests.

making the acceptance determination shall be made available

3.3.2.2 When seven SRM’s are used in the qualification

on request to all parties concerned when there is a question of

procedure, at least six of the seven differences between

acceptance of a cement.

duplicates obtained of any single component shall not exceed

3.2 Optional Analyses—The alternative test methods pro-

the limits shown in Column 2 of Table 1 and the remaining

vide, in some cases, procedures that are shorter or more

differences by no more than twice that value. When more than

convenient to use for routine determination of certain constitu-

seven SRM’s are used, the values for at least 77 % of the

ents than are the reference test methods (Note 2). Longer, more

samples shall be within the prescribed limits, while the values

complex procedures, in some instances, have been retained as

for the remainder shall differ by no more than twice that value.

alternative test methods to permit comparison of results by

3.3.2.3 For each component and each SRM, the average

different procedures or for use when unusual materials are

obtained shall be compared to the certified concentrations.

being examined, where unusual interferences may be sus-

Where a certificate value includes a subscript number, that

pected, or when unusual preparation for analysis is required.

subscript shall be assumed to be a significant number. When

Test results from alternative test methods may be used as a

seven SRM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.