ASTM D5987-96(2015)

(Test Method)Standard Test Method for Total Fluorine in Coal and Coke by Pyrohydrolytic Extraction and Ion Selective Electrode or Ion Chromatograph Methods (Withdrawn 2020)

Standard Test Method for Total Fluorine in Coal and Coke by Pyrohydrolytic Extraction and Ion Selective Electrode or Ion Chromatograph Methods (Withdrawn 2020)

SIGNIFICANCE AND USE

4.1 This test method permits measurement of the fluorine content of coal and coke for the evaluation of potential fluorine emission from coal combustion or conversion processes. When coal samples are combusted in accordance with this test method, the fluorine is quantitatively released from the coal and retained in the pyrohydrolysate so that it is representative of the total fluorine concentration in coal.

SCOPE

1.1 This test method covers the analysis of total fluorine in coal and coke.

1.2 This analysis was successfully tested on coals containing 37 % ash or less (see AS 1038.10.4 and Conrad2).

1.3 The values stated in SI units shall be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Note 4.

1.5 All accountability and quality control aspects of Guide D4621 apply to this test method.

WITHDRAWN RATIONALE

This test method covers the analysis of total fluorine in coal and coke.

Formerly under the jurisdiction of Committee D05 on Coal and Coke, this test method was withdrawn in July 2020 and replaced by Test Method D8247 for the Determination of Total Fluorine and Total Chlorine in Coal by Oxidative Pyrohydrolytic Combustion Followed by Ion Chromatography Detection.1

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5987 − 96 (Reapproved 2015)

Standard Test Method for

Total Fluorine in Coal and Coke by Pyrohydrolytic

Extraction and Ion Selective Electrode or Ion

Chromatograph Methods

This standard is issued under the fixed designation D5987; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope from As-Determined to Different Bases

D4621Guide for Quality Management in an Organization

1.1 This test method covers the analysis of total fluorine in

That Samples or Tests Coal and Coke (Withdrawn 2010)

coal and coke.

D5142Test Methods for ProximateAnalysis of theAnalysis

1.2 This analysis was successfully tested on coals contain-

Sample of Coal and Coke by Instrumental Procedures

ing 37% ash or less (see AS 1038.10.4 and Conrad ).

(Withdrawn 2010)

1.3 The values stated in SI units shall be regarded as 2.2 Australian Standard:

standard. The values given in parentheses are for information AS 1038.10.4Determination of Trace Elements—Coal,

only. Coke and Fly-Ash-Determination of Fluorine Content—

Pyrohydrolysis Method

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Summary of Test Method

responsibility of the user of this standard to establish appro-

3.1 Total fluorine is determined in this test method by first

priate safety and health practices and determine the applica-

subjecting the weighed test portion to pyrohydrolytic condi-

bility of regulatory limitations prior to use. For specific hazard

tions which separate fluorine from the coal/coke matrix. The

statements see Note 4.

pyrohydrolysate is then gravimetrically processed and final

1.5 All accountability and quality control aspects of Guide

determinations are made by either ion-selective electrode or

D4621 apply to this test method.

ion chromatographic techniques.

2. Referenced Documents

4. Significance and Use

2.1 ASTM Standards:

4.1 This test method permits measurement of the fluorine

D346Practice for Collection and Preparation of Coke

contentofcoalandcokefortheevaluationofpotentialfluorine

Samples for Laboratory Analysis

emissionfromcoalcombustionorconversionprocesses.When

D1193Specification for Reagent Water

coal samples are combusted in accordance with this test

D2013Practice for Preparing Coal Samples for Analysis

method, the fluorine is quantitatively released from the coal

D2234/D2234MPractice for Collection of a Gross Sample

and retained in the pyrohydrolysate so that it is representative

of Coal

of the total fluorine concentration in coal.

D3174Test Method forAsh in theAnalysis Sample of Coal

and Coke from Coal

5. Apparatus

D3180Practice for Calculating Coal and Coke Analyses

5.1 Laboratory Ware—Except as noted, all laboratory ware,

for example, volumetric flasks, beakers, bottles, etc., used for

This test method is under the jurisdiction of ASTM Committee D05 on Coal

solutions containing fluoride ions must be made of

and Coke and is the direct responsibility of Subcommittee D05.29 on Major

polyethylene, polystyrene, or a heat-resistant polymer such as

Elements in Ash and Trace Elements of Coal.

polypropylene.

Current edition approved Nov. 1, 2015. Published December 2015. Originally

published approved in 1996. Last previous edition approved in 2007 as

5.2 Vials—Glass or polystyrene, 10 to 30-mLcapacity with

D5987–96(2007). DOI: 10.1520/D5987-96R15.

2 tightly fitting snap-on plastic lids.

Conrad, V. B., and Brownlee, W. D., “Hydropyrolytic—Ion Chromatographic

DeterminationofFluorideinCoalandGeologicalMaterials,” Analytical Chemistry,

Vol 60, No. 4, 1988, pp. 365–369.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5987 − 96 (2015)

5.3 Bottles—Polypropylene, 125-mL capacity, wide-mouth, 5.8 Balance—Analytical, with a sensitivity of 0.1 mg. The

with liner-less leakproof polyethylene screw cap, for tube- balanceshallbecheckedperiodicallytodetermineitsaccuracy.

furnace pyrohydrolysate processing.

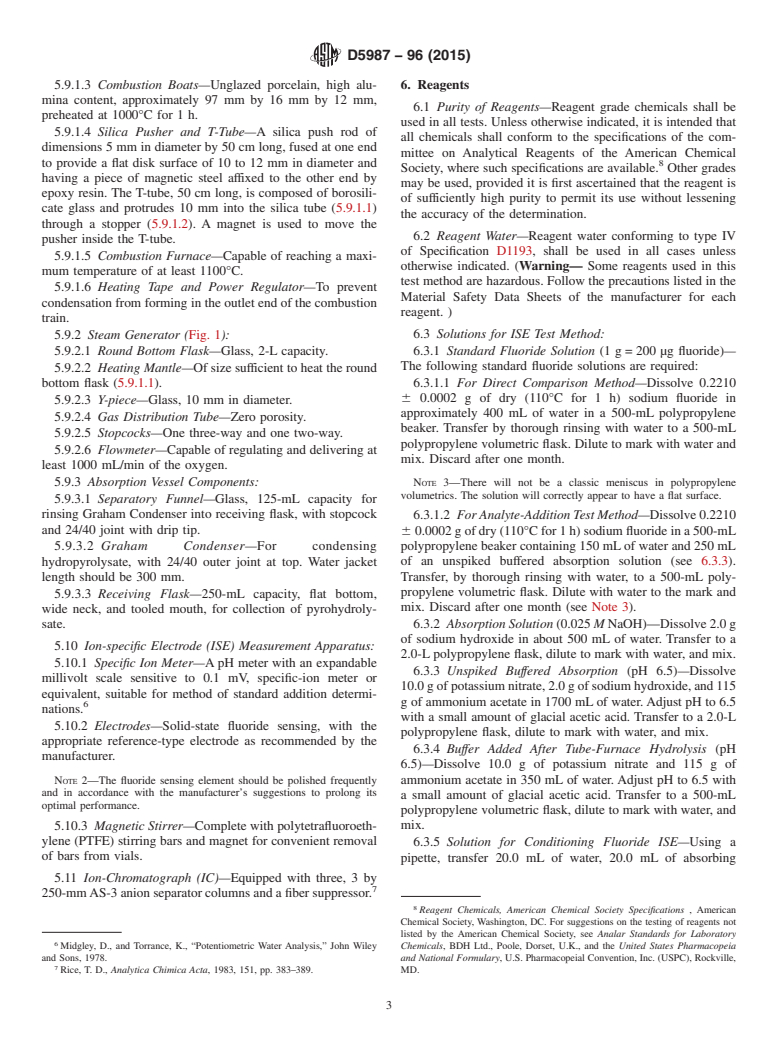

5.9 Apparatus for Tube-Furnace Pyrohydrolysis (see Fig.

1):

5.4 Vials—Polystyrene, 70-mL capacity, with liner-less

5.9.1 Silica Tube-Furnace and Accessories:

leakproof polyethylene screw cap.

5.9.1.1 Quartz Combustion Tube—Translucent, pure silica

5.5 Dispensing Bottles—Polyethylene,250-mLcapacity,for

(25-mm outside diameter, 20-mm inside diameter) of length

the standard fluorine solution (6.3.1) and of 600-mL capacity

appropriate to the particular furnace used. Preferably, the gas

for the absorption solution (6.3.3) and buffer (6.3.5).

outlet end should be narrowed to a tubulure of approximately

5.6 Micropipettes—Polypropylene or other suitable

7 mm in diameter.

polymer, variable volumes ranging from 0.1 mLto at least 2.0

NOTE 1—Combustion tubes of alternative refractory compositions do

mL.This is a satisfactory alternative to the 250-mLdispensing

nothaveadequatethermalstresscharacteristicsforoperationwiththistest

bottle (5.5), for the delivery of small volumes of the standard

method.

fluorine solution.

5.9.1.2 Silicone Stoppers—20mmindiameter,positionedat

5.7 Glass Dropper Bottle—30-mL capacity for dispensing inlet end and outlet, if applicable, of silica combustion tube

glacial acetic acid. (5.9.1.1).

FIG. 1 Pyrohydrolysis Furnace and Fluorine Absorption Assembly

D5987 − 96 (2015)

5.9.1.3 Combustion Boats—Unglazed porcelain, high alu- 6. Reagents

mina content, approximately 97 mm by 16 mm by 12 mm,

6.1 Purity of Reagents—Reagent grade chemicals shall be

preheated at 1000°C for 1 h.

used in all tests. Unless otherwise indicated, it is intended that

5.9.1.4 Silica Pusher and T-Tube—A silica push rod of

all chemicals shall conform to the specifications of the com-

dimensions 5 mm in diameter by 50 cm long, fused at one end

mittee on Analytical Reagents of the American Chemical

to provide a flat disk surface of 10 to 12 mm in diameter and

Society, where such specifications are available. Other grades

having a piece of magnetic steel affixed to the other end by

may be used, provided it is first ascertained that the reagent is

epoxy resin. The T-tube, 50 cm long, is composed of borosili-

of sufficiently high purity to permit its use without lessening

cate glass and protrudes 10 mm into the silica tube (5.9.1.1)

the accuracy of the determination.

through a stopper (5.9.1.2). A magnet is used to move the

6.2 Reagent Water—Reagent water conforming to type IV

pusher inside the T-tube.

of Specification D1193, shall be used in all cases unless

5.9.1.5 Combustion Furnace—Capable of reaching a maxi-

otherwise indicated. (Warning— Some reagents used in this

mum temperature of at least 1100°C.

test method are hazardous. Follow the precautions listed in the

5.9.1.6 Heating Tape and Power Regulator—To prevent

Material Safety Data Sheets of the manufacturer for each

condensationfromformingintheoutletendofthecombustion

reagent. )

train.

6.3 Solutions for ISE Test Method:

5.9.2 Steam Generator (Fig. 1):

5.9.2.1 Round Bottom Flask—Glass, 2-L capacity. 6.3.1 Standard Fluoride Solution (1 g=200 µg fluoride)—

The following standard fluoride solutions are required:

5.9.2.2 Heating Mantle—Ofsizesufficienttoheattheround

bottom flask (5.9.1.1). 6.3.1.1 For Direct Comparison Method—Dissolve 0.2210

6 0.0002 g of dry (110°C for 1 h) sodium fluoride in

5.9.2.3 Y-piece—Glass, 10 mm in diameter.

approximately 400 mL of water in a 500-mL polypropylene

5.9.2.4 Gas Distribution Tube—Zero porosity.

beaker. Transfer by thorough rinsing with water to a 500-mL

5.9.2.5 Stopcocks—One three-way and one two-way.

polypropylene volumetric flask. Dilute to mark with water and

5.9.2.6 Flowmeter—Capable of regulating and delivering at

mix. Discard after one month.

least 1000 mL/min of the oxygen.

5.9.3 Absorption Vessel Components: NOTE 3—There will not be a classic meniscus in polypropylene

volumetrics. The solution will correctly appear to have a flat surface.

5.9.3.1 Separatory Funnel—Glass, 125-mL capacity for

rinsing Graham Condenser into receiving flask, with stopcock

6.3.1.2 For Analyte-Addition Test Method—Dissolve0.2210

and 24/40 joint with drip tip.

60.0002gofdry(110°Cfor1h)sodiumfluorideina500-mL

5.9.3.2 Graham Condenser—For condensing polypropylenebeakercontaining150mLofwaterand250mL

hydropyrolysate, with 24/40 outer joint at top. Water jacket of an unspiked buffered absorption solution (see 6.3.3).

Transfer, by thorough rinsing with water, to a 500-mL poly-

length should be 300 mm.

propylene volumetric flask. Dilute with water to the mark and

5.9.3.3 Receiving Flask—250-mL capacity, flat bottom,

mix. Discard after one month (see Note 3).

wide neck, and tooled mouth, for collection of pyrohydroly-

sate. 6.3.2 Absorption Solution(0.025 MNaOH)—Dissolve2.0g

of sodium hydroxide in about 500 mL of water. Transfer to a

5.10 Ion-specific Electrode (ISE) Measurement Apparatus:

2.0-Lpolypropylene flask, dilute to mark with water, and mix.

5.10.1 Specific Ion Meter—ApH meter with an expandable

6.3.3 Unspiked Buffered Absorption (pH 6.5)—Dissolve

millivolt scale sensitive to 0.1 mV, specific-ion meter or

10.0gofpotassiumnitrate,2.0gofsodiumhydroxide,and115

equivalent, suitable for method of standard addition determi-

g of ammonium acetate in 1700 mLof water.Adjust pH to 6.5

nations.

with a small amount of glacial acetic acid. Transfer to a 2.0-L

5.10.2 Electrodes—Solid-state fluoride sensing, with the

polypropylene flask, dilute to mark with water, and mix.

appropriate reference-type electrode as recommended by the

6.3.4 Buffer Added After Tube-Furnace Hydrolysis (pH

manufacturer.

6.5)—Dissolve 10.0 g of potassium nitrate and 115 g of

NOTE 2—The fluoride sensing element should be polished frequently ammonium acetate in 350 mL of water.Adjust pH to 6.5 with

and in accordance with the manufacturer’s suggestions to prolong its

a small amount of glacial acetic acid. Transfer to a 500-mL

optimal performance.

polypropylene volumetric flask, dilute to mark with water, and

5.10.3 Magnetic Stirrer—Complete with polytetrafluoroeth- mix.

ylene (PTFE) stirring bars and magnet for convenient removal

6.3.5 Solution for Conditioning Fluoride ISE—Using a

of bars from vials.

pipette, transfer 20.0 mL of water, 20.0 mL of absorbing

5.11 Ion-Chromatograph (IC)—Equipped with three, 3 by

250-mmAS-3anionseparatorcolumnsandafibersuppressor.

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Midgley, D., and Torrance, K., “Potentiometric Water Analysis,” John Wiley Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and Sons, 1978. and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

Rice, T. D., Analytica Chimica Acta, 1983, 151, pp. 383–389. MD.

D5987 − 96 (2015)

solution (6.3.2), and 10.0 mL of buffer (6.3.4) into a polysty- (5.9.2.1) containing 1600 mL of water. Allow the steam

rene vial (5.2). Add 200 µL of standard fluoride solution generator to achieve a gentle boil. Place an empty receiving

(6.3.1.1) and mix. flask (5.9.3.3) under the Graham condenser. With the furnace

set at an operational temperature of 1100°C, pass oxygen

6.4 Solutions for Ion-Chromatographic Measurement:

through the steam generator into the furnace at approximately

6.4.1 Standard Fluoride Solution (1000 µg/mL fluoride)—

1000 mL/min for 15 min.

Dissolve 2.2110 6 0.0002 g of dry (105°C for 1 h) sodium

8.2.2 Pyrohydrolysis:

fluorideina250-mLpolypropylenebeakercontainingapproxi-

8.2.2.1 Add 50 6 1 mL of the appropriate absorption

mately150mLofwater.Transferwiththoroughrinsesofwater

solution (6.3.2) for ISE finish or 65 6 1 mL of the absorption

toa1.0-Lpolypropylenevolumetricflask.Dilutewithwaterto

solution (6.4.5) for the IC finish to a clean receiving flask

the mark and mix (see Note 3).

(5.9.3). Place the flask underneath the condenser. Ensure that

6.4.2 Standard Fluoride Solution (1.0 µg/mL fluoride)—

cooling water is passing through the condenser.

Transfer, by means of polypropylene pipette, 1.0 mL of

8.2.2.2 Allow oxygen to flow, bypassing the steam

standard fluoride solution (6.4.1) to a 1.0-L polypropylene

generator, at 750 mL/min into the furnace. Place the analysis

volumetric flask; dilute to mark with water and mix (see Note

sampleboatintoazoneatwhichthetemperatureofthesample

3). Prepare fresh solution daily.

will not exceed 300°C. Redirect the oxygen flow through the

6.4.3 Sulfuric Acid, Standard (2.5 N)—Cautiously dilute 71

steam generator and into the furnace. At subsequent intervals

mL of sulfuric acid (H SO , sp gr 1.834 to 1.836) to 1 L with

2 4

of approximately 30 s, push the analysis sample boat into

water. Mix well.

hotterzoneswiththetemperaturenotexceeding400,500,750,

6.4.4 Sulfuric Acid, Standard (0.025 N)—For use as sup-

and 1000°C, with a final push into the hottest zone.

pressor regenerator. Using a pipette, cautiously dilute 10.0 mL

8.2.2.3 Continue the pyrohydrolysis for a further 15 min,

of 2.5 N H SO (6.4.3) to 1 L with water. Mix well.

2 4

while monitoring the flow of oxygen and the level of water in

6.4.5 Sodium Bicarbonate Solution (0.0015 M)—Weak

the round bottom flask.

eluent, for use as the absorbing solution and the Graham

8.2.3 Pyrohydrolysate Processing for ISE Finish:

condenser rinsing solution. Dissolve 0.2520 g of dry (105°C

8.2.3.1 At the completion of the pyrohydrolysis time, redi-

for 1 h) NaHCO in water and dilute to 2.0 L. Mix well.

rect the oxygen flow around the steam generator and allow

6.4.6 Sodium Bicarbonate Solution (0.02 M)—Strong elu-

excess steam to escape.

ent.Dissolve1.6801gofdry(105°Cfor1h)NaHCO inwater

and dilute to 1.0-L. Mix well.

NOTE 4—Caution should be exercised as to the direction in which the

steam is vented. Preferably it should be allowed to escape into a sink or

6.5 Oxygen—Free of combustible matter and guaranteed to

similar facility.

be 99.5% pure.

8.2.3.2 Rinsethecondenserwithtwo5-mLaliquotsofwater

6.6 Helium—Refer to ion chromatograph ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.