ASTM D3245-03

(Test Method)Standard Test Method for Pumpability of Industrial Fuel Oils (Withdrawn 2010)

Standard Test Method for Pumpability of Industrial Fuel Oils (Withdrawn 2010)

SIGNIFICANCE AND USE

This test method is designed to give an indication of the minimum storage and minimum handling temperatures which may be used for a given fuel oil. This test method is cited in Specification D 396.

SCOPE

1.1 This test method is intended for use on petroleum fuel oils, such as those covered in Specification D 396 Grade No 4(Light), 4, 5(Light), 5, and 6, or similar fuels.

1.2 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method is intended for use on petroleum fuel oils, such as those covered in Specification D 396 Grade No 4(Light), 4, 5(Light), 5, and 6, or similar fuels.

This test method is being balloted for withdrawal with no replacement because the test method is no longer in use, and there is no report from the CS92 ILCP.

Formerly under the jurisdiction of Committee D02 on Petroleum Products and Lubricants, this test method was withdrawn in May 2010.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3245–03

Standard Test Method for

1

Pumpability of Industrial Fuel Oils

This standard is issued under the fixed designation D3245; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.3 storage point—an indication of the minimum tem-

perature to which an oil should be heated in any part of an

1.1 This test method is intended for use on petroleum fuel

oil-handlinginstallationwhenstartingupafterashutdown.Itis

oils, such as those covered in Specification D396 Grade No

alsoanindicationoftheminimumtemperatureatwhichtheoil

4(Light), 4, 5(Light), 5, and 6, or similar fuels.

should be stored in a tank fitted with an outflow heater.

1.2 The values stated in SI units are to be regarded as

3.1.4 Itisdefinedasthattemperatureatwhichtheoilhasan

standard. The values in parentheses are for information only.

apparent viscosity of 2.5 Pa·s (25 P), at a rate of shear of 9.7

1.3 This standard does not purport to address all of the

−1

s , when cooled and tested under prescribed conditions.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Asampleoftheoil,preheatedifnecessarytoaspecified

bility of regulatory limitations prior to use.

temperature to make it fluid, is poured into the cup of the

2. Referenced Documents portable viscometer. This is immersed in a bath at a predeter-

2

mined temperature.After 15 min, the viscometer is started at a

2.1 ASTM Standards:

s−1

2

rateofshearof9.7 .Afterafurther5min,thebathiscooled

D396 Specification for Fuel Oils

at 0.5°C/min (1°F/min). The temperatures at which apparent

D445 Test Method for Kinematic Viscosity of Transparent

viscositiesof0.6Pa·s(6P)and2.5Pa·s(25P)areobtainedare

and Opaque Liquids (and Calculation of Dynamic Viscos-

3

determined.

ity)

E1 Specification for ASTM Liquid-in-Glass Thermometers

5. Significance and Use

3. Terminology 5.1 This test method is designed to give an indication of the

minimum storage and minimum handling temperatures which

3.1 Definitions:

may be used for a given fuel oil. This test method is cited in

3.1.1 handling point—an indication of the minimum tem-

Specification D396.

perature to which an oil should be heated in any part of the

suctionordeliverylineofanoil-handlinginstallationwhenthe

6. Apparatus

installationisoperating.Ifthestoragetankdoesnotcontainan

6.1 Temperature Measuring Device—conforming to speci-

outflowheater,thistemperatureisnecessarilytheminimumoil

fications for ASTM thermometers 63C, 64C, and 12C, or

storage temperature.

equivalent, in accordance with Specification E1, or any other

3.1.2 Itisdefinedasthattemperatureatwhichtheoilhasan

−1 temperature measruing device with equal or better accuracy

apparentviscosityof0.6Pa·s(6P),atarateofshearof9.7s ,

and equal temperature response.

when cooled and tested under prescribed conditions.

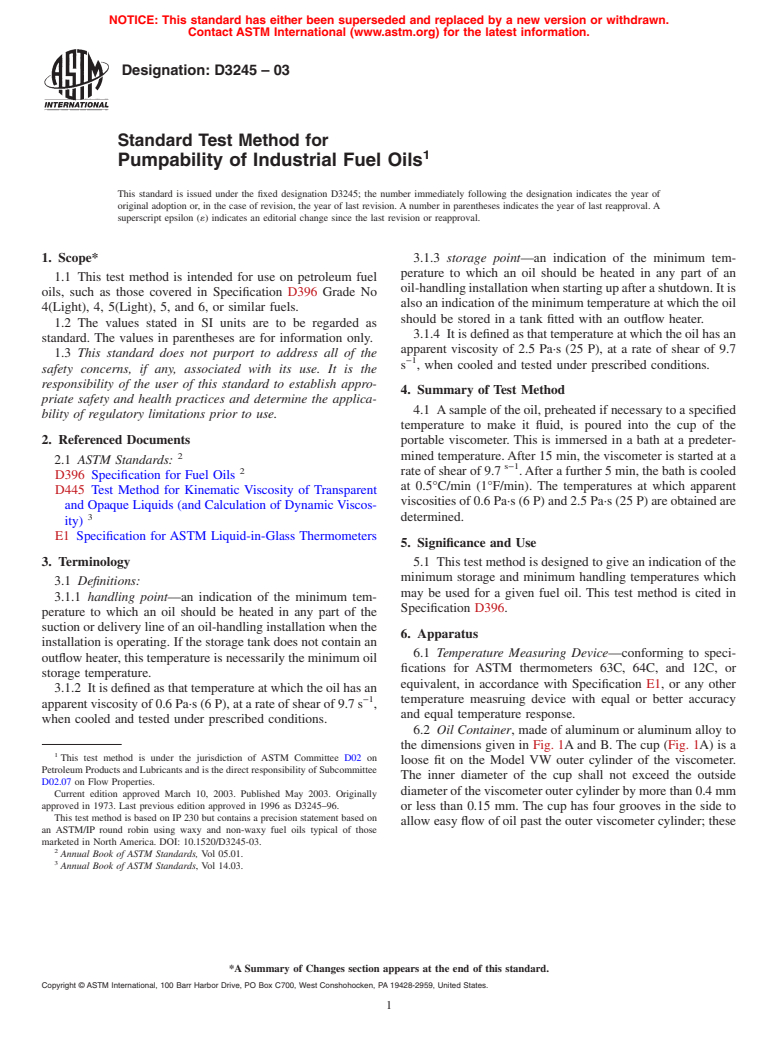

6.2 Oil Container, made of aluminum or aluminum alloy to

the dimensions given in Fig. 1Aand B. The cup (Fig. 1A) is a

1

This test method is under the jurisdiction of ASTM Committee D02 on

loose fit on the Model VW outer cylinder of the viscometer.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

The inner diameter of the cup shall not exceed the outside

D02.07 on Flow Properties.

diameteroftheviscometeroutercylinderbymorethan0.4mm

Current edition approved March 10, 2003. Published May 2003. Originally

approved in 1973. Last previous edition approved in 1996 as D3245–96.

or less than 0.15 mm. The cup has four grooves in the side to

This test method is based on IP230 but contains a precision statement based on

allow easy flow of oil past the outer viscometer cylinder; these

an ASTM/IP round robin using waxy and non-waxy fuel oils typical of those

marketed in North America. DOI: 10.1520/D3245-03.

2

Annual Book of ASTM Standards, Vol 05.01.

3

Annual Book of ASTM Standards, Vol 14.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3245–03

FIG. 1 Details of Oil Container for Viscosity Determinations

align with four recesses in the cap (Fig. 1B) when in position.

The cap supports the viscometer cup to which it is secured by

a bayonet fitting.

4

6.3 Three-Speed Portable Viscometer Model VH, fitted

with a 2 mN·m (20 gf·cm) spring and a Model VM outer

cylinder having a plastic shaft and B inner cylinder (Fig. 2).A

viscom

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.