ASTM D7603-13

(Test Method)Standard Test Method for Determination of Storage Stability and Compatibility in Automotive Gear Oils (Withdrawn 2022)

Standard Test Method for Determination of Storage Stability and Compatibility in Automotive Gear Oils (Withdrawn 2022)

SIGNIFICANCE AND USE

5.1 To avoid equipment failure, a gear oil should remain a homogeneous liquid and the performance-enhancing additives should not separate out when the oil is stored for an extended period of time.

5.2 In addition, because different oils are often mixed when topping off, gear oils from different manufacturers, or containing different base fluids or performance-enhancing additives should be completely miscible and compatible with each other. Any incompatibility of such mixtures can also result in equipment failure if gelation or additive dropout occurs.

5.3 The test procedures described in this test method are designed to evaluate the performance of gear oils in each of the above circumstances.

5.4 This test method is based on the separate test methods FED-STD-791/3440.1 and FED-STD-791/3440.2. Minor changes have been made to the FED test methods to provide a coherent unified procedure. These changes do not significantly alter the test procedures. This test method has, therefore, potential for use as an alternative to the FED test methods in gear oil specifications such as SAE J2360 and Specification D5760.

SCOPE

1.1 This test method covers the determination of storage stability characteristics and the compatibility of automotive gear lubricants when blended with reference lubricants. The purpose of the test is to determine if performance-enhancing additives separate out under defined conditions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7603 − 13

Standard Test Method for

Determination of Storage Stability and Compatibility in

1

Automotive Gear Oils

This standard is issued under the fixed designation D7603; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope* 2.3 Federal Test Method Standard:

FED-STD-791/3440.1 Storage Solubility Characteristics of

1.1 This test method covers the determination of storage

Universal Gear Lubricants

stability characteristics and the compatibility of automotive

FED-STD-791/3440.2 Compatibility Characteristics of Uni-

gear lubricants when blended with reference lubricants. The

versal Gear Lubricants

purpose of the test is to determine if performance-enhancing

additives separate out under defined conditions.

3. Terminology

1.2 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. No other units of measurement are included in this

3.1.1 calibrate, v—todeterminetheindicationoroutputofa

standard.

measuring device (for example, thermometer, manometer,

1.3 This standard does not purport to address all of the

engine) with respect to that of a standard.

safety concerns, if any, associated with its use. It is the

3.1.2 candidate oil, n—an oil that is intended to have the

responsibility of the user of this standard to establish appro-

performance characteristics necessary to satisfy a specification

priate safety and health practices and determine the applica-

and is to be tested against that specification. D4175

bility of regulatory limitations prior to use.

3.1.3 reference oil, n—an oil of known performance

characteristics, used as a basis for comparison.

2. Referenced Documents

3.1.3.1 Discussion—Reference oils are used to calibrate

2

2.1 ASTM Standards:

testing facilities, to compare the performance of other oils, or

D235 Specification for Mineral Spirits (Petroleum Spirits)

to evaluate other materials (such as seals) that interact with

(Hydrocarbon Dry Cleaning Solvent)

oils. D4175

D1193 Specification for Reagent Water

3.1.4 test oil, n—any oil subjected to evaluation in an

D4175 Terminology Relating to Petroleum, Petroleum

established procedure. D4175

Products, and Lubricants

D5760 Specification for Performance of Manual Transmis-

4. Summary of Test Method

sion Gear Lubricants

4.1 Separation of the performance-enhancing additives in a

E542 Practice for Calibration of Laboratory Volumetric

test oil during storage is determined by heating it to 120 °C,

Apparatus

storing at room temperature for 30 days, and making a

E1272 Specification for Laboratory Glass Graduated Cylin-

qualitative observation as to whether any material has sepa-

ders

3

rated out.

2.2 SAE Standards:

4.1.1 An optional, non-mandatory test method is also de-

J2360 Lubricating Oil, Gear Multipurpose (Metric) Military

scribed in Appendix X1 and Appendix X2 for quantifying the

Use

percent of the additive that separated out during storage of the

test oil.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

4.2 The compatibility of a test oil is determined by blending

Subcommittee D02.B0.01 on Passenger Car Engine Oils.

it with different reference oils, heating to 120 ºC, storing at

Current edition approved June 15, 2013. Published July 2013. Originally

room temperature for 30 days, and making a qualitative

approved in 2010. Last previous edition approved in 2010 as D7603 – 10.

DOI:10.1520/D7603-13. observation as to whether any material has separated out.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available online at www.assistdocs.com (search for FED-STD-791 in the

the ASTM website. document ID field or from Standardization Documents Order Desk, DODSSP, Bldg.

3

Available from SAE International (SAE), 400 Commonwealth Dr.,Warrendale, 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

PA 15096-0001, http://www.sae.org. dodssp.daps.dla.mil.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7603 − 13

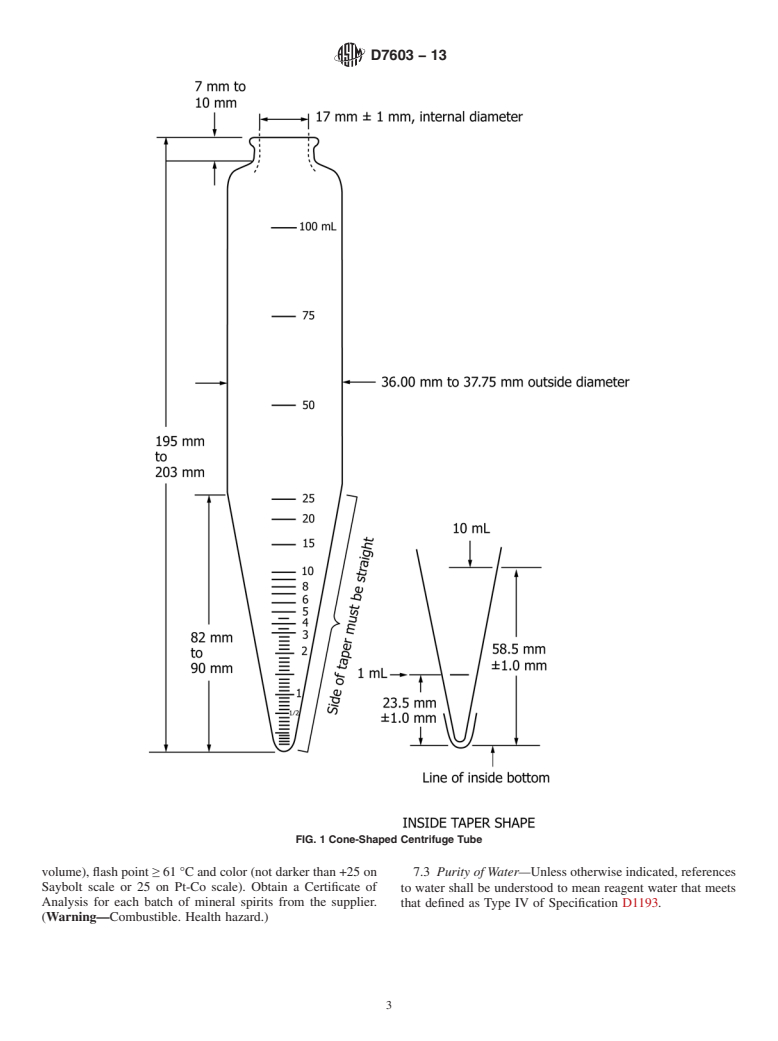

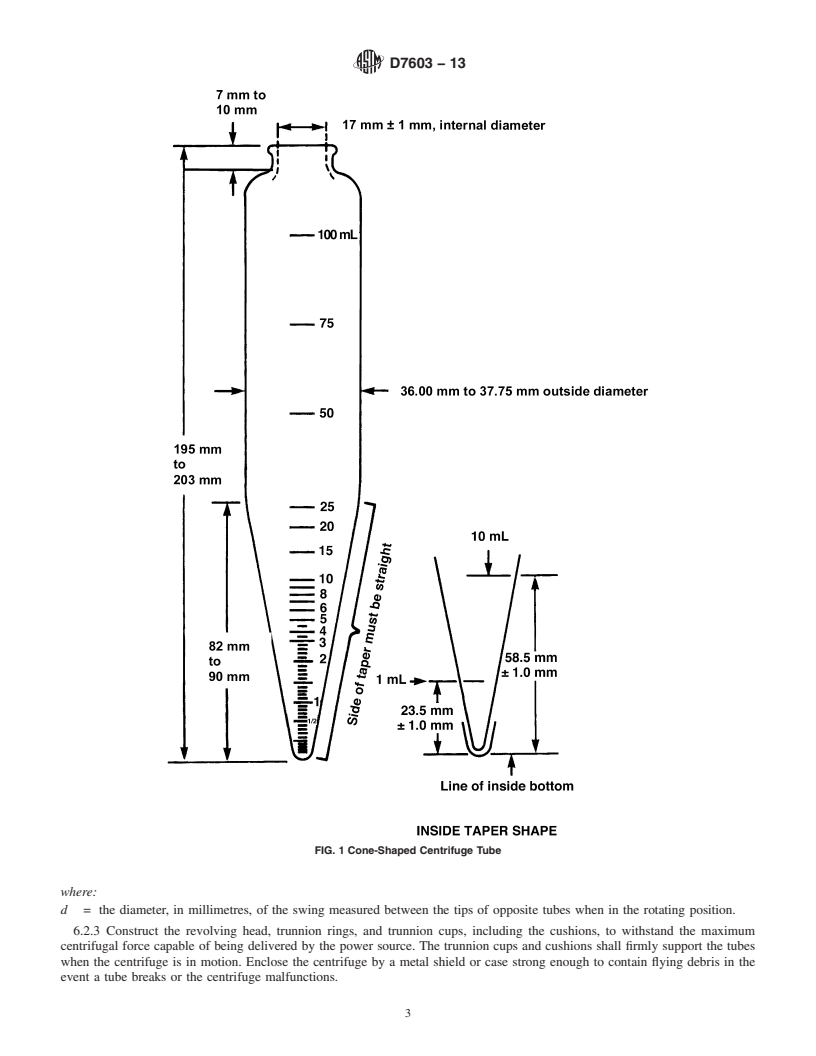

4.2.1 An optional, non-mandatory test method is also de- 6.2 Centrifuge:

scribed in Appendix X1 and Appendix X2 for quantifying the 6.2.1 Use a centrifuge meeting all safety requirements for

percent of the additive that separat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7603 − 10 D7603 − 13

Standard Test Method for

Determination of Storage Stability and Compatibility in

1

Automotive Gear Oils

This standard is issued under the fixed designation D7603; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of storage stability characteristics and the compatibility of automotive gear

lubricants when blended with reference lubricants. The purpose of the test is to determine if performance-enhancing additives

separate out under defined conditions.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

D1193 Specification for Reagent Water

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D5760 Specification for Performance of Manual Transmission Gear Lubricants

E542 Practice for Calibration of Laboratory Volumetric Apparatus

E1272 Specification for Laboratory Glass Graduated Cylinders

3

2.2 SAE Standards:

J2360 Lubricating Oil, Gear Multipurpose (Metric) Military Use

4

2.3 Federal Test Method Standard:

FED-STD-791/3440.1 Storage Solubility Characteristics of Universal Gear Lubricants

FED-STD-791/3440.2 Compatibility Characteristics of Universal Gear Lubricants

3. Terminology

3.1 Definitions:

3.1.1 calibrate, v—to determine the indication or output of a measuring device (for example, thermometer, manometer, engine)

with respect to that of a standard.

3.1.2 candidate oil, n—an oil that is intended to have the performance characteristics necessary to satisfy a specification and

is to be tested against that specification. D4175

3.1.3 reference oil, n—an oil of known performance characteristics, used as a basis for comparison.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B0.03D02.B0.01 on Automotive Gear Lubricants & FluidsPassenger Car Engine Oils.

Current edition approved April 1, 2010June 15, 2013. Published June 2010July 2013. DOI:10.1520/D7603–10.Originally approved in 2010. Last previous edition approved

in 2010 as D7603 – 10. DOI:10.1520/D7603-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from SAE International (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

4

Available online at www.assistdocs.com (search for FED-STD-791 in the document ID field or from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section

D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://dodssp.daps.dla.mil.

3.1.3.1 Discussion—

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7603 − 13

Reference oils are used to calibrate testing facilities, to compare the performance of other oils, or to evaluate other materials (such

as seals) that interact with oils. D4175

3.1.4 test oil, n—any oil subjected to evaluation in an established procedure. D4175

4. Summary of Test Method

4.1 Separation of the performance-enhancing additives in a test oil during storage is determined by heating it to 120 °C, storing

at room temperature for 30 days, and making a qualitative observation as to whether any material has separated out.

4.1.1 An optional, non-mandatory test method is also described in Appendix X1 and Appendix X2 for quantifying the percent

of the additive whichthat separated out during storage of the test oil.

4.2 The compatibility of a test oil is determined by blending it with different reference oils, hea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.