ASTM D3241-08

(Test Method)Standard Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels (JFTOT Procedure)

Standard Test Method for Thermal Oxidation Stability of Aviation Turbine Fuels (JFTOT Procedure)

SIGNIFICANCE AND USE

The test results are indicative of fuel performance during gas turbine operation and can be used to assess the level of deposits that form when liquid fuel contacts a heated surface that is at a specified temperature.

SCOPE

1.1 This test method covers the procedure for rating the tendencies of gas turbine fuels to deposit decomposition products within the fuel system.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are for information only. The differential pressure values in mm Hg are defined only in terms of this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and Annex A3.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3241–08

Designation 323/99

Standard Test Method for

Thermal Oxidation Stability of Aviation Turbine Fuels

1

(JFTOT Procedure)

This standard is issued under the fixed designation D 3241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope* 2.2 ASTM Adjuncts:

Color Standard for Tube Deposit Rating

1.1 This test method covers the procedure for rating the

tendencies of gas turbine fuels to deposit decomposition

3. Terminology

products within the fuel system.

3.1 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as the

3.1.1 deposits—oxidative products laid down on the test

standard. The inch-pound values given in parentheses are for

area of the heater tube or caught in the test filter, or both.

information only. The differential pressure values in mm Hg

3.1.1.1 Discussion—Fuel deposits will tend to predominate

are defined only in terms of this test method.

at the hottest portion of the heater tube, which is between the

1.3 This standard does not purport to address all of the

30-mm and 50-mm position.

safety concerns, if any, associated with its use. It is the

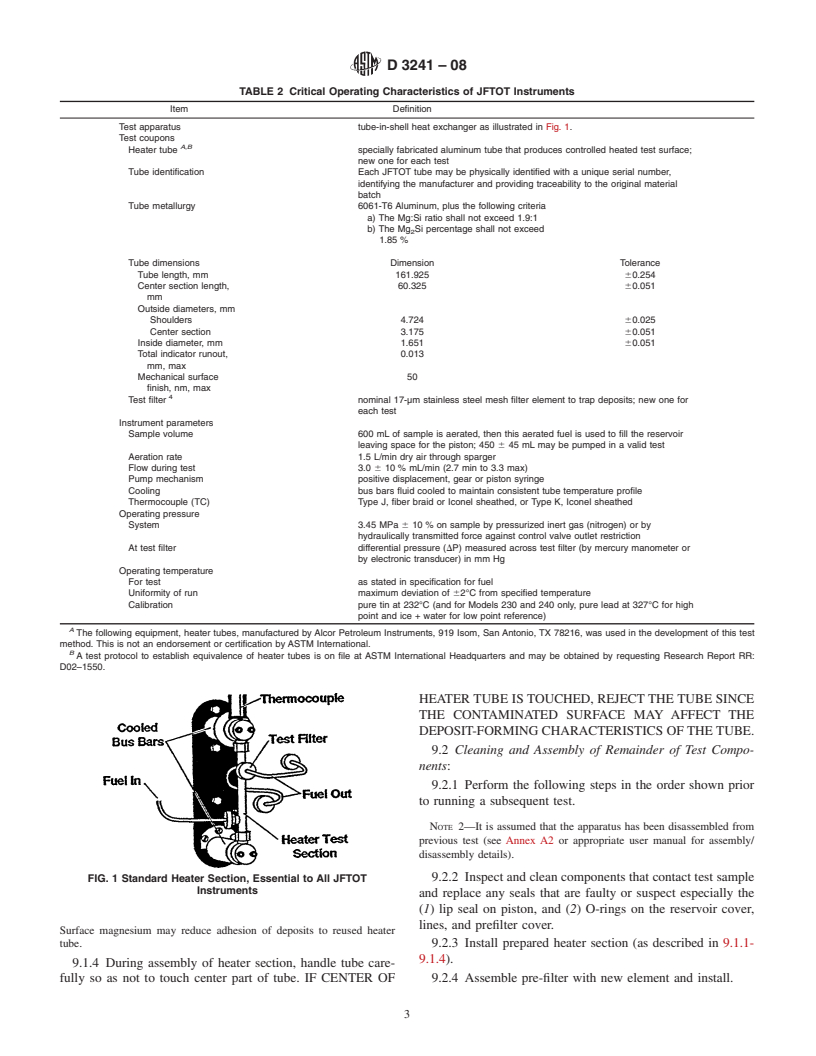

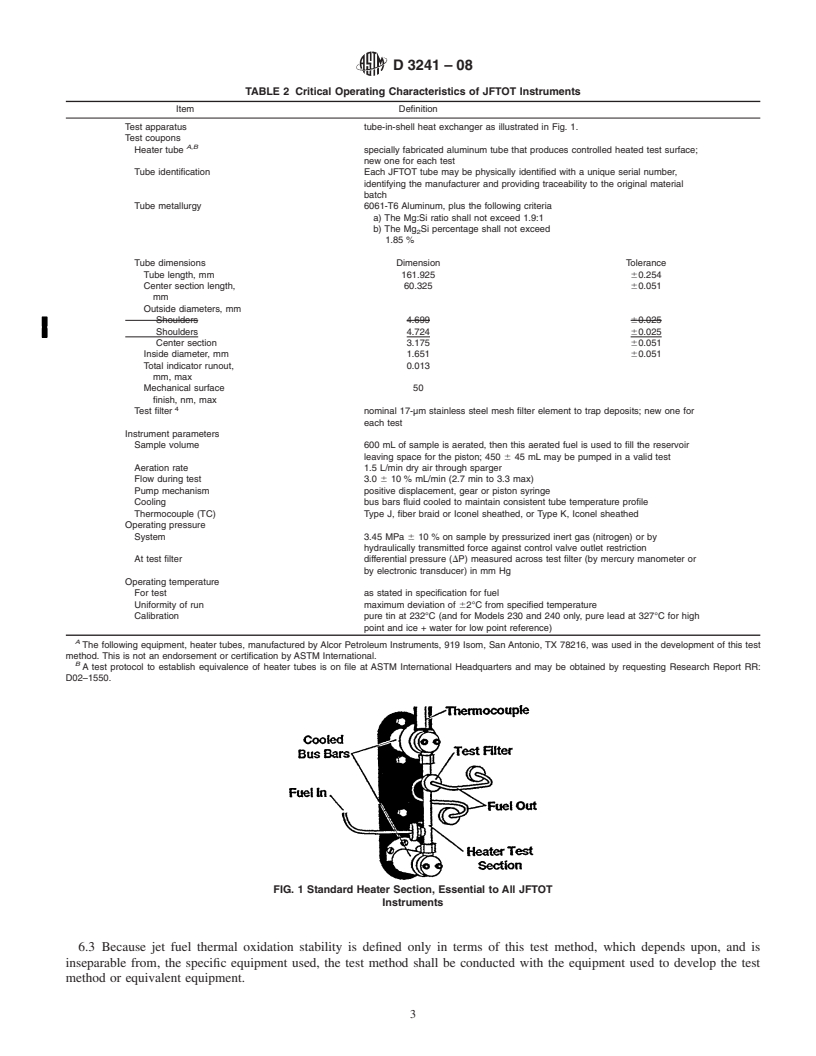

3.1.2 heater tube—an aluminum coupon controlled at el-

responsibility of the user of this standard to establish appro-

evated temperature, over which the test fuel is pumped.

priate safety and health practices and determine the applica-

3.1.2.1 Discussion—The tube is resistively heated and con-

bility of regulatory limitations prior to use. For specific

trolled in temperature by a thermocouple positioned inside.

warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and

The critical test area is the thinner portion, 60 mm in length,

Annex A3.

betweentheshouldersofthetube.Fuelinlettothetubeisatthe

2. Referenced Documents 0-mm position, and fuel exit is at 60 mm.

2 3.2 Abbreviations:

2.1 ASTM Standards:

3.2.1 DP—differential pressure.

D 1655 Specification for Aviation Turbine Fuels

D 4306 Practice for Aviation Fuel Sample Containers for

4. Summary of Test Method

Tests Affected by Trace Contamination

4.1 This test method for measuring the high temperature

E 177 Practice for Use of the Terms Precision and Bias in

stability of gas turbine fuels uses the Jet Fuel Thermal

ASTM Test Methods

Oxidation Tester (JFTOT) that subjects the test fuel to condi-

E 691 Practice for Conducting an Interlaboratory Study to

tions that can be related to those occurring in gas turbine

Determine the Precision of a Test Method

engine fuel systems. The fuel is pumped at a fixed volumetric

flow rate through a heater, after which it enters a precision

1

stainless steel filter where fuel degradation products may

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

become trapped.

D02.J0.03 on Combustion and Thermal Properties.

4.1.1 The apparatus uses 450 mL of test fuel ideally during

Current edition approved Jan. 15, 2008. Published February 2008. Originally

a 2.5-h test. The essential data derived are the amount of

approved in 1973. Last previous edition approved in 2006 as D 3241–06.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD3241. Original adjunct produced in 1986.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3241–08

TABLE 1 Models of JFTOT

7.2 Use methyl pentane, 2,2,4-trimethylpentane, or

JFTOT User Pressurize Pump n-heptane (technical grade, 95 mol % minimum purity) as

Differential Pressure By

Model Manual With Principle

general cleaning solvent. This solvent will effectively clean

A

202 202/203 nitrogen gear Hg Manometer; No Record

internal metal surfaces of apparatus before a test, especially

A

203 202/203 nitrogen gear Manometer + Graphical

those surfaces (before the test section) that contact fresh

Record

B

sample. (Warning—Extremely flammable. Harmful if inhaled

215 215 nitrogen gear Transducer + Printed

Record

(see Annex A3).)

C

230 230/240 hydraulic syringe Transducer + Printout

7.2.1 Use trisolvent (equal mix of acetone (1), tolu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D3241–06 Designation:D3241–08

Designation 323/99

Standard Test Method for

Thermal Oxidation Stability of Aviation Turbine Fuels

1

(JFTOT Procedure)

This standard is issued under the fixed designation D 3241; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 Thistestmethodcoverstheprocedureforratingthetendenciesofgasturbinefuelstodepositdecompositionproductswithin

the fuel system.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are for

information only. The differential pressure values in mm Hg are defined only in terms of this test method.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific warning statements, see 6.1.1, 7.2, 7.2.1, 7.3, 11.1.1, and Annex A3.

2. Referenced Documents

2

2.1 ASTM Standards:

D 1655 Specification for Aviation Turbine Fuels

D 4306 Practice for Aviation Fuel Sample Containers for Tests Affected by Trace Contamination

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.J0.03

on Combustion and Thermal Properties.

Current edition approved Dec. 1, 2006. Published January 2007. Originally approved in 1973. Last previous edition approved in 2005 as D3241–05b.

Current edition approved Jan. 15, 2008. Published February 2008. Originally approved in 1973. Last previous edition approved in 2006 as D 3241–06.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3241–08

3

2.2 ASTM Adjuncts:

Color Standard for Tube Deposit Rating

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 deposits—oxidative products laid down on the test area of the heater tube or caught in the test filter, or both.

3.1.1.1 Discussion—Fueldepositswilltendtopredominateatthehottestportionoftheheatertube,whichisbetweenthe30-mm

and 50-mm position.

3.1.2 heater tube—an aluminum coupon controlled at elevated temperature, over which the test fuel is pumped.

3.1.2.1 Discussion—The tube is resistively heated and controlled in temperature by a thermocouple positioned inside. The

critical test area is the thinner portion, 60 mm in length, between the shoulders of the tube. Fuel inlet to the tube is at the 0-mm

position, and fuel exit is at 60 mm.

3.2 Abbreviations:

3.2.1 DP—differential pressure.

4. Summary of Test Method

4.1 ThistestmethodformeasuringthehightemperaturestabilityofgasturbinefuelsusestheJetFuelThermalOxidationTester

(JFTOT) that subjects the test fuel to conditions that can be related to those occurring in gas turbine engine fuel systems. The fuel

is pumped at a fixed volumetric flow rate through a heater, after which it enters a precision stainless steel filter where fuel

degradation products may become trapped.

4.1.1 The apparatus uses 450 mL of test fuel ideally during a 2.5-h test. The essential data derived are the amount of deposits

on an aluminum heater tube, and the rate of plugging of a 17 µm nominal porosity precision filter located just downstream of the

heater tube.

5. Significance and Use

5.1 Thetestresultsareindicativeoffuelperformanceduringgasturbineoperationandcanbeusedtoassessthelevelofdeposits

that form when liquid fuel contacts a heated surface that is at a specified temperature.

6. Apparatus

4

6.1 Jet Fuel Thermal Oxidation Tester (JFTOT)—Five models of suitable equ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.