ASTM D5776-07(2012)

(Test Method)Standard Test Method for Bromine Index of Aromatic Hydrocarbons by Electrometric Titration

Standard Test Method for Bromine Index of Aromatic Hydrocarbons by Electrometric Titration

SIGNIFICANCE AND USE

This test method is suitable for setting specification, for use as an internal quality control tool, and for use in development or research work on industrial aromatic hydrocarbons and related material. This test method gives a broad indication of olefinic content. It does not differentiate between the types of aliphatic unsaturation.

SCOPE

1.1 This test method determines the amount of bromine-reactive material in aromatic hydrocarbons and is thus a measure of trace amounts of unsaturates in these materials. It is applicable to materials having bromine indexes below 500.

1.2 This test method is applicable to aromatic hydrocarbons containing no more than trace amounts of olefins and that are substantially free from material lighter than isobutane and have a distillation end point under 288°C (550°F).

1.3 In determining the conformance of the test results using this method to applicable specifications, results shall be rounded off in accordance with the rounding-off method of Practice E29.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement see Section 8.

General Information

Relations

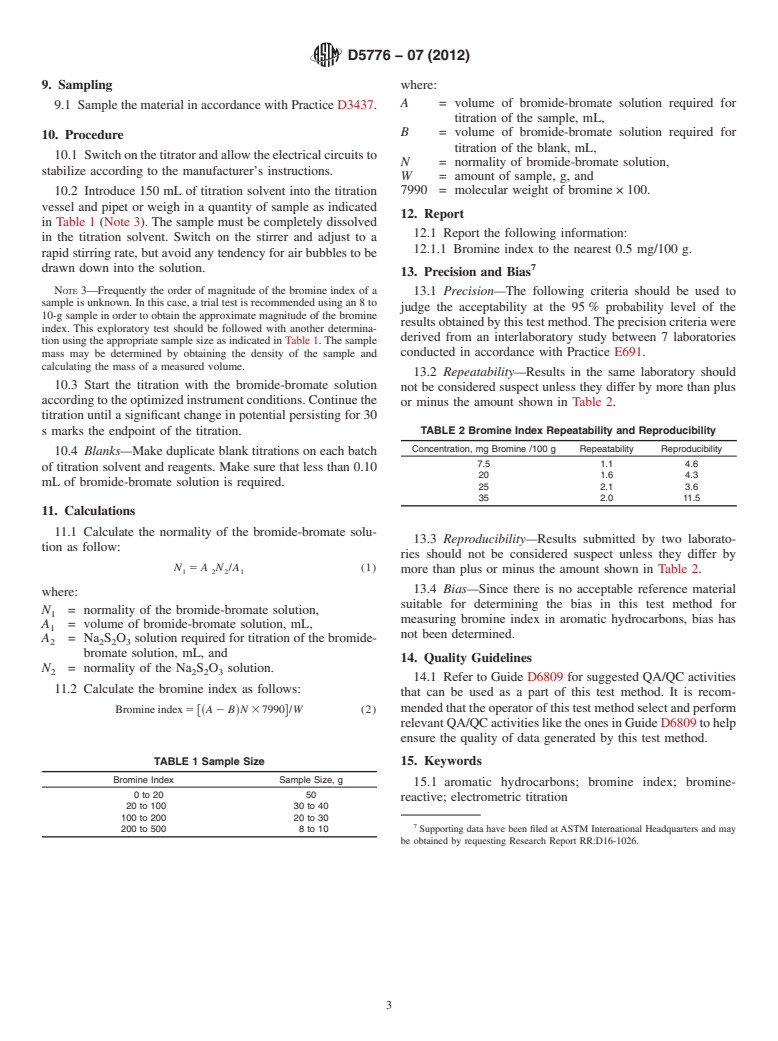

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5776 − 07 (Reapproved2012)

Standard Test Method for

Bromine Index of Aromatic Hydrocarbons by Electrometric

Titration

This standard is issued under the fixed designation D5776; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* D6809Guide for Quality Control and Quality Assurance

Procedures for Aromatic Hydrocarbons and Related Ma-

1.1 This test method determines the amount of bromine-

terials

reactive material in aromatic hydrocarbons and is thus a

E29Practice for Using Significant Digits in Test Data to

measureoftraceamountsofunsaturatesinthesematerials.Itis

Determine Conformance with Specifications

applicable to materials having bromine indexes below 500.

E691Practice for Conducting an Interlaboratory Study to

1.2 This test method is applicable to aromatic hydrocarbons

Determine the Precision of a Test Method

containing no more than trace amounts of olefins and that are

2.2 Other Document:

substantiallyfreefrommateriallighterthanisobutaneandhave

OSHA Regulations, 29 CFRparagraphs 1910.1000 and

a distillation end point under 288°C (550°F).

1910.1200

1.3 In determining the conformance of the test results using

this method to applicable specifications, results shall be

3. Terminology

rounded off in accordance with the rounding-off method of

3.1 Definitions:

Practice E29.

3.1.1 bromine index, n—the number of milligrams of bro-

1.4 The values stated in SI units are to be regarded as the

mine consumed by 100 g of sample under given conditions.

standard. The values given in parentheses are for information

only. 4. Summary of Test Method

1.5 This standard does not purport to address all of the

4.1 The specimen dissolved in a specified solvent is titrated

safety concerns, if any, associated with its use. It is the

with standard bromide-bromate solution. The end point is

responsibility of the user of this standard to establish appro-

indicatedbyafixedend-pointelectrometrictitrationapparatus,

priate safety and health practices and determine the applica-

when the presence of free bromine causes a sudden change in

bility of regulatory limitations prior to use. For a specific

the polarization voltage of the system.

hazard statement see Section 8.

5. Significance and Use

2. Referenced Documents

5.1 This test method is suitable for setting specification, for

2.1 ASTM Standards:

use as an internal quality control tool, and for use in develop-

D1159Test Method for Bromine Numbers of Petroleum

mentorresearchworkonindustrialaromatichydrocarbonsand

Distillates and Commercial Aliphatic Olefins by Electro-

related material. This test method gives a broad indication of

metric Titration

olefinic content. It does not differentiate between the types of

D1193Specification for Reagent Water

aliphatic unsaturation.

D3437Practice for Sampling and Handling Liquid Cyclic

Products

6. Apparatus

6.1 Fixed End Point Electrometric Titration Apparatus—

Any fixed end-point apparatus may be used incorporating a

This test method is under the jurisdiction of ASTM Committee D16 on

high resistance polarizing current supply capable of maintain-

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

ing approximately 10 to 50 µA across two platinum plate

Subcommittee D16.04 on Instrumental Analysis.

Current edition approved Jan. 1, 2012. Published January 2012. Originally

electrodes or a combination platinum electrode and with a

ε1

approved in 1995. Last previous edition approved in 2007 as D5776–07 . DOI:

10.1520/D5776-07R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Standards volume information, refer to the standard’s Document Summary page on 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

the ASTM website. www.access.gpo.gov.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5776 − 07 (2012)

sensitivity such that a voltage change of approximately 500 titrationadd1mLofstarchindicatorsolutionandtitrateslowly

mV at these electrodes is sufficient to indicate the end point to the disappearance of the blue color.

(see Note 1).

7.4 Electronic Standardization of Bromide-Bromate

Solution—Standardize to four significant figures as follows:

NOTE 1—The reagents and techniques may be checked by determining

the bromine index of a 100 mg/kg cyclohexene in heptane. This is

Place 50 mLof glacial acetic acid and 1.0 mLof concentrated

expected to give a bromine index of 18 to 20 mg/100 g sample. Refer to

hydrochloricacid(HCl,spgr1.19)ina500-mLiodinenumber

Test Method D1159 for a list of expected bromine indexes of various

flask.Chillthesolutioninanicebathforapproximately10min

compounds.

with constant swirling of the flask; add 4.00 mL of bromide

6.2 Titration Vessel—A tall form glass beaker of approxi-

bromate solution from the auto buret. Stopper the flask

mately 250-mL capacity or a water jacketed titration vessel of

immediatelyand,shakethecontents,thencoolitinanicebath

approximately 250-mL capacity connected to a refrigerated

for5min.Add4.0mLofpotassiumiodide(KI)tothelipofthe

circulating water bath controlling the temperature at 0 to 5°C.

flask, remove the flask from the ice bath and allow the KI

Apairofplatinumelectrodesspacednotmorethan5mmapart,

solution to slowly flow into the flask by removing the stopper.

shallbemountedtoextendwellbelowtheliquidlevel.Stirring

Shake vigorously, transfer to a chilled beaker and rinse the

shallbebyamechanicalorelectromagneticstirrerandshallbe

flask including stopper with 100 mL of water. Immerse the

rapid but not so vigorous as to draw air bubbles down to the

electrodes into the solution, titrate with standard sodium

electrodes.

thiosulphate (Na S O ) to an end point indicated by a signifi-

2 2 3

6.3 Iodine Number Flasks, glass-stoppered, 500-mL capac- cant change in potential that persists for 30 s (see Note 2).

ity.

NOTE 2—With commercial titrators, a sudden change in potential

indicated on the meter or dial of the instrument as the endpoint is

7. Reagents and Materials

approached. When this change persists for 30 s it marks the end of the

titration. With each instrument, the manufacturer’s instructions should be

7.1 Purity of Reagents—Reagent grade chemicals shall be

followed to achieve the sensitivity achieved in the platinum electrode

used in all tests. Unless otherwise indicated, it is intended that

circuit.

allreagentsshallconformtothespecificationsoftheAmerican

7.5 Potassium Iodide Solution (150 g/L)—Dissolve150gof

Chemical Society where such specifications are available.

potassium iodide (KI) in water and dilute to 1.0 L.

Other grades may be used, providing it is first ascertained that

7.6 Sodium Thiosulphate, Standard Solution (0.10 N)—

the reagent is of sufficiently high purity to permit its use

Dissolve 25.0 g of sodium thiosulphate pentahydrate

without lessening the accuracy of the determination.

(Na S O ·5H O) in water and add 0.02 g of sodium carbonate

2 2 3 2

7.2 Purity of Water—Unless otherwise indicated references

(Na CO ) to stabilize the solution. Dilute to 1.0 L and mix

2 3

towatershallbeunderstoodtomeanreagentwaterconforming

thoroughlybyshaking.Standardizebyanyacceptedprocedure

to Type III of Specification D1193.

that determines the normality with an error not greater than

7.3 Bromide-Bromate Standard Solution (0.10 N) —

60.0002. Restandardize at intervals frequent enough to detect

Dissolve 10.1 g of potassium bromide (KBr) and 2.8 g

changes of 0.0005 in normality.

potassium bromate (KBrO ) in water and dilute to 1.0 L.

3 6

7.7 Starch Solution —Mill5gofarrow-rootstarchwith3to

Standardize to four significant figures as follows: Place 50 mL

5 mLof water.Add the suspension to 2 Lof boiling water.As

of glacial acetic acid and 1.0 mLof concentrated hydrochloric

apreservative,5to10mgofmercuriciodide(H I)or0.2gof

g 2

acid (HCl, sp gr 1.19) in a 500-mL iodine number flask. Chill

salicylic acid can also be added. Boil for 5 to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.