ASTM C232-99

(Test Method)Standard Test Methods for Bleeding of Concrete

Standard Test Methods for Bleeding of Concrete

SCOPE

1.1 These test methods cover the determination of the relative quantity of mixing water that will bleed from a sample of freshly mixed concrete. Two test methods, that differ primarily in the degree of vibration to which the concrete sample is subjected, are included.

1.2 The two test methods are not expected to yield the same test results when samples of concrete from the same batch are tested by each method. When various concretes are to be compared, all the tests should be conducted using the same method, and if the batches are of similar unit weight, the sample masses should not differ by more than 2 lb (0.9 kg).

1.3 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 232 – 99

Standard Test Methods for

Bleeding of Concrete

This standard is issued under the fixed designation C 232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope environment, or other factors in the bleeding of concrete. It is

also permitted to be used to determine the conformance of a

1.1 These test methods cover the determination of the

product or treatment with a requirement relating to its effect on

relative quantity of mixing water that will bleed from a sample

bleeding of concrete.

of freshly mixed concrete. Two test methods, that differ

3.2 Method A—For a sample consolidated by rodding only

primarily in the degree of vibration to which the concrete

and tested without further disturbance, thus simulating condi-

sample is subjected, are included.

tions in which the concrete, after placement, is not subjected to

1.2 The two test methods are not expected to yield the same

intermittent vibration.

test results when samples of concrete from the same batch are

3.3 Method B—For a sample consolidated by vibration and

tested by each method. When various concretes are to be

tested with further intermittent periods of vibration, thus

compared, all the tests must be conducted using the same

simulating conditions in which concrete, after being placed, is

method, and if the batches are of similar unit weight, the

subjected to intermittent vibration.

sample masses shall not differ by more than 1 kg (2 lb).

1.3 The values stated in SI units are to be regarded as

METHOD A—SAMPLE CONSOLIDATED BY

standard. The values in parentheses are provided for informa-

TAMPING

tion purposes only.

1.4 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 Container—A cylindrical container of approximately

responsibility of the user of this standard to establish appro- 3

14L ( ⁄2-ft ) capacity, having an inside diameter of 255 65mm

priate safety and health practices and determine the applica-

1 1

(10 6 ⁄4 in.) and an inside height of 280 65mm(11 6 ⁄4 in.).

bility of regulatory limitations prior to use.

The container shall be made of metal having a thickness of

2.67 to 3.40 mm (0.105 to 0.134 in.) and shall be externally

2. Referenced Documents

reinforced around the top with a 2.67 to 3.40 mm (0.105 to

2.1 ASTM Standards:

0.134 in.) metal band, 40 mm (1 ⁄2 in.) wide. The inside shall

C 138 Test Method for Unit Weight, Yield, and Air Content

be smooth and free of corrosion, coatings, or lubricants.

(Gravimetric) of Concrete

4.2 Scale, of sufficient capacity to determine the mass of the

C 172 Practice for Sampling Freshly Mixed Concrete

load required with an accuracy of 0.5 %.

C 192 Practice for Making and Curing Concrete Test Speci-

4.3 Pipet, or similar instrument, for drawing off free water

mens in the Laboratory

from the surface of the test specimen.

C 670 Practice for Preparing Precision and Bias Statements

4.4 Glass Graduate, 100-mL capacity for collecting and

for Test Methods for Construction Materials

measuring the quantity of water withdrawn.

4.5 Tamping Rod—A round, straight steel rod, 16 mm ( ⁄8

3. Significance and Use

in.) in diameter and approximately 610 mm (24 in.) in length,

3.1 This test method provides procedures to be used for

having the tamping end rounded to a hemispherical tip, the

determining the effect of variables of composition, treatment,

diameter of which is 16 mm ( ⁄8 in.).

4.6 Metal Beaker (Optional)—A 1000-mL metal beaker for

1 collecting the decanted supernatant water and sludge (Note 1).

These test methods are under the jurisdiction of ASTM Committee C-9 on

Concrete and Concrete Aggregates and are the direct responsibility of Subcommittee 4.7 Balance (Optional)—A balance sensitive to1gfor

C09.60 on Fresh Concrete Testing.

determining the mass of the decanted water and sludge (Note

Current edition approved July 10, 1999. Published September 1999. Originally

1).

published as C 232 – 1949. Last previous edition C 232 – 92.

Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 232

4.8 Hot Plate (Optional)—A small electric hot plate or other

where:

source of heat for evaporating decanted water (Note 1).

V 5 volume of bleeding water measured during the se-

lected time interval, mL, and

NOTE 1—The apparatus listed in 4.6, 4.7, and 4.8 will be required if the

A 5 area of exposed concrete, cm .

procedure of measuring the amount of bleeding water recovered is one

The comparative rate of bleeding shall be determined as the

involving weighing, evaporation, and reweighing.

test progresses by comparing the volume of bleeding water for

5. Test Specimen

each equal time interval.

7.2 Calculate the accumulated bleeding water, expressed as

5.1 For concrete made in the laboratory prepare the concrete

as described in Practice C 192. For concrete made in the field, a percentage of the net mixing water contained within the test

specimen, as follows:

sample the concrete as described in Practice C 172. The

apparatus described in this test method is permitted to be used

C 5 ~w/W! 3 S (2)

with samples of concrete containing any size of aggregate

Bleeding, % 5 D/C 3 100

~ !

graded up to and including a nominal maximum size of 50 mm

(2 in.). Concrete containing aggregate larger than 50 mm (2 in.)

where:

in nominal maximum size shall be wet sieved over a 3.75 mm

C 5 mass of the water in the test specimen, g,

(1 ⁄2-in.) sieve and the test performed on a portion of the

W 5 total mass of the batch, kg,

sample that passes through the sieve. w 5 net mixing water (the total amount of water minus the

5.2 Fill the container with the concrete in accordance with water absorbed by the aggregates), kg,

S 5 mass of the sample, g, and

Test Method C 138 except that the container shall be filled to

D 5 mass of the bleeding water, g, or total volume

a height of 254 6 3mm(10 6 ⁄8 in.). Level the top surface of

withdrawn from the test specimen in cubic centime-

the concrete to a reasonably smooth surface by a minimum

ters multiplied by 1 g/cm .

amount of troweling.

METHOD B—SAMPLE CONSOLIDATED BY

6. Procedure

VIBRATION

6.1 During the test, maintain the ambient temperature be-

tween 18 and 24°C (65 and 75°F). Immediately after troweling

8. Apparatus

the surface of the specimen, record the time and determine the

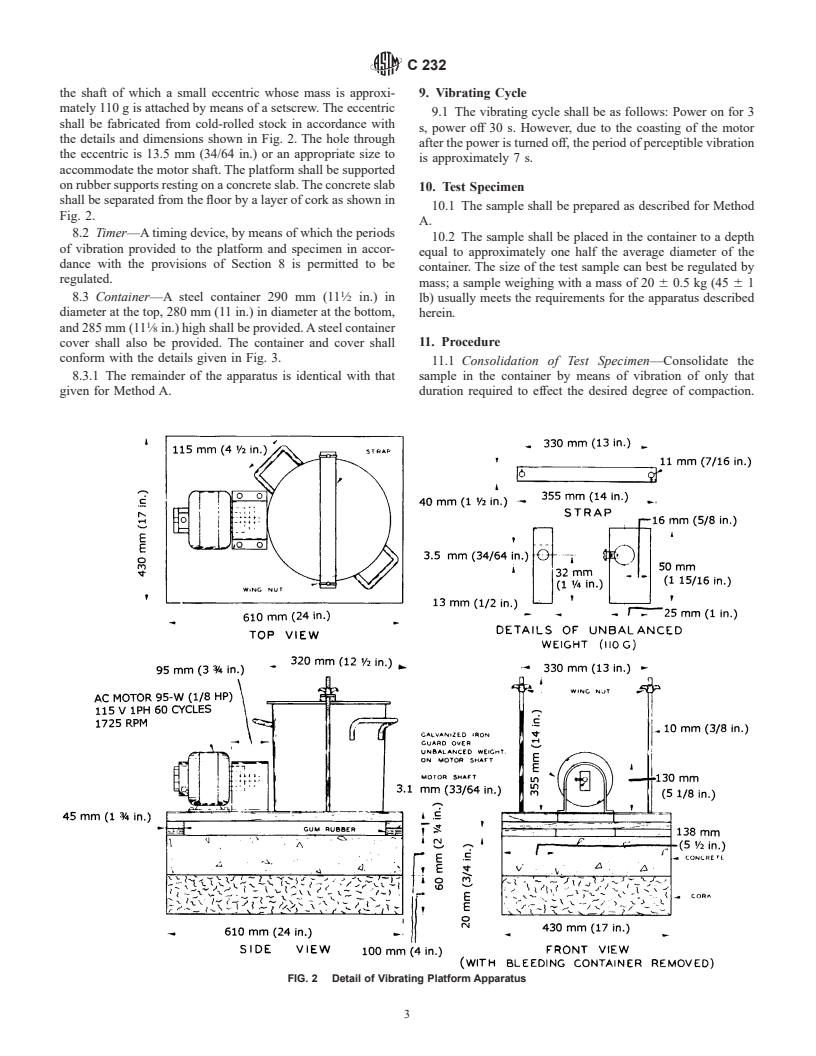

8.1 Vibrating Platform—A platform shall be provided upon

mass of the container and its contents. Place the specimen and

which the filled container shall be mounted. The platform shall

container on a level platform or floor free of noticeable

be equipped with a suitable device so that intermittent periods

vibration and cover the container to prevent evaporation of the

of vibration of reproducible duration, frequency, and ampli-

bleed water. Keep the cover in place throughout the test, except

tu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.