ASTM F1839-08(2012)

(Specification)Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices and Instruments

Standard Specification for Rigid Polyurethane Foam for Use as a Standard Material for Testing Orthopaedic Devices and Instruments

ABSTRACT

This specification covers rigid polyurethane foam blocks or sheets recommended for use as a standard material for mechanical testing using orthopedic devices and instruments. Although the physical properties of the foam are in the order of those reported for human cancellous bones, these materials are not intended for implantation into the human body. All materials should conform to the specified quality of appearance, dimensional stability, and composition, and values of void content, compressive strength, compressive modulus, shear strength, shear modulus, and screw pullout.

SIGNIFICANCE AND USE

5.1 This specification describes the compositional requirements, physical requirements, mechanical requirements, and test methods for rigid unicellular polyurethane foam for use in testing orthopaedic devices or instruments.

5.2 This foam described in this specification is not intended to replicate the mechanical properties of human or animal bone. The requirements of this specification are intended to provide a consistent and uniform material with properties on the order of human cancellous bone to use as a test medium when testing various orthopaedic devices, such as bone screws.

SCOPE

1.1 This specification covers rigid unicellular polyurethane foam for use as a standard material for performing mechanical tests utilizing orthopaedic devices or instruments. The specification is applicable to sheets or blocks of foam, or foam that is made by the user using a two-part liquid mixture.

1.2 This specification covers polyurethane foam material that is used in the laboratory for mechanical testing, as described in 1.1. These materials are not intended for implantation into the human body.

1.3 The foam described herein possesses mechanical properties which are on the order of those reported for human cancellous bone. See Appendix X1, Rationale, for further information regarding the appropriateness of using the specified foam as a model for human cancellous bone.

1.4 This specification covers compositional requirements, physical requirements, mechanical requirements, and test methods for rigid polyurethane foam in the solid final form.

1.5 This specification provides qualification criteria for vendor or end-user processes and acceptance criteria for individual material lots.

1.6 This specification provides mechanical properties of five different grades of foam in the solid final form. A foam that does not meet the specified mechanical properties shall be identified as an ungraded foam.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 The following precautionary statement pertains to the test method portion only, Section 8, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1839 −08(Reapproved 2012)

Standard Specification for

Rigid Polyurethane Foam for Use as a Standard Material for

Testing Orthopaedic Devices and Instruments

This standard is issued under the fixed designation F1839; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

1.1 This specification covers rigid unicellular polyurethane

tions prior to use.

foam for use as a standard material for performing mechanical

tests utilizing orthopaedic devices or instruments. The specifi-

2. Referenced Documents

cation is applicable to sheets or blocks of foam, or foam that is

2.1 ASTM Standards:

made by the user using a two-part liquid mixture.

C273 Test Method for Shear Properties of Sandwich Core

1.2 This specification covers polyurethane foam material

Materials

that is used in the laboratory for mechanical testing, as

D1621 Test Method for Compressive Properties of Rigid

described in 1.1. These materials are not intended for implan-

Cellular Plastics

tation into the human body.

D1622 Test Method for Apparent Density of Rigid Cellular

Plastics

1.3 The foam described herein possesses mechanical prop-

E4 Practices for Force Verification of Testing Machines

erties which are on the order of those reported for human

F543 Specification and Test Methods for Metallic Medical

cancellous bone. See Appendix X1, Rationale, for further

Bone Screws

information regarding the appropriateness of using the speci-

fied foam as a model for human cancellous bone.

3. Terminology

1.4 This specification covers compositional requirements,

3.1 Definitions:

physical requirements, mechanical requirements, and test

3.1.1 final form—the condition of the foam product when

methods for rigid polyurethane foam in the solid final form.

used by the end user to perform tests of orthopaedic devices or

instruments.

1.5 This specification provides qualification criteria for

3.1.1.1 Discussion—This is the condition of the foam prod-

vendor or end-user processes and acceptance criteria for

uct of which all physical and mechanical tests required by this

individual material lots.

specification are performed.

1.6 Thisspecificationprovidesmechanicalpropertiesoffive

3.1.1.1 solid—the foam is in a uniform solid form, such as

different grades of foam in the solid final form. A foam that

a slab, plate, or block.

does not meet the specified mechanical properties shall be

identified as an ungraded foam. 3.1.2 foam rise direction—the nominal direction that the

foam rises during the polymerization (“foaming”) process,

1.7 The values stated in SI units are to be regarded as

either at the supplier’s production facilities for the solid

standard. No other units of measurement are included in this

supplied foam, or at the end-user’s facilities for foam produced

standard.

from the liquid supplied form. The foam rise direction shall be

1.8 The following precautionary statement pertains to the

marked on the foam block or indicated in the shipping

test method portion only, Section 8, of this specification: This

documentation for foam that is supplied in the solid form.

standard does not purport to address all of the safety concerns,

3.1.3 grades—The grade designation refers to the nominal

if any, associated with its use. It is the responsibility of the user

density of the foam, in its solid final form, expressed in units

of kg/m . Ten grades of foam have been defined in this

specification. Their nominal densities are:

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.21 on Osteosynthesis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2012. Published October 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε2

approved in 1997. Last previous edition approved in 2008 as F1839 – 08 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1839-08R12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1839−08 (2012)

3 TABLE 1 Requirements for Voids, Cracks, and Nonuniform Areas

Grade 5: 80.1 kg/m

Grade 10: 160.2 kg/m

Defects Requirements

Grade 12: 192.2 kg/m

Voids

Grade 15: 240.3 kg/m

Grade 20: 320.4 kg/m

Void depth (measured perpendicular Void depth shall be less than 50 % of

Grade 25: 400.5 kg/m

to slab’s transverse plane) the slab thickness, and less than

Grade 30: 480.5 kg/m

6.35 mm

Grade 35: 560.6 kg/m

Grade 40: 640.7 kg/m

Void diameter (measured parallel to

Grade 50: 800.9 kg/m

slab’s transverse plane)

Foam that does not fit into one of these ten grades be-

Larger than 6.35 mm None allowed in any grade

cause it does not meet one or more of the physical require-

Between 3.18 mm No more than 10 allowed per 230

ments of Section 4 is termed ungraded.

and 6.35 mm cm surface area for Grades 5 and

3.1.3.1 Discussion—Grade 5 designates the nominal value

10. No more than 1 allowed for

of 5 lbm/ft .

Grades 12, 15, 20, 25, 30, and 35.

None allowed for Grades 40 and 50.

3.1.4 supplied form—the condition of the foam product

when received from the supplier by the end user. Between 1.57 mm No more than 20 allowed per 230

and 3.18 mm cm surface area for Grades 5 and

3.1.4.1 Discussion—The supplied form may be a solid or a

10. No more than 6 allowed for

liquid.Thefoammaybeinauniformsolidformsuchasaslab,

Grades 12, 15, 20, 25, 30, and 35.

No more than 3 allowed for Grades

plate, or block or a liquid in which two liquid components

40 and 50.

(base and activator) can be mixed by the end user to produce

a rigid, unicellular foam slab.

Cracks None allowed

Non-uniform areas Concentrated areas of poor

4. Physical and Mechanical Requirements

construction, irregular cells, and hard

and soft spots shall not exceed 10 %

4.1 Composition—The material shall be supplied either in

of the visible surface area

solid or liquid form. The solid or combined liquid parts shall

produce a foam consisting of polyether polyurethane.

TABLE 2 Grade Designation and Density

4.2 Appearance:

Minimum Density, Maximum Density,

4.2.1 Solid Supplied Form—The solid supplied form shall

Grade

3 3

kg/m kg/m

befreeofobviousextraneousmatter,andappeartotheunaided

5 72.10 88.10

eye to be uniform throughout the slab in color and porosity.

10 144.0 176.0

4.2.2 Liquid Supplied Form—The two liquid components 12 173.0 211.5

15 216.0 264.5

shall appear to the unaided eye throughout their volumes to be

20 288.5 352.5

uniform and free from obvious extraneous matter or particulate

25 360.5 440.5

debris. 30 432.5 528.5

35 504.5 617.0

4.2.3 SolidFinalForm—Thesolidfinalformshallbefreeof

40 576.5 705.0

obvious extraneous matter, and appear to the unaided eye to be

50 721.0 881.0

uniform throughout the slab in color and porosity.

4.3 Void Content—The material in the solid final form shall

TABLE 3 Requirements for Compressive Strength

meet the requirements of Table 1 for voids, cracks and

Minimum Maximum

nonuniform areas, when examined using the procedures de-

Compressive Compressive

Grade

scribed in 8.1. All specimens shall meet this requirement.

Strength, Strength,

MPa MPa

4.4 Density—The material in the solid final form shall have

5 0.4495 0.7800

a density within the ranges specified in Table 2, according to

10 1.745 2.820

12 2.485 3.970

the foam’s grade specification.The density shall be determined

15 3.820 6.050

using the method described in 8.2. All specimens shall meet

20 6.630 10.45

this requirement.

25 10.15 16.00

30 14.30 22.70

4.5 Dimensional Stability—The material in the solid final

35 19.15 30.55

form shall have an average percentage thickness change less 40 24.60 39.55

50 37.35 61.05

than 5.0 %, when tested according to the method described in

8.3.

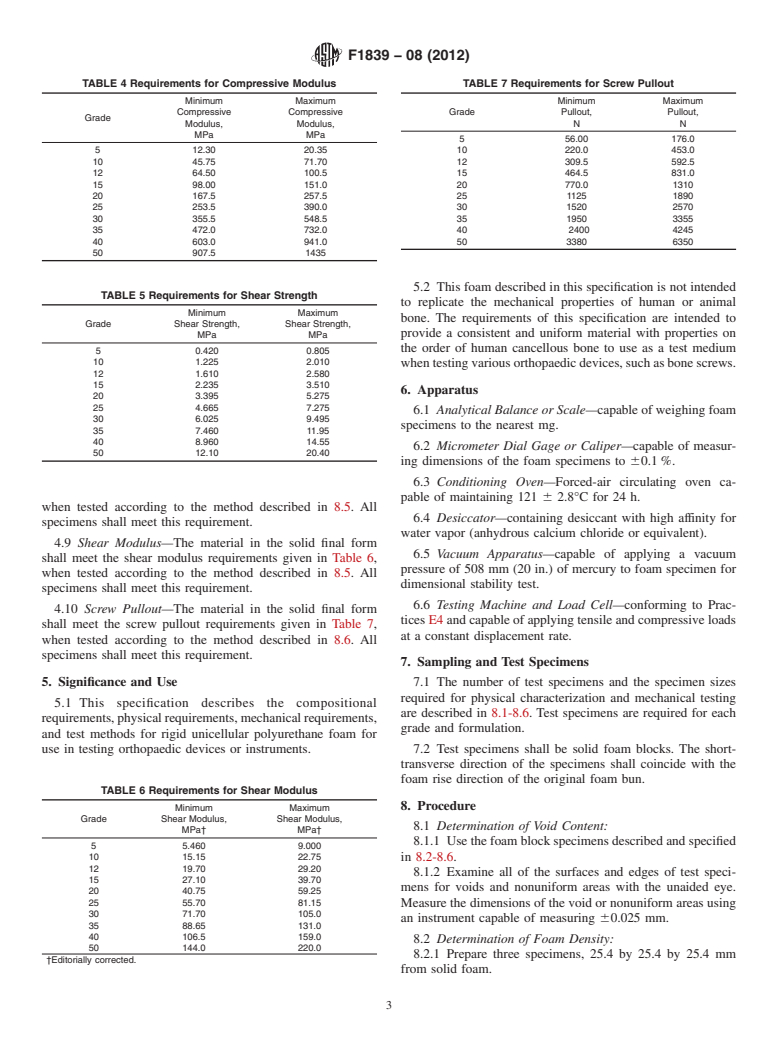

4.6 Compressive Strength—The material in the solid final

formshallmeetthecompressivestrengthrequirementsgivenin

Table 3, when tested according to the method described in 8.4.

in Table 4, when tested according to the method described in

All specimens shall meet this requirement.

8.4. All specimens shall meet this requirement.

4.7 Compressive Modulus—The material in the solid final 4.8 Shear Strength—The material in the solid final form

form shall meet the compressive modulus requirements given shall meet the shear strength requirements given in Table 5,

F1839−08 (2012)

TABLE 4 Requirements for Compressive Modulus TABLE 7 Requirements for Screw Pullout

Minimum Maximum Minimum Maximum

Compressive Compressive Grade Pullout, Pullout,

Grade

Modulus, Modulus, N N

MPa MPa

5 56.00 176.0

5 12.30 20.35 10 220.0 453.0

10 45.75 71.70 12 309.5 592.5

12 64.50 100.5 15 464.5 831.0

15 98.00 151.0

20 770.0 1310

20 167.5 257.5 25 1125 1890

25 253.5 390.0 30 1520 2570

30 355.5 548.5 35 1950 3355

35 472.0 732.0 40 2400 4245

40 603.0 941.0 50 3380 6350

50 907.5 1435

5.2 This foam described in this specification is not intended

TABLE 5 Requirements for Shear Strength

to replicate the mechanical properties of human or animal

Minimum Maximum

bone. The requirements of this specification are intended to

Grade Shear Strength, Shear Strength,

provide a consistent and uniform material with properties on

MPa MPa

the order of human cancellous bone to use as a test medium

5 0.420 0.805

10 1.225 2.010

whentestingvariousorthopaedicdevices,suchasbonescrews.

12 1.610 2.580

15 2.235 3.510

6. Apparatus

20 3.395 5.275

25 4.665 7.275

6.1 Analytical Balance or Scale—capable of weighing foam

30 6.025 9.495

specimens to the nearest mg.

35 7.460 11.95

40 8.960 14.55

6.2 Micrometer Dial Gage or Caliper—capable of measur-

50 12.10 20.40

ing dimensions of the foam specimens to 60.1 %.

6.3 Conditioning Oven—Forced-air circulating oven ca-

pable of maintaining 121 6 2.8°C for 24 h.

when tested according to the method described in 8.5. All

6.4 Desiccator—containing desiccant with high affinity for

specimens shall meet this requirement.

water vapor (anhydrous calcium chloride or equivalent).

4.9 Shear Modulus—The material in the solid final form

6.5 Vacuum Apparatus—capable of applying a vacuum

shall meet the shear modulus requirements given in Table 6,

pressure of 508 mm (20 in.) of mercury to foam specimen for

when tested according to the method described in 8.5. All

dimensional stability test.

specimens shall meet this requirement.

6.6 Testing Machine and Load Cell—conforming to Prac-

4.10 Screw Pullout—The material in the solid final form

tices E4 and capable of applying tensile and compressive loads

shall meet the screw pullout requirements given in Table 7,

at a constant displacement rate.

when tested according to the method described in 8.6. All

specimens shall meet this requirement.

7. Sampling and Test Specimens

5. Significance and Use 7.1 The number of test specimens and the specimen sizes

required for physical characterization and mechanical testing

5.1 This specification describes the compositional

are described in 8.1-8.6. Test specimens are required for each

requirements,physicalrequirements,mechanicalrequirements,

grade and formulation.

and test methods for rigid unicellular polyurethane foam for

use in testing orthopaedic devices or instruments. 7.2 Test specimens shall be solid foam blocks. The short-

transverse direction of the specimens shall coincide with the

foam rise direction of the original foam bun.

TABLE 6 Requirements for Shear Modulus

8. Procedure

Minimum Maximum

Grade Shear Modulus, Shear Modulus,

8.1 Determination of Void Content:

MPa† MPa†

8.1.1 Use the foam block specimens described and specified

5 5.460 9.000

10 15.15 22.75

in 8.2-8.6.

12 19.70 29.20

8.1.2 Examine all of the surfaces and edges of test speci-

15 27.10 39.70

mens for voids and nonuniform areas with the unaided eye.

20 40.75 59.25

25 55.70 81.15 Measure the dimensions of the void or nonuniform areas using

30 71.70 105.0

an instrument capable of measuring 60.025 mm.

35 88.65 131.0

40 106.5 159.0

8.2 Determination of Foam Density:

50 144.0 220.0

8.2.1 Prepare three specimens, 25.4 by 25.4 by 25.4 mm

†Editorially corrected.

from solid foam.

F1839−08 (2012)

8.2.2 Determine the apparent density of the three foam Grades 5, 10, 12, 15, 20, and 25 shall use screws or threaded

specimens, in kg/m , in accordance with Test Method D1622. tools with the thread form of HB 6.5 screws (seeTable A4.4 of

8.2.3 Calculate the average apparent density of the three Specification F543,Annex 4), while Grades 30, 35, 40, and 50

foam specimens. shall utilize screws or threaded tools with the thread form of

HA 4.5 screws (see Table A4.2 of Specification F543, Annex

8.3 Determination of Dimensional Stability:

4).

8.3.1 Prepare three specimens, 25.4 by 25.4 by 12.7 mm

8.6.3 Drill a 3.2-mm hole in the center of each foam

from solid foam.

specimen, parallel to the thickness direction. The hole shall be

8.3.2 Condition the specimen for 24 h at 21 6 2.8°C and

positioned a minimum of 10 mm from any void or nonuniform

50 6 10 % relative humidity. Measure the specimen thickness

area. Tap the hole to a minimum depth of 25.4 mm using a tap

near the center of the length to 60.025 mm and mark the

that corresponds to HB 6.5 or HA 4.5, as appropriate.

location of the measurement.

8.6.4 Insert the screw or threaded tool into each foam

8.3.3 Place the specimen on a 6.35-mm thick aluminum

specimen to a depth of 20 mm.

plate and apply a minimum vacuum pressure of 508 mm of

8.6.5 Test in accordance with Specification F543, Annex

mercury under a vacuum bag or diaphragm. Place this assem-

A3.

bly in a circulating forced-air oven for not less than2hat121

8.6.6 Determine the maximum force, in Newtons, required

6 2.8°C. Remove the assembly and allow to cool to 49°C or

to remove the screw or threaded tool from the foam specimen.

less while maintaining the vacuum.

8.6.7 Calculate the average pullout force for the five speci-

8.3.4 Recondition and remeasure the thickness at the

mens.

marked location in accordance with 8.3.2. Calculate the per-

cent thickness change.

9. Report

8.3.5 Calculate the average percent thickness change of the

9.1 Include the following information in the test report of

three specimens.

the mechanical properties of the foam:

8.4 Determination of Compressive Strength and Modulus:

9.1.1 The lot number, specified grade (if applicable),

8.4.1 Prep

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.