ASTM D4255/D4255M-83(1994)e1

(Guide)Standard Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

Standard Test Method for In-Plane Shear Properties of Polymer Matrix Composite Materials by the Rail Shear Method

SCOPE

1.1 This test method determines the in-plane shear properties of high-modulus fiber-reinforced composite materials by either of two procedures. In Procedure A, laminates clamped between two pairs of loading rails are tested. When loaded in tension the rails introduce shear forces in the specimen. In Procedure B, laminates clamped on opposite edges with a tensile or compressive load applied to a third pair of rails in the center are tested.

1.2 Application of this test method is limited to continuous-fiber or discontinuous-fiber-reinforced polymer matrix composites in the following material forms:

1.2.1 Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or perpendicular to the fixture rails.

1.2.2 Laminates composed only of woven fabric filamentary laminae with the warp direction oriented either parallel or perpendicular to the fixture rails.

1.2.3 Laminates of balanced and symmetric construction, with the 0 direction oriented either parallel or perpendicular to the fixture rails.

1.2.4 Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

Note 1—Additional test methods for determining in-plane shear properties of polymer matrix composites may be found in Test Methods D 5379/D 5379M and D 5448/D 5448M, and Practice D 3518/D 3518M.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pounds units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4255/D 4255M – 83 (Reapproved 1994)

Standard Guide for Testing

In-plane Shear Properties of Composite Laminates

This standard is issued under the fixed designation D 4255/D 4255M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 12 was added and other editorial changes were made in December 1994.

1. Scope

1.1 The in-plane shear properties are determined by impos-

ing edgewise shear loads on the specimen using Method A, a

fixture consisting of two pairs of rails tensile loaded; or Method

B, a fixture consisting of three pairs of rails in tension or

compression loading.

1.2 Two methods are presented as follows:

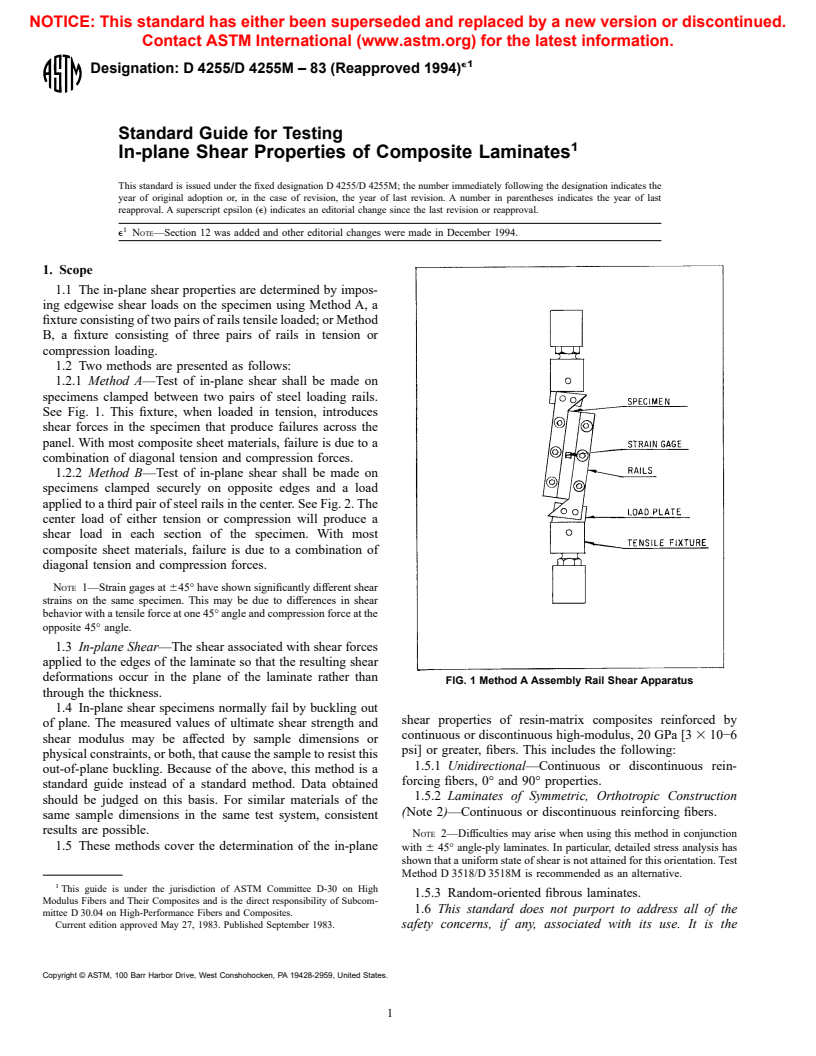

1.2.1 Method A—Test of in-plane shear shall be made on

specimens clamped between two pairs of steel loading rails.

See Fig. 1. This fixture, when loaded in tension, introduces

shear forces in the specimen that produce failures across the

panel. With most composite sheet materials, failure is due to a

combination of diagonal tension and compression forces.

1.2.2 Method B—Test of in-plane shear shall be made on

specimens clamped securely on opposite edges and a load

applied to a third pair of steel rails in the center. See Fig. 2. The

center load of either tension or compression will produce a

shear load in each section of the specimen. With most

composite sheet materials, failure is due to a combination of

diagonal tension and compression forces.

NOTE 1—Strain gages at 645° have shown significantly different shear

strains on the same specimen. This may be due to differences in shear

behavior with a tensile force at one 45° angle and compression force at the

opposite 45° angle.

1.3 In-plane Shear—The shear associated with shear forces

applied to the edges of the laminate so that the resulting shear

deformations occur in the plane of the laminate rather than

FIG. 1 Method A Assembly Rail Shear Apparatus

through the thickness.

1.4 In-plane shear specimens normally fail by buckling out

shear properties of resin-matrix composites reinforced by

of plane. The measured values of ultimate shear strength and

continuous or discontinuous high-modulus, 20 GPa [3 3 10−6

shear modulus may be affected by sample dimensions or

psi] or greater, fibers. This includes the following:

physical constraints, or both, that cause the sample to resist this

1.5.1 Unidirectional—Continuous or discontinuous rein-

out-of-plane buckling. Because of the above, this method is a

forcing fibers, 0° and 90° properties.

standard guide instead of a standard method. Data obtained

1.5.2 Laminates of Symmetric, Orthotropic Construction

should be judged on this basis. For similar materials of the

(Note 2)—Continuous or discontinuous reinforcing fibers.

same sample dimensions in the same test system, consistent

results are possible.

NOTE 2—Difficulties may arise when using this method in conjunction

1.5 These methods cover the determination of the in-plane

with 6 45° angle-ply laminates. In particular, detailed stress analysis has

shown that a uniform state of shear is not attained for this orientation. Test

Method D 3518/D 3518M is recommended as an alternative.

This guide is under the jurisdiction of ASTM Committee D-30 on High

1.5.3 Random-oriented fibrous laminates.

Modulus Fibers and Their Composites and is the direct responsibility of Subcom-

1.6 This standard does not purport to address all of the

mittee D 30.04 on High-Performance Fibers and Composites.

safety concerns, if any, associated with its use. It is the

Current edition approved May 27, 1983. Published September 1983.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4255/D 4255M

bolts. A tensile force is applied to the rails which induces an

in-plane shear load on the specimen. If shear modulus is

required, a strain gage is mounted in the center of the specimen

at 45° to the specimen’s longitudinal axis. The load is applied

to failure. The failure strength, elastic shear strain, and failure

mode should be recorded. A typical two rail shear fixture is

shown in Figs. 1 and 3 with details in Figs. 4-6.

3.1.2 Method B—The test fixture consists of three pairs of

rails that are fastened to the test specimen usually by bolts. The

two outside pairs of rails are attached to a base plate which

rests on the test machine. A third pair of rails (middle rails) are

guided through a slot in the top of the base fixture. The unit

shown is loaded in compression. It would also be permissible

to tensile load the middle rails but this will require fastening

the base fixture to the test machine. If modulus values are

desired, the strain gage should be mounted in the center of both

test sections at 45° to the specimen’s longitudinal axis. The

load is applied to failure. The failure strength, elastic shear

strain, and failure mode should be recorded. A typical three rail

shear fixture is shown in Fig. 2, Fig. 7, and Fig. 8. Details are

shown in Figs. 9-11.

4. Significance and Use

4.1 These shear tests are designed to produce in-plane

shear-property data for material specifications, research and

development, and design. Factors that influence the shear

properties and should therefore be reported are: material, fiber

orientation, fiber form (continuous or chopped), stacking

FIG. 2 Method B Assembly Rail Shear Fixture

sequence, methods of material and specimen preparation,

specimen conditioning, environment of testing, void content,

responsibility of the user of this standard to establish appro-

volume percent reinforcement, specimen dimensions, and test

priate safety and health practices and determine the applica-

method chosen.

bility of regulatory limitations prior to use.

1.7 The values stated in either SI or inch-pound units are to

5. Apparatus

be regarded separately as standard. Within the text the inch-

5.1 Gages, suitable for reading to within 1 % of the sample

pound units are shown in brackets. The values stated in each

length and thickness.

system are not exact equivalents; therefore each system must

5.2 Testing Machine, comprised of the following:

be used independently of the other. Combining values from the

5.2.1 Fixed Member—A fixed or essentially stationary

two systems may result in nonconformance with the standard.

member supporting the load fixture.

2. Referenced Documents

5.2.2 Movable Member, capable of applying a compressive

2.1 ASTM Standards: or tensile load to the test fixture.

5.2.3 Drive Mechanism—A drive for imparting to the mov-

D 618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing able member a controlled velocity with respect to the stationary

member.

D 3518/D 3518M Test Method for In-Plane Shear Response

of Polymer Matrix Composite Materials by Tensile Test of 5.2.4 Load Indicator—A suitable load-indicating mecha-

nism shall be provided that is capable of showing the total

a 645° Laminate

E 4 Practices for Force Verification of Testing Machines compressive or tensile load carried by the test fixture. This

mechanism should indicate the load with an accuracy of 1 % or

E 83 Practice for Verification and Classification of Exten-

someters better of the true value. The accuracy of the testing machine

shall be verified in accordance with Practices E 4.

3. Summary of Methods

5.2.5 Strain Recording—A suitable strain-recording system

3.1 A flat rectangular plate is tested in a rail shear fixture as

is required for modulus determinations.

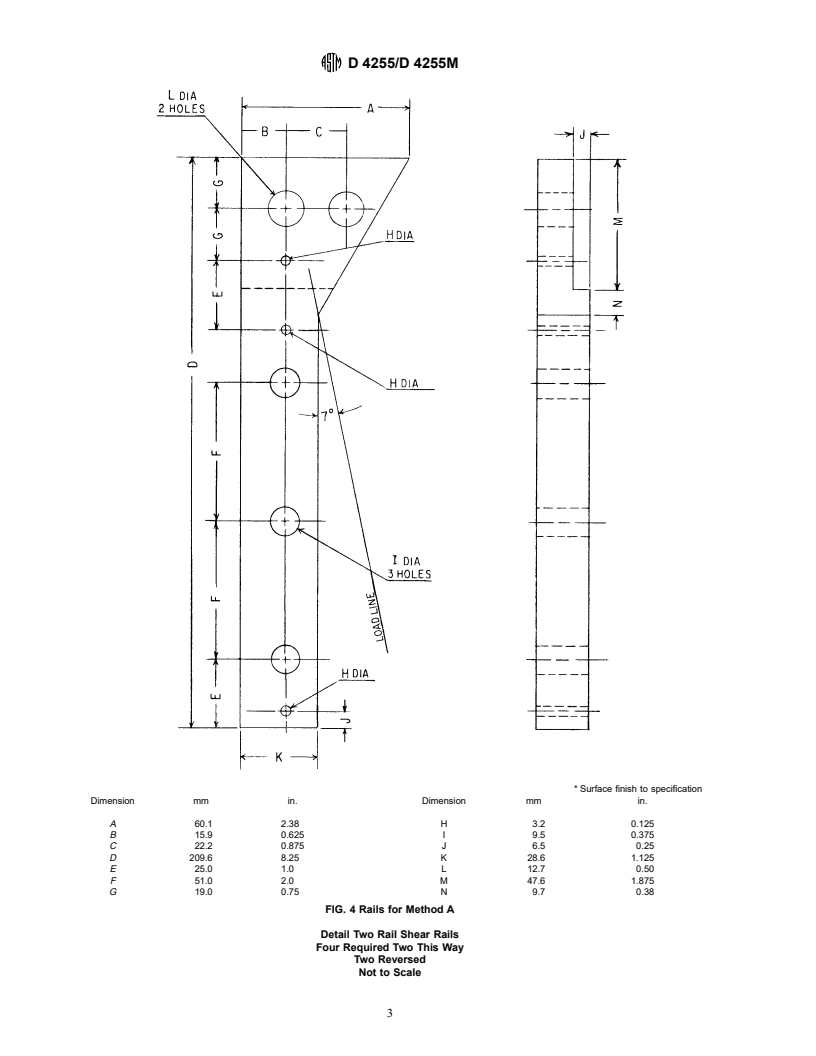

follows: 5.3 Rails—Rails are shown in Fig. 4, Fig. 9, Fig. 10, and

3.1.1 Method A—The test fixture consists of two pairs of

Fig. 11 for clamping the test specimen. Drilled holes should be

rails which can be fastened to the test specimen usually by oversized to prevent stress risers when the bolts are tightened.

Hole tolerances will depend on the material tested and gripping

methods.

Annual Book of ASTM Standards, Vol 08.01.

5.3.1 The following modifications have been used to grip

Annual Book of ASTM Standards, Vol 15.03.

Annual Book of ASTM Standards, Vol 03.01. the specimens:

D 4255/D 4255M

* Surface finish to specification

Dimension mm in. Dimension mm in.

A 60.1 2.38 H 3.2 0.125

B 15.9 0.625 I 9.5 0.375

C 22.2 0.875 J 6.5 0.25

D 209.6 8.25 K 28.6 1.125

E 25.0 1.0 L 12.7 0.50

F 51.0 2.0 M 47.6 1.875

G 19.0 0.75 N 9.7 0.38

FIG. 4 Rails for Method A

Detail Two Rail Shear Rails

Four Required Two This Way

Two Reversed

Not to Scale

D 4255/D 4255M

Dimension mm in.

Dimension mm in.

A 25 1 ⁄8

A 33.0 to 3.5 1 ⁄4 to 12

B 12 ⁄2

B 38.0 1 ⁄2

C 22 ⁄8

C 13.0 ⁄2

1 D 67 2 ⁄8

D 6.0 ⁄4

E 98 3 ⁄8

E 24.0 ⁄16

9 F 25 1

F 7.0 ⁄32

G 48 1 ⁄8

G 76.0 3

H 128.5 5 ⁄16

FIG. 6 Load Plate for Method A

I 41.3 1 ⁄8

Two Required—Cold-Rolled Steel

J 25.0 1

K 51.0 2

specimen usually by bolts. The rails are then attached to the test

FIG. 5 Tensile Head for Method A

machine through pins, a plate that acts as an aligning fixture,

Two Required—Cold-Rolled Steel

and a clevis that connects directly to the test machine. This

5.3.1.1 Abrasive paper or cloth adhered to the rails, equipment is typical but not the only configuration usable.

5.3.1.2 Machining V grooves in the rails, Note that earlier tests have been run where the two rail shear

5.3.1.3 Center punching rails in random order, fixtures were compression loaded. Also see 5.3.1 for rail

5.3.1.4 Changing number of bolt holes from three up to modifications.

eight per rail associated with smaller holes, 5.4.2 Method B—A typical three-rail shear fixture is shown

5.3.1.5 Soft metal shims, and in Fig. 2, Fig. 7, and Fig. 8. Details are shown in Figs. 9-11.

5.3.1.6 Tabbing specimens in rail areas. The test fixture consists of three pairs of rails that are fastened

5.3.2 The above list is not inclusive but was typical of to the test specimen usually by bolts. The two outside pairs of

methods used by various laboratories to meet the requirements rails are attached to a base plate that rests on the test machine.

of specific materials. Items that work for one material may be

The third pair of rails (middle rails) are guided through a slot

unacceptable for another. If these modifications are to be used in the top of the base fixture. The unit shown is loaded in

as part of a specification, it is important that the rail grip system

compression. It would also be permissible to tensile load the

be completely specified and these modifications noted in the middle rails, but this will require fastening the base fixture to

test report. the test machine. This equipment is typical but not the only

5.4 Test Fixtures: configuration that is usable. Also see 5.3.1 for rail modifica-

5.4.1 Method A—A typical two-rail shear fixture is shown in tions.

Fig. 1 and Fig. 3 with details in Figs. 4-6. The test fixture 5.5 Strain—Where load-strain data are desired, the speci-

consists of two pairs of rails which can be fastened to the test men may be instrumented with strain gages.

D 4255/D 4255M

be supported by rails dimensioned in Fig. 4. Note that while the

sample outer dimensions are uniform, many variations of hole

patterns and tabbed edges have been used. See 5.3.1.

NOTE 4—It is recommended that laminates be 1.27 to 3.17 mm [0.050

to 0.125 in.] thick. Thin laminates tend to exhibit buckling at low loads

while thicker laminates can have shear strengths in excess of the

rail-clamping capacity.

6.1.2 Method B—The test specimen shall conform to the

dimensions shown in Fig. 13 (Note 4) and shall be supported

by rails dimensioned in Figs. 9-11.

6.2 The straight edges of the specimen may have coarse tool

marks from the machining operation; however, the holes

should be drilled and reamed if minor delamination occurs.

The holes shown are oversize to the bolts, although press fit

bolts have been used with success, particularly with tabbed

specimens.

6.3 Number of Specimens—At least five specimens shall be

tested for each sample.

6.4 Health and Safety—When fabricating composite speci-

mens by machining operations, a fine dust consisting of

particles of fibers or the matrix material, or both, may be

formed. These fine dusts can be a serious health or safety, or

both, hazard. Adequate protection should be afforded operating

personnel and equipment. This may require adequate ventila-

tion or dust collecting, or both, facilities at a minimum.

7. Conditioning

7.1 Standard Conditioning Procedure—The test specimen

shall be conditioned and tested in a room or enclosed space

maintained at 23 6 2°C [73.4 6 3.6°F] and 50 6 5 % relative

humidity in accordance with Procedure A of Practice D 618.

FIG. 7 Method B Assembled Typical Test Fixture

8. Procedure

5.5.1 Location—The strain gages should be located at the

8.1 Method A:

center of the specimen at a 45° angle to the rails as illustrated

8.1.1 Speed of Testing, shall be determined by the specifi-

in Fig. 1 and Fig. 6. The gages, surface preparation, and

cations for the material being tested or by agreement between

bonding agents should be chosen to provide for adequate

those concerned. However, when the speed of testing is not

performance on the subject material, and suitable automatic-

specified, a speed of 1 to 1.5 mm/min [0.04 to 0.06 in./min]

strain recording equipment shall be employed. Some laborato-

should be used.

ries have found it necessary to reduce the rail size in the

8.1.2 Measure the least length between the rails to the

strain-gage area to have sufficient space for the strain gages and

nearest 0.25 mm [0.01 in.] and several thicknesses along the

wire leads.

length of the specimen to the nearest 0.025 mm [0.001 in.].

5.5.2 For initial trials of the equipment, modification of

Record the minimum cross-sectional area.

equipment, or a new material, it is recommended that strain

8.1.3 Place the specimen between the pairs of rails. Align

rosettes of 0 and 645° be used. Using this method, it is

the rails with the specimen. Place a 12.5-mm [ ⁄2-in.] spacer

possible to see if the major shear strains are at 645° and if they

between opposite pairs of rails. Ensure that there is no bearing

are equal. If the major shear strains are not at 645°, it is

contact, in the direction of loading, between the 9.5-mm

possible to rotate the strains with use of the 0° data. Equations 3 1

[ ⁄8-in.] diameter bolts and the 12.5-mm [ ⁄2-in.] diameter holes.

to rotate strains are available from several references, including

Orient the rail guides and apply a torque of 7 to 70 N·m [5 to

most strain-gage manufacturers li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.