ASTM D1987-95(2002)

(Test Method)Standard Test Method for Biological Clogging of Geotextile or Soil/Geotextile Filters

Standard Test Method for Biological Clogging of Geotextile or Soil/Geotextile Filters

SIGNIFICANCE AND USE

This test method is performance oriented for determining if, and to what degree, different liquids create biological activity on geotextile filters thereby reducing their flow capability. The use of the method is primarily oriented toward landfill leachates but can be performed with any liquid coming from a particular site or synthesized from a predetermined mixture of biological microorganisms.

The test can be used to compare the flow capability of different types of geotextiles or soil/geotextile combinations.

This test will usually take considerable time, for example, up to 1000 h, for the biological activity to initiate, grow, and reach an equilibrium condition. The curves resulting from the test are intended to indicate the in situ behavior of a geotextile or soil/geotextile filter.

The test specimen can be incubated under non-saturated drained conditions between readings, or kept saturated at all times. The first case allows for air penetration into the flow column and thus aerobic conditions. The second case can result in the absence of air, thus it may simulate anaerobic conditions.

The flow rate can be determined using either a constant head test procedure or on the basis of a falling head test procedure. In either case the flow column containing the geotextile or soil/geotextile is the same, only the head control devices change.

Note 1—It has been found that once biological clogging initiates, constant head tests often pass inadequate quantities of liquid to accurately measure. It thus becomes necessary to use falling head tests which can be measured on the basis of time of movement of a relatively small quantity of liquid between two designated points on a clear plastic standpipe.

If the establishment of an unacceptably high degree of clogging is seen in the flow rate curves, the device allows for backflushing with water or with water containing a biocide.

The resulting flow rate curves are intended for use in the design of full scale geote...

SCOPE

1.1 This test method is used to determine the potential for, and relative degree of, biological growth which can accumulate on geotextile or geotextile/soil filters.

1.2 This test method uses the measurement of flow rates over an extended period of time to determine the amount of clogging.

1.3 This test method can be adapted for nonsaturated as well as saturated conditions.

1.4 This test method can use constant head or falling head measurement techniques.

1.5 This test method can also be used to give an indication as to the possibility of backflushing and/or biocide treatment for remediation purposes if biological clogging does occur.

1.6 The values in SI units are to be regarded as the standard. The values provided in inch-pound units are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1987–95 (Reapproved 2002)

Standard Test Method for

Biological Clogging of Geotextile or Soil/Geotextile Filters

This standard is issued under the fixed designation D1987; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method is used to determine the potential for, 3.1 Definitions:

andrelativedegreeof,biologicalgrowthwhichcanaccumulate 3.1.1 geotextile, n—a permeable geosynthetic comprised

on geotextile or geotextile/soil filters. solely of textiles.

1.2 This test method uses the measurement of flow rates 3.1.2 permeability, n—the rate of flow of a liquid under a

over an extended period of time to determine the amount of differential pressure through a material.

clogging. 3.1.2.1 Discussion—In geotextiles, permeability refers to

1.3 Thistestmethodcanbeadaptedfornonsaturatedaswell hydraulic conductivity.

−1

as saturated conditions. 3.1.3 permittivity, (C)(t ), n—of geotextiles, the volumet-

1.4 This test method can use constant head or falling head ric flow rate of water per unit, in a cross sectional area head

measurement techniques. under laminar flow conditions.

1.5 This test method can also be used to give an indication 3.1.4 aerobic, n—aconditioninwhichameasurablevolume

as to the possibility of backflushing and/or biocide treatment of air is present in the incubation chamber or system.

for remediation purposes if biological clogging does occur. 3.1.4.1 Discussion—In geotextiles, this condition can po-

1.6 ThevaluesinSIunitsaretoberegardedasthestandard. tentially contribute to the growth of micro-organisms.

The values provided in inch-pound units are for information 3.1.5 anaerobic, n—a condition in which no measurable

only. volume of air is present in the incubation chamber or system.

1.7 This standard does not purport to address all of the 3.1.5.1 Discussion—In geotextiles, this condition cannot

safety concerns, if any, associated with its use. It is the contribute to the growth of microorganisms.

responsibility of the user of this standard to establish appro- 3.1.6 back flushing, n—a process by which liquid is forced

priate safety and health practices and determine the applica- in the reverse direction to the flow direction.

bility of regulatory limitations prior to use. 3.1.6.1 Discussion—In other drainage application areas,

this process is commonly used to free clogged drainage

2. Referenced Documents

systemsofmaterialsthatimpedetheintendeddirectionofflow.

2.1 ASTM Standards: 3.1.7 biocide, n—a chemical used to kill bacteria and other

D123 Terminology Relating to Textiles

microorganisms.

D1776 Practice for Conditioning Testing Textiles 3.2 For definitions of other terms used in this test method,

D4354 Practice for Sampling of Geosynthetics forTesting

refer to Terminology D123 and D4439.

D4439 Terminology for Geotextiles

4. Summary of Test Method

D4491 Test Methods forWater Permeability of Geotextiles

by Permittivity 4.1 A geotextile filter specimen or geotextile/soil filter

D5101 Test Method for Measuring the Soil-Geotextile composite specimen is positioned in a flow column so that a

System Clogging Potential By the Gradient Ratio designated liquid flows through it under either constant or

G22 Practice for Determining Resistance of Plastics to falling head conditions.

Bacteria 4.1.1 The designated liquid might contain micro-organisms

from which biological growth can occur.

4.2 Flow rate is measured over time, converted to either

This test method is under the jurisdiction of ASTM Committee D35 on

permittivity or permeability, and reported according.

Geosynthetics and is the direct responsibility of Subcommittee D35.02 on Endur-

4.2.1 Betweenreadings,thetestspecimencanbeallowedto

ance Properties.

be in either nonsaturated or saturated conditions.

Current edition approved Dec. 10, 1996. Published June 1996. Originally

published as D1987–91. Last previous edition D1987–91.

4.2.2 Back flushing can be introduced from the direction

Annual Book of ASTM Standards, Vol 07.01.

opposite to the intended flow direction and evaluated accord-

Annual Book of ASTM Standards, Vol 04.13.

ingly.

Discontinued; see 2001 Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1987–95 (2002)

4.2.3 Biocide can be introduced with the back flushing

liquid, or introduced within the test specimen, and evaluated

accordingly.

5. Significance and Use

5.1 This test method is performance oriented for determin-

ing if, and to what degree, different liquids create biological

activity on geotextile filters thereby reducing their flow capa-

bility. The use of the method is primarily oriented toward

landfill leachates but can be performed with any liquid coming

from a particular site or synthesized from a predetermined

mixture of biological microorganisms.

5.2 The test can be used to compare the flow capability of

different types of geotextiles or soil/geotextile combinations.

5.3 This test will usually take considerable time, for ex-

ample,upto1000h,forthebiologicalactivitytoinitiate,grow,

and reach an equilibrium condition. The curves resulting from

the test are intended to indicate the in situ behavior of a

geotextile or soil/geotextile filter.

5.4 The test specimen can be incubated under non-saturated

drained conditions between readings, or kept saturated at all

times. The first case allows for air penetration into the flow

columnandthusaerobicconditions.Thesecondcasecanresult

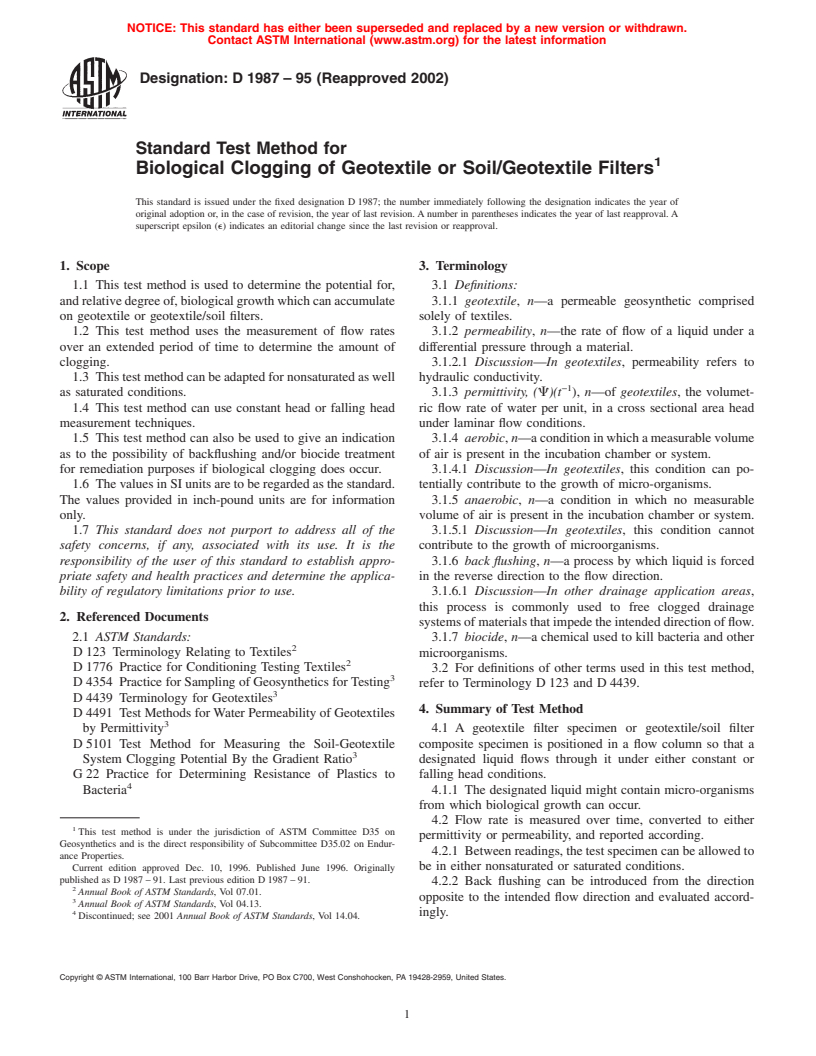

FIG. 1 Flow Column to Contain Geotextile Test Specimen

intheabsenceofair,thusitmaysimulateanaerobicconditions.

5.5 The flow rate can be determined using either a constant

NOTE 2—If piezoemetric heads in the material (soil or solid waste)

head test procedure or on the basis of a falling head test

located above the filter are desired, the upper flow column of the

procedure. In either case the flow column containing the

permeameter can be modified to accommodate such measurements.

geotextile or soil/geotextile is the same, only the head control

Recommended are ports immediately above the filter (as close to it as

1 1 3

devices change.

possible), and at ⁄4, ⁄2, ⁄4 and above the soil or solid waste in question.

Duplicate ports on each side of the permeameter at the above elevations

NOTE 1—It has been found that once biological clogging initiates,

are considered good practice in measurements of this type. Other

constant head tests often pass inadequate quantities of liquid to accurately

configurations are at the option of the parties involved.

measure. It thus becomes necessary to use falling head tests which can be

The ports are connected by flexible tubing to a manometer board for

measured on the basis of time of movement of a relatively small quantity

readingsinamannerthatistypicalformeasurementsofthistype.SeeTest

of liquid between two designated points on a clear plastic standpipe.

Method D5101, the Gradient Ratio test, for additional details.

5.6 If the establishment of an unacceptably high degree of

6.2 Hydraulic head control devices, are required at both the

clogging is seen in the flow rate curves, the device allows for

inlet and outlet ends of the flow column. Fig. 2 shows the

backflushing with water or with water containing a biocide.

complete setup based on constant hydraulic head monitoring

5.7 Theresultingflowratecurvesareintendedforuseinthe

where concentric plastic cylinders are used with the inner

design of full scale geotextile or soil/geotextile filtration

systems and possible remediation schemes in the case of

landfill lechate collection and removal systems.

6. Apparatus

6.1 The flow column and specimen mount, consists of a 100

mm(4.0in.)insidediametercontainmentringforplacementof

the geotextile specimen along with upper and lower flow tubes

to allow for uniform flow trajectories (see Fig. 1). The flow

tubes are each sealed with end caps which have entry and exit

tubing connections (see Fig. 1). The upper tube can be made

sufficientlylongsoastoprovideforasoilcolumntobeplaced

above the geotextile. When this type of combined soil/

geotextile cross section is used, however, it is difficult to

distinguish which material is clogging, for example, the soil or

the geotextile. It does however simulate many existing filtra-

tion systems. In such cases, a separate test setup with the

geotextile by itself will be required as a control test and the

difference in behavior between the two tests will give an

indication as to the contribution of soil clogging to the flow

FIG. 2 Flow Column with Inlet and Outlet Hydraulic Head Control

reduction. Devices for Constant Head Test

D1987–95 (2002)

cylinders being at the elevation from which head is measured. length along the selvage from each sample roll so that the

The elevation difference between the inner cylinder at the inlet requirements of the following section can be met. Take a

end and the inner cylinder at the outlet end is the total head samplethatwillexcludematerialfromtheouterwrapandinner

across the geotextile test specimen (or soil/geotextile test wrap around the core unless the sample is taken at the

specimen in the case of a combined test column). Note that the production site, then inner and outer wrap material may be

elevation of the outlet must be above the elevation of the used.

geotextile. 7.3 Test Specimens—From the laboratory sample select the

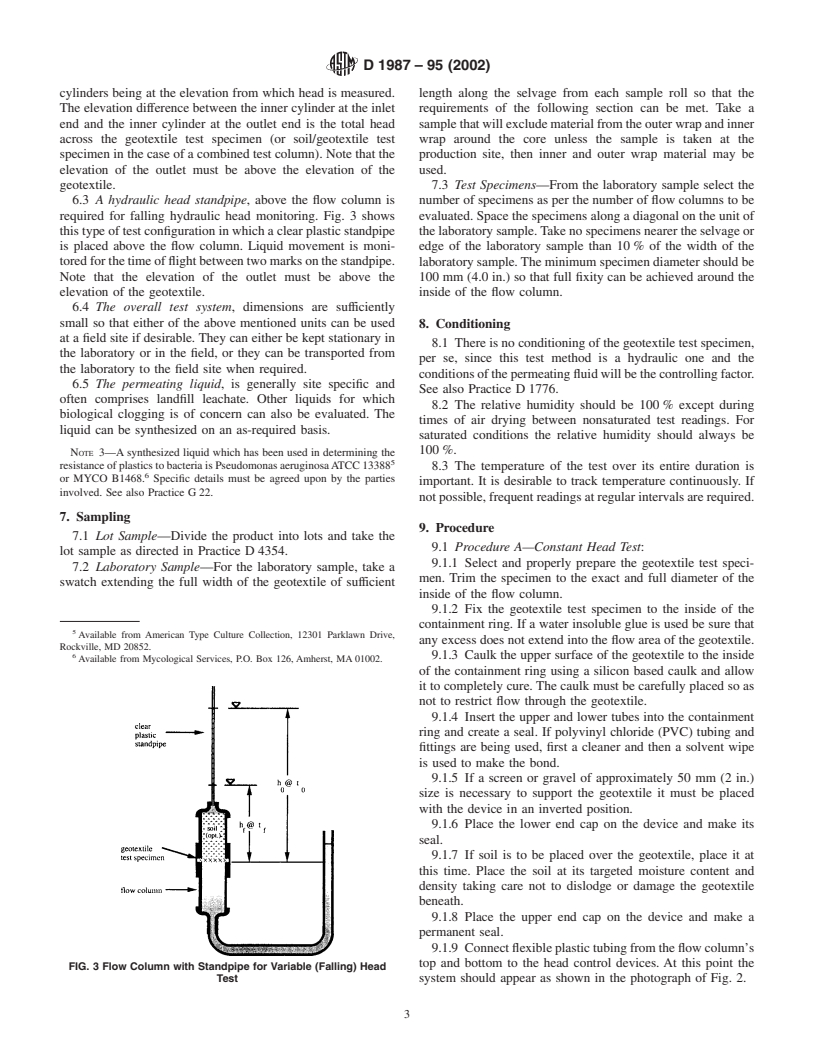

6.3 A hydraulic head standpipe, above the flow column is number of specimens as per the number of flow columns to be

required for falling hydraulic head monitoring. Fig. 3 shows evaluated. Space the specimens along a diagonal on the unit of

thistypeoftestconfigurationinwhichaclearplasticstandpipe thelaboratorysample.Takenospecimensnearertheselvageor

is placed above the flow column. Liquid movement is moni- edge of the laboratory sample than 10% of the width of the

toredforthetimeofflightbetweentwomarksonthestandpipe. laboratorysample.Theminimumspecimendiametershouldbe

Note that the elevation of the outlet must be above the 100 mm (4.0 in.) so that full fixity can be achieved around the

elevation of the geotextile. inside of the flow column.

6.4 The overall test system, dimensions are sufficiently

small so that either of the above mentioned units can be used

8. Conditioning

at a field site if desirable. They can either be kept stationary in

8.1 Thereisnoconditioningofthegeotextiletestspecimen,

the laboratory or in the field, or they can be transported from

per se, since this test method is a hydraulic one and the

the laboratory to the field site when required.

conditionsofthepermeatingfluidwillbethecontrollingfactor.

6.5 The permeating liquid, is generally site specific and

See also Practice D1776.

often comprises landfill leachate. Other liquids for which

8.2 The relative humidity should be 100% except during

biological clogging is of concern can also be evaluated. The

times of air drying between nonsaturated test readings. For

liquid can be synthesized on an as-required basis.

saturated conditions the relative humidity should always be

100%.

NOTE 3—Asynthesized liquid which has been used in determining the

resistanceofplasticstobacteriaisPseudomonasaeruginosaATCC13388

8.3 The temperature of the test over its entire duration is

or MYCO B1468. Specific details must be agreed upon by the parties

important. It is desirable to track temperature continuously. If

involved. See also Practice G22.

notpossible,frequentreadingsatregularintervalsarerequired.

7. Sampling

9. Procedure

7.1 Lot Sample—Divide the product into lots and take the

9.1 Procedure A—Constant Head Test:

lot sample as directed in Practice D4354.

9.1.1 Select and properly prepare the geotextile test speci-

7.2 Laboratory Sample—For the laboratory sample, take a

men. Trim the specimen to the exact and full diameter of the

swatch extending the full width of the geotextile of sufficient

inside of the flow column.

9.1.2 Fix the geotextile test specimen to the inside of the

containment ring. If a water insoluble glue is used be sure that

Available from American Type Culture Collection, 12301 Parklawn Drive,

any excess does not extend into the flow area of the geotextile.

Rockville, MD 20852.

9.1.3 Caulk the upper surface of the geotextile to the inside

Available from Mycological Services, P.O. Box 126, Amherst, MA 01002.

of the containment ring using a silicon based caulk and allow

it to completely cure.The caulk must be carefully placed so as

not to restrict flow through the geotextile.

9.1.4 Insert the upper and lower tubes into the containment

ring and create a seal. If polyvinyl chloride (PVC) tubing and

fittings are being used, first a cleaner and then a solvent wipe

is used to make the bond.

9.1.5 If a screen or gravel of approximately 50 mm (2 in.)

size is necessary to support the geotextile it must be placed

with the device in an inverted position.

9.1.6 Place the lower end cap on the device and make its

seal.

9.1.7 If soil is to be placed over the geotextile, place it at

this time. Place the soil at its targeted moisture content and

density taking care not to dislodge or damage the geotextile

beneath.

9.1.8 Place the upper end cap on the device and make a

permanent seal.

9.1.9 Connectflexibleplastictubingfromtheflowcolumn’s

top and bottom to the head control devices. At this point the

FIG. 3 Flow Column with Standpipe for Variable (Falling) Head

Test system should appear as shown in the photograph of Fig. 2.

D1987–95 (2002)

9.1.10 Adjust the total head lost to 50 mm (2.0 in.) and 9.2.11 Allow for flow through the system until the liquid

initiate flow via the introduction of the permeating fluid to the level reaches the upper mark and then start a stopwatch.

system. When using leachate, proper safety and health precau-

9.2.12 Allow flow to continue unimpeded until the liquid

tions must be maintained depending upon the nature of the

level reaches the lower standpipe mark and immediately stop

leachate itself.

the stopwatch so as to record the elapsed time.

NOTE 4—Itissuggestedtouse50mm(2in.)totalheaddifferencesince 9.2.13 Repeat this measurement procedure three times. The

this is the prescribed value used in the permittivity test of Test Method

average of this value is to be reported.

D4491. Other values of head or hydraulic gradient, as mutually decided

9.2.14 After readings are completed, disconnect the head

upon by the parties involved, could also be used.

control devices. If nonsaturated conditions are desi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.