ASTM D3638-93(1998)

(Test Method)Standard Test Method for Comparative Tracking Index of Electrical Insulating Materials

Standard Test Method for Comparative Tracking Index of Electrical Insulating Materials

SCOPE

1.1 This test method evaluates in a short period of time the low-voltage (up to 600 V) track resistance or comparative tracking index (CTI) of materials in the presence of aqueous contaminants.

1.2 The values stated in metric (SI) units are to be regarded as standard. The inch-pound equivalents of the metric units may be approximate.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3638–93 (Reapproved 1998)

Standard Test Method for

Comparative Tracking Index of Electrical Insulating

Materials

This standard is issued under the fixed designation D3638; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 tracking—the process that produces tracks as a result

of the action of electric discharges on or close to an insulation

1.1 This test method evaluates in a short period of time the

surface.

low-voltage (up to 600 V) track resistance or comparative

3.1.3 tracking, contamination—tracking caused by scintil-

tracking index (CTI) of materials in the presence of aqueous

lations that result from the increased surface conduction due to

contaminants.

contamination.

1.2 The values stated in metric (SI) units are to be regarded

3.1.4 tracking resistance—thequantitativeexpressionofthe

as standard. The inch-pound equivalents of the metric units

voltage and the time required to develop a track under the

may be approximate.

specified conditions.

1.3 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety problems, if any, associated with its use. It is the

3.2.1 comparative tracking index—an index for electrical

responsibility of the user of this standard to establish appro-

insulating materials which is arbitrarily defined as the numeri-

priate safety and health practices and determine the applica-

cal value of that voltage which will cause failure by tracking

bility of regulatory limitations prior to use.

when the number of drops of contaminant required to cause

2. Referenced Documents

failure is equal to 50. This value is obtained from a plot of the

number of drops required to cause failure by tracking versus

2.1 ASTM Standards:

the applied voltage.

D618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

4. Summary of Test Method

D647 Practice for Design of Molds for Test Specimens of

4.1 The surface of a specimen of electrical insulating

Plastic Molding Materials

material is subjected to a low-voltage alternating stress com-

D1711 Terminology Relating to Electrical Insulation

2 bined with a low current which results from an aqueous

D1898 Practice for Sampling of Plastics

contaminant (electrolyte) which is dropped between two op-

2.2 IEC Publication:

posing electrodes every 30 s. The voltage applied across these

112, Recommended Method for Determining the Compara-

electrodes is maintained until the current flow between them

tive Track Index of Solid Insulating Materials Under

4 exceeds a predetermined value which constitutes failure. Ad-

Moist Conditions, 1971 Second Edition

ditional specimens are tested at other voltages so that a

3. Terminology relationship between applied voltage and number of drops to

failure can be established through graphical means. The

3.1 Definitions:

numerical value of the voltage which causes failure with the

3.1.1 track—a partially conducting path of localized dete-

application of 50 drops of the electrolyte is arbitrarily called

rioration on the surface of an insulating material.

the comparative tracking index. This value provides an indi-

cation of the relative track resistance of the material.

This test method is under the jurisdiction of ASTM Committee D-9 on 5. Significance and Use

Electrical and Electronic Insulating Materials and is the direct responsibility of

5.1 Electrical equipment may fail as a result of electrical

Subcommittee D09.12 on Electrical Tests.

tracking of insulating material that is exposed to various

Current edition approved Oct. 15, 1993. Published December 1993. Originally

e1

published as D3638–77. Last previous edition D3638–85(1992) .

contaminating environments and surface conditions. There are

Annual Book of ASTM Standards, Vol 08.01.

a number of ASTM and other tests designed to quantify

Annual Book of ASTM Standards, Vol 10.01.

4 behavior of materials, especially at relatively high voltages.

Available from the International Electrotechnical Commission, Geneva, Swit-

zerland. This method is an accelerated test which at relatively low test

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3638

NOTE 1—The need for a shorting switch can be considered optional. It

voltages, provides a comparison of the performance of insu-

is possible to couple the variable resistor with the autotransformer which

lating materials under wet and contaminated conditions. The

gives an automatic setting of the current throughout the range of the

comparative tracking index is not related directly to the

instrument. Then whenever it is necessary to check the calibration of the

suitable operating voltage in service.

instrument, the shorting action can be accomplished by a jumper wire

5.2 When organic electrical insulating materials are sub-

placedacrosstheelectrodes.Thiscouplingoftheautotransformerwiththe

jected to conduction currents between electrodes on their

variable resistor can be considered another option.

surfaces, many minute tree-like carbonaceous paths or tracks

6.1.6 Over-Current Relay (R0), which has to be inserted in

are developed near the electrodes. These tracks are oriented

the circuit shall not trip at currents up to 0.1Aand the tripping

randomly, but generally propagate between the electrodes

time on short circuit shall be at least 0.5 s (the current shall be

under the influence of the applied potential difference. Even-

limited on short circuit to 1 A with a tolerance of 610%ata

tually a series of tracks spans the electrode gap, and failure

power factor of 0.9 to 1.0).

occurs by shorting of the electrodes.

NOTE 2—Some instruments have used a Heinemann breaker, which is

5.3 The conditions specified herein are intended, as in other

probably the closest standard commercial breaker to that described in the

tracking test methods, to produce a condition conducive to the

IEC Method. This breaker is Heinemann Model Series JA, Curve 2.Also

formation of surface discharges and possible subsequent track-

the tripping action can be accomplished with electronic circuitry.

ing. Test conditions are chosen to reproducibly and conve-

6.1.7 Testing Fixture (J1), adjustable platform which sup-

niently accelerate a process; for this reason, they rarely

ports the specimen and electrode setup.

reproduce the varied conditions found in actual service.There-

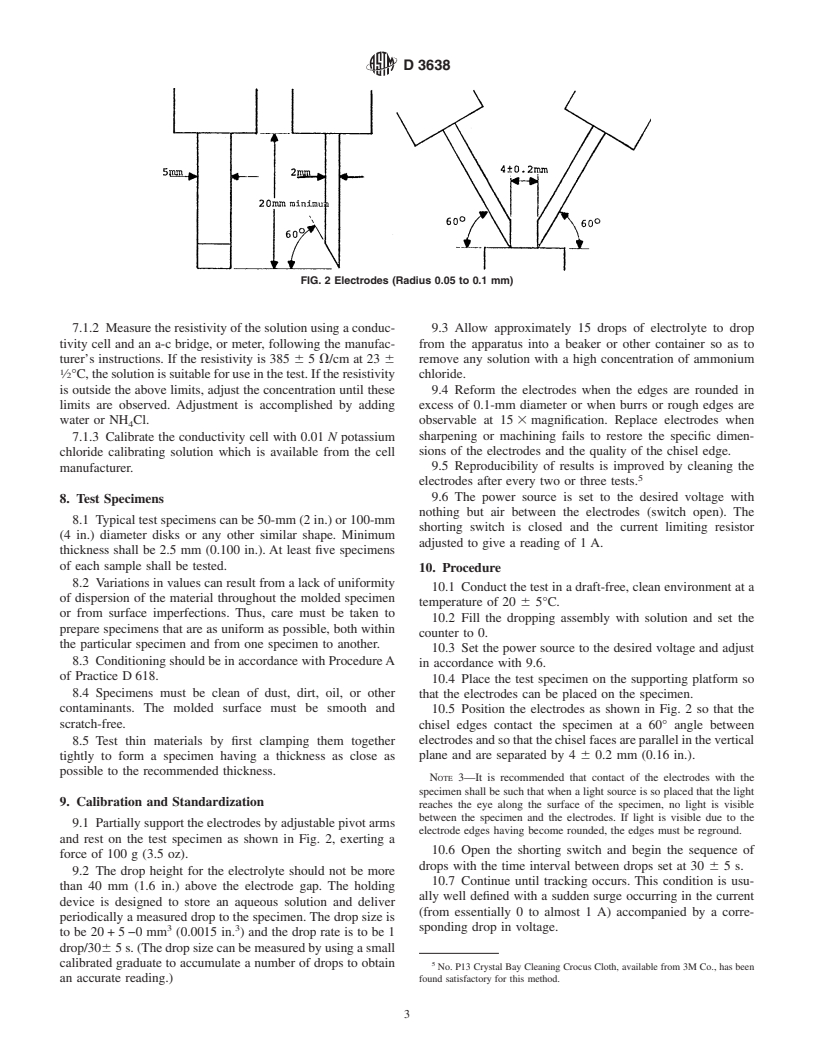

6.1.8 Platinum Electrodes, having a rectangular cross sec-

fore, while tracking tests serve to differentiate materials under

tion measuring 5 by 2 mm (0.2 by 0.08 in.), extending 20 mm

given conditions, results of tracking tests cannot be used to

(0.8 in) minimum from suitable mounting shanks (Fig. 2). The

infer either direct or comparative service behavior of an

end of each electrode is machined to form a 30° chisel-point

application design. Rather, tracking test results provide a tool

edge, having a radius from 0.05 to 0.10 mm, extending along

for judging the suitability of materials for a given application.

the 5-mm (0.2-in) side of the electrode. This is the radius that

The suitability can only be verified through testing the design

generally results from polishing a “Omm” radius electrode.

inactualenduseorunderconditionswhichsimulateenduseas

Since the direction of polish may influence the results, all

closely as possible.

electrodes should be polished in a direction perpendicular to

6. Apparatus the long dimension of the electrode face.

6.1.9 Dropping Apparatus, which should drop the electro-

6.1 The simplified electrical circuitry used in this test is

lyte precisely as specified. Included should also be a means of

illustrated in Fig. 1. For necessary information on the cleanli-

electricallystartingandstoppingthedroppingoftheelectrolyte

nessofapparatus,seeAnnexA1.Theessentialcomponentsare

as well as a counting device for monitoring the number of

as follows:

drops. The orifice diameter of the drop mechanism is approxi-

6.1.1 Variable Power Source, consisting of a transformer

mately 1.5 mm. However, it may be necessary to adjust this

type supply, such as the combinationT1 andT2 in Fig. 1, with

diameter somewhat so as to obtain the proper drop size in

a variable output of 0 to 1000V, 60 Hz capable of maintaining

accordance with 9.2.

a current of 1 A (1 kVA).

6.1.2 Voltmeter (V1), capable of measuring the varying a-c

7. Reagents

output of the power source. A 0 to 600-V voltmeter with an

accuracy of at least6 2.5% of full scale. 7.1 Electrolyte Solution of Ammonium Chloride in Water:

6.1.3 Ammeter (A1), with a range of 0 to 1 A a-c and an 7.1.1 Prepare a solution of ammonium chloride at an ap-

accuracy of at least 610% of full scale. proximate concentration of 0.1% by dissolving1gof reagent

6.1.4 Current Limiting Resistor (R1), continuously vari- gradeammoniumchloridein1Lofwater.Thewaterusedshall

able, wire wound, rated at greater than 1 A. have a volume resistivity of no less than 0.5 MV/cm at 23°C.

6.1.5 Shorting Switch (S1), single-pole single-throw rated Allow the solution to stand overnight in a covered, but not

at 1000 V and greater than 1 A. sealed, container.

FIG. 1 Electrical Circuit Components

D3638

FIG. 2 Electrodes (Radius 0.05 to 0.1 mm)

7.1.2 Measuretheresistivityofthesolutionusingaconduc- 9.3 Allow approximately 15 drops of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.