ASTM D2475-88(2000)

(Specification)Standard Specification for Felt

Standard Specification for Felt

SCOPE

1.1 This specification covers all standard types of felt in the form of rolls and sheets that are suitable for mechanical use. Certain special-purpose felts are also covered.

1.2 This specification is not applicable to felt-like products that utilize weaving, knitting, stitching, or bonding such as papermaker's felt.

1.3 Trade practice in the felt industry deals in pounds, yards, and inches, therefore the values stated in inch-pound units are to be regarded as standard. The values in SI units are provided as information only.

1.3.1 The specification referenced in 2.2 uses only inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2475 – 88 (Reapproved 2000)

Standard Specification for

Wool Felt

This standard is issued under the fixed designation D 2475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2.1 Discussion—In practice, light needling or tacking

may be used to supplement the ability of the fibers to interlock

1.1 This specification covers all standard types of wool and

and consolidate.

part-wool felt in the form of rolls and sheets that are suitable

3.1.3 gray felt, n—a blend of white fibers with naturally

for mechanical use. Certain special-purpose felts are also

colored or dyed fibers or both and that has an overall gray

covered.

appearance.

1.2 This specification is not applicable to felt-like products

3.1.4 needled felt, n—a textile structure composed entirely

that utilize weaving, knitting, stitching, or bonding such as

of fibers physically interlocked and reoriented through the

papermaker’s felt.

action of felting needles.

1.3 Trade practice in the felt industry deals in pounds, yards,

3.1.5 orthopedic and surgical felt, n—a white, soft, low

and inches, therefore the values stated in inch-pound units are

density, highly resilient felt.

to be regarded as standard. The values in SI units are provided

3.1.5.1 Discussion—Such felts are commonly used in splint

as information only.

pads, abdominal supports, orthopedic devices, and fracture cast

1.3.1 The specification referenced in 2.2 uses only inch-

linings as well as other medical applications.

pound units.

3.1.6 papermaker’s felt, n—a fabric, made from wool or

2. Referenced Documents man-made fibers or mixtures of both, fabricated as an endless

belt for use on a paper making machine. (See also felt and

2.1 ASTM Standards:

needled felt.)

D 123 Terminology Relating to Textiles

3.1.6.1 Discussion—Papermaker’s felt received its name

D 461 Test Methods for Felt

because it replaced the sheets of felt used in squeezing the

2.2 Federal Standard:

water from newly formed, manually made sheets of paper.

C-F-206, Felt Sheet: Cloth Felt, Wool, Pressed

Some finished papermaker’s felts have matted surfaces similar

2.3 Felt Manufacturers Council:

to wool felts.

FS14-68/71 Wool Felt Standard Specifications

3.1.7 part wool felt, n—a felt composed of any one of or a

2.4 SAE Standard:

combination of new and recycled wool fibers mixed with one

J314b Felts-Wool and Part Wool

or more man-made fibers, vegetable fibers, or animal fibers

3. Terminology

other than wool.

3.1.8 recycled wool, n— as defined in the Wool Products

3.1 Definitions:

Labeling Act of 1939 as amended in 1980, 88the resulting fiber

3.1.1 black felt, n—those classifications of felt manufac-

when wool has been woven or felted into a wool product

tured to various shades of the color black.

which, without ever having been utilized in any way by the

3.1.2 felt, n—a textile structure characterized by interlock-

ultimate consumer, subsequently has been made into a fibrous

ing and consolidation of its constituent fibers achieved by the

state, or the resulting fiber when wool or reprocessed wool has

interaction of a suitable combination of mechanical energy,

been spun, woven, knitted or felted into a wool product which,

chemical action, moisture, and heat but without the use of

after having been used in any way by the ultimate consumer,

weaving, knitting, stitching, thermal bonding, or adhesives.

subsequently has been made into a fibrous state.’’

3.1.8.1 Discussion—In the amended Act of 1980, the term

This specification is under the jurisdiction of ASTM Committee D-13 on

88recycled wool’’ replaced the terms 88reprocessed wool’’ and

Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool

Felt.

88reused wool.’’

Current edition approved April 29, 1988. Published June 1988. Originally

3.1.9 specialty felt, n—one of a number of special purpose

published as D 2475 – 65 T, replacing D 114. Last previous edition D 2475 – 88.

2 felt structures available for, but not limited to, a specific

Annual Book of ASTM Standards, Vol 07.01.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 end-use application.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from the Northern Textile Association, 230 Congress Street, Boston,

MA 02110.

5 6

Available from the Society of Automotive Engineers, 2 Pennsylvania Plaza, Act of Congress, “Wool Products Labeling Act of 1939,’’ 76th Congress, Third

New York, NY 10001. Session, approved October 14, 1939, the amended Act of 1980.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2475

3.1.9.1 Discussion—Orthopedic and surgical felts are ex- 3.1.15.1 Discussion—For the purpose of this standard, the

amples of specialty felts. Additional information on these types term 88wool’’ includes both wool as defined in the Wool

is available in NTA Specifications FS14-68/71. Products Labeling Act of 1939 as well as recycled wool as

3.1.10 specific gravity, n— of felt, the relative mass per unit defined in the amended Act of 1980.

volume of felt expressed as a percentage of the mass per unit

3.1.16 wool content, n—the quantity of new and recycled

volume of water.

wool, as defined in the Wool Products Labeling Act, which is

3.1.11 supported needled felt, n—a needled felt that is

determined by chemical analysis.

composed entirely of fibers physically interlocked and reori-

3.1.16.1 Discussion—Felt 34R1, as an example, which

ented in combination with interlay, scrim, or foundation of

theoretically is made from 100 % wool fiber, may contain

knitted, stitched, bonded, or extruded structure.

incidental amounts of other natural or man-made fibers, re-

3.1.12 unsupported needled felt, n—a needled felt that is

sidual wool fats and oils, and processing soaps which may

composed entirely of fibers physically interlocked and reori-

reduce the actual wool content on the chemical analysis basis

ented with, and of themselves without an interlay, scrim, or

to 95 %.

foundation of knitted, stitched, bonded, or extruded structure.

3.1.17 wool felt, n—a felt composed wholly of any one of or

3.1.13 white wool, n—wool having shade variations from

a combination of new or recycled wool fibers.

true white to creamy white but free of pigmented, dyed, or

3.1.18 For definitions of other textile terms, refer to Termi-

otherwise colored wools.

nology D 123.

3.1.13.1 Discussion—The shade variations in white wool

can be caused by range conditions including forage, soil, rain,

4. Types of Felts

or lack thereof as well as the health of the animal.

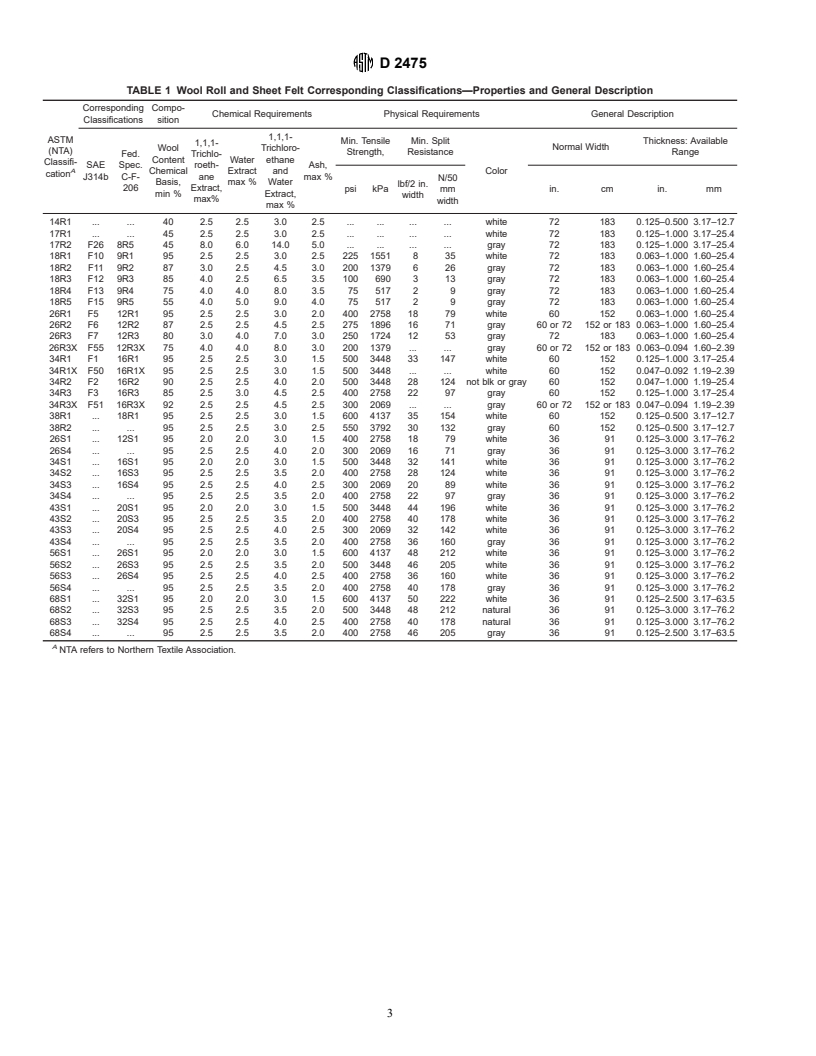

4.1 ASTM Classification:

3.1.14 wool, n—the fibrous covering of the sheep, Ovis

species. 4.1.1 The ASTM Classification number in Tables 1-3 is the

3.1.15 wool, n—as defined in the Wool Products Labeling percent specific gravity of that class. It may be computed from

Act of 1939, 88the fiber from the fleece of sheep or lamb, or hair the mass (weight), thickness, and area values in these tables.

of the Angora goat or Cashmere goat (and may include the so This number is followed by the letter R or S, which designates

called specialty fibers from the hair of the camel, alpaca, llama, the method of manufacture as roll or sheet form, respectively.

and vicuna) which has never been reclaimed from any woven The last digit is the overall quality index in decreasing order of

or felted wool product.’’ quality from one to four (see Note 1).

D 2475

TABLE 1 Wool Roll and Sheet Felt Corresponding Classifications—Properties and General Description

Corresponding Compo-

Chemical Requirements Physical Requirements General Description

Classifications sition

1,1,1-

ASTM

Min. Tensile Min. Split Thickness: Available

1,1,1-

Normal Width

Wool Trichloro-

(NTA)

Strength, Resistance Range

Fed. Trichlo-

Content Water ethane

Classifi-

SAE Spec. roeth- Ash,

A

Chemical Extract and Color

cation

J314b C-F- ane max %

N/50

Basis, max % Water

lbf/2 in.

206 Extract,

psi kPa mm in. cm in. mm

min % Extract,

width

max%

width

max %

14R1 . . 40 2.5 2.5 3.0 2.5 . . . . white 72 183 0.125–0.500 3.17–12.7

17R1 . . 45 2.5 2.5 3.0 2.5 . . . . white 72 183 0.125–1.000 3.17–25.4

17R2 F26 8R5 45 8.0 6.0 14.0 5.0 . . . . gray 72 183 0.125–1.000 3.17–25.4

18R1 F10 9R1 95 2.5 2.5 3.0 2.5 225 1551 8 35 white 72 183 0.063–1.000 1.60–25.4

18R2 F11 9R2 87 3.0 2.5 4.5 3.0 200 1379 6 26 gray 72 183 0.063–1.000 1.60–25.4

18R3 F12 9R3 85 4.0 2.5 6.5 3.5 100 690 3 13 gray 72 183 0.063–1.000 1.60–25.4

18R4 F13 9R4 75 4.0 4.0 8.0 3.5 75 517 2 9 gray 72 183 0.063–1.000 1.60–25.4

18R5 F15 9R5 55 4.0 5.0 9.0 4.0 75 517 2 9 gray 72 183 0.063–1.000 1.60–25.4

26R1 F5 12R1 95 2.5 2.5 3.0 2.0 400 2758 18 79 white 60 152 0.063–1.000 1.60–25.4

26R2 F6 12R2 87 2.5 2.5 4.5 2.5 275 1896 16 71 gray 60 or 72 152 or 183 0.063–1.000 1.60–25.4

26R3 F7 12R3 80 3.0 4.0 7.0 3.0 250 1724 12 53 gray 72 183 0.063–1.000 1.60–25.4

26R3X F55 12R3X 75 4.0 4.0 8.0 3.0 200 1379 . . gray 60 or 72 152 or 183 0.063–0.094 1.60–2.39

34R1 F1 16R1 95 2.5 2.5 3.0 1.5 500 3448 33 147 white 60 152 0.125–1.000 3.17–25.4

34R1X F50 16R1X 95 2.5 2.5 3.0 1.5 500 3448 . . white 60 152 0.047–0.092 1.19–2.39

34R2 F2 16R2 90 2.5 2.5 4.0 2.0 500 3448 28 124 not blk or gray 60 152 0.047–1.000 1.19–25.4

34R3 F3 16R3 85 2.5 3.0 4.5 2.5 400 2758 22 97 gray 60 152 0.125–1.000 3.17–25.4

34R3X F51 16R3X 92 2.5 2.5 4.5 2.5 300 2069 . . gray 60 or 72 152 or 183 0.047–0.094 1.19–2.39

38R1 . 18R1 95 2.5 2.5 3.0 1.5 600 4137 35 154 white 60 152 0.125–0.500 3.17–12.7

38R2 . . 95 2.5 2.5 3.0 2.5 550 3792 30 132 gray 60 152 0.125–0.500 3.17–12.7

26S1 . 12S1 95 2.0 2.0 3.0 1.5 400 2758 18 79 white 36 91 0.125–3.000 3.17–76.2

26S4 . . 95 2.5 2.5 4.0 2.0 300 2069 16 71 gray 36 91 0.125–3.000 3.17–76.2

34S1 . 16S1 95 2.0 2.0 3.0 1.5 500 3448 32 141 white 36 91 0.125–3.000 3.17–76.2

34S2 . 16S3 95 2.5 2.5 3.5 2.0 400 2758 28 124 white 36 91 0.125–3.000 3.17–76.2

34S3 . 16S4 95 2.5 2.5 4.0 2.5 300 2069 20 89 white 36 91 0.125–3.000 3.17–76.2

34S4 . . 95 2.5 2.5 3.5 2.0 400 2758 22 97 gray 36 91 0.125–3.000 3.17–76.2

43S1 . 20S1 95 2.0 2.0 3.0 1.5 500 3448 44 196 white 36 91 0.125–3.000 3.17–76.2

43S2 . 20S3 95 2.5 2.5 3.5 2.0 400 2758 40 178 white 36 91 0.125–3.000 3.17–76.2

43S3 . 20S4 95 2.5 2.5 4.0 2.5 300 2069 32 142 white 36 91 0.125–3.000 3.17–76.2

43S4 . . 95 2.5 2.5 3.5 2.0 400 2758 36 160 gray 36 91 0.125–3.000 3.17–76.2

56S1 . 26S1 95 2.0 2.0 3.0 1.5 600 4137 48 212 white 36 91 0.125–3.000 3.17–76.2

56S2 . 26S3 95 2.5 2.5 3.5 2.0 500 3448 46 205 white 36 91 0.125–3.000 3.17–76.2

56S3 . 26S4 95 2.5 2.5 4.0 2.5 400 2758 36 160 white 36 91 0.125–3.000 3.17–76.2

56S4 . . 95 2.5 2.5 3.5 2.0 400 2758 40 178 gray 36 91 0.125–3.000 3.17–76.2

68S1 . 32S1 95 2.0 2.0 3.0 1.5 600 4137 50 222 white 36 91 0.125–2.500 3.17–63.5

68S2 . 32S3 95 2.5 2.5 3.5 2.0 500 3448 48 212 natural 36 91 0.125–3.000 3.17–76.2

68S3 . 32S4 95 2.5 2.5 4.0 2.5 400 2758 40 178 natural 36 91 0.125–3.000 3.17–76.2

68S4 . . 95 2.5 2.5 3.5 2.0 400 2758 46 205 gray 36 91 0.125–2.500 3.17–63.5

A

NTA refers to Northern Textile Association.

D 2475

TABLE 2 Wool Roll Felt Thicknesses and Weights

NOTE 1—The F-50, F-51, and F-55 classifications are available in limited thickness ranges. See Table 1.

ASTM Thickness Tolerances Mass (Weight) Per Unit Area

(NTA) SAE Fed. Spec. Trade Designa-

Color Inches Millimetres Nominal Tolerances

Classifi- J314b C-F-206 tion

Nominal Nominal

2 2

cation Roll Cutparts Roll Cutparts lb/yd kg/m

14R1 . . White Soft Pad 0.125 6 6 3.18 6 1.02 6 1.22 0.83 6 0.10 0.45 6 0.05

0.040 0.048

0.250 0.056 0.064 6.35 1.42 1.63 1.65 0.20 0.90 0.11

0.375 0.072 0.082 9.53 1.83 2.08 2.48 0.30 1.35 0.16

0.500 0.088 0.098 12.70 2.24 2.49 3.30 0.40 1.79 0.22

17R1 . . White Soft Pad 0.125 0.040 0.044 3.18 1.02 1.12 0.9 0.09 0.49 0.05

17R2 F-26 8R5 Gray 0.250 0.056 0.062 6.35 1.42 1.58 1.8 0.18 0.98 0.10

0.375 0.072 0.079 9.53 1.83 2.01 2.7 0.27 1.47 0.15

0.500 0.088 0.098 12.70 2.24 2.49 3.6 0.36 1.95 0.20

0.750 0.120 0.135 19.05 3.05 3.43 5.4 0.54 2.93 0.29

1.000 0.152 0.170 25.40 3.86 4.32 7.2 0.72 3.91 0.39

18R1 F-10 9R1 White Firm Pad 0.125 0.020 0.023 3.18 0.51 0.58 1.06 0.08 0.58 0.04

18R2 F-11 9R2 Gray Firm Pad 0.188 0.023 0.026 4.78 0.58 0.66 1.59 0.12 0.86 0.07

18R3 F-12 9R3 Gray Firm Pad 0.250 0.026 0.031 6.35 0.66 0.79 2.12 0.16 1.15 0.09

18R4 F-13 9R4 Gray Firm Pad 0.313 0.029 0.033 7.95 0.74 0.84 2.65 0.20 1.44 0.11

18R5 F-15 9R5 Gray Firm Pad 0.375 0.032 0.036 9.53 0.81 0.91 3.18 0.24 1.73 0.13

0.500 0.038 0.044 12.70 0.97 1.12 4.24 0.32 2.31 0.18

0.625 0.044 0.050 15.88 1.12 1.27 5.30 0.40 2.89 0.22

0.750 0.050 0.060 19.05 1.27 1.52 6.36 0.48 3.46 0.26

0.875 0.056 0.065 22.23 1.42 1.65 7.42 0.56 4.03 0.30

1.000 0.062 0.070 25.40 1.58 1.78 8.48 0.64 4.62 0.35

26R1 F-5 12R1 White Ex Firm Pad 0.063 0.007 0.012 1.60 0.18 0.31 0.75 0.04 0.41 0.02

26R2 F-6 12R2 Gray Ex Firm Pad 0.094 0.007 0.012 2.39 0.18 0.31 1.12 0.05 0.61 0.03

26R3 F-7 12R3 Gray Ex Firm Pad & 0.125 0.014 0.016 3.18 0.36 0.41 1.53 0.08 0.83 0.04

Gray or Black 0.188 0.016 0.018 4.78 0.41 0.46 2.29 0.12 1.24 0.07

26R3X F-55 12R3X . Lining 0.250 0.018 0.020 6.35 0.46 0.51 3.06 0.16 1.66 0.09

0.313 0.020 0.022 7.95 0.51 0.56 3.82 0.20 2.07 0.11

0.375 0.022 0.025 9.53 0.56 0.64 4.59 0.24 2.49 0.13

0.500 0.026 0.029 12.70 0.66 0.74 6.12 0.32 3.32 0.18

0.625 0.030 0.033 15.88 0.76 0.84 7.65 0.40 4.15 0.22

0.750 0.034 0.038 19.05 0.86 0.97 9.18 0.48 4.98 0.26

0.875 0.038 0.042 22.23 0.97 1.07 10.71 0.56 5.82 0.30

1.000 0.042 0.046 25.40 1.07 1.17 12.24 0.64 6.65 0.35

34R1 F-1 16R1 White Backcheck & 0.047 0.007 0.010 1.19 0.18 0.25 0.75 0.04 0.41 0.02

34R1X F-50 16R1X White Ball Bearing 0.063 0.007 0.010 1.60 0.18 0.25 0.98 0.04 0.53 0.02

34R2 F-2 16R2 Not Black Backcheck 0.078 0.007 0.010 1.98 0.18 0.25 1.20 0.04 0.65 0.02

or Gray 0.094 0.007 0.011 2.39 0.18 0.28 1.43 0.04 0.78 0.02

34R3 F-3 16R3 Gray Backcheck & 0.125 0.012 0.015 3.18 0.31 0.38 2.00 0.10 1.09 0.05

34R3X F-51 16R3X Gray Ball Bearing 0.188 0.013 0.017 4.78 0.33 0.43 3.00 0.15 1.63 0.08

0.250 0.014 0.020 6.35 0.36 0.51 4.00 0.20 2.17 0.11

0.313 0.015 0.021 7.95 0.38 0.53 5.00 0.25 2.72 0.14

0.375 0.016 0.023 9.53 0.41 0.58 6.00 0.30 3.26 0.16

0.500 0.019 0.025 12.70 0.48 0.64 8.00 0.40 4.34 0.22

0.625 0.022 0.027 15.88 0.56 0.69 10.00 0.50 5.43 0.27

0.750 0.025 0.030 19.05 0.64 0.76 12.00 0.60 6.52 0.33

0.875 0.028 0.035 22.23 0.71 0.89 14.00 0.70 7.60 0.38

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.