ASTM D2475-00

(Specification)Standard Specification for Felt

Standard Specification for Felt

SCOPE

1.1 This specification covers all standard types of felt in the form of rolls and sheets that are suitable for mechanical use. Certain special-purpose felts are also covered.

1.2 This specification is not applicable to felt-like products that utilize weaving, knitting, stitching, or bonding such as papermaker's felt.

1.3 Trade practice in the felt industry deals in pounds, yards, and inches, therefore the values stated in inch-pound units are to be regarded as standard. The values in SI units are provided as information only.

1.3.1 The specification referenced in 2.2 uses only inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2475 – 00

Standard Specification for

1

Felt

This standard is issued under the fixed designation D 2475; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

6

1. Scope 2.4 SAE Standard:

J314b Felts-Wool and Part Wool

1.1 This specification covers all standard types of felt in the

form of rolls and sheets that are suitable for mechanical use.

3. Terminology

Certain special-purpose felts are also covered.

3.1 Definitions:

1.2 This specification is not applicable to felt-like products

3.1.1 felt, n—a textile structure characterized by interlock-

that utilize weaving, knitting, stitching, or bonding such as

ing and consolidation of its constituent fibers.

papermaker’s felt.

3.1.2 machined felt, n—a felt structure achieved by the

1.3 Trade practice in the felt industry deals in pounds, yards,

interaction of a suitable combination of mechanical energy,

and inches, therefore the values stated in inch-pound units are

chemical action, moisture and heat causing the constituent

to be regarded as standard. The values in SI units are provided

fibers to migrate and interlock.

as information only.

3.1.3 needled felt, n—a structure composed entirely of

1.3.1 The specification referenced in 2.2 uses only inch-

fibers physically interlocked and reoriented through the action

pound units.

of felting needles.

2. Referenced Documents 3.1.4 For standard terminology relating to wool, refer to

Terminology D 4845.

2.1 ASTM Standards:

2

3.1.5 For definitions of other textile terms used in these test

D 123 Terminology Relating to Textiles

2 methods, refer to Terminology D 123.

D 461 Test Methods for Felt

3

3.1.5.1 Discussion—For the purpose of this document, there

D 4845 Terminology Relating to Wool

are only two types of felt, machined and needled. All other

2.2 Federal Standard:

4

terms alluded to as types of felt, such as papermakers, black,

C-F-206, Felt Sheet: Cloth Felt, Wool, Pressed

unsupported, supported, part wool, wool, etc. are considered to

2.3 Felt Manufacturers Council:

5

be simply terms describing attributes of these two types of

FS14-68/71 Wool Felt Standard Specifications

felts.

3.1.6 relative density, n—the ratio of the mass of a volume

of felt to the mass of an equivalent volume of water, alterna-

tively, use density.

4. Types of Felts

4.1 ASTM Classification:

1

4.1.1 The ASTM Classification number in Tables 1-3 is the

This specification is under the jurisdiction of ASTM Committee D13 on

Textiles and is the direct responsibility of Subcommittee D13.13 on Wool and Wool percent specific gravity of that class. It may be computed from

Felt.

the mass (weight), thickness, and area values in these tables.

Current edition approved Nov. 10, 2000. Published February 2001. Originally

This number is followed by the letter R or S, which designates

published as D 2475 – 65 T, replacing D 114. Last previous edition D 2475 – 88

the method of manufacture as roll or sheet form, respectively.

(2000).

2

Annual Book of ASTM Standards, Vol 07.01.

The last digit is the overall quality index in decreasing order of

3

Annual Book of ASTM Standards, Vol 07.02.

quality from one to four (see Note 1).

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5 6

Available from the Northern Textile Association, 230 Congress Street, Boston, Available from the Society of Automotive Engineers, 2 Pennsylvania Plaza,

MA 02110. New York, NY 10001.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 2475

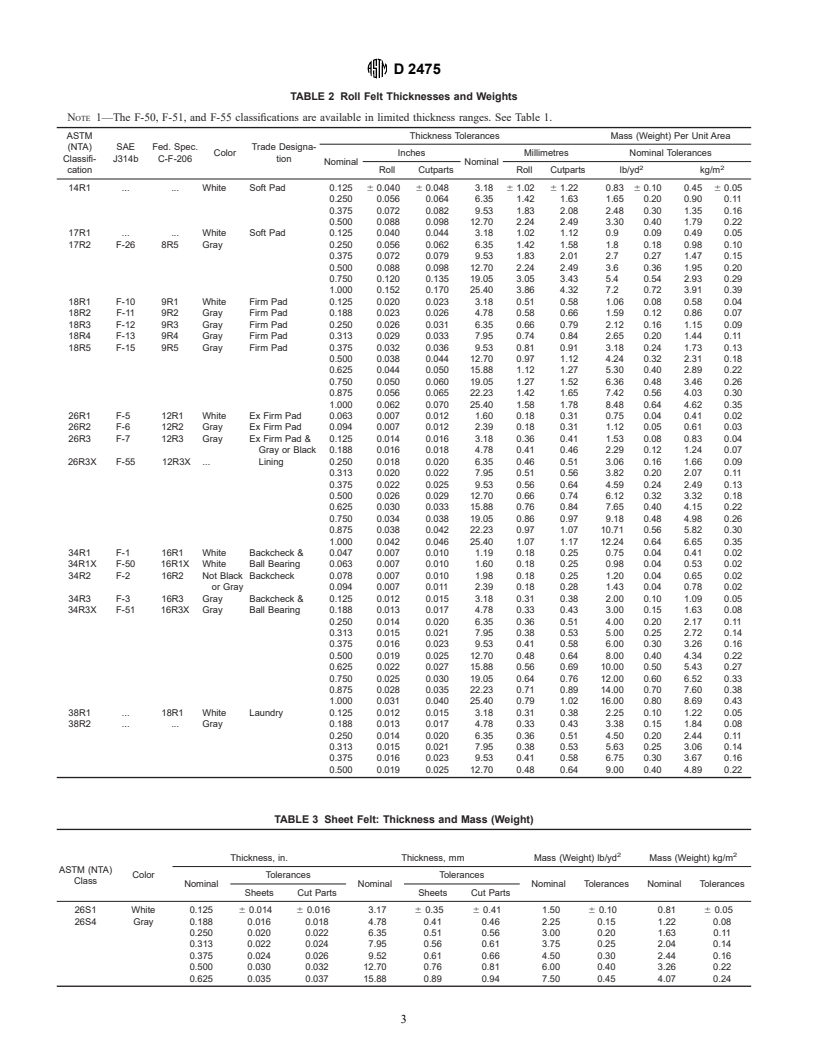

TABLE 1 Roll and Sheet Felt Corresponding Classifications—Properties and General Description

Corresponding

Physical Requirements General Description

Classifications

ASTM

Min. Tensile Min. Split

(NTA) Normal Width Thickness: Available Range

Fed.

Strength, Resistance

Classifi-

SAE Spec.

A

Color

cation

N/50

J314b C-F-

lbf/2 in.

psi kPa mm in. cm in. mm

206

width

width

14R1 . . . . . . white 72 183 0.125–0.500 3.17–12.7

17R1 . . . . . . white 72 183 0.125–1.000 3.17–25.4

17R2 F26 8R5 . . . . gray 72 183 0.125–1.000 3.17–25.4

18R1 F10 9R1 225 1551 8 35 white 72 183 0.063–1.000 1.60–25.4

18R2 F11 9R2 200 1379 6 26 gray 72 183 0.063–1.000 1.60–25.4

18R3 F12 9R3 100 690 3 13 gray 72 183 0.063–1.000 1.60–25.4

18R4 F13 9R4 75 517 2 9 gray 72 183 0.063–1.000 1.60–25.4

18R5 F15 9R5 75 517 2 9 gray 72 183 0.063–1.000 1.60–25.4

26R1 F5 12R1 400 2758 18 79 white 60 152 0.063–1.000 1.60–25.4

26R2 F6 12R2 275 1896 16 71 gray 60 or 72 152 or 183 0.063–1.000 1.6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.