ASTM D5947-06

(Test Method)Standard Test Methods for Physical Dimensions of Solid Plastics Specimens

Standard Test Methods for Physical Dimensions of Solid Plastics Specimens

SIGNIFICANCE AND USE

These test methods shall be used where precise dimensions are necessary for the calculation of properties expressed in physical units. They are not intended to replace practical thickness measurements based on commercial portable tools, nor is it implied that thickness measurements made by the procedures will agree exactly.

SCOPE

1.1 These test methods cover determination of the physical dimensions of solid plastic specimens where the dimensions are used directly in determining the results of tests for various properties. Use these test methods except as otherwise required in material specifications.

1.2 The values stated in SI units are to be regarded as standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5947 – 06

Standard Test Methods for

1

Physical Dimensions of Solid Plastics Specimens

This standard is issued under the fixed designation D5947; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 These test methods cover determination of the physical 3.1 Definitions—See Terminologies D883 and D4805, and

dimensions of solid plastic specimens where the dimensions ISO 472 for definitions pertinent to these test methods.

are used directly in determining the results of tests for various 3.2 Definitions of Terms Specific to This Standard:

properties.Usethesetestmethodsexceptasotherwiserequired 3.2.1 absolute uncertainty (of a measurement), n—the

in material specifications. smallest division that may be read directly on the instrument

1.2 The values stated in SI units are to be regarded as used for measurement.

standard. 3.2.2 calibration—the set of operations that establishes,

1.3 This standard does not purport to address all of the under specified conditions, the relationship between values

safety concerns, if any, associated with its use. It is the measured or indicated by an instrument or system, and the

responsibility of the user of this standard to establish appro- corresponding reference standard or known values derived

priate safety and health practices and determine the applica- from the appropriate reference standards.

bility of regulatory limitations prior to use. 3.2.3 micrometer, n—an instrument for measuring any di-

mension within absolute uncertainty of 25 µm or smaller.

NOTE 1—There is no similar or equivalent ISO standard.

3.2.4 verification—proof, with the use of calibrated stan-

dards or standard reference materials, that the calibrated

2. Referenced Documents

2 instrument is operating within specified requirements.

2.1 ASTM Standards:

3.2.5 1 mil, n—a dimension equivalent to 25 µm [0.0010

D618 Practice for Conditioning Plastics for Testing

in.].

D638 Test Method for Tensile Properties of Plastics

D790 Test Methods for Flexural Properties of Unreinforced

4. Summary of Test Methods

and Reinforced Plastics and Electrical Insulating Materials

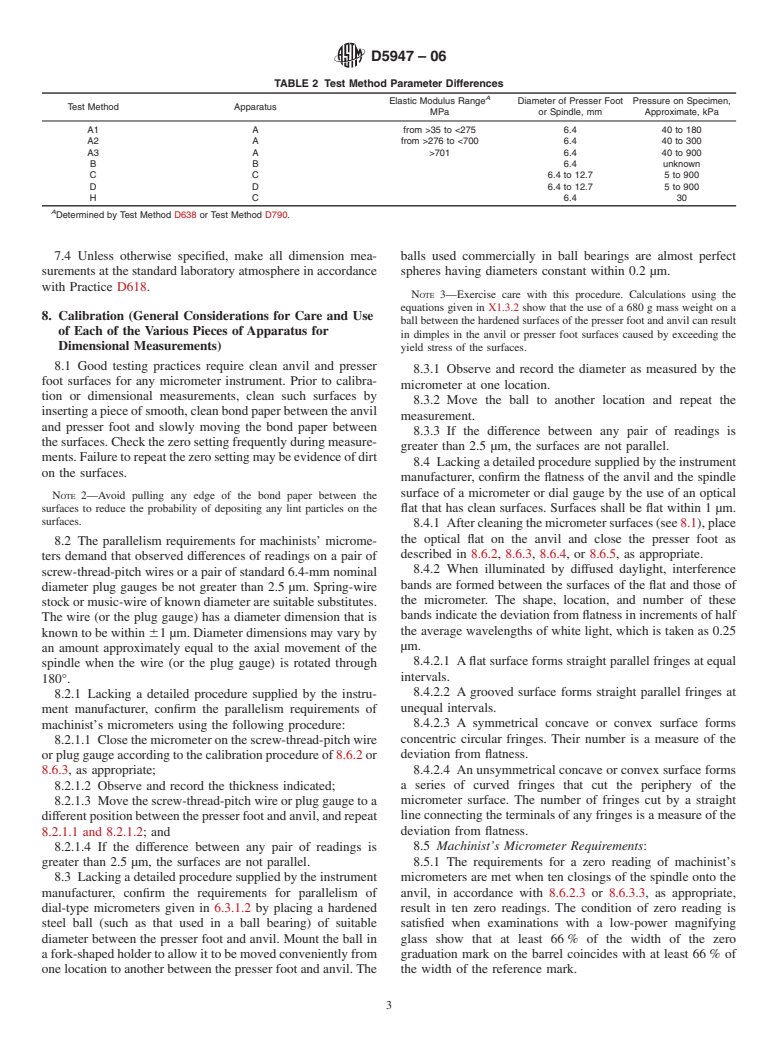

4.1 These test methods provide five different test methods

D883 Terminology Relating to Plastics

for the measurement of physical dimensions of solid plastic

D2240 Test Method for Rubber Property—Durometer

specimens. The test methods (identified as Test Methods A

Hardness

through D, and H) use different micrometers that exert various

3

D4805 Terminology for Plastics Standards

pressures for varying times upon specimens of different geom-

2.2 ISO Standard:

etries. Tables 1 and 2 display the basic differences of each test

4

ISO 472 Plastics—Vocabulary

method and identify methods applicable for use on various

plastics materials.

1

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical 5. Significance and Use

Properties.

5.1 These test methods shall be used where precise dimen-

Current edition approved April 1, 2006. Published May 2006. Originally

sions are necessary for the calculation of properties expressed

approved in 1996. Last previous edition approved in 2003 as D5947 – 03. DOI:

10.1520/D5947-06.

in physical units. They are not intended to replace practical

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

thickness measurements based on commercial portable tools,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

nor is it implied that thickness measurements made by the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. procedures will agree exactly.

3

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

4

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5947 – 06

TABLE 1 Test Methods Suitable for Specific Materials

with the presser foot spindle (or any weight attached thereto),

Material Test Method will produce a deflection of the frame not greater than the

Plastics specimens A, B, C, or D

smallest scale division or digital count on the indicator; and

A

Other elastomers H

6.3.1.6 A dial diameter at least 50 mm and graduated

A

Materials with D2240 TypeAhardness of 30 to 80 (approximately equivalent to

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.