ASTM D5705-03(2008)

(Test Method)Standard Test Method for Measurement of Hydrogen Sulfide in the Vapor Phase Above Residual Fuel Oils

Standard Test Method for Measurement of Hydrogen Sulfide in the Vapor Phase Above Residual Fuel Oils

SIGNIFICANCE AND USE

Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H2S in the tank atmosphere for those working in the vicinity require a consistent method for the assessment of potentially hazardous levels of H2S in fuel oils (Warning—H2S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are suspected of containing high levels of H2S.).

This test method has been developed to provide refineries, fuel terminals, and independent testing laboratories, which do not have access to analytical instruments such as a gas chromatograph, with a simple and consistent field test method for the rapid determination of H2S in the vapor phase of residual fuel oils.

This test method does not necessarily simulate the vapor phase H2S concentration of a fuel storage tank. It does, however, provide a level of consistency so that the test result is only a function of the residual fuel oil sample and not the test method, operator, or location. No general correlation can be established between this field test and actual vapor phase concentrations of H2S in residual fuel oil storage or transports. However, a facility that produces fuel oil from the same crude source under essentially constant conditions might be able to develop a correlation for its individual case.

SCOPE

1.1 This test method covers the field determination of hydrogen sulfide (H2S) in the vapor phase (equilibrium headspace) of a residual fuel oil sample.

1.2 The test method is applicable to liquids with a viscosity range of 5.5 mm2/s at 40°C to 50 mm2/s at 100°C. The test method is applicable to fuels conforming to Specification D 396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5705 – 03 (Reapproved 2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

1

Above Residual Fuel Oils

This standard is issued under the fixed designation D5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope refining process and lighter distillates blended to a fuel oil

viscosity specification.

1.1 This test method covers the field determination of

3.1.2.1 Discussion—Under the conditions of this test (1:1

hydrogen sulfide (H S) in the vapor phase (equilibrium head-

2

liquid/vapor ratio, temperature, and agitation) the HSinthe

space) of a residual fuel oil sample. 2

vapor phase (sample’s headspace) will be in equilibrium with

1.2 The test method is applicable to liquids with a viscosity

2 2

the H S in the liquid phase.

range of 5.5 mm /s at 40°C to 50 mm /s at 100°C. The test 2

methodisapplicabletofuelsconformingtoSpecificationD396

4. Summary of Test Method

Grade Nos. 4, 5 (Heavy), and 6.

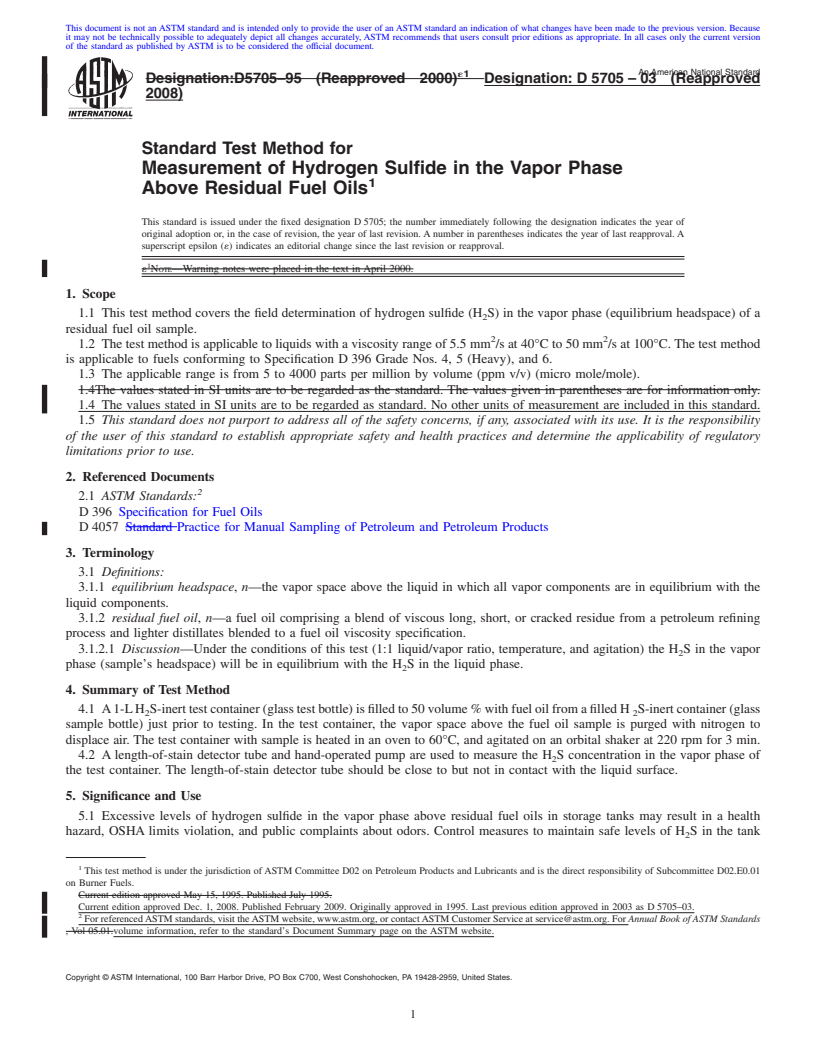

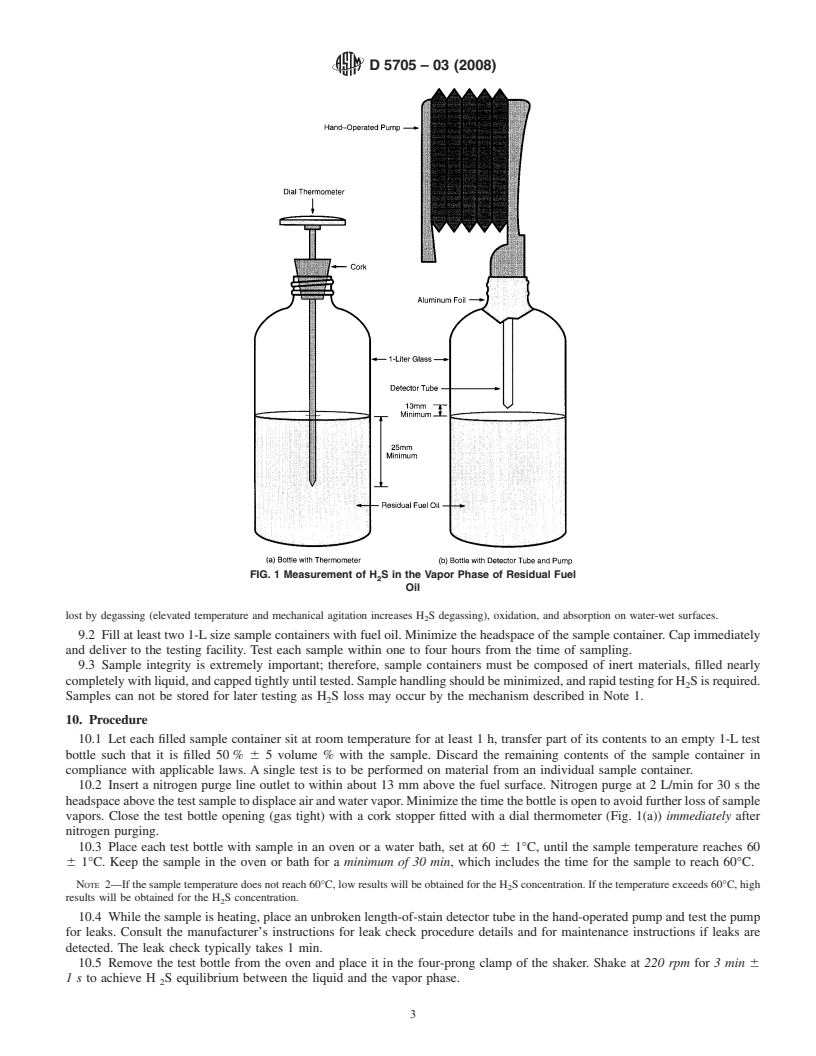

4.1 A1-LH S-inert test container (glass test bottle) is filled

2

1.3 The applicable range is from 5 to 4000 parts per million

to 50 volume % with fuel oil from a filled H S-inert container

2

by volume (ppm v/v) (micro mole/mole).

(glass sample bottle) just prior to testing. In the test container,

1.4 The values stated in SI units are to be regarded as

the vapor space above the fuel oil sample is purged with

standard. No other units of measurement are included in this

nitrogen to displace air. The test container with sample is

standard.

heated in an oven to 60°C, and agitated on an orbital shaker at

1.5 This standard does not purport to address all of the

220 rpm for 3 min.

safety concerns, if any, associated with its use. It is the

4.2 Alength-of-stain detector tube and hand-operated pump

responsibility of the user of this standard to establish appro-

are used to measure the H S concentration in the vapor phase

2

priate safety and health practices and determine the applica-

of the test container. The length-of-stain detector tube should

bility of regulatory limitations prior to use.

be close to but not in contact with the liquid surface.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards:

5.1 Excessive levels of hydrogen sulfide in the vapor phase

D396 Specification for Fuel Oils

above residual fuel oils in storage tanks may result in a health

D4057 Practice for Manual Sampling of Petroleum and

hazard, OSHA limits violation, and public complaints about

Petroleum Products

odors. Control measures to maintain safe levels of HSinthe

2

3. Terminology tank atmosphere for those working in the vicinity require a

consistent method for the assessment of potentially hazardous

3.1 Definitions:

levels of H S in fuel oils (Warning—H S is a highly toxic

2 2

3.1.1 equilibrium headspace, n—the vapor space above the

substance. Use extreme care in the sampling and handling of

liquid in which all vapor components are in equilibrium with

samples that are suspected of containing high levels of H S.).

2

the liquid components.

5.2 This test method has been developed to provide refin-

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of

eries, fuel terminals, and independent testing laboratories,

viscous long, short, or cracked residue from a petroleum

which do not have access to analytical instruments such as a

gas chromatograph, with a simple and consistent field test

1

This test method is under the jurisdiction of ASTM Committee D02 on method for the rapid determination of H S in the vapor phase

2

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

of residual fuel oils.

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

5.3 Thistestmethoddoesnotnecessarilysimulatethevapor

Current edition approved Dec. 1, 2008. Published February 2009. Originally

phase H S concentration of a fuel storage tank. It does,

approved in 1995. Last previous edition approved in 2003 as D5705–03. DOI:

2

10.1520/D5705-03R08.

however, provide a level of consistency so that the test result is

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

only a function of the residual fuel oil sample and not the test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

method, operator, or location. No general correlation can be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. established between this field test and actual vapor phase

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-------------------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D5705–03 Designation: D 5705 – 03 (Reapproved 2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

1

Above Residual Fuel Oils

This standard is issued under the fixed designation D 5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 This test method covers the field determination of hydrogen sulfide (H S) in the vapor phase (equilibrium headspace) of a

2

residual fuel oil sample.

2 2

1.2 The test method is applicable to liquids with a viscosity range of 5.5 mm /s at 40°C to 50 mm /s at 100°C. The test method

is applicable to fuels conforming to Specification D 396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 396 Specification for Fuel Oils

D 4057 Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 equilibrium headspace, n—the vapor space above the liquid in which all vapor components are in equilibrium with the

liquid components.

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of viscous long, short, or cracked residue from a petroleum refining

process and lighter distillates blended to a fuel oil viscosity specification.

3.1.2.1 Discussion—Under the conditions of this test (1:1 liquid/vapor ratio, temperature, and agitation) the H S in the vapor

2

phase (sample’s headspace) will be in equilibrium with the H S in the liquid phase.

2

4. Summary of Test Method

4.1 A1-LH S-inerttestcontainer(glasstestbottle)isfilledto50volume %withfueloilfromafilledH S-inertcontainer(glass

2 2

sample bottle) just prior to testing. In the test container, the vapor space above the fuel oil sample is purged with nitrogen to

displace air. The test container with sample is heated in an oven to 60°C, and agitated on an orbital shaker at 220 rpm for 3 min.

4.2 A length-of-stain detector tube and hand-operated pump are used to measure the H S concentration in the vapor phase of

2

the test container. The length-of-stain detector tube should be close to but not in contact with the liquid surface.

5. Significance and Use

5.1 Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health

hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H S in the tank

2

atmosphere for those working in the vicinity require a consistent method for the assessment of potentially hazardous levels of H S

2

in fuel oils ( Warning—H S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are

2

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0 on

Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

´1

Current edition approved Nov. 1, 2003. Published December 2003. Originally approved in 1995. Last previous edition approved in 2000 as D5705–95(2000) .on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01 on Burner Fuels.

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1995. Last previous edition approved in 2003 as D 5705–03.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D5705–95 (Reapproved 2000) Designation: D 5705 – 03 (Reapproved

2008)

Standard Test Method for

Measurement of Hydrogen Sulfide in the Vapor Phase

1

Above Residual Fuel Oils

This standard is issued under the fixed designation D5705; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Warning notes were placed in the text in April 2000.

1. Scope

1.1 This test method covers the field determination of hydrogen sulfide (H S) in the vapor phase (equilibrium headspace) of a

2

residual fuel oil sample.

2 2

1.2 Thetestmethodisapplicabletoliquidswithaviscosityrangeof5.5mm /sat40°Cto50mm /sat100°C.Thetestmethod

is applicable to fuels conforming to Specification D396 Grade Nos. 4, 5 (Heavy), and 6.

1.3 The applicable range is from 5 to 4000 parts per million by volume (ppm v/v) (micro mole/mole).

1.4The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D396 Specification for Fuel Oils

D4057 Standard Practice for Manual Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions:

3.1.1 equilibrium headspace, n—the vapor space above the liquid in which all vapor components are in equilibrium with the

liquid components.

3.1.2 residual fuel oil, n—a fuel oil comprising a blend of viscous long, short, or cracked residue from a petroleum refining

process and lighter distillates blended to a fuel oil viscosity specification.

3.1.2.1 Discussion—Under the conditions of this test (1:1 liquid/vapor ratio, temperature, and agitation) the H S in the vapor

2

phase (sample’s headspace) will be in equilibrium with the H S in the liquid phase.

2

4. Summary of Test Method

4.1 A1-LH S-inerttestcontainer(glasstestbottle)isfilledto50volume%withfueloilfromafilledH S-inertcontainer(glass

2 2

sample bottle) just prior to testing. In the test container, the vapor space above the fuel oil sample is purged with nitrogen to

displace air. The test container with sample is heated in an oven to 60°C, and agitated on an orbital shaker at 220 rpm for 3 min.

4.2 Alength-of-stain detector tube and hand-operated pump are used to measure the H S concentration in the vapor phase of

2

the test container. The length-of-stain detector tube should be close to but not in contact with the liquid surface.

5. Significance and Use

5.1 Excessive levels of hydrogen sulfide in the vapor phase above residual fuel oils in storage tanks may result in a health

hazard, OSHA limits violation, and public complaints about odors. Control measures to maintain safe levels of H S in the tank

2

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.E0.01

on Burner Fuels.

Current edition approved May 15, 1995. Published July 1995.

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1995. Last previous edition approved in 2003 as D5705–03.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5705 – 03 (2008)

atmosphereforthoseworkinginthevicinityrequireaconsistentmethodfortheassessmentofpotentiallyhazardouslevelsofH S

2

in fuel oils ( Warning—H S is a highly toxic substance. Use extreme care in the sampling and handling of samples that are

2

suspected of containing high levels of H S.).

2

5.2 This test method has been developed to provide refineries, fuel terminals, and independent testing laboratories, which do

nothaveaccesstoanalyticalins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.