ASTM D6526-00

(Test Method)Standard Test Method for Analysis of Toluene by Capillary Column Gas Chromatography

Standard Test Method for Analysis of Toluene by Capillary Column Gas Chromatography

SCOPE

1.1 This test method covers the determination of hydrocarbon impurities typically found in, and the purity of, samples containing 98 wt % and greater toluene. This test method is applicable to impurity concentrations in the range of 0.0010 to 0.500 wt %.

1.2 Monocyclic aromatic hydrocarbons containing 6 through 8 carbon atoms, cumene, 1,4-dioxane, and nonaromatic aliphatic hydrocarbons containing up to 12 carbon atoms can be detected by this test method. The nonaromatic compounds are determined as a composite.

1.3 The following applies to all specified limits in this test method: for purposes of determining conformance with this test method, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6526 – 00

Standard Test Method for

Analysis of Toluene by Capillary Column Gas

Chromatography

This standard is issued under the fixed designation D 6526; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1510 Practice for Installing Fused Silica Open Tubular

Capillary Columns in Gas Chromatographs

1.1 This test method covers the determination of hydrocar-

2.2 Other Document:

bon impurities typically found in, and the purity of, samples

OSHA Regulations, 29 CFR, paragraphs 1910.1000 and

containing 98 wt % and greater toluene. This test method is

1910.1200

applicable to impurity concentrations in the range of 0.0010 to

0.500 wt %.

3. Terminology

1.2 Monocyclic aromatic hydrocarbons containing 6

3.1 See Terminology D 4790 for definitions of terms used in

through 8 carbon atoms, cumene, 1,4–dioxane, and nonaro-

this test method.

matic aliphatic hydrocarbons containing up to 12 carbon atoms

can be detected by this test method. The nonaromatic com-

4. Summary of Test Method

pounds are determined as a composite.

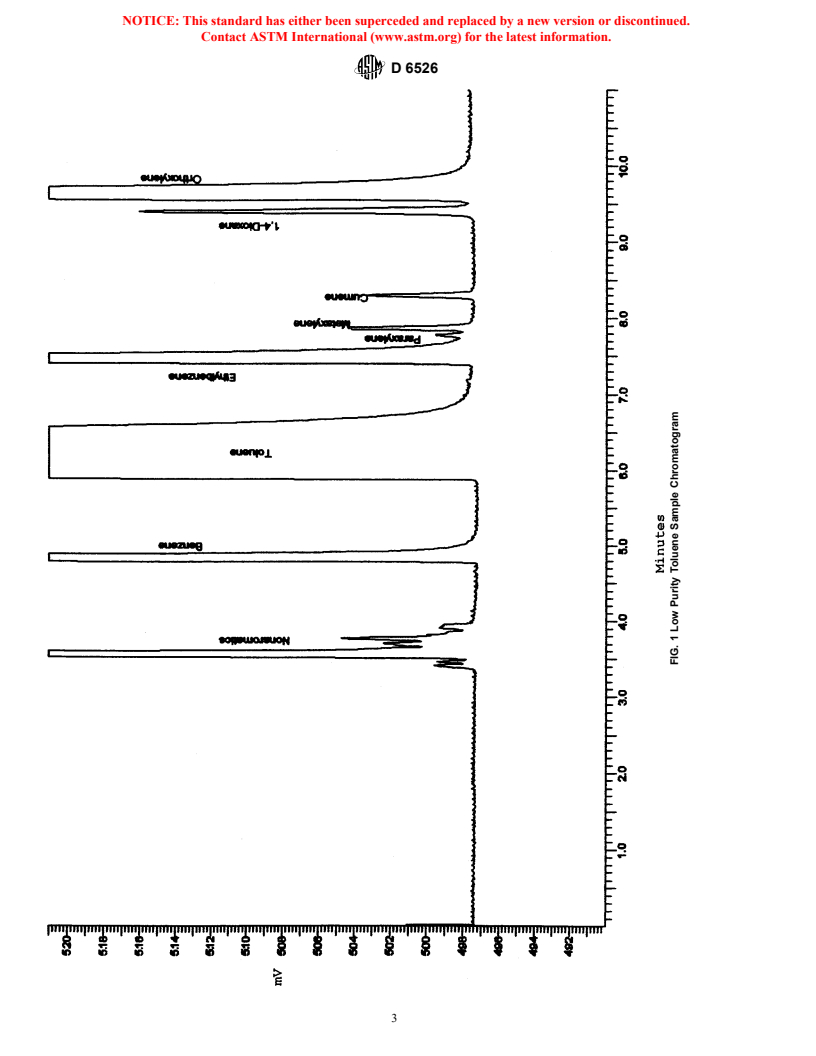

4.1 A portion of the sample is injected into a gas chromato-

1.3 The following applies to all specified limits in this test

graph using a microlitre syringe at the specified conditions of

method: for purposes of determining conformance with this

the test method. The toluene and other components are

test method, an observed value or a calculated value shall be

separated as they are transported through the column by an

rounded off “to the nearest unit” in the last right-hand digit

inert carrier gas. The components in the effluent are measured

used in expressing the specification limit, in accordance with

by a flame ionization detector (FID). The area of the impurity

the rounding-off method of Practice E 29.

peaks and toluene are electronically integrated. The peak areas

1.4 This standard does not purport to address all of the

are corrected with effective carbon number (ECN) response

safety concerns, if any, associated with its use. It is the

factors and normalized to 100.0000 %.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use. For specific hazard

5.1 This test method is suitable for determining the concen-

statements, see Section 9.

trations of known impurities in refined toluene and for use as

an integral quality control tool where toluene is produced or

2. Referenced Documents

used in manufacturing.

2.1 ASTM Standards:

5.2 Toluene purity is reported, but a chromatographic analy-

D 3437 Practice for Sampling and Handling Liquid Cyclic

2 sis cannot determine absolute purity if unknown or undetected

Products

components are present in the sample.

D 4790 Terminology of Aromatic Hydrocarbons and Re-

lated Chemicals

6. Interferences

E 29 Practice for Using Significant Digits in Test Data to

6.1 If present, nonaromatic hydrocarbons of 13 carbons or

Determine Conformance with Specifications

greater, alcohols, ethers, and other similar organic compounds

E 355 Practice for Gas Chromatography Terms and Rela-

can interfere with this test method by co-eluting with the

tionships

aromatic hydrocarbons.

E 691 Practice for Conducting an Interlaboratory Study to

6.2 Compounds not detected by a FID are not determined by

Determine the Precision of a Test Method

this test method.

6.3 Nonvolatile material is not determined.

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

Subcommittee D16.01 on Benzene, Toluene, Xylenes, Cyclohexane, and Their Available from the Superintendent of Documents, U.S. Government Printing

Derivatives. Office, Washington, DC 20402.

Current edition approved Feb. 10, 2000. Published April 2000. Scanlon, J. T., and Willis, D. E., “Calculation of Ionization Detector Relative

Annual Book of ASTM Standards, Vol 06.04. Response Factors Using the Effective Carbon Number Concept”, Journal of

Annual Book of ASTM Standards, Vol 014.02. Chromatographic Science, Vol 35, August, 1985, pp. 333-339.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6526

7. Apparatus Safety Data Sheets, and local regulations for all materials used

in this test method.

7.1 Gas Chromatograph (GC)—any GC built for capillary

column chromatography. The system shall have sufficient

10. Sample Handling

sensitivity, linearity, and range to obtain a minimum peak

10.1 Collect the samples in accordance with Practice

height response for 0.0010 wt % impurity of twice the height

D 3437.

of the signal background noise, while not exceeding the full

10.2 To preserve sample integrity (consistency) and prevent

scale of either the detector or the electronic integration for the

the loss of volatile components, which may be in some

major component. It shall have a split injection system that will

samples, do not uncover samples any longer than necessary.

not discriminate over the boiling range of the samples ana-

lyzed. The system should be capable of operating at conditions

11. Preparation of Apparatus

given in Table 1.

11.1 Follow the manufacturer’s instructions for mounting

TABLE 1 Typical Instrumental Parameters and conditioning the column in the chromatograph.

11.2 Adjust the instrument to the conditions as described in

Detector: Flame ionization

Detector temperature, °C 150°C

Table 1 to give the proper separations. Allow sufficient time for

Column: 50 m by 0.25 mm

the instrument to reach equilibrium as indicated by a stable

Tubing Fused silica

baseline. See Practices E 355 and E 1510 for additional infor-

Stationary phase TCEP

Film

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.