ASTM D8413-21

(Guide)Standard Guide for Measuring the Water Pore Volume of Catalytic Materials by Centrifuge

Standard Guide for Measuring the Water Pore Volume of Catalytic Materials by Centrifuge

SIGNIFICANCE AND USE

5.1 This guide provides an alternative way to measure the porosity of catalytic materials without the use of mercury porosimetry. It is useful for research and development as well as quality control purposes. (See Test Methods D4284 and D6761.)

SCOPE

1.1 This guide describes how to measure the pore volume of catalytic materials by water immersion with the excess water removed with a centrifuge. The measured pore volume is converted to the dry pore volume by using the loss on ignition (LOI) of the material. It is generally applicable to both powdered materials and particles greater than about 1 mm.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D8413 − 21

Standard Guide for

Measuring the Water Pore Volume of Catalytic Materials by

1

Centrifuge

This standard is issued under the fixed designation D8413; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 Other ASTM Documents:

STP 447A Manual on Test Sieving Methods

1.1 This guide describes how to measure the pore volume of

catalytic materials by water immersion with the excess water

3. Terminology

removed with a centrifuge. The measured pore volume is

3.1 Definitions—See Terminology D3766.

converted to the dry pore volume by using the loss on ignition

(LOI) of the material. It is generally applicable to both

3.2 Definitions of Terms Specific to This Standard:

powdered materials and particles greater than about 1 mm.

3.2.1 water pore volume, n—also known as the pore volume

determined by water absorption, is a measure of the porosity of

1.2 Units—The values stated in SI units are to be regarded

a catalytic material.

as standard. No other units of measurement are included in this

standard.

4. Summary of Guide

1.3 This standard does not purport to address all of the

4.1 This guide measures pore volume by water immersion

safety concerns, if any, associated with its use. It is the

withtheexcesswaterremovedwithacentrifuge.Themeasured

responsibility of the user of this standard to establish appro-

pore volume is converted to the dry pore volume by using the

priate safety, health, and environmental practices and deter-

LOI of the material.

mine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accor-

5. Significance and Use

dance with internationally recognized principles on standard-

5.1 This guide provides an alternative way to measure the

ization established in the Decision on Principles for the

porosity of catalytic materials without the use of mercury

Development of International Standards, Guides and Recom-

porosimetry. It is useful for research and development as well

mendations issued by the World Trade Organization Technical

as quality control purposes. (See Test Methods D4284 and

Barriers to Trade (TBT) Committee.

D6761.)

2. Referenced Documents

6. Interferences

2

2.1 ASTM Standards:

6.1 There are no known interferences. This method cannot

D3766 Terminology Relating to Catalysts and Catalysis

be used for materials that react with or dissolve in water.

D4284 Test Method for Determining Pore Volume Distribu-

tion of Catalysts and Catalyst Carriers by Mercury Intru- 7. Apparatus

sion Porosimetry

7.1 Balance, accurate to nearest 0.0001 g.

D6761 Test Method for Determination of the Total Pore

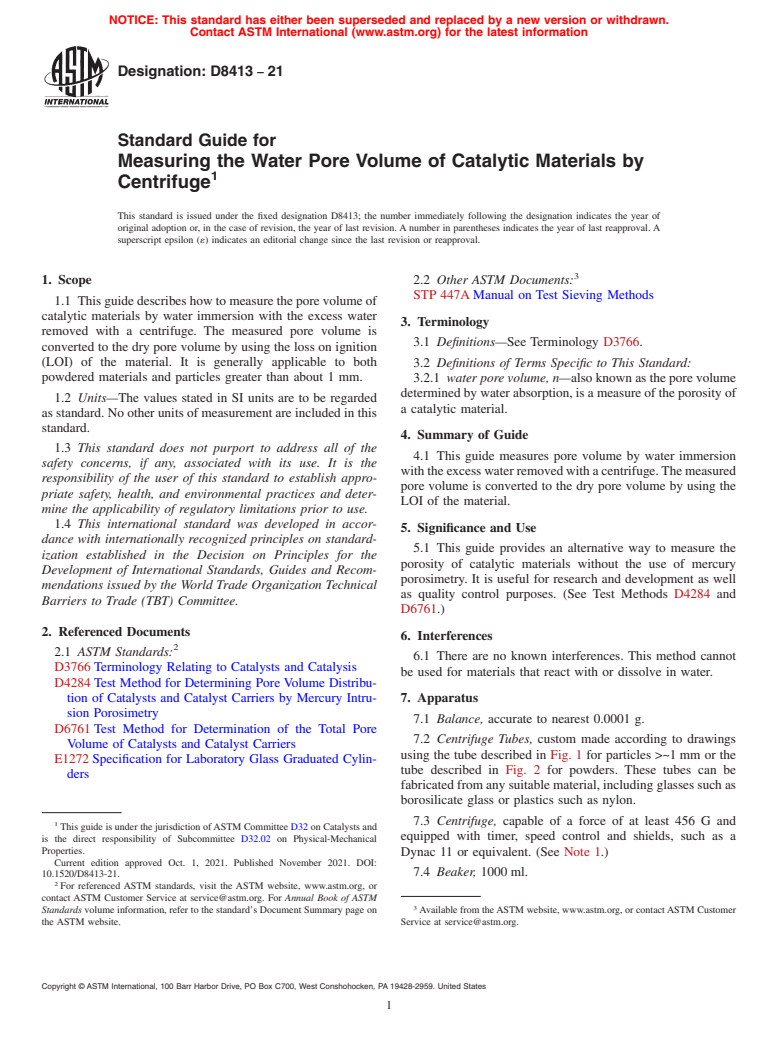

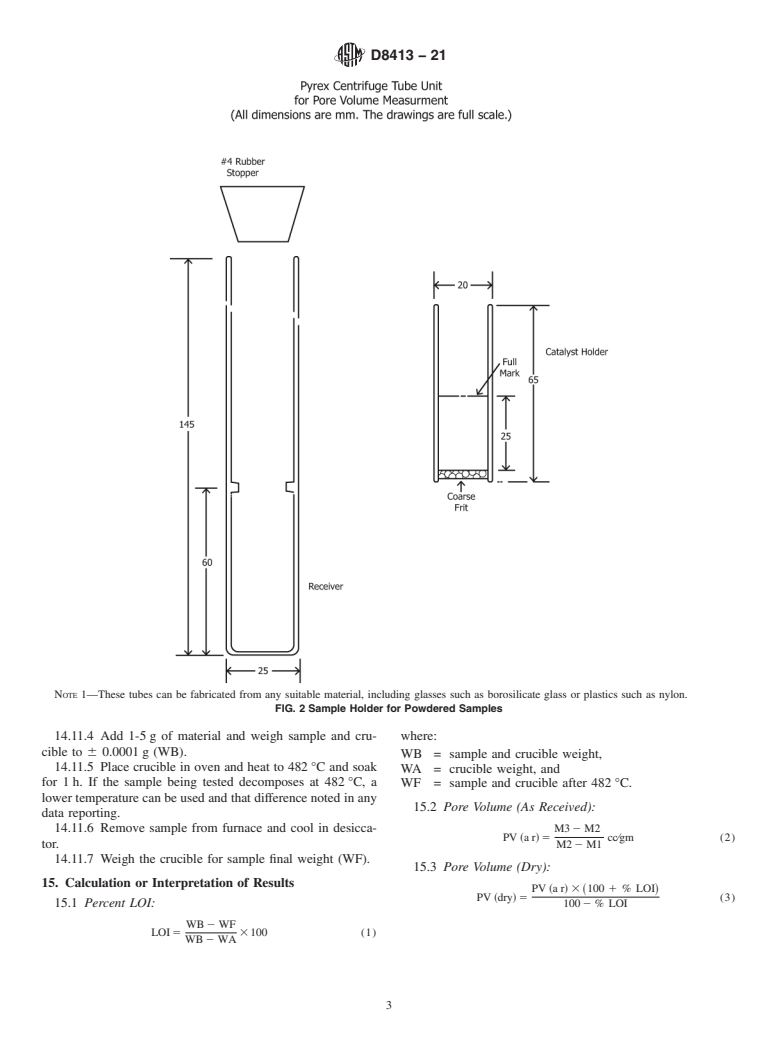

7.2 Centrifuge Tubes, custom made according to drawings

Volume of Catalysts and Catalyst Carriers

using the tube described in Fig. 1 for particles >~1 mm or the

E1272 Specification for Laboratory Glass Graduated Cylin-

tube described in Fig. 2 for powders. These tubes can be

ders

fabricated from any suitable material, including glasses such as

borosilicate glass or plastics such as nylon.

7.3 Centrifuge, capable of a force of at least 456 G and

1

This guide is under the jurisdiction ofASTM Committee D32 on Catalysts and

equipped with timer, speed control and shields, such as a

is the direct responsibility of Subcommittee D32.02 on Physical-Mechanical

Properties.

Dynac 11 or equivalent. (See Note 1.)

Current edition approved Oct. 1, 2021. Published November 2021. DOI:

7.4 Beaker, 1000 ml.

10.1520/D8413-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from theASTM website, www.astm.org, or contactASTM Customer

the ASTM website. Service at service@astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8413 − 21

NOTE 1—These tubes can be fabricated from any suitable material, including glasses such as borosilicate glass or plastics such as nylon.

FIG. 1 Sample Holder for >1 mm Particles

7.5 Graduated Cylinder, capacity 100 mL, conforming to 14.2 Divide 85 6 10 cc of sample between the two centri-

Specification E1272, Class A. fuge tubes. The final weight of the tubes should be within

6 0.2 g of each other.

7.6 Porcelain Crucible, 100 ml.

14.3 Weigh each of the filled tubes to the nearest 0.01 g and

7.7 Furnace, capable of 482 °C.

record this weight as (M2).

7.8 Timer.

14.4 Set the speed of the centrifuge at the approx

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.