ASTM F1306-16

(Test Method)Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates

Standard Test Method for Slow Rate Penetration Resistance of Flexible Barrier Films and Laminates

SIGNIFICANCE AND USE

4.1 Penetration resistance is an important end-use performance of thin flexible materials where a sharp-edged product can destroy the integrity of a barrier wrap. This will permit package entry/exit of gases, odors, and unwanted contaminates, causing potential harm to the product and reducing shelf-life. Material response to penetration will vary with numerous factors, such as film thickness, elastic modulus, rate of penetration, temperature, shape and type of probe. Consequently, material responses from puncture to stretch may be observed and quantified using this method. Although numerous combinations of experimental factors can be devised and used to simulate specific end-use applications, the recommended conditions in this method should be followed for standard comparisons of materials.

SCOPE

1.1 This test method permits flexible barrier films and laminates to be characterized for slow rate penetration resistance to a driven probe. The test is performed at room temperature, by applying a biaxial stress at a single test velocity on the material until perforation occurs. The force, energy, and elongation to perforation are determined.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1306 − 16

Standard Test Method for

Slow Rate Penetration Resistance of Flexible Barrier Films

1

and Laminates

This standard is issued under the fixed designation F1306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 penetration resistance—the ability of a flexible sheet

material to withstand elongation and/or puncture by a driven

1.1 This test method permits flexible barrier films and

probe.

laminates to be characterized for slow rate penetration resis-

3.1.3 perforation—the development of a measurable flaw

tance to a driven probe. The test is performed at room

through a barrier film undergoing penetration.

temperature, by applying a biaxial stress at a single test

velocity on the material until perforation occurs. The force, 3.1.4 probe penetration to failure—distance probe travels

energy, and elongation to perforation are determined. from film contact to an instantaneous drop in load as observed

on Universal Testing Equipment recorder.

1.2 The values stated in SI units are to be regarded as

3.1.5 puncture—the brittle elastic fracture of a flexible sheet

standard. The values given in parentheses are mathematical

material under penetration by a driven probe.

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

4. Significance and Use

1.3 This standard does not purport to address all of the

4.1 Penetration resistance is an important end-use perfor-

safety concerns, if any, associated with its use. It is the

mance of thin flexible materials where a sharp-edged product

responsibility of the user of this standard to establish appro-

can destroy the integrity of a barrier wrap. This will permit

priate safety and health practices and determine the applica-

package entry/exit of gases, odors, and unwanted

bility of regulatory limitations prior to use.

contaminates, causing potential harm to the product and

reducing shelf-life. Material response to penetration will vary

2. Referenced Documents

with numerous factors, such as film thickness, elastic modulus,

2

2.1 ASTM Standards:

rate of penetration, temperature, shape and type of probe.

D374 Test Methods for Thickness of Solid Electrical Insu-

Consequently, material responses from puncture to stretch may

lation (Metric) D0374_D0374M

be observed and quantified using this method. Although

D618 Practice for Conditioning Plastics for Testing

numerous combinations of experimental factors can be devised

D638 Test Method for Tensile Properties of Plastics

and used to simulate specific end-use applications, the recom-

E691 Practice for Conducting an Interlaboratory Study to

mended conditions in this method should be followed for

Determine the Precision of a Test Method

standard comparisons of materials.

3. Terminology

5. Apparatus

3.1 Definitions of Terms Specific to This Standard:

5.1 Universal Testing Apparatus, with a recording device.

3.1.1 elongation (stretch)—the elastic/plastic deformation

5.2 Compression Load Cell(s).

of flexible sheet material under penetration by a driven probe.

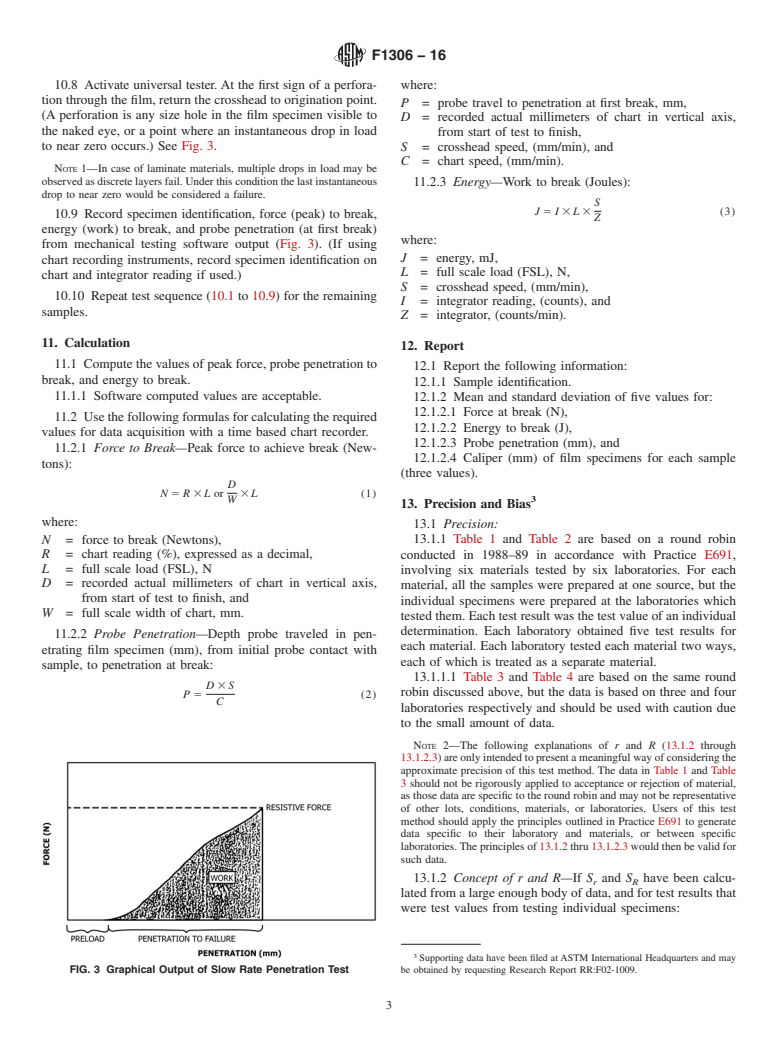

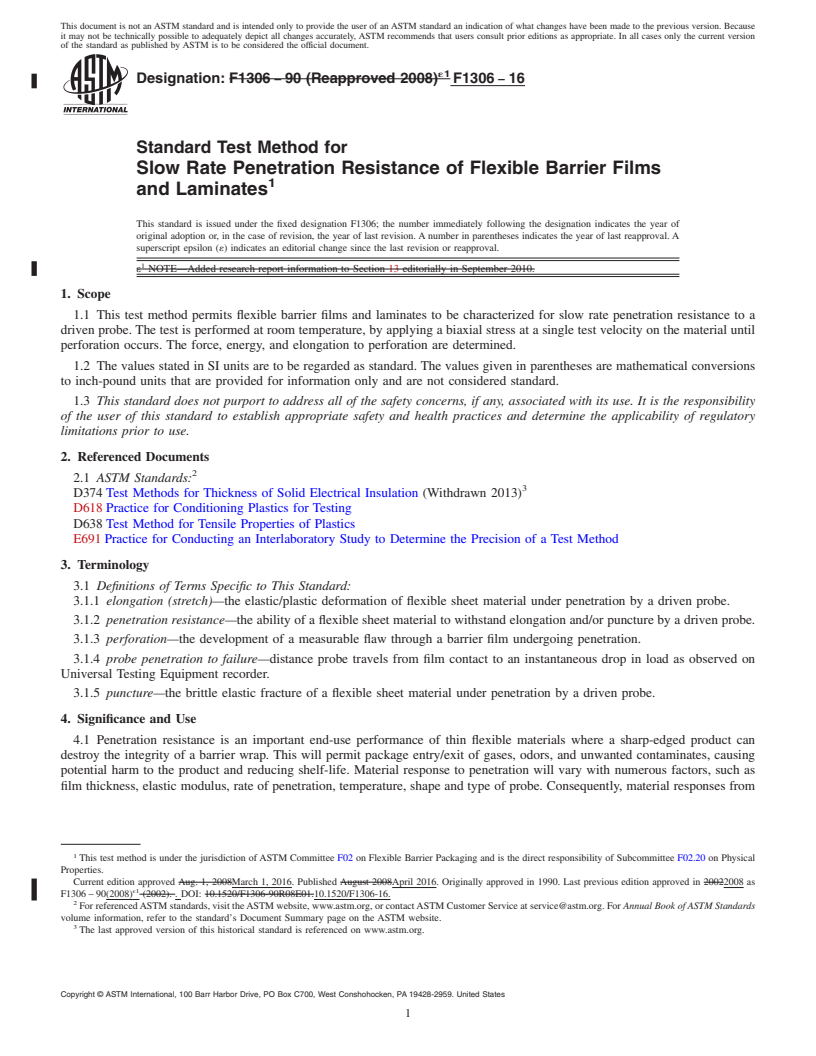

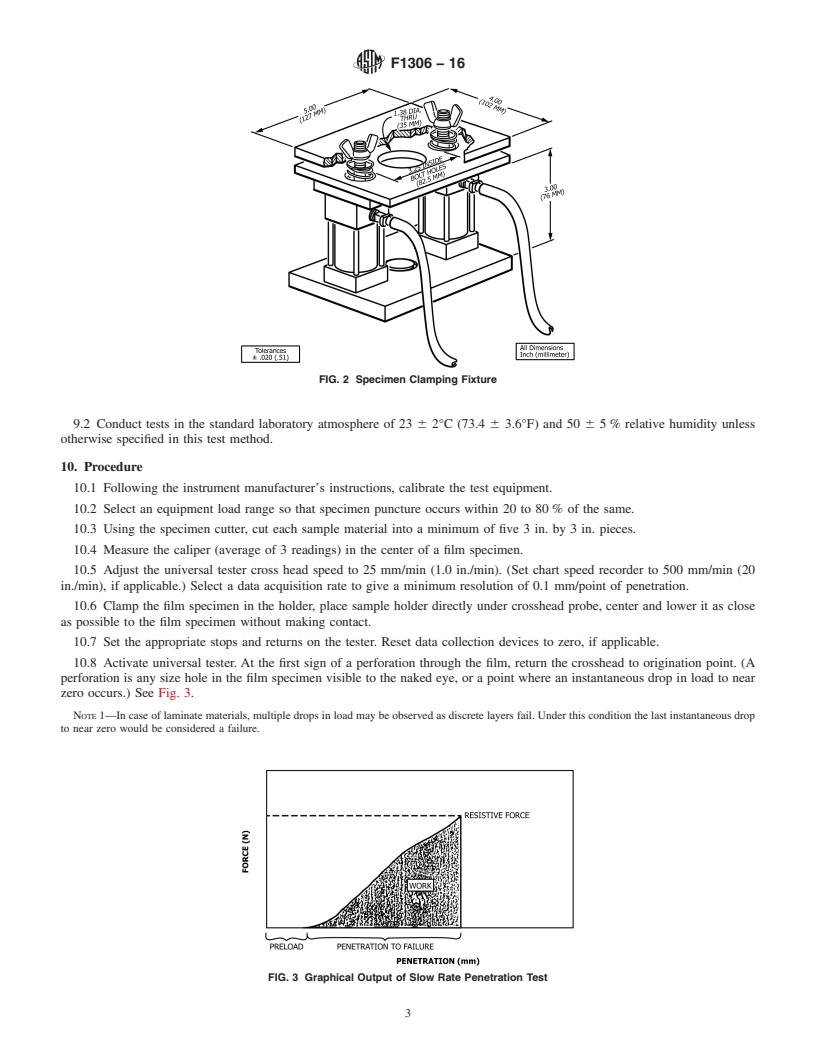

5.3 Penetration Probe, as per Fig. 1.

5.3.1 A 3.2 mm (0.125 in.) diameter hemispherical (biaxial

stress) probe is recommended for general application and

1

This test method is under the jurisdiction ofASTM Committee F02 on Primary

standard comparison of materials and interlaboratory results.

Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on

Physical Properties.

5.4 Specimen Clamping Fixture, as per Fig. 2 or equivalent.

Current edition approved March 1, 2016. Published April 2016. Originally

5.4.1 A sample test diameter of 34.9 mm (1.375 in.) is

ɛ1

approved in 1990. Last previous edition approved in 2008 as F1306 – 90(2008) .

required for interlaboratory comparison of results. (If other

DOI: 10.1520/F1306-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or probes are used, a minimum clamp to probe diameter ratio of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10 to 1 is required.)

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 5.5 Specimen Cutter.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1306 − 16

FIG. 1 Penetration Probe

8. Number of Test Specimens

8.1 Test at least five specimens for each sample.

9. Conditioning

9.1 Condition the test specimens at 23 6 2°C (73.4 6

3.6°F) and 50 6 5 % relative humidity for not less than 40 h

prior to test in accordan

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F1306 − 90 (Reapproved 2008) F1306 − 16

Standard Test Method for

Slow Rate Penetration Resistance of Flexible Barrier Films

1

and Laminates

This standard is issued under the fixed designation F1306; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Added research report information to Section 13 editorially in September 2010.

1. Scope

1.1 This test method permits flexible barrier films and laminates to be characterized for slow rate penetration resistance to a

driven probe. The test is performed at room temperature, by applying a biaxial stress at a single test velocity on the material until

perforation occurs. The force, energy, and elongation to perforation are determined.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 elongation (stretch)—the elastic/plastic deformation of flexible sheet material under penetration by a driven probe.

3.1.2 penetration resistance—the ability of a flexible sheet material to withstand elongation and/or puncture by a driven probe.

3.1.3 perforation—the development of a measurable flaw through a barrier film undergoing penetration.

3.1.4 probe penetration to failure—distance probe travels from film contact to an instantaneous drop in load as observed on

Universal Testing Equipment recorder.

3.1.5 puncture—the brittle elastic fracture of a flexible sheet material under penetration by a driven probe.

4. Significance and Use

4.1 Penetration resistance is an important end-use performance of thin flexible materials where a sharp-edged product can

destroy the integrity of a barrier wrap. This will permit package entry/exit of gases, odors, and unwanted contaminates, causing

potential harm to the product and reducing shelf-life. Material response to penetration will vary with numerous factors, such as

film thickness, elastic modulus, rate of penetration, temperature, shape and type of probe. Consequently, material responses from

1

This test method is under the jurisdiction of ASTM Committee F02 on Flexible Barrier Packaging and is the direct responsibility of Subcommittee F02.20 on Physical

Properties.

Current edition approved Aug. 1, 2008March 1, 2016. Published August 2008April 2016. Originally approved in 1990. Last previous edition approved in 20022008 as

ϵ1

F1306 – 90(2008) (2002). . DOI: 10.1520/F1306-90R08E01.10.1520/F1306-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1306 − 16

puncture to stretch may be observed and quantified using this method. Although numerous combinations of experimental factors

can be devised and used to simulate specific end-use applications, the recommended conditions in this method should be followed

for standard comparisons of materials.

5. Apparatus

5.1 Universal Testing Apparatus , Apparatus, with a recording device.

5.2 Compression Load Cell(s).

5.3 Penetration Probe, as per Fig. 1.

5.3.1 A 3.2 mm (0.125 in.) diameter hemispherical (biaxial stress) probe is recommended for general application and standard

comparison of materials and interlaboratory resul

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.