ASTM B853-07

(Specification)Standard Specification for Powder Metallurgy (PM) Boron Stainless Steel Structural Components

Standard Specification for Powder Metallurgy (PM) Boron Stainless Steel Structural Components

ABSTRACT

This specification covers stainless steel powder metallurgy (PM) structural components with minimum densities that are fabricated from prealloyed powder consisting primarily of iron, chromium, nickel, molybdenum, and boron2 and are intended for use in corrosive service. Structural components shall be made by cold pressing and sintering prealloyed powder. The chemical composition; physical properties such as density; and mechanical properties such as tensile strength, elongation and hardness; are detailed.

SCOPE

1.1 This specification covers stainless steel powder metallurgy (PM) structural components with a 7.7-g/cm3 minimum density that are fabricated from prealloyed powder consisting primarily of iron, chromium, nickel, molybdenum, and boron and are intended for use in corrosive service.

1.2 With the exception of density values, for which g/cm3 is the industry standard, the values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are converted in accordance with IEEE/ASTM SI 10 and are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B853 −07

StandardSpecification for

Powder Metallurgy (PM) Boron Stainless Steel Structural

1

Components

This standard is issued under the fixed designation B853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* G48 Test Methods for Pitting and Crevice Corrosion Resis-

tance of Stainless Steels and Related Alloys by Use of

1.1 This specification covers stainless steel powder metal-

3 Ferric Chloride Solution

lurgy (PM) structural components with a 7.7-g/cm minimum

IEEE/ASTM SI 10 American National Standard for Metric

density that are fabricated from prealloyed powder consisting

2 Practice

primarily of iron, chromium, nickel, molybdenum, and boron

and are intended for use in corrosive service.

3. Terminology

1.2 With the exception of density values, for which g/cm3 is

3.1 Definitions—Definitions of powder metallurgy terms

the industry standard, the values stated in inch-pound units are

can be found in Terminology B243. Additional descriptive

to be regarded as the standard. The SI values given in

information is in the Related Material section of Volume 02.05

parentheses are converted in accordance with IEEE/ASTM SI

of the Annual Book of ASTM Standards.

10 and are for information only.

4. Ordering Information

2. Referenced Documents

4.1 Orders for components under this specification shall

3

2.1 ASTM Standards: include the following information:

A262 Practices for Detecting Susceptibility to Intergranular 4.1.1 Dimensions (see Section 9),

Attack in Austenitic Stainless Steels 4.1.2 Chemical composition (see Section 6 and Table 1),

B117 Practice for Operating Salt Spray (Fog) Apparatus 4.1.3 Density (see Section 7),

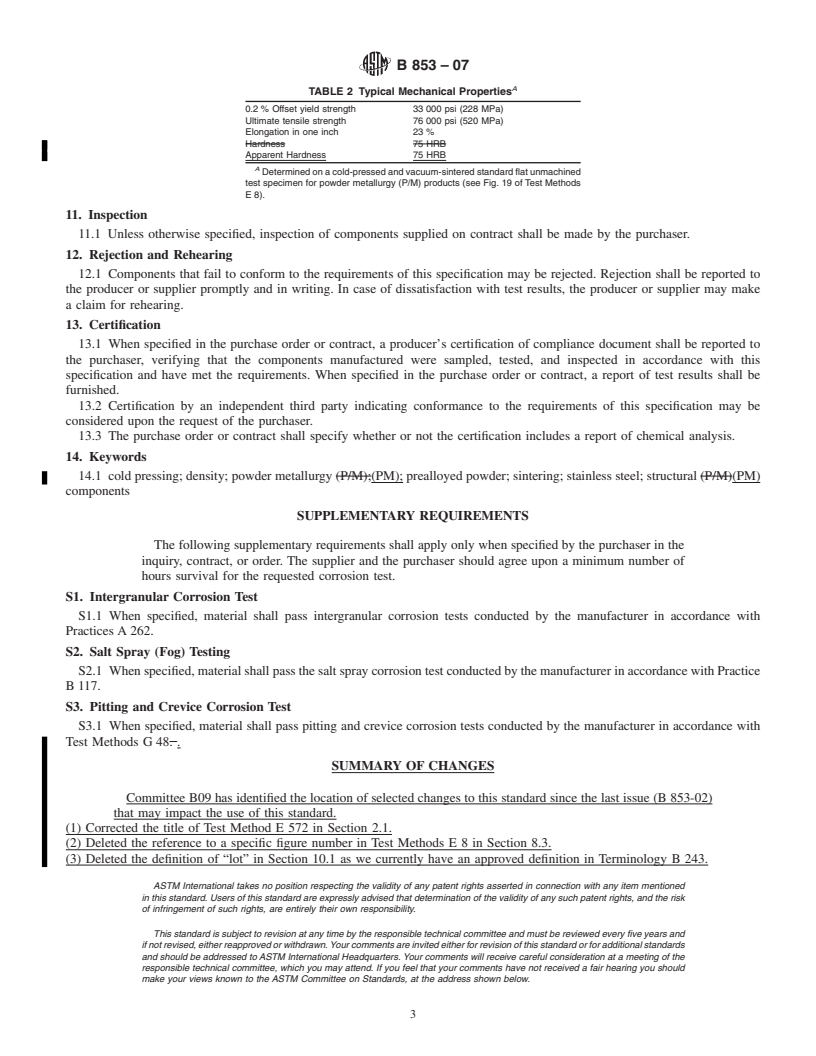

B243 Terminology of Powder Metallurgy 4.1.4 Mechanical properties (see Section 8 and Table 2),

B311 Test Method for Density of Powder Metallurgy (PM) 4.1.5 Certification (see Section 13),

Materials Containing Less Than Two Percent Porosity 4.1.6 Reference to the standard.

E8 Test Methods for Tension Testing of Metallic Materials

5. Materials and Manufacture

E354 Test Methods for Chemical Analysis of High-

5.1 Structural components shall be made by cold pressing

Temperature,Electrical,Magnetic,andOtherSimilarIron,

and sintering prealloyed powder.

Nickel, and Cobalt Alloys

E572 Test Method forAnalysis of Stainless andAlloy Steels

5.2 The sintering temperature is dependent on the chemical

by X-ray Fluorescence Spectrometry

composition of the powder.

E1019 Test Methods for Determination of Carbon, Sulfur,

6. Chemical Composition

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Fusion Techniques

6.1 The material shall conform to the composition limits

E1086 Test Method for Atomic Emission Vacuum Spectro-

specified in Table 1.

metric Analysis of Stainless Steel by Point-to-Plane Ex-

6.2 Chemical analysis should be made in accordance with

citation Technique

Test Methods E354, E572, E1019, and E1086.

7. Physical Properties

1

This specification is under the jurisdiction ofASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

7.1 Density:

mittee B09.11 on Near Full Density Powder Metallurgy Materials.

3

7.1.1 The sintered density shall be 7.7 g/cm minimum.

Current edition approved Oct. 1, 2007. Published November 2007. Originally

7.1.2 Density shall be determined in accordance with Test

approved in 1994. Last previous edition approved in 2002 as B853 – 02. DOI:

10.1520/B0853-07.

Method B311.

2

U.S. Patents 3980444, 4014680, 4032336.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 8. Mechanical Properties

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

8.1 The purchaser and manufacturer shall agree upon the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. method to be used to verify the typical yield or tensile strength

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B853−07

TABLE 1 Chemical Composition Requirements

10. Sampling

Element Composition Limits, Weight %

10.1 Chemical Analysis—If required by purchase agree-

Carbon 0.05 max

ment, at least one sample for chemical analysis shall be taken

Manganese 2.00 max

from each lot. A representative sample of chips may be

Phosphorus 0.03 max

Sulfur 0.03 max

obtained by dry-milling, drilling, or crushing at least two

Silicon 1.0 max

pieces without lubrication using

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 853–02 Designation: B 853 – 07

Standard Specification for

Powder Metallurgy (P/M)(PM) Boron Stainless Steel

1

Structural Components

This standard is issued under the fixed designation B 853; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

*

1.1This specification covers stainless steel powder metallurgy (P/M) structural components with a 7.7-g/cm

3

1.1 This specification covers stainless steel powder metallurgy (PM) structural components with a 7.7-g/cm minimum density

2

that are fabricated from prealloyed powder consisting primarily of iron, chromium, nickel, molybdenum, and boron and are

intended for use in corrosive service.

1.2The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are for

information only.

1.2 With the exception of density values, for which g/cm3 is the industry standard, the values stated in inch-pound units are to

be regarded as the standard. The SI values given in parentheses are converted in accordance with IEEE/ASTM SI 10 and are for

information only.

2. Referenced Documents

3

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

B 117 Practice for Operating Salt Spray (Fog) Apparatus

B 243 Terminology of Powder Metallurgy

B 311 Test Method for Density Determination for Powder Metallurgy (P/M) Materials Containing Less thanThan Two Percent

Porosity

E 8 Test Methods for Tension Testing of Metallic Materials

E 354 Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and

Cobalt Alloys

7

E 572Test Method for X-Ray Emission Spectrometric Analysis of Stainless Steel Test Method for Analysis of Stainless and

Alloy Steels by X-ray Fluorescence Spectrometry

E 1019 TestMethodsforDeterminationofCarbon,Sulfur,Nitrogen,andOxygeninSteelandinIron,Nickel,andCobaltAlloys

E 1086 Test Method for Optical Emission Vacuum Spectrometric Analysis of Stainless Steel by the Point-to-Plane Excitation

Technique

G 48Test Method for Pitting and Crevice Corrosion Resistance of Stainless Steels and RelatedAlloys by Use of Ferric Chloride

4

Solution Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and RelatedAlloys by Use of Ferric

Chloride Solution

IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric System

3. Terminology

3.1 Definitions— Definitions of powder metallurgy terms can be found in Terminology B 243. Additional descriptive

information is in the Related Material section of Volume 02.05 of the Annual Book of ASTM Standards.

4. Ordering Information

4.1 Orders for components under this specification shall include the following information:

1

This specification is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee

B09.11 on Near Full Density Powder Metallurgy Materials.

Current edition approved Oct. 10, 2002. Published November 2002. Originally published as B853–94. Last previous edition B853–98.

Current edition approved Oct. 1, 2007. Published November 2007. Originally approved in 1994. Last previous edition approved in 2002 as B 853 – 02.

2

U.S. Patents 3980444, 4014680, 4032336.

3

Annual Book of ASTM Standards, Vol 01.03.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 853–07

4.1.1 Dimensions (see Section 9),

4.1.2 Chemical composition (see Section 6 and Table 1),

4.1.3 Density (see Section 7),

4.1.4 Mechanical properties (see Section 8 and Table 2),

4.1.5 Certification (see Section 13),

4.1.6 Reference to the standard.

5. Materials and Manufacture

5.1 Structural components shall be made by cold pressing and sintering prealloyed powder.

5.2 The sintering temperature is dependent on the chemical composition of the powder.

6. Chemical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.