ASTM D4707-09(2017)

(Test Method)Standard Test Method for Measuring Paint Spatter Resistance During Roller Application

Standard Test Method for Measuring Paint Spatter Resistance During Roller Application

SIGNIFICANCE AND USE

4.1 Paint spatter generated by roller application is dependent on the properties of both the paint being applied and the paint roller cover used for the application. To eliminate the influence of the paint roller cover as a variable, and thus restrict the spatter-inducing variable to the paint under test only, the paint roller cover is replaced by a standard notched spool roller to generate spatter by a mechanism that simulates that of a paint-applying roller cover.

4.2 Although most of the development work to establish this test method was undertaken using latex paints, sufficient work was also done to show its applicability to solvent-reducible paints.

4.3 Tests during the development of this test method showed that the spattering properties of paints, like other physical properties, may in time change. Therefore, the results of this test are valid only for the time when the test is run.

SCOPE

1.1 This test method covers the determination of the tendency of a paint to spatter when applied with a paint roller to a substrate.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4707 − 09 (Reapproved 2017)

Standard Test Method for

Measuring Paint Spatter Resistance During Roller

Application

This standard is issued under the fixed designation D4707; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope onanessentiallyverticalsurfaceaboveasheetofpaperusedto

catch any spatter. A specially designed notched spool roller

1.1 This test method covers the determination of the ten-

(see 5.1) is rolled through the film following a defined

dency of a paint to spatter when applied with a paint roller to

procedure, tending to generate spatter. Any spatter falls upon

a substrate.

the spatter catch paper and, after drying, is rated against the

1.2 This standard does not purport to address all of the

pictorial standards.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

4.1 Paint spatter generated by roller application is depen-

bility of regulatory limitations prior to use.

dent on the properties of both the paint being applied and the

1.3 This international standard was developed in accor-

paint roller cover used for the application. To eliminate the

dance with internationally recognized principles on standard-

influenceofthepaintrollercoverasavariable,andthusrestrict

ization established in the Decision on Principles for the

the spatter-inducing variable to the paint under test only, the

Development of International Standards, Guides and Recom-

paint roller cover is replaced by a standard notched spool roller

mendations issued by the World Trade Organization Technical

to generate spatter by a mechanism that simulates that of a

Barriers to Trade (TBT) Committee.

paint-applying roller cover.

2. Referenced Documents

4.2 Althoughmostofthedevelopmentworktoestablishthis

test method was undertaken using latex paints, sufficient work

2.1 ASTM Standards:

was also done to show its applicability to solvent-reducible

D3924 Specification for Environment for Conditioning and

paints.

Testing Paint, Varnish, Lacquer, and Related Materials

(Withdrawn 2016)

4.3 Tests during the development of this test method

D3925 Practice for Sampling Liquid Paints and Related

showed that the spattering properties of paints, like other

Pigmented Coatings

physical properties, may in time change. Therefore, the results

2.2 Other Document:

of this test are valid only for the time when the test is run.

Pictorial Standards of Paint Roller Spatter

5. Apparatus

3. Summary of Test Method

5,6

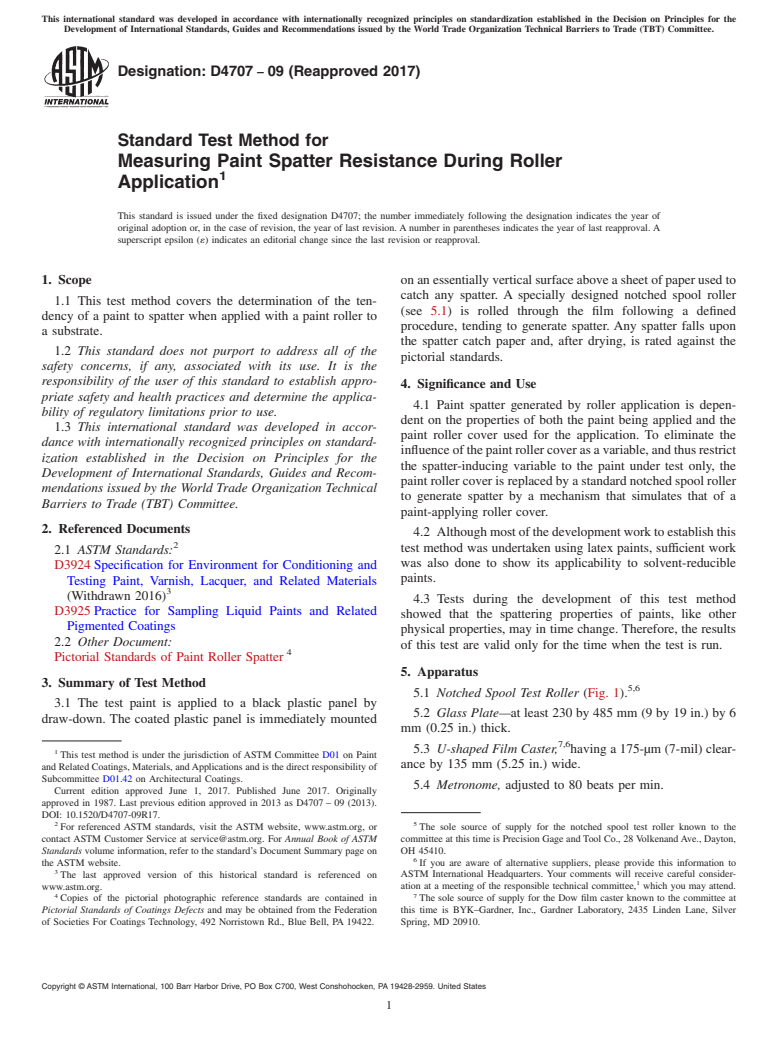

5.1 Notched Spool Test Roller (Fig. 1).

3.1 The test paint is applied to a black plastic panel by

5.2 Glass Plate—at least 230 by 485 mm (9 by 19 in.) by 6

draw-down. The coated plastic panel is immediately mounted

mm (0.25 in.) thick.

7,6

5.3 U-shaped Film Caster, having a 175-µm (7-mil) clear-

This test method is under the jurisdiction of ASTM Committee D01 on Paint

ance by 135 mm (5.25 in.) wide.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

5.4 Metronome, adjusted to 80 beats per min.

Current edition approved June 1, 2017. Published June 2017. Originally

approved in 1987. Last previous edition approved in 2013 as D4707 – 09 (2013).

DOI: 10.1520/D4707-09R17.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply for the notched spool test roller known to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM committee at this time is Precision Gage and Tool Co., 28 VolkenandAve., Dayton,

Standards volume information, refer to the standard’s Document Summary page on OH 45410.

the ASTM website. If you are aware of alternative suppliers, please provide this information to

The last approved version of this historical standard is referenced on ASTM International Headquarters. Your comments will receive careful consider-

www.astm.org. ation at a meeting of the responsible technical committee, which you may attend.

Copies of the pictorial photographic reference standards are contained in The sole source of supply for the Dow film caster known to the committee at

Pictorial Standards of Coatings Defects and may be obtained from the Federation this time is BYK–Gardner, Inc., Gardner Laboratory, 2435 Linden Lane, Silver

of Societies For Coatings Technology, 492 Norristown Rd., Blue Bell, PA 19422. Spring, MD 20910.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

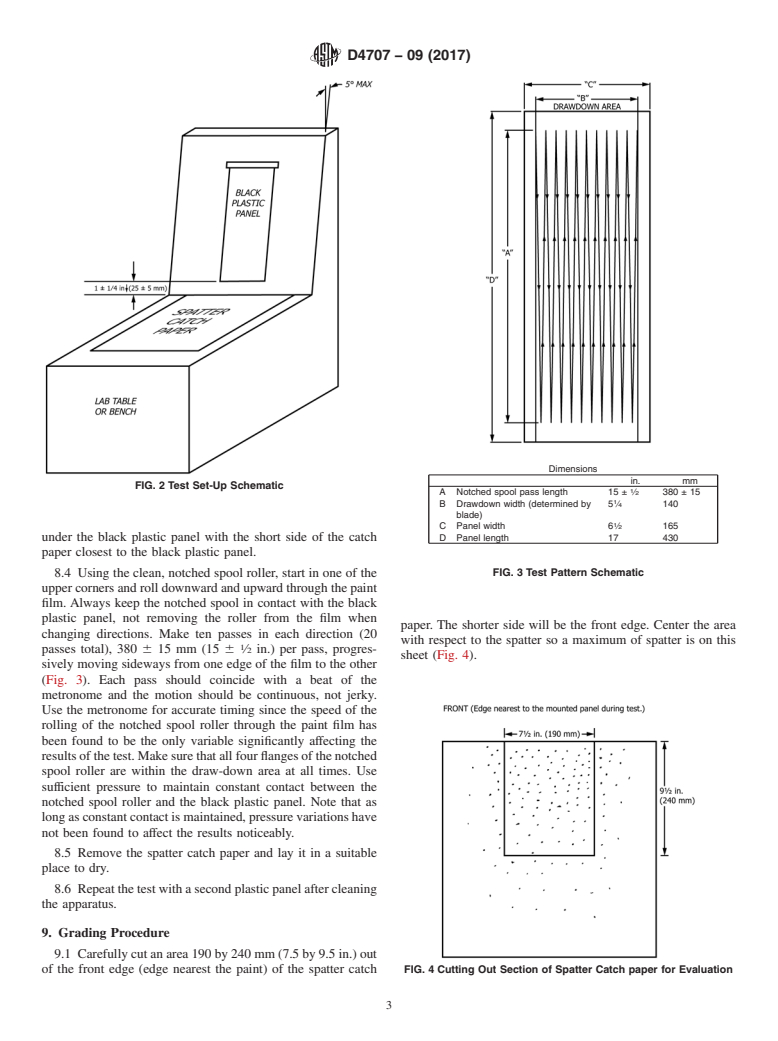

D4707 − 09 (2017)

Dimensions

in. mm

A Flange thickness 0.063± 0.005 1.60 ± 0.13

B Space between flanges 0.343 ± 0.005 8.71± 0.13

C Total diameter 1.600± 0.015 40.16 ± 0.38

D Diameter under notches 1.400 ± 0.015 35.56 ± 0.38

E Hole diameter 0.281 ± 0.005 7.14 ± 0.13

FIG. 1 Notched Spool Roller

6. Materials the black plastic panel on the glass plate and tape the narrow

8,6

end at the top to the glass plate. Smooth the panel along the

6.1 Black Plastic Panels, 165 by 430 mm (6.5 by 17 in.).

plate to ensure a close fit.

6.2 Flannel Cloth.

8.2 Stir the paint under test thoroughly and strain to remove

6.3 Masking Tape, 25 mm (1 in.) wide.

all skins and particles. Place the film caster with the 175-µm

6.4 SpatterCatchPaper,minimumsize190by240mm(7.5

(7.0-mil)sidedownimmediatelybelowthetapedportionofthe

by 9.5 in.). This paper can be any convenient paper to which

black plastic panel. Turn on the metronome. Into the well

the spatter droplets will adhere and of a color to contrast that

formed by the film caster, pour sufficient paint that the well is

of the paint under test.

filled from corner to corner. Draw down the paint the full

length of the black plastic panel until the film caster is fully

7. Sampling and Conditioning

beyond the far edge. The rate of application should be fairly

7.1 Sample the material in accordance with Practice D3925.

slow, 3 to 4 seconds from end to end, to prevent pinholes or

7.2 Prior to testing, the samples shall be conditioned in

holidays in the paint film.

accordance with the standard atmosphere described in Speci-

8.3 Immediately upon completion of the draw-down, re-

fication D3924. The testing shall take place under the same

move the black plastic panel from the glass plate, keeping the

conditions.

masking tape intact, and tape, with the long direction vertical

8. Procedure to a surface that is vertical or nearly vertical (within 5° of

vertical, top sloping away from the operator) with the bottom

8.1 Clean the top of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.