ASTM D4604-95

(Test Method)Standard Test Methods for Measurement of Cotton Fibers by High Volume Instruments (HVI) (Motion Control Fiber Information System) (Withdrawn 2001)

Standard Test Methods for Measurement of Cotton Fibers by High Volume Instruments (HVI) (Motion Control Fiber Information System) (Withdrawn 2001)

SCOPE

1.1 These test methods cover procedures for the operation of several instruments measuring various properties of cotton fibers; specifically micronaire, color, trash content, length, length uniformity, strength, and fiber elongation. These instruments are connected through a computer communications network and collectively are known as the Motion Control HVI Fiber Information System (See Fig. 1). These methods are applicable to loose cotton fibers taken from raw or partially processed cotton or some types of cotton wastes.

1.1.1 The micronaire reading of loose cotton fibers is determined by measuring the resistance of a "plug" of cotton fibers to air flow under prescribed conditions.

1.1.2 The measurement of length and length uniformity is made by an air flow measuring instrument outputting a voltage directly proportional to the amount of fiber in the prepared specimen at a given distance from the base of the prepared test beard, which is held in a clamp.

1.1.3 The measurements of tensile strength or breaking tenacity and elongation are made by an instrument in which the fibers are clamped between jaws with 1/8-in. (3.2-mm) spacing. A strain-gage device is used to measure breaking force, and a displacement measuring device is used to determine the fiber elongation at breaking load.

1.1.4 The measurement of the color of raw cotton is done by means of a cotton color meter of the Nickerson-Hunter type. It can be used to measure color of any type of raw cotton.

1.1.5 The measurement of the surface trash content of raw cotton is accomplished through optical analysis of the sample by a computer governing the scanning action of the sample through a video camera.

1.2 These test methods may exhibit shifts in the levels of the instrument outputs depending on the stage of processing at which the cotton fiber exists for testing.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only; the conversion may be approximate.

1.4 This standard contains the following sections: Sections Scope 1 Referenced Documents 2 Terminology 3 Sampling 4 Conditioning 5 Micronaire Method 6-11 Length and Length Uniformity Method 12-20 Strength and Elongation Determination Method 21-29 Color and Trash Determination Method 30-34 Calculations 35 Report 36 Precision and Bias 37-39 Keywords 40

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Note 6 and Section 17.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4604 – 95

Standard Test Methods for

Measurement of Cotton Fibers by High Volume Instruments

(HVI) (Motion Control Fiber Information System)

This standard is issued under the fixed designation D 4604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Sections

Scope 1

1.1 These test methods cover procedures for the operation

Referenced Documents 2

of several instruments measuring various properties of cotton

Terminology 3

Sampling 4

fibers; specifically micronaire, color, trash content, length,

Conditioning 5

length uniformity, strength, and fiber elongation. These instru-

Micronaire Method 6-11

ments are connected through a computer communications Length and Length Uniformity Method 12-20

Strength and Elongation Determination Method 21-29

network and collectively are known as the Motion Control HVI

Color and Trash Determination Method 30-34

Fiber Information System (See Fig. 1). These methods are

Calculations 35

applicable to loose cotton fibers taken from raw or partially Report 36

Precision and Bias 37-39

processed cotton or some types of cotton wastes.

Keywords 40

1.1.1 The micronaire reading of loose cotton fibers is

1.5 This standard does not purport to address all of the

determined by measuring the resistance of a “plug” of cotton

safety concerns, if any, associated with its use. It is the

fibers to air flow under prescribed conditions.

responsibility of the user of this standard to establish appro-

1.1.2 The measurement of length and length uniformity is

priate safety and health practices and determine the applica-

made by an air flow measuring instrument outputting a voltage

bility of regulatory limitations prior to use. Specific precau-

directly proportional to the amount of fiber in the prepared

tionary statements are given in Note 6 and Section 16.

specimen at a given distance from the base of the prepared test

beard, which is held in a clamp.

2. Referenced Documents

1.1.3 The measurements of tensile strength or breaking

2.1 ASTM Standards:

tenacity and elongation are made by an instrument in which the

D 123 Terminology Relating to Textiles

fibers are clamped between jaws with ⁄8-in. (3.2-mm) spacing.

D 1441 Practice for Sampling Cotton Fibers for Testing

A strain-gage device is used to measure breaking force, and a

D 1445 Test Method for Breaking Strength and Elongation

displacement measuring device is used to determine the fiber

of Cotton Fibers (Flat Bundle Method)

elongation at breaking load.

D 1448 Test Method for Micronaire Reading of Cotton

1.1.4 The measurement of the color of raw cotton is done by

Fibers

means of a cotton color meter of the Nickerson-Hunter type. It

D 1776 Practice for Conditioning Textiles for Testing

can be used to measure color of any type of raw cotton.

D 2253 Test Method for Color of Raw Cotton Using the

1.1.5 The measurement of the surface trash content of raw

Nickerson-Hunter Cotton Colorimeter

cotton is accomplished through optical analysis of the sample

D 3025 Practice for Standardizing Cotton Fiber Test Results

by a computer governing the scanning action of the sample

by Use of Calibration Cotton Standards

through a video camera.

1.2 These test methods may exhibit shifts in the levels of the

3. Terminology

instrument outputs depending on the stage of processing at

3.1 Definitions:

which the cotton fiber exists for testing.

3.1.1 breaking tenacity, n—the tenacity corresponding to

1.3 The values stated in inch-pound units are to be regarded

the breaking load, for example, grams-force per tex or grams-

as standard. The values given in parentheses are for informa-

force per denier.

tion only; the conversion may be approximate.

3.1.2 calibration cotton standards, n—cotton samples taken

1.4 This standard contains the following sections:

from a blended bulk source on which fiber properties have been

determined under the International Calibration Cotton Stan-

These test methods are under the jurisdiction of ASTM Committee D-13 on

dards Program.

Textiles and are the direct responsibility of Subcommittee D13.11 on Cotton Fibers.

3.1.2.1 Discussion—Currently there are ten such cottons,

Current edition approved May 15, 1995. Published October 1995. Originally

published as D 4604 – 86. Last previous edition D 4604 – 86.

Equipment is available from Motion Control, Inc., P.O. Box 29218, 2615

Brenner Dr., Dallas, TX 75220. Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4604

FIG. 1 Motion Control HVI Fiber Information System

which cover the range of the micronaire scale. 3.1.9 micronaire reading, n—a relative measurement of

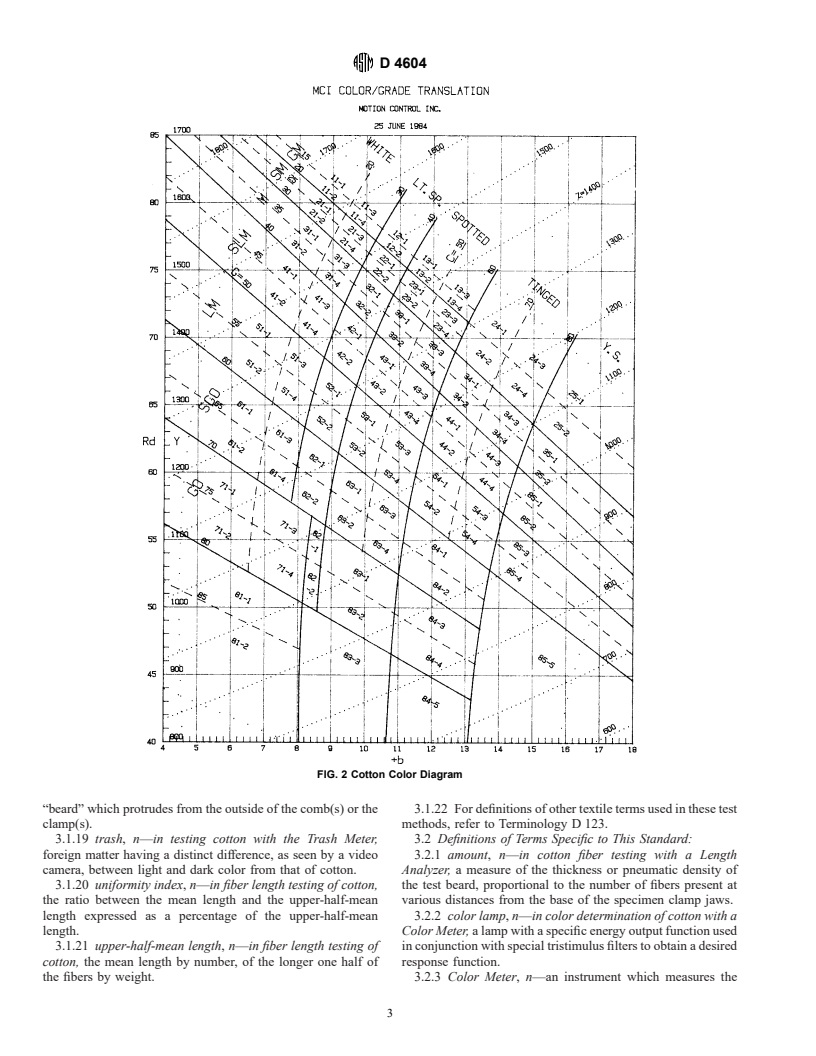

3.1.3 cotton color diagram, n—a diagram showing the color fiber fineness derived from the porous plug air-flow method.

ranges of standards officially established by the U.S. Depart- 3.1.10 mote, n—a whole, immature cotton seed.

ment of Agriculture for the various grades of cotton in relation 3.1.11 number of pieces of trash, n—in testing cotton with

to scales of reflectance, R , on the vertical axis, and yellow- the Trash Meter, a number correlated with the total number of

d

ness, +b, on the horizontal axis. pieces of trash on the surface of the sample of cotton over the

3.1.3.1 Discussion—Delineations also exist showing viewing window.

boundary values of G and C (see Fig. 2 and 31.1). Cotton color 3.1.12 percent area, n—in testing cotton with the Trash

diagrams based on grade standards for American Pima cotton

Meter, the ratio of total area of trash on the surface of a sample

and for cotton linters are also available. of cotton to that of the area of the viewing window, expressed

3.1.4 elongation, n—the ratio of the extension of a material

in a percentage of the area of the viewing window.

to the length of the material prior to stretching, expressed as a 3.1.13 seed coat fragment, n—in cotton, a portion of a

percent.

cotton seed, usually black or dark brown in color, broken from

3.1.4.1 Discussion—Elongation may be measured at any a mature or immature seed, and to which fibers or linters may

specified force or at rupture and is usually expressed in percent.

or may not be attached.

3.1.5 elongation at breaking load, n—in fiber strength 3.1.13.1 Discussion—Seed coat fragments are distinct from

testing of cotton, the elongation corresponding to the maximum

certain other imperfections found in cotton, such as neps,

load, and expressed as a percentage of the ⁄8-in. (3.2-mm) gage motes, leaf trash, and pieces of the stem. Seed coat fragments

length.

do not include “motes” or whole immature seeds; however,

3.1.6 fibrogram, n—in testing cotton fibers for length, the motes are one source of seed coat fragments when the motes

curve representing the second cumulation of the length distri-

are crushed or broken.

bution of the fibers sensed by the length measuring instrument 3.1.14 standard atmosphere for preconditioning textiles,

in scanning the fiber beard.

n—an atmosphere having a relative humidity of 5 to 25 % and

3.1.7 fineness, n—a relative measure of size, diameter, a temperature not over 122°F (50°C).

linear density, or mass per unit length expressed in a variety of

3.1.15 standard atmosphere for testing textiles, n—air

units. maintained at a relative humidity of 65 6 2 % and at a

3.1.7.1 Discussion—For cotton, the weighted mean linear

temperature of 70 6 2°F (21 6 1°C).

density is expressed in micrograms per inch or in millitex.

3.1.16 tenacity, n—in a tensile test, the force exerted on the

3.1.8 linters, n—the short, fibrous material adhering to a

specimen based on the linear density of the unstrained speci-

cotton seed after the spinnable lint has been removed by

men.

ginning and which is subsequently recovered from the seed by

3.1.17 tensile strength, n—the strength shown by a speci-

a process called “delinting.”

men subjected to tension, as distinct from torsion, compres-

sion, or shear.

3.1.18 test beard, n—in length testing of cotton, the portion

The International Calibration Cottons are available from the Cotton Division,

Agricultural Marketing Service, USDA, 4841 Summer Ave., Memphis, TN 38122. of the test specimen that has been combed and brushed into a

D 4604

FIG. 2 Cotton Color Diagram

“beard” which protrudes from the outside of the comb(s) or the 3.1.22 For definitions of other textile terms used in these test

clamp(s). methods, refer to Terminology D 123.

3.1.19 trash, n—in testing cotton with the Trash Meter, 3.2 Definitions of Terms Specific to This Standard:

foreign matter having a distinct difference, as seen by a video 3.2.1 amount, n—in cotton fiber testing with a Length

camera, between light and dark color from that of cotton. Analyzer, a measure of the thickness or pneumatic density of

3.1.20 uniformity index, n—in fiber length testing of cotton, the test beard, proportional to the number of fibers present at

the ratio between the mean length and the upper-half-mean various distances from the base of the specimen clamp jaws.

length expressed as a percentage of the upper-half-mean 3.2.2 color lamp, n—in color determination of cotton with a

length. Color Meter, a lamp with a specific energy output function used

3.1.21 upper-half-mean length, n—in fiber length testing of in conjunction with special tristimulus filters to obtain a desired

cotton, the mean length by number, of the longer one half of response function.

the fibers by weight. 3.2.3 Color Meter, n—an instrument which measures the

D 4604

fiber sample color as presented in the viewing window, in of specimens tested on each laboratory sample and turn off

terms of the tristimulus values Y and Z and transmits these instruments not being used in operating the system.

values to the IC/TC for further processing.

3.2.16 Strength Analyzer, n—an instrument which deter-

3.2.4 Comber/Brusher, n—an instrument which prepares

mines tensile strength and elongation at breaking load for a test

the test beard of fibers for length, length uniformity, strength,

beard of cotton.

and elongation measurements by combing the test specimen to

3.2.16.1 Discussion—Units of strength are expressed in

remove loose or unclamped fibers and paralleling the individu-

grams-force/tex, and elongation is expressed as a percentage.

ally clamped fibers, and by brushing the clamped fibers to

3.2.17 test specimen, n—in cotton length tests with the

remove fiber crimp and smooth the test beard of cotton.

Length Analyzer, the cotton fibers protruding randomly from

3.2.5 control limits, n—predetermined ranges based on the

the base of a Motion Control Inc. specimen clamp for fiber

variability of past observations between which the instrument

length measurement before being combed or brushed.

data for a test must fall to be considered valid.

3.2.18 Trash Meter, n—an instrument which optically mea-

3.2.6 elevator, n—a general term describing a mechanical

sures the amount of trash on the surface of a raw cotton sample

device on the Motion Control, Inc. Fiber Information System

as presented to the viewing window.

which moves the specimen clamp while preparing the speci-

3.2.19 tristimulus filters, n—in cotton fiber color testing

men or while taking a length/uniformity index or strength/

with the Color Meter, optical filters used in conjunction with

elongation measurement.

specific color lamps to obtain a response function approximat-

3.2.6.1 Discussion—Specifically, elevators are used on the

ing the tristimulus functions of the CIE Standard Observer for

Comber/Brusher unit and Length/Strength Analyzers.

Source C.

3.2.7 Fiberweigh, n—an instrument having a capacity for

3.2.19.1 Discussion—These filters will provide as outputs,

weighing a 51 grain (3.30 g) specimen with a sensitivity of at

least 0.2 % of the mass being weighed. values defining the yellowness and reflectance of the sample.

These values, in turn are used for color determination of raw

3.2.8 Fibronaire, n—an instrument which determines the

cotton samples.

micronaire reading of raw cotton fibers using the “porous-

plug” air flow technique.

4. Sampling

3.2.9 grain, n—a unit of mass equal to 1/7000 of a pound or

0.0648 g.

4.1 Lot Sample—As a lot sample for acceptance testing,

3.2.10 IC/TC, n—abbreviation for Intelligent Color/Trash

take at random the number of shipping containers directed in

Coordinator.

an applicable material specification or other agreement be-

3.2.10.1 Discussion—The IC/TC computes the color and

tween the purchaser and the supplier, such as an agreement to

surface trash content of the fiber sample being tested using the

use Practice D 1441 for bales of fiber and containers of sliver.

information obtained from the Color Meter and Trash Meter.

Consider bales or shipping containers to be the primary

3.2.11 IDT, n—abbreviation for Intelligent Data Terminal.

sampling units.

3.2.11.1 Discussion—The IDT contains software which en-

NOTE 1—An adequate specification or other agreement between the

ables the HVI 3000 Fiber Information System to communicate

purchaser and the supplier requires taking into account the variability

with a host processing device, and where decisions are made

between the sampling units, between laboratory samples within a sam-

regarding control limits, output of data, format of data, and

pling unit, and between test specimens within a laboratory sample to

sample identification.

provide a sampling plan with a meaningful producer’s risk, consumer’s

3.2.12 Length Analyzer, n—an instrument which determines

risk, acceptable quality level, and limiting quality level.

the upper-half-mean length and length uniformity index of a

4.2 Laboratory Sample—For fiber in bales, or sliver in

test beard of cotton.

containers, systematically take laboratory sample units from

3.2.12.1 Discussion—The Length Analyzer also determines

each bale or container in the lot sample as directed in Practice

a point of constant mass on the test beard of cotton to which the

D 1441.

strength analyzer indexes for breaking. Units of length are in

4.3 Test Specimens—Take test specimens as directed in each

hundredths of an inch and units of uniformity index are in

of the individual test methods.

percentage points of upper-half-mean length.

3.2.13 specimen clamp, n—the device which is used to

5. Conditioning

transport the fiber test beard of cotton through the gathering,

combing, brushing, length, length uniformity, strength, and

5.1 Bring the laboratory sample to moisture equilibrium for

elongation measurement operations

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.