ASTM E2191-02

(Test Method)Standard Test Method for Examination of Gas-Filled Filament-Wound Composite Pressure Vessels Using Acoustic Emission

Standard Test Method for Examination of Gas-Filled Filament-Wound Composite Pressure Vessels Using Acoustic Emission

SIGNIFICANCE AND USE

Due to safety considerations, the Compressed Gas Association (CGA) and others have produced guidelines which address in-service inspection of NGV fuel containers (see 2.2-2.4). AE examination is listed as an alternative to the minimum three-year visual examination which generally requires that the container be removed from the vehicle to expose the entire container surface. The AE method allows “in-situ” examination of the container.

5.1.1 Slow-fill pressurization must proceed at flow rates that do not produce background noise from flow of the pressurizing medium. Acoustic emission data are recorded throughout a pressurization range (that is, 50 % to 100 % of AE test pressure).

5.1.2 Fast-fill pressurization can be used if hold periods are provided. Acoustic emission data are recorded only during the hold periods.

5.1.3 Background noise above the threshold will contaminate the AE data and render them useless. Users must be aware of the following common causes of background noise: high fill rate (measurable flow noise); mechanical contact with the vessel by objects; electromagnetic interference (EMI) and radio frequency interference (RFI) from nearby broadcasting facilities and from other sources; leaks at pipe or hose connections and airborne particles, insects, rain and snow. This test method should not be used if background noise cannot be eliminated or controlled.

SCOPE

1.1 This test method provides guidelines for acoustic emission (AE) examination of filament-wound composite pressure vessels, for example, the type used for fuel tanks in vehicles which use natural gas fuel.

1.2 This test method requires pressurization to a level equal to or greater than what is encountered in normal use. The tanks' pressurization history must be known in order to use this test method. Pressurization medium may be gas or liquid.

1.3 This test method is limited to vessels designed for less than 10 000 psi (689 bar) maximum allowable working pressure and water volume less than 2.5 ft3 (0.07 m3).

1.4 AE measurements are used to detect emission sources. Other nondestructive examination (NDE) methods may be used to evaluate the significance of AE sources. Procedures for other NDE methods are beyond the scope of this test method.

1.5 This test method applies to examination of new and in-service filament-wound composite pressure vessels.

1.6 This test method applies to examinations conducted at ambient temperatures above 70°F (21°C). This test method may be used at ambient temperatures below 70°F if provision has been made to fill to the tank's rated pressure at 70°F.

1.7 The values stated in inch-pound units are to be regarded as the standard. SI units which are in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2191–02

Standard Test Method for

Examination of Gas-Filled Filament-Wound Composite

Pressure Vessels Using Acoustic Emission

This standard is issued under the fixed designation E 2191; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 650 Guide for Mounting PiezoelectricAcoustic Emission

Sensors

1.1 This test method provides guidelines for acoustic emis-

E 976 Guide for Determining the Reproducibility ofAcous-

sion (AE) examination of filament-wound composite pressure

tic Emission Sensor Response

vessels, for example, the type used for fuel tanks in vehicles

E 1316 Terminology for Nondestructive Examinations

which use natural gas fuel.

2.2 Natural Gas Vehicle Standard:

1.2 This test method requires pressurization to a level equal

American National Standard for Basic Requirements for

toorgreaterthanwhatisencounteredinnormaluse.Thetanks’

Compressed Natural Gas Vehicle (NGV) Fuel

pressurization history must be known in order to use this test

Containers ANSI/AGA/NGV2

method. Pressurization medium may be gas or liquid.

2.3 Compressed Gas Association Standard:

1.3 This test method is limited to vessels designed for less

Pamphlet C-6.4, Methods for Visual Inspection of AGA

than 10 000 psi (689 bar) maximum allowable working pres-

3 3

NGV2 Containers

sure and water volume less than 2.5 ft (0.07 m ).

2.4 U.S. Department of Transportation Reference:

1.4 AE measurements are used to detect emission sources.

NHTSA Federal Motor Vehicle Safety Standard No. 304,

Other nondestructive examination (NDE) methods may be

March 27, 1995

used to evaluate the significance ofAE sources. Procedures for

2.5 ASNT Standards:

other NDE methods are beyond the scope of this test method.

ANSI/ASNT CP-189, Standard for Qualification and Cer-

1.5 This test method applies to examination of new and

tification of Nondestructive Testing Personnel

in-service filament-wound composite pressure vessels.

SNT-TC-1A, Recommended Practice for Nondestructive

1.6 This test method applies to examinations conducted at

Testing Personnel Qualification and Certification

ambient temperatures above 70°F (21°C). This test method

may be used at ambient temperatures below 70°F if provision

3. Terminology

has been made to fill to the tank’s rated pressure at 70°F.

3.1 Definitions—See Terminology E 1316 for general ter-

1.7 The values stated in inch-pound units are to be regarded

minology applicable to this test method.

as the standard. SI units which are in parentheses are for

3.2 Definitions of Terms Specific to This Standard:

information only.

3.2.1 AE test pressure, n—110 % of the greatest pressure

1.8 This standard does not purport to address all of the

which the test article contains during previous service. Usually

safety concerns, if any, associated with its use. It is the

125 % of the filling pressure is an acceptableAE test pressure.

responsibility of the user of this standard to establish appro-

(Normally, gas is heated when compressed during the filling

priate safety and health practices and determine the applica-

process; hence, tanks are filled to more than rated service

bility of regulatory limitations prior to use. Specific precau-

pressure). After filling, pressure should settle to rated service

tionary statements are given in Section 8.

pressure as gas temperature within the tank becomes equal to

2. Referenced Documents ambient temperature.

2.1 ASTM Standards:

E 543 Practice for Agencies Performing Nondestructive

Testing

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036.

Available from Compressed GasAssociation, 1725 Jefferson Davis Hwy, Suite

This test method is under the jurisdiction of ASTM Committee E07 on 1004, Arlington, VA 22202–4102.

Nondestructive Testing and is the direct responsibility of Subcommittee E07.04 on Available from DODSSP, Bldg 4, Section D, 700 Robbins Ave., Philadelphia,

Acoustic Emission Method. PA 19111–5098.

Current edition approved March 10, 2002. Published May 2002. Available fromAmerican Society for Nondestructive Testing, P.O. Box 28518,

Annual Book of ASTM Standards, Vol 03.03. 1711 Arlington Lane, Columbus, OH 43228–0518.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2191–02

3.2.2 detectability distance, n—the maximum distance from rate (measurable flow noise); mechanical contact with the

a sensor at which a defined simulated AE source can be vessel by objects; electromagnetic interference (EMI) and

detected by the instrumentation with defined settings and using radio frequency interference (RFI) from nearby broadcasting

appropriate pressurization medium. facilities and from other sources; leaks at pipe or hose

connections and airborne particles, insects, rain and snow.This

4. Summary of Test Method

test method should not be used if background noise cannot be

4.1 AE sensors are mounted on a vessel and emission is

eliminated or controlled.

monitored while the vessel is pressurized to the “AE test

pressure”.

6. Basis of Application

4.2 Thistestmethodprovidesguidelinesforthedetectionof

6.1 Personnel Qualification—NDE personnel shall be

AE from structural flaws in the composite overwrap in gas-

qualifiedinaccordancewithanationallyrecognizedpracticeor

filled, filament-wound composite pressure vessels. Damage

standard such as ANSI/ASNT-CP-189, SNT-TC-1A, or a

mechanisms which produce AE include: resin cracking, fiber

similar document. The practice or standard used and its

debonding, fiber pullout, fiber breakage, delamination and

applicable revisions shall be specified in any contractual

bond failure. Flaws in liner portions of a vessel may not be

agreement between the using parties.

detected.

6.2 Qualification of Nondestructive TestAgencies—Ifspeci-

4.3 This test method and others found in ASTM, ASME,

fied in the contractual agreement, NDT agencies shall be

ASNT, SPI relate Acoustic Emission to applied load on the

qualified and evaluated as described in Practice E 543. The

composite material. At relatively low load (safe operating

applicable edition of Practice E 543 shall be specified in the

conditions) the acoustic emission from the composite material

contractual agreement.

is low. At higher loads (unsafe operating conditions) the slope

6.3 Extent of Examination—Theextentofexaminationshall

of theAE versus load curve changes drastically. In some cases

be in accordance with 4.2 unless otherwise specified.

this phenomenon can be identified and quantified by a single

6.4 Reporting Criteria/Acceptance Criteria—Reporting cri-

AE parameter (that is, AE counts).

teria for the examination results shall be in accordance with

4.4 Structurally insignificant flaws or processes (for ex-

Section 11 unless otherwise specified.Acceptance criteria shall

ample, leaks) may produce emission.

be specified in the contractual agreement.

4.5 This test method is convenient for periodic examination

6.5 Personnel Training/Test Requirements—NDE personnel

of vessels in-service.

(examiner) shall be familiar with CGA Pamphlet C6 and shall

4.6 Gas-filled filament-wound pressure vessels which ex-

have attended a training course and passed a written test which

hibit unacceptable levels of AE should be examined by other

cover the following topics.

methods; for example, visual, ultrasound, dye penetrant, etc.,

6.5.1 Basic technology of acoustic emission.

and may be repaired and re-examined in accordance with

6.5.2 Failure mechanisms of reinforced plastics.

government regulations and manufacturers guidelines. Repair

6.5.3 Acoustic emission instrumentation.

and repair examination procedures are outside the scope of this

6.5.4 Instrumentation check out.

test method.

6.5.5 Vessel filling requirements.

4.7 Any number of pressure vessels may be examined

6.5.6 Data collection and interpretation.

simultaneously as long as the appropriate number of sensors

6.5.7 Test report.

and instrumentation channels are used.

7. Apparatus

5. Significance and Use

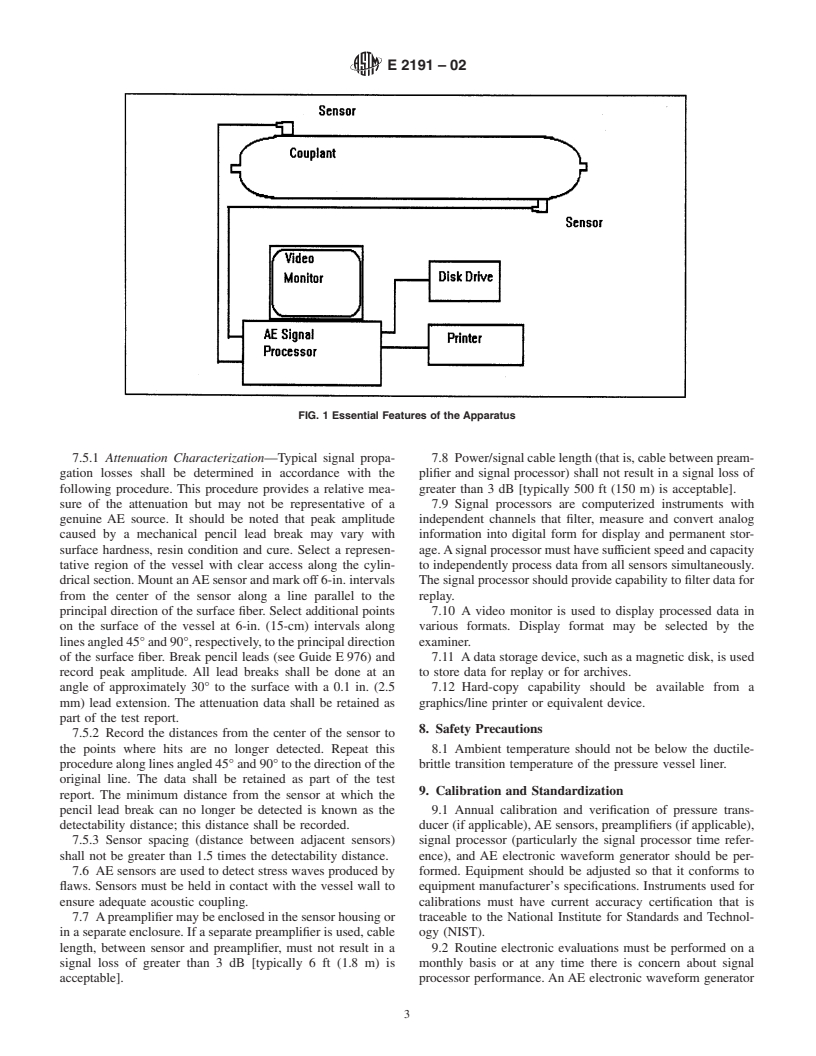

7.1 Essential features of the apparatus required for this

5.1 Due to safety considerations, the Compressed Gas

standard are shown in Fig. 1. Specifications are provided in

Association(CGA)andothershaveproducedguidelineswhich

Annex A1.

address in-service inspection of NGV fuel containers (see

7.2 Couplant must be used to acoustically couple sensors to

2.2-2.4). AE examination is listed as an alternative to the

the vessel surface. Adhesives that have acceptable acoustic

minimum three-year visual examination which generally re-

properties and traditional couplants are acceptable.

quiresthatthecontainerberemovedfromthevehicletoexpose

the entire container surface. The AE method allows “in-situ” 7.3 Sensors may be held in place with elastic straps,

adhesive tape, or other mechanical means.

examination of the container.

5.1.1 Slow-fillpressurizationmustproceedatflowratesthat 7.4 On small vessels (that is, where 100 % coverage can be

do not produce background noise from flow of the pressurizing achieved with two sensors) the sensor locations on the vessel

medium. Acoustic emission data are recorded throughout a wall will be determined by accessibility. Ideally they should be

pressurization range (that is, 50 % to 100 % of AE test placed 180° apart at opposite ends of the container on the

pressure). shoulders.

5.1.2 Fast-fill pressurization can be used if hold periods are 7.5 On larger vessels (that is, where two sensors cannot

provided. Acoustic emission data are recorded only during the provide 100 % coverage) sensors are positioned on the vessel

hold periods. wall so as to provide complete coverage. Sensor spacings are

5.1.3 Background noise above the threshold will contami- governed by the attenuation of the material. If attenuation

nate theAE data and render them useless. Users must be aware characteristics are not available from previous examinations of

of the following common causes of background noise: high fill similar vessels follow the directions found below.

E2191–02

FIG. 1 Essential Features of the Apparatus

7.5.1 Attenuation Characterization—Typical signal propa- 7.8 Power/signalcablelength(thatis,cablebetweenpream-

gation losses shall be determined in accordance with the plifier and signal processor) shall not result in a signal loss of

following procedure. This procedure provides a relative mea- greater than 3 dB [typically 500 ft (150 m) is acceptable].

sure of the attenuation but may not be representative of a 7.9 Signal processors are computerized instruments with

genuine AE source. It should be noted that peak amplitude independent channels that filter, measure and convert analog

caused by a mechanical pencil lead break may vary with information into digital form for display and permanent stor-

surface hardness, resin condition and cure. Select a represen- age.Asignal processor must have sufficient speed and capacity

tative region of the vessel with clear access along the cylin- to independently process data from all sensors simultaneously.

drical section. Mount anAE sensor and mark off 6-in. intervals The signal processor should provide capability to filter data for

from the center of the sensor along a line parallel to the replay.

principal direction of the surface fiber. Select additional points 7.10 A video monitor is used to display processed data in

on the surface of the vessel at 6-in. (15-cm) intervals along various formats. Display format may be selected by the

linesangled45°and90°,respectively,totheprincipaldirection examiner.

of the surface fiber. Break pencil leads (see Guide E 976) and 7.11 Adata storage device, such as a magnetic disk, is used

record peak amplitude. All lead breaks shall be done at an to store data for replay or for archives.

angle of approximately 30° to the surface with a 0.1 in. (2.5 7.12 Hard-copy capability should be available from a

mm) lead extension. The attenuation data shall be retained as graphics/line printer or equivalent device.

part of the test report.

8. Safety Precautions

7.5.2 Record the distances from the center of the sensor to

the points where hits are no longer detected. Repeat this 8.1 Ambient temperature should not be below the ductile-

procedurealonglinesangled45°and90°tothedirectionofthe brittle transition temperature of the pressure vessel liner.

original line. The data shall be retained as part of the test

9. Calibration and Standardization

report. The minimum distance from the sensor at which the

pencil lead break can no longer be detected is known as the 9.1 Annual calibration and verification of pressure trans-

detectability distance; this distance shall be recorded. ducer (if applicable),AE sensors, preamplifiers (if applicable),

7.5.3 Sensor spacing (distance between adjacent sensors) signal processor (particularly the signal processor time refer-

shall not be greater than 1.5 times the detectability distance. ence), and AE electronic waveform generator should be per-

7.6 AE sensors are used to detect stress waves produced by formed. Equipment should be adjusted so that it conforms to

flaws. Sensors must be held in contact with the vessel wall to equipment manufacturer’s specifications. Instruments used for

ensure adequate acoustic coupling. calibrations must have current accuracy certification that is

7.7 Apreamplifier may be enclosed in the sensor housing or traceable to the National Institute for Standards and Technol-

in a separate enclosure. If a separate preamplifier is used, cable ogy (NIST).

length, between sensor and preamplifier, must not result in a 9.2 Routine electronic evaluations must be performed on a

signal loss of greater than 3 dB [typically 6 ft (1.8 m) is monthly basis or at any time there is concern about signal

acceptable]. processor performance. An AE electronic waveform generator

E2191–02

should be used in making evaluations. Each signal processor 10.8 Monitor test by observing displays that show plots of

channel must respond with peak amplitude reading within 62 AE activity versus time or pressure. If unusual response is

dB of the electronic waveform generator output. observed, interrupt pressurization and conduct an investigation

9.3 Routine performance checking of each sensor should be to determine the cause.

10.9 Store all data on mass storage media. Stop test when

conducted on a monthly basis or at any time there is concern

about the sensor performance. Peak amplitude response and pressure reaches AE test pressure.

electron

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.