ASTM D4398-95

(Test Method)Standard Test Method for Determining the Chemical Resistance of Fiberglass-Reinforced Thermosetting Resins by One-Side Panel Exposure

Standard Test Method for Determining the Chemical Resistance of Fiberglass-Reinforced Thermosetting Resins by One-Side Panel Exposure

SCOPE

1.1 This test method is intended for use in the evaluation of the chemical resistance of fiberglass-reinforced thermosetting resins that are subjected to one-side panel exposure to specific environments. It takes into consideration the coldwall effects and radiation losses of heat transfer through the laminate wall.

1.2 This test method is supplemental to Practice C 581 and does not supersede it.

Note 1—There is no similar or equivalent ISO standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 4398 – 95

Standard Test Method for

Determining the Chemical Resistance of Fiberglass-

Reinforced Thermosetting Resins by One-Side Panel

1,2

Exposure

This standard is issued under the fixed designation D 4398; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 thermosetting resins—linear, relatively low molecular

weight thermoplastic polymer chains with 88crosslinks’’ which

1.1 This test method is intended for use in the evaluation of

bond the chains together with primary valence bonds. Once

the chemical resistance of fiberglass-reinforced thermosetting

cross-linked, such three-dimensional polymers will not soften

resins that are subjected to one-side panel exposure to specific

up appreciably to their decomposition temperature. Typical of

environments. It takes into consideration the coldwall effects

such resin systems are the polymers, vinyl esters, and epoxies.

and radiation losses of heat transfer through the laminate wall.

1.2 This test method is supplemental to Practice C 581 and

4. Significance and Use

does not supersede it.

4.1 The results obtained by this test method may serve as a

NOTE 1—There is no similar or equivalent ISO standard.

guide in, but not as the sole basis for, predicting the possible

1.3 This standard does not purport to address all of the performance of the particular glass-fiber-reinforced thermoset-

ting resin laminate in the one-side exposure to the specific

safety problems, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- environment under evaluation. No attempt has been made to

incorporate into the test method all of the factors that may enter

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. into the serviceability of a glass-fiber-reinforced resin structure

when subjected to chemical environments.

2. Referenced Documents

4.2 This test method provides for the determination of

2.1 ASTM Standards: changes in the physical properties of the test panel and test

C 581 Practice for Determining Chemical Resistance of media during and after the one-side exposure in the test media.

Thermosetting Resins Used in Glass Fiber Reinforced Determination of changes include: Barcol hardness, appear-

Structures Intended for Liquid Service ance of panel, appearance of test media, flexural properties,

D 790 Test Methods for Flexural Properties of Unreinforced and thickness.

and Reinforced Plastics and Electrical Insulating Materi-

5. Apparatus

als

5.1 Test Cell—This is a laboratory unit in which only the

D 2583 Test Method for Indentation Hardness of Rigid

surface of one side of a test panel is subjected to the corrosive

Plastics by Means of a Barcol Impressor

or aggressive environment, which is the normal experience of

3. Terminology

chemical processing equipment in actual plant operations. It

3.1 Definitions of Terms Specific to This Standard: consists of an open-ended glass cylinder, with several ground-

3.1.1 glass fiber—glass filaments for engineering applica- glass joint nozzles for insertion of appropriate auxiliaries. The

tions, chiefly of a so-called 88E’’ type made from a lime- ends of the open glass cylinder are closed off with the

alumina borosilicate glass that is relatively soda free, of high fiberglass-reinforced resin panel to be tested, and are tightly

strength-to-weight ratio. Glass fibers are used commercially in sealed with chemical-resistant gaskets, allowing one side of the

the reinforcement of rigid engineering plastic structures. panel to come in contact with the test media.

5.1.1 Typical of such test cells are the Corrocell shown in

Fig. 1, and the Atlas Test Cell shown in Fig. 2. Other

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

laboratory units for one-side corrosion testing of equal or larger

Piping Systems and Chemical Equipment.

Current edition approved July 15, 1995. Published September 1995. Originally

published as D 4398 – 84. Last previous edition D 4398 – 89.

2 6

This revision included the addition of Note 1 and Section 12. Available from The CORROCELLt Division, Fenner and Associates Inc., 7303

Annual Book of ASTM Standards, Vol 08.04. Springside Ave., Houston, TX 77040.

4 7

Annual Book of ASTM Standards, Vol 08.01. Available from Custom Scientific Products, 190 DuPont Highway, Bldg. 34,

Annual Book of ASTM Standards, Vol 08.02. Air Park Business Center, New Castle, DE 19720.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4398

FIG. 1 Corrocell Test Unit

FIG. 2 Atlas Test Cell

diameter may be used also with correspondingly appropriate 5.2 Reflux Condenser—To maintain a constant liquid level

panel sizes. and constant concentration of the test media.

D 4398

5.3 Electrical Heating Mantle—Wrapped on the exterior to posites conforming to the construction used in fabrication of

supply heat through the glass cylinder into the liquid, but not that specific structure, may be employed for testing.

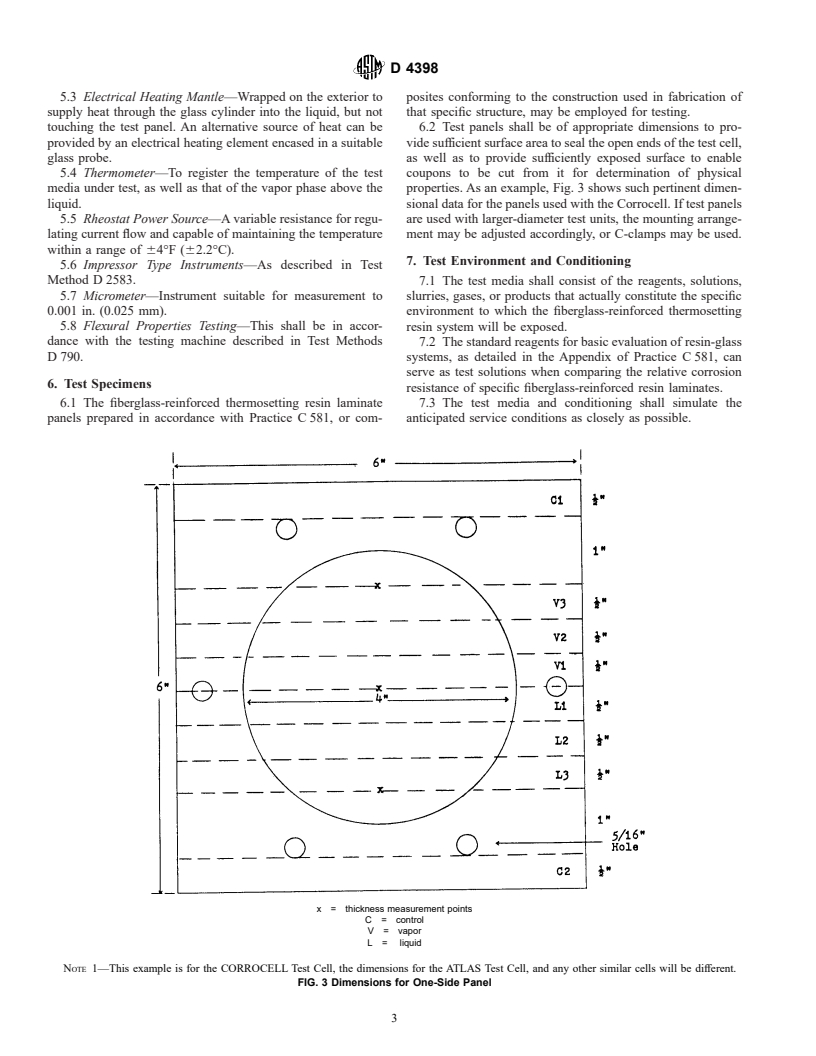

touching the test panel. An alternative source of heat can be 6.2 Test panels shall be of appropriate dimensions to pro-

provided by an electrical heating element encased in a suitable vide sufficient surface area to seal the open ends of the test cell,

glass probe. as well as to provide sufficiently exposed surface to enable

5.4 Thermometer—To register the temperature of the test coupons to be cut from it for determination of physical

media under test, as well as that of the vapor phase above the properties. As an example, Fig. 3 shows such pertinent dimen-

liquid. sional data for the panels used with the Corrocell. If test panels

5.5 Rheostat Power Source—A variable resistance for regu- are used with larger-diameter test units, the mounting arrange-

lating current flow and capable of maintaining the temperature ment may be adjusted accordingly, or C-clamps may be used.

within a range of 64°F (62.2°C).

7. Test Environment and Conditioning

5.6 Impressor Type Instruments—As described in Test

Method D 2583. 7.1 The test media shall consist of the reagents, solutions,

5.7 Micrometer—Instrument suitable for measurement to slurries, gases, or products that actually constitute the specific

0.001 in. (0.025 mm). environment to which the fiberglass-reinforced thermosetting

5.8 Flexural Properties Testing—This shall be in accor- resin system will be exposed.

dance with the testing machine described in Test Methods 7.2 The standard reagents for basic evaluation of resin-glass

D 790. systems, as detailed in the Appendix of Practice C 581, can

serve as test solutions when comparing the relative corrosion

6. Test Specimens

resistance of specific fiberglass-reinforced resin laminates.

6.1 The fiberglass-reinforced thermosetting resin laminate 7.3 The test media and conditioning shall simulate the

panels prepared in accordance with Practice C 581, or com- anticipated service conditions as closely as possible.

x = thickness measurement points

C = control

V = vapor

L = liquid

NOTE 1—This example is for the CORROCELL Test Cell, the dimensions for the ATLAS Test Cell, and any other similar cells will be different.

FIG. 3 Dimensions for One-Side Panel

D 4398

7.4 Mechanical agitation, or mixing through aeration, may sections. Identify vapor phase strips as V-1, V-2, and V-3, and

be employed to eliminate stratification of liquids, or to prevent those from the liquid phase as L-1, L-2, and L-3, with control

sedimentation or settling out of the slurry. strips marked C-1 and C-2 (see Fig. 3). With test units of

different dimensions employing larger size panels, a similar

8. Procedure

group of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.