ASTM F2028-08(2012)e1

(Test Method)Standard Test Methods for Dynamic Evaluation of Glenoid Loosening or Disassociation

Standard Test Methods for Dynamic Evaluation of Glenoid Loosening or Disassociation

SIGNIFICANCE AND USE

5.1 This test method is intended to investigate the resistance of a glenoid component to loosening. Glenoid loosening is the most common clinical complication in total shoulder arthroplasty (see X1.1). The method assumes that loosening occurs because of edge loading, often called the rocking-horse phenomenon.

5.2 This test method can be used both to detect potential problems and to compare design features. Factors affecting loosening performance include articular geometry, flange geometry, materials, fixation design, bone quality, and surgical technique.

SCOPE

1.1 These test methods measure how much a prosthetic glenoid component rocks or pivots following cyclic displacement of the humeral head to opposing glenoid rims (for example, superior-inferior or anterior-posterior). Performance is judged by the tensile displacement opposite each loaded rim after dynamic rocking.

1.2 The same setup can be used to test the locking mechanism of modular glenoid components, for example, for disassociation.

1.3 These test methods cover shoulder replacement designs with monolithic or modular glenoid components for cemented fixation.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2028 − 08(Reapproved 2012)

Standard Test Methods for

Dynamic Evaluation of Glenoid Loosening or

Disassociation

This standard is issued under the fixed designation F2028; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units information was editorially corrected in January 2013.

1. Scope 3. Terminology

1.1 These test methods measure how much a prosthetic 3.1 Definitions:

glenoid component rocks or pivots following cyclic displace- 3.1.1 glenoid—the prosthetic portion that replaces the gle-

ment of the humeral head to opposing glenoid rims (for

noid fossa of the scapula and articulates with a prosthetic

example, superior-inferior or anterior-posterior). Performance replacementofthehumeralhead.Itmayconsistofoneormore

is judged by the tensile displacement opposite each loaded rim

componentsfromoneormorematerials,forexample,eitherall

after dynamic rocking. polyethylene or a metal baseplate with a polymeric insert.

1.2 The same setup can be used to test the locking mecha- 3.1.2 humeral head—the prosthetic portion that replaces the

proximal humerus or humeral head and articulates with the

nism of modular glenoid components, for example, for disas-

sociation. natural glenoid fossa or a prosthetic replacement.

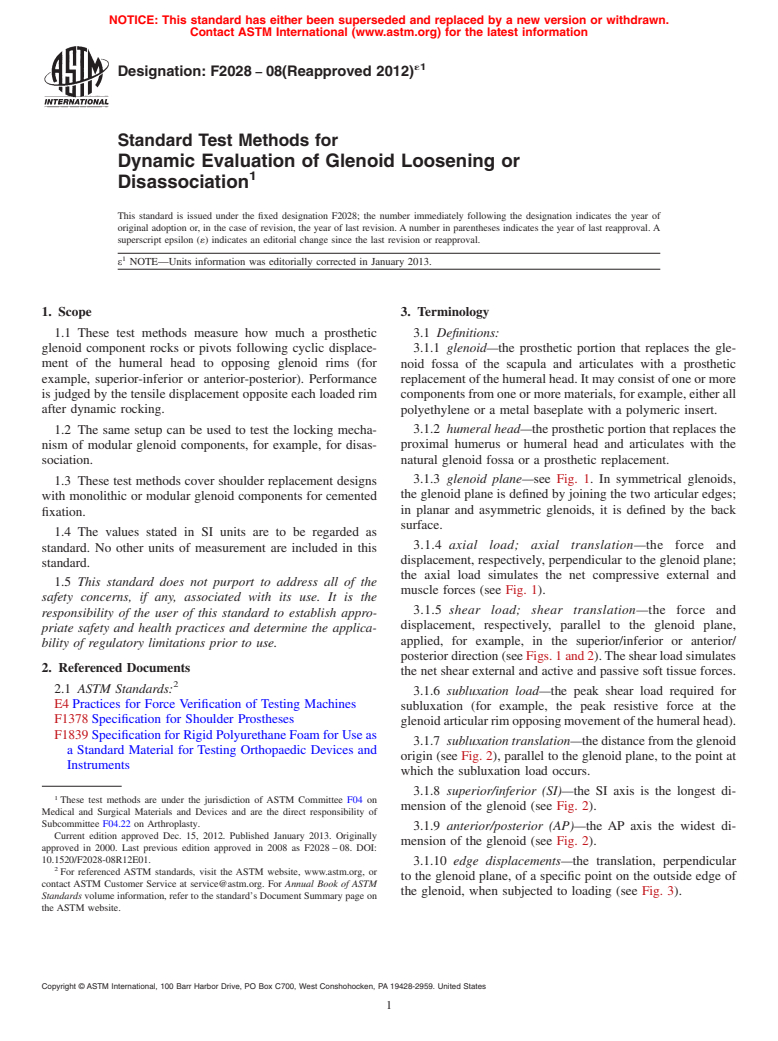

3.1.3 glenoid plane—see Fig. 1. In symmetrical glenoids,

1.3 These test methods cover shoulder replacement designs

the glenoid plane is defined by joining the two articular edges;

with monolithic or modular glenoid components for cemented

in planar and asymmetric glenoids, it is defined by the back

fixation.

surface.

1.4 The values stated in SI units are to be regarded as

3.1.4 axial load; axial translation—the force and

standard. No other units of measurement are included in this

displacement, respectively, perpendicular to the glenoid plane;

standard.

the axial load simulates the net compressive external and

1.5 This standard does not purport to address all of the

muscle forces (see Fig. 1).

safety concerns, if any, associated with its use. It is the

3.1.5 shear load; shear translation—the force and

responsibility of the user of this standard to establish appro-

displacement, respectively, parallel to the glenoid plane,

priate safety and health practices and determine the applica-

applied, for example, in the superior/inferior or anterior/

bility of regulatory limitations prior to use.

posteriordirection(seeFigs.1and2).Theshearloadsimulates

2. Referenced Documents

the net shear external and active and passive soft tissue forces.

2.1 ASTM Standards:

3.1.6 subluxation load—the peak shear load required for

E4 Practices for Force Verification of Testing Machines

subluxation (for example, the peak resistive force at the

F1378 Specification for Shoulder Prostheses

glenoidarticularrimopposingmovementofthehumeralhead).

F1839 Specification for Rigid Polyurethane Foam for Use as

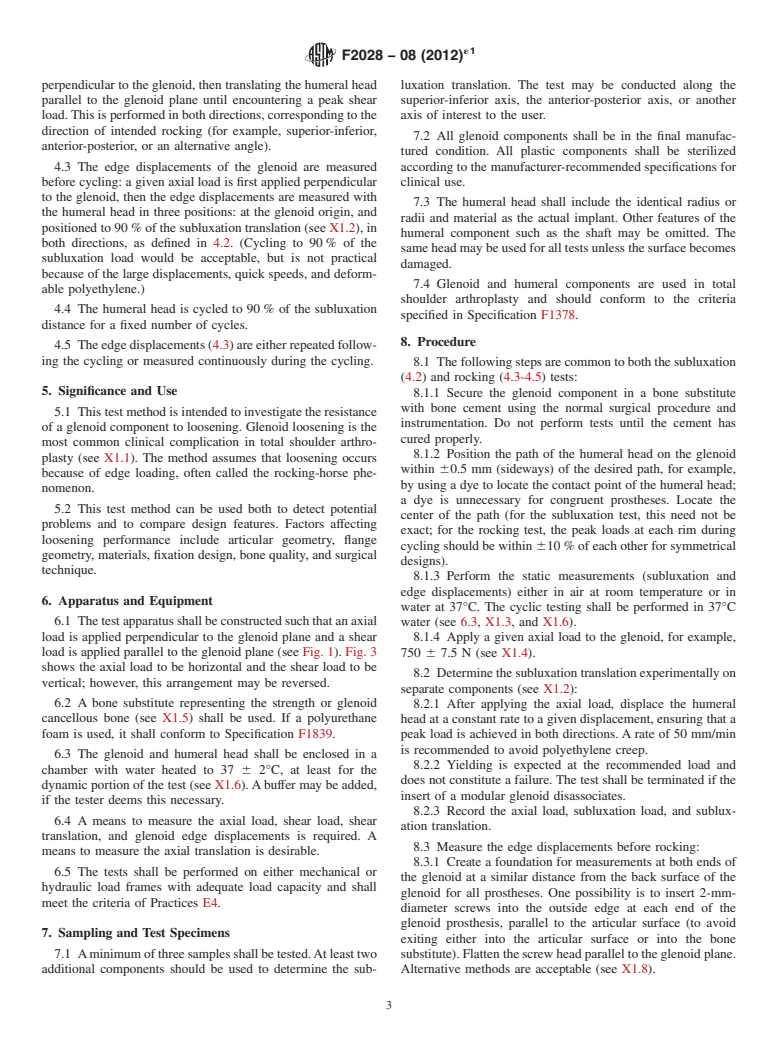

3.1.7 subluxation translation—thedistancefromtheglenoid

a Standard Material for Testing Orthopaedic Devices and

origin (see Fig. 2), parallel to the glenoid plane, to the point at

Instruments

which the subluxation load occurs.

3.1.8 superior/inferior (SI)—the SI axis is the longest di-

These test methods are under the jurisdiction of ASTM Committee F04 on

mension of the glenoid (see Fig. 2).

Medical and Surgical Materials and Devices and are the direct responsibility of

Subcommittee F04.22 on Arthroplasty.

3.1.9 anterior/posterior (AP)—the AP axis the widest di-

Current edition approved Dec. 15, 2012. Published January 2013. Originally

mension of the glenoid (see Fig. 2).

approved in 2000. Last previous edition approved in 2008 as F2028 – 08. DOI:

10.1520/F2028-08R12E01.

3.1.10 edge displacements—the translation, perpendicular

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to the glenoid plane, of a specific point on the outside edge of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the glenoid, when subjected to loading (see Fig. 3).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2028 − 08 (2012)

FIG. 1 Glenoid Plane and Load Directions

FIG. 2 Glenoid Axes and Origin

FIG. 3 Biaxial Testing Apparatus

GLENOID LOOSENING TEST METHOD

4. Summary of Test Method

4.1 The prosthetic glenoid component is fixed with bone 4.2 The subluxation translation is determined experimen-

cement into a bone substitute using the normal surgical tally on additional components. This is accomplished, using a

technique. biaxial apparatus (see Fig. 3) by applying an axial load

´1

F2028 − 08 (2012)

perpendicular to the glenoid, then translating the humeral head luxation translation. The test may be conducted along the

parallel to the glenoid plane until encountering a peak shear superior-inferior axis, the anterior-posterior axis, or another

load.This is performed in both directions, corresponding to the axis of interest to the user.

direction of intended rocking (for example, superior-inferior,

7.2 All glenoid components shall be in the final manufac-

anterior-posterior, or an alternative angle).

tured condition. All plastic components shall be sterilized

4.3 The edge displacements of the glenoid are measured according to the manufacturer-recommended specifications for

before cycling: a given axial load is first applied perpendicular clinical use.

to the glenoid, then the edge displacements are measured with

7.3 The humeral head shall include the identical radius or

the humeral head in three positions: at the glenoid origin, and

radii and material as the actual implant. Other features of the

positioned to 90 % of the subluxation translation (see X1.2), in

humeral component such as the shaft may be omitted. The

both directions, as defined in 4.2. (Cycling to 90 % of the

same head may be used for all tests unless the surface becomes

subluxation load would be acceptable, but is not practical

damaged.

because of the large displacements, quick speeds, and deform-

7.4 Glenoid and humeral components are used in total

able polyethylene.)

shoulder arthroplasty and should conform to the criteria

4.4 The humeral head is cycled to 90 % of the subluxation

specified in Specification F1378.

distance for a fixed number of cycles.

8. Procedure

4.5 Theedgedisplacements(4.3)areeitherrepeatedfollow-

ing the cycling or measured continuously during the cycling.

8.1 Thefollowingstepsarecommontoboththesubluxation

(4.2) and rocking (4.3-4.5) tests:

5. Significance and Use

8.1.1 Secure the glenoid component in a bone substitute

with bone cement using the normal surgical procedure and

5.1 This test method is intended to investigate the resistance

instrumentation. Do not perform tests until the cement has

of a glenoid component to loosening. Glenoid loosening is the

cured properly.

most common clinical complication in total shoulder arthro-

8.1.2 Position the path of the humeral head on the glenoid

plasty (see X1.1). The method assumes that loosening occurs

within 60.5 mm (sideways) of the desired path, for example,

because of edge loading, often called the rocking-horse phe-

by using a dye to locate the contact point of the humeral head;

nomenon.

a dye is unnecessary for congruent prostheses. Locate the

5.2 This test method can be used both to detect potential

center of the path (for the subluxation test, this need not be

problems and to compare design features. Factors affecting

exact; for the rocking test, the peak loads at each rim during

loosening performance include articular geometry, flange

cycling should be within 610 % of each other for symmetrical

geometry, materials, fixation design, bone quality, and surgical

designs).

technique.

8.1.3 Perform the static measurements (subluxation and

edge displacements) either in air at room temperature or in

6. Apparatus and Equipment

water at 37°C. The cyclic testing shall be performed in 37°C

6.1 Thetestapparatusshallbeconstructedsuchthatanaxial

water (see 6.3, X1.3, and X1.6).

load is applied perpendicular to the glenoid plane and a shear 8.1.4 Apply a given axial load to the glenoid, for example,

load is applied parallel to the glenoid plane (see Fig. 1). Fig. 3

750 6 7.5 N (see X1.4).

shows the axial load to be horizontal and the shear load to be

8.2 Determinethesubluxationtranslationexperimentallyon

vertical; however, this arrangement may be reversed.

separate components (see X1.2):

6.2 A bone substitute representing the strength or glenoid

8.2.1 After applying the axial load, displace the humeral

cancellous bone (see X1.5) shall be used. If a polyurethane head at a constant rate to a given displacement, ensuring that a

foam is used, it shall conform to Specification F1839.

peak load is achieved in both directions. A rate of 50 mm/min

is recommended to avoid polyethylene creep.

6.3 The glenoid and humeral head shall be enclosed in a

8.2.2 Yielding is expected at the recommended load and

chamber with water heated to 37 6 2°C, at least for the

does not constitute a failure. The test shall be terminated if the

dynamic portion of the test (see X1.6).Abuffer may be added,

insert of a modular glenoid disassociates.

if the tester deems this necessary.

8.2.3 Record the axial load, subluxation load, and sublux-

6.4 A means to measure the axial load, shear load, shear

ation translation.

translation, and glenoid edge displacements is required. A

8.3 Measure the edge displacements before rocking:

means to measure the axial translation is desirable.

8.3.1 Create a foundation for measurements at both ends of

6.5 The tests shall be performed on either mechanical or

the glenoid at a similar distance from the back surface of the

hydraulic load frames with adequate load capacity and shall

glenoid for all prostheses. One possibility is to insert 2-mm-

meet the criteria of Practices E4.

diameter screws into the outside edge at each end of the

glenoid prosthesis, parallel to the articular surface (to avoid

7. Sampling and Test Specimens

exiting either into the articular surface or into the bone

7.1 Aminimumofthreesamplesshallbetested.Atleasttwo substitute).Flattenthescrewheadparalleltotheglenoidplane.

additional components should be used to determine the sub- Alternative methods are acceptable (see X1.8).

´1

F2028 − 08 (2012)

8.3.2 Rest a displacement measuring device, for example, test termination. Testing parameters that differ from those

linear variable differential transformer (LVDT), differential recommended shall be justified.

variable reluctance transducer (DVRT), or dial gauge, on each 9.1.5 Displacement Test—The edge displacements before

foundation to measure the displacements perpendicular to the andfollowingcycling,highlightingthetensiledisplacementon

glenoid plane (see X1.8). Continuous measurement is theunloadedsidefollowingrocking(forexample,thedisplace-

desirable, but measurement at the beginning and end of the ment opposite the loaded side minus the value with the head at

rocking is sufficient. the glenoid origin).

8.3.3 Condition the prosthesis/bone substitute system, for 9.1.6 If the amplitude of the axial translation decreases

example, for ten cycles at 0.25 Hz. suddenly during the test (indicating a tilt of the glenoid and the

8.3.4 Measure the edge displacements with the humeral probable onset of loosening), the number of cycles at which

head located at the glenoid origin (see Fig. 2). this occurred should be recorded.

8.3.5 Translate the humeral head parallel to the glenoid

10. Precision and Bias

plane to 90 % of the subluxation translation determined previ-

ously (8.2) in one direction. Measure both edge displacements. 10.1 Precision—The precision of this test method was

8.3.6 Translate the humeral head to 90 % of the subluxation established by an interlaboratory comparison among four

translation in the opposite direction and measure both edge

laboratories, with each laboratory testing three specimens. The

displacements. specimens tested were commercially available UHMWPE

8.3.7 Repeat the three readings at least once to ensure

glenoid components and cobalt chrome humeral heads. The

repeatability. population mean micromotion before and after testing was 368

6 330 µm and 496 6 275 µm, respectively. Each laboratory

8.4 Cyclically translate the humeral head to 90 % of the

utilized different methods for measuring the edge

subluxation translation to cause a rocking motion of the

displacements, and one laboratory performed the test using a

glenoid at a given frequency (for example, 2 Hz as a result of

lubricantatthecontactsurfaceinsteadofperformingthetestin

the large translations, or up to a maximum of 6 Hz) to a

solution (see X1.8).

maximumnumberofcycles(forexample,100 000)(seeX1.7).

10.1.1 Repeatability—For replicate results obtained by the

Maintain the axial load and specified displacement.

same laboratory on nominally identical test specimens, the

8.5 Terminate the test when either the maximum number of

repeatability standard deviation (s ) was 72.3 µm before testing

r

cycles has been reached or a modular glenoid insert disasso-

and 268.0 µm after testing. All laboratories were within the

ciates.

critical k values for the before and after testing condition.

8.6 Repeat the glenoid edge displacement measurements 10.1.2 Reproducibility—For replicate results obtained by

(8.3) if measurements were not taken continuously. the same laboratory on nominally identical test specimens, the

reproducibility standard deviation (s ) was 335.9 µm before

R

8.7 Testing may be continued to a higher number of cycles

testingand359.4µmaftertesting.Onelaboratoryexceededthe

if desired.

critical h value for the before testing condition (h=1.50 vs.

9. Report h =1.49).Alllaboratorieswerewithinthecritical hvaluesfor

crit

the after testing condition.

9.1 The test report shall include the following:

9.1.1 All details relevant to the particular implants tested 10.2 The above round robin data represent initial efforts at

establishing a precision and bias statement for this test method

including type, size, and lot number as well as the glenoid

radius, humeral head radius or radii, and the prosthesis and have been published before documentation of full lab

participation has been completed (4 out of 6). Additionally,

material.

9.1.2 Theaxisanddirectionoftesting(forexample,central- some labs experienced difficulty with measurement of micro-

motion resulting in test metho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.