ASTM D7249/D7249M-06

(Test Method)Standard Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure

Standard Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure

SCOPE

1.1 This test method covers determination of facing properties of flat sandwich constructions subjected to flexure in such a manner that the applied moments produce curvature of the sandwich facing planes and result in compressive and tensile forces in the facings. Permissible core material forms include those with continuous bonding surfaces (such as balsa wood and foams) as well as those with discontinuous bonding surfaces (such as honeycomb).

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1 - Alternate procedures for determining the compressive strength of unidirectional polymer matrix composites materials in a sandwich beam configuration may be found in Test Method D 5467.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7249/D7249M − 06

StandardTest Method for

Facing Properties of Sandwich Constructions by Long

Beam Flexure

This standard is issued under the fixed designation D7249/D7249M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope erties and Equilibrium Conditioning of Polymer Matrix

Composite Materials

1.1 This test method covers determination of facing prop-

D5467/D5467MTest Method for Compressive Properties of

erties of flat sandwich constructions subjected to flexure in

Unidirectional Polymer Matrix Composite Materials Us-

such a manner that the applied moments produce curvature of

ing a Sandwich Beam

the sandwich facing planes and result in compressive and

D7250/D7250MPractice for Determining Sandwich Beam

tensile forces in the facings. Permissible core material forms

Flexural and Shear Stiffness

include those with continuous bonding surfaces (such as balsa

E6Terminology Relating to Methods of Mechanical Testing

wood and foams) as well as those with discontinuous bonding

E122PracticeforCalculatingSampleSizetoEstimate,With

surfaces (such as honeycomb).

Specified Precision, the Average for a Characteristic of a

1.2 The values stated in either SI units or inch-pound units

Lot or Process

are to be regarded separately as standard. Within the text the

E177Practice for Use of the Terms Precision and Bias in

inch-pound units are shown in brackets. The values stated in

ASTM Test Methods

each system are not exact equivalents; therefore, each system

E251Test Methods for Performance Characteristics of Me-

must be used independently of the other. Combining values

tallic Bonded Resistance Strain Gauges

from the two systems may result in nonconformance with the

E456Terminology Relating to Quality and Statistics

standard.

E1309 Guide for Identification of Fiber-Reinforced

1.3 This standard does not purport to address all of the Polymer-Matrix Composite Materials in Databases

safety concerns, if any, associated with its use. It is the

E1434Guide for Recording Mechanical Test Data of Fiber-

responsibility of the user of this standard to establish appro- Reinforced Composite Materials in Databases

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions—Terminology D3878 defines terms relating

NOTE 1—Alternate procedures for determining the compressive

to high-modulus fibers and their composites. Terminology

strength of unidirectional polymer matrix composites materials in a

sandwich beam configuration may be found in Test Method D5467/ C274 defines terms relating to structural sandwich construc-

D5467M.

tions. Terminology C393 defines terms relating to plastics.

Terminology E6 defines terms relating to mechanical testing.

2. Referenced Documents

Terminology E456 and Practice E177 define terms relating to

2.1 ASTM Standards:

statistics.Intheeventofaconflictbetweenterms,Terminology

C274Terminology of Structural Sandwich Constructions

D3878 shall have precedence over the other terminologies.

C393Test Method for Flexural Properties of Sandwich

3.2 Symbols:

Constructions

D3878Terminology for Composite Materials

b = specimen width

D5229/D5229MTestMethodforMoistureAbsorptionProp-

c = core thickness

CV = coefficient of variation statistic of a sample popu-

lation for a given property (in percent)

This test method is under the jurisdiction of ASTM Committee D30 on

d = sandwich total thickness

Composite Materials and is the direct responsibility of Subcommittee D30.09 on F,nom

D = effective sandwich flexural stiffness

Sandwich Construction.

f

E = effective facing chord modulus

Current edition approved Sept. 1, 2006. Published October 2006. DOI: 10.1520/

ε = measuring strain in facing

D7249_D7249M-06.

u

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F = facing ultimate strength (tensile or compressive)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

F = core shear allowable strength

s

Standards volume information, refer to the standard’s Document Summary page on

F = core compression allowable strength

c

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7249/D7249M − 06

5.5 Factors that influence the facing strength and shall

k = core shear strength factor to ensure facing failure

therefore be reported include the following: facing material,

l = length of loading span

core material, adhesive material, methods of material

L = length of support span

l = length of loading pad fabrication, facing stacking sequence and overall thickness,

pad

n = number of specimens

core geometry (cell size), core density, adhesive thickness,

P = applied force

specimen geometry, specimen preparation, specimen

P = maximum force carried by test specimen before

max conditioning, environment of testing, specimen alignment,

failure

loading procedure, speed of testing, facing void content,

S = standard deviation statistic of a sample population

n–1

adhesive void content, and facing volume percent reinforce-

for a given property

ment. Further, facing strength may be different between

σ = facing stress

precured/bonded and co-cured facesheets of the same material.

t = facing thickness

NOTE 2—Concentrated forces on beams with thin facings and low

x = test result for an individual specimen from the

density cores can produce results that are difficult to interpret, especially

sample population for a given property

close to the failure point. Wider loading blocks and rubber pressure pads

x¯ = mean or average (estimate of mean) of a sample

may assist in distributing the forces.

population for a given property

NOTE 3—To ensure that simple sandwich beam theory is valid, a good

rule of thumb for the four-point bending test is the span length divided by

the sandwich thickness should be greater than 20 (L/d > 20) with the ratio

4. Summary of Test Method

of facing thickness to core thickness less than 0.1 (t/c < 0.1).

4.1 This test method consists of subjecting a long beam of

sandwich construction to a bending moment normal to the

6. Interferences

plane of the sandwich, using a 4-point loading fixture. Deflec-

6.1 Material and Specimen Preparation—Poormaterialfab-

tion and strain versus force measurements are recorded.

rication practices and damage induced by improper specimen

4.2 The only acceptable failure modes for sandwich

machiningareknowncausesofhighdatascatterincomposites

facesheet strength are those which are internal to one of the

and sandwich structures in general. A specific material factor

facesheets. Failure of the sandwich core or the core-to-

that affects sandwich cores is variability in core density.

facesheetbondprecedingfailureofoneofthefacesheetsisnot

Important aspects of sandwich core specimen preparation that

an acceptable failure mode. Careful post-test inspection of the

contribute to data scatter include the existence of joints, voids

specimenisrequiredasfacingfailureoccurringinproximityto

or other core discontinuities, out-of-plane curvature, and sur-

the loading points can be caused by local through-thickness

face roughness.

compressionorshearfailureofthecorethatprecedesfailureof

6.2 Geometry—Specific geometric factors that affect sand-

the facing.

wich facing strength include facing thickness, core cell

geometry, and facing surface flatness (toolside or bagside

5. Significance and Use

surface in compression).

5.1 Flexure tests on flat sandwich construction may be

6.3 Environment—Resultsareaffectedbytheenvironmental

conductedtodeterminethesandwichflexuralstiffness,thecore

conditions under which specimens are conditioned, as well as

shear strength, and shear modulus, or the facings’compressive

the conditions under which the tests are conducted. Specimens

and tensile strengths.Tests to evaluate core shear strength may

tested in various environments can exhibit significant differ-

also be used to evaluate core-to-facing bonds.

ences in both strength behavior and failure mode. Critical

5.2 This test method is limited to obtaining the strength and

environmentsmustbeassessedindependentlyforeachspecific

stiffness of the sandwich panel facings, and to obtaining

combination of core material, facing material, and core-to-

load-deflection data for use in calculating sandwich beam

facing interfacial adhesive (if used) that is tested.

flexural and shear stiffness using Standard Practice D7250/

6.4 Core Material—If the core material has insufficient

D7250M. Due to the curvature of the flexural test specimen

shear or compressive strength, it is possible that the core may

when loaded, facesheet compression strength from this test

locally crush at or near the loading points thereby resulting in

maynotbeequivalenttothefacesheetcompressionstrengthof

facesheet failure due to local stresses. In other cases, facing

sandwich structures subjected to pure edgewise (in-plane)

failurecancauselocalcorecrushing.Whenthereisbothfacing

compression.

and core failure in the vicinity of one of the loading points it

5.3 Core shear strength and shear modulus are best deter-

can be difficult to determine the failure sequence in a post-

mined in accordance with Test Method C273 provided bare mortem inspection of the specimen as the failed specimens

core material is available.Test Method C393 may also be used

look very similar for both sequences.

to determine core shear strength. Standard Practice D7250/

D7250M may be used to calculate the flexural and shear

7. Apparatus

stiffness of sandwich beams.

7.1 Micrometers and Calipers—A micrometer having a flat

5.4 This test method can be used to produce facing strength anvil interface, or a caliper of suitable size, shall be used. The

data for structural design allowables, material specifications, instrument(s) shall have an accuracy of 625 mm [60.001 in.]

andresearchanddevelopmentapplications;itmayalsobeused for thickness measurement, and an accuracy of 6250 mm

as a quality control test for bonded sandwich panels. [60.010 in.] for length and width measurement.

D7249/D7249M − 06

NOTE 4—The accuracies given above are based on achieving measure-

ments that are within 1% of the sample length, width and thickness.

7.2 Loading Fixtures

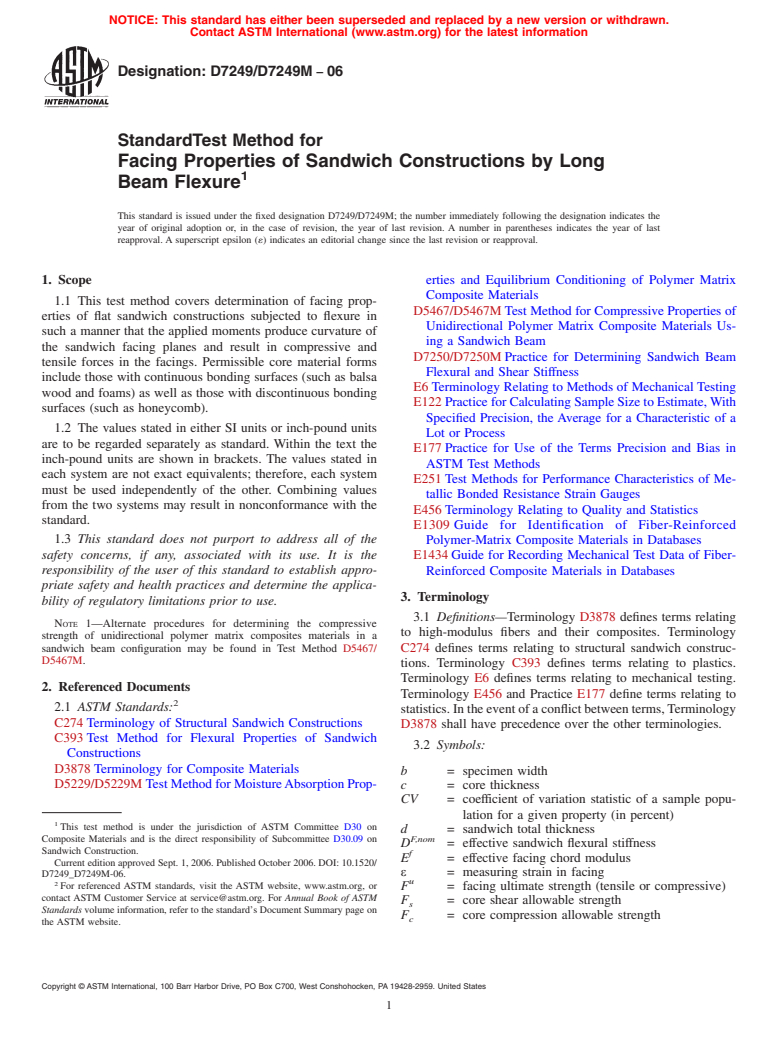

7.2.1 Standard Configuration—The standard loading fixture

shall consist of a 4-point loading configuration with two

support bars that span the specimen width located below the

specimen, and two loading bars that span the specimen width

located on the top of the specimen (Fig. 1), The force shall be

applied vertically through the loading bars, with the support

bars fixed in place in the test machine. The standard loading

fixture shall have the centerlines of the support bars separated

Configuration Support Span (S) Load Span (L)

by a distance of 560 mm [22.0 in.] and the centerlines of the

Standard 4-Point 560 mm [22.0 in.] 100 mm [4.0 in.]

loading bars separated by a distance of 100 mm [4.0 in.].

Non-Standard 3-Point (Mid- S 0.0

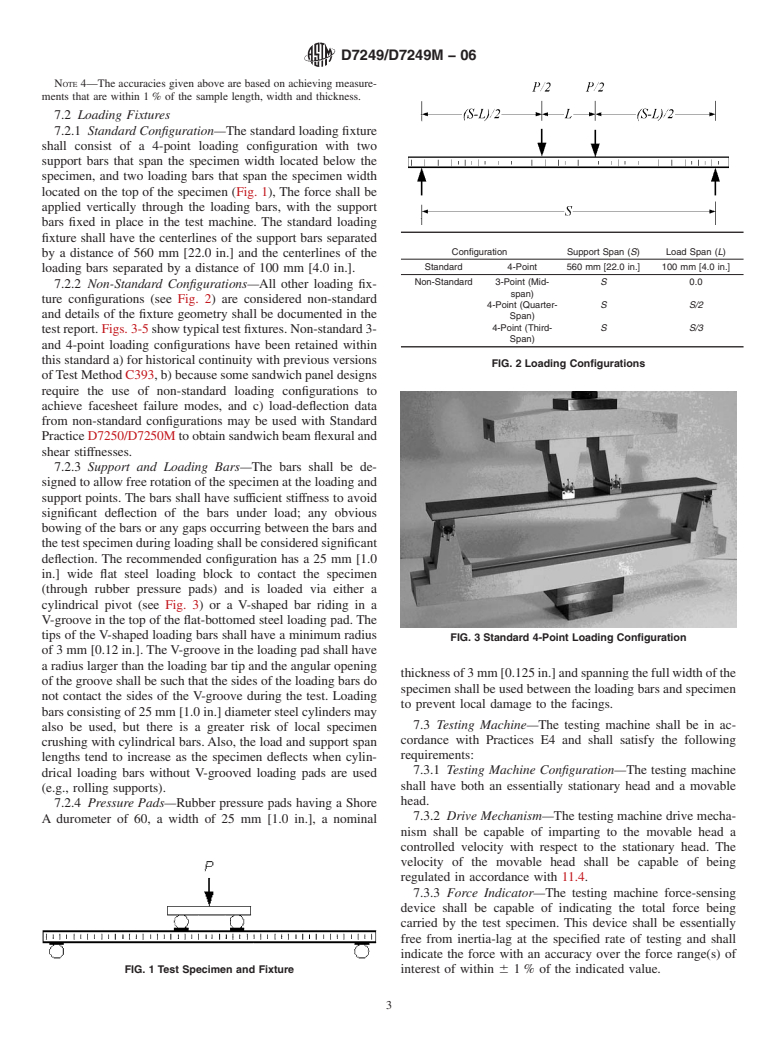

7.2.2 Non-Standard Configurations—All other loading fix-

span)

ture configurations (see Fig. 2) are considered non-standard

4-Point (Quarter-SS/2

and details of the fixture geometry shall be documented in the

Span)

4-Point (Third- SS/3

testreport.Figs.3-5showtypicaltestfixtures.Non-standard3-

Span)

and 4-point loading configurations have been retained within

this standard a) for historical continuity with previous versions

FIG. 2 Loading Configurations

ofTestMethodC393,b)becausesomesandwichpaneldesigns

require the use of non-standard loading configurations to

achieve facesheet failure modes, and c) load-deflection data

from non-standard configurations may be used with Standard

PracticeD7250/D7250Mtoobtainsandwichbeamflexuraland

shear stiffnesses.

7.2.3 Support and Loading Bars—The bars shall be de-

signedtoallowfreerotationofthespecimenattheloadingand

support points. The bars shall have sufficient stiffness to avoid

significant deflection of the bars under load; any obvious

bowing of the bars or any gaps occurring between the bars and

thetestspecimenduringloadingshallbeconsideredsignificant

deflection. The recommended configuration has a 25 mm [1.0

in.] wide flat steel loading block to contact the specimen

(through rubber pressure pads) and is loaded via either a

cylindrical pivot (see Fig. 3) or a V-shaped bar riding in a

V-groove in the top of the flat-bottomed steel loading pad.The

tips of the V-shaped loading bars shall have a minimum radius

FIG. 3 Standard 4-Point Loading Configuration

of 3 mm [0.12 in.].TheV-groove in the loading pad shall have

a radius larger than the loading bar tip and the angular opening

thicknessof3mm[0.125in.]andspanningthefullwidthofthe

ofthegrooveshallbesuchthatthesidesoftheloadingbarsdo

specimen shall be used between the loading bars and specimen

not contact the sides of the V-groove during the test. Loading

to prevent local damage to the facings.

barsconsistingof25mm[1.0in.]diametersteelcylindersmay

7.3 Testing Machine—The testing machine shall be in ac-

also be used, but there is a greater risk of local specimen

cordance with Practices E4 and shall satisfy the following

crushing with cylindrical bars.Also, the load and support span

requirements:

lengths tend to increase as the specimen deflects when cylin-

7.3.1 Testing Machine Configuration—The testing machine

drical loading bars without V-grooved loading pads are used

shall have both an essentially stationary head and a movable

(e.g., rolling supports).

head.

7.2.4 Pressure Pads—Rubber pressure pads having a Shore

7.3.2 Drive Mechanism—The testing machine drive mecha-

A durometer of 60, a width of 25 mm [1.0 in.], a nominal

nism shall be capable of imparting to the movable head a

controlled velocity with respect to the stationary head. The

velocity of the movable head shall be capable of being

regulated in accordance with 11.4.

7.3.3 Force Indicator—The testing machine force-sensing

device shall be capable of indicating the total force being

carried by the test specimen. This device shall be essentially

free from inertia-lag at the specified rate of testing and shall

indicate the force with an accuracy over the force range(s) of

FIG. 1 Test Specimen and Fixture interest of within 6 1% of the indicated value.

D7249/D7249M − 06

standard practices for strain gage installation surface prepara-

tion of fiber-reinforced composite materials.

7.5.1.2 Consideration should be given to the selection of

gageshavinglargerresistancestoreduceheatingeffectsonlow

c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.