ASTM D350-08

(Test Method)Standard Test Methods for Flexible Treated Sleeving Used for Electrical Insulation

Standard Test Methods for Flexible Treated Sleeving Used for Electrical Insulation

SIGNIFICANCE AND USE

The dielectric breakdown voltage of the sleeving is of importance as a measure of its ability to withstand electrical stress without failure. This value does not correspond to the dielectric breakdown voltage expected in service, but is of value in comparing different materials or different lots, in controlling manufacturing processes or, when coupled with experience, for a limited degree of design work. The comparison of dielectric breakdown voltage of the same sleeving before and after environmental conditioning (moisture, heat, and the like) gives a measure of its ability to resist these effects. For a more detailed discussion, refer to Test Method D 149.

SCOPE

1.1 These test methods cover procedures for testing electrical insulating sleeving comprising a flexible tubular product made from a woven textile fibre base, such as cotton, rayon, nylon, or glass, thereafter impregnated, or coated, or impregnated and coated, with a suitable dielectric material.

1.2 The procedures appear in the following sections:

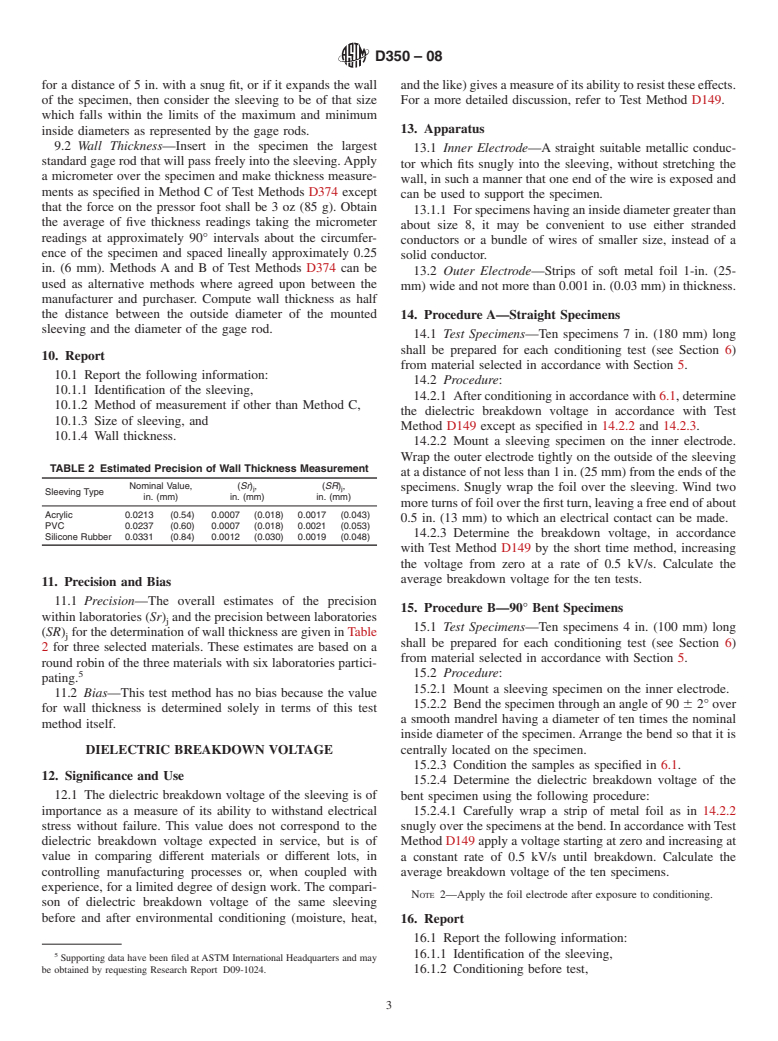

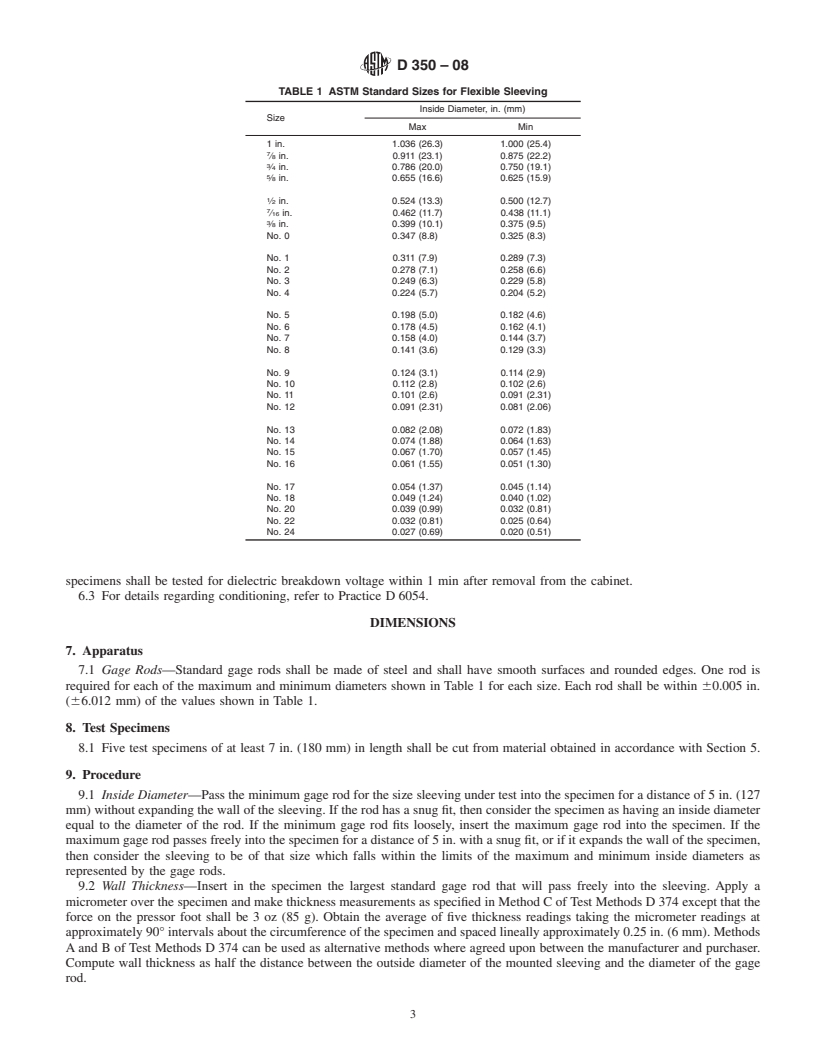

ProceduresSections Brittleness Temperature18 to 21 Compatibility of Sleeving with Magnet Wire Insulation45 to 59 Conditioning 6 Dielectric Breakdown Voltage12 to 17 Dielectric Breakdown Voltage After Short-Time Aging29 to 33 Dimensions 7 to 11 Effect of Push-Back After Heat Aging73 to 78 Flammability22 to 28 Hydrolytic Stability66 to 72 Oil Resistance34 to 37 Selection of Test Material5 Solvent Resistance60 to 65 Thermal Endurance38 to 44

1.3 The values stated in inch-pound units, except for °C, are to be regarded as the standard. The values in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This is a fire-test-response standard. See Sections 22 through 28, which are the procedures for flammability tests.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 45.2 and 63.1.1.

Note 1—This standard resembles IEC 60684-2, Specification for Flexible Insulating Sleeving—Part 2 Methods of Test, in a number of ways, but is not consistently similar throughout. The data obtained using either standard may not be technically equivalent.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D350–08

Standard Test Methods for

1

Flexible Treated Sleeving Used for Electrical Insulation

This standard is issued under the fixed designation D350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

1.1 These test methods cover procedures for testing electri-

statements, see 45.2 and 63.1.1.

cal insulating sleeving comprising a flexible tubular product

made from a woven textile fibre base, such as cotton, rayon,

NOTE 1—This standard resembles IEC 60684-2, Specification for Flex-

nylon, or glass, thereafter impregnated, or coated, or impreg- ible Insulating Sleeving—Part 2 Methods of Test, in a number of ways,

but is not consistently similar throughout. The data obtained using either

nated and coated, with a suitable dielectric material.

standard may not be technically equivalent.

1.2 The procedures appear in the following sections:

Procedures Sections

2. Referenced Documents

2

Brittleness Temperature 18 to 21

2.1 ASTM Standards:

Compatibility of Sleeving with Magnet Wire Insulation 45 to 59

D149 Test Method for Dielectric Breakdown Voltage and

Conditioning 6

Dielectric Strength of Solid Electrical Insulating Materials

Dielectric Breakdown Voltage 12 to 17

Dielectric Breakdown Voltage After Short-Time Aging 29 to 33

at Commercial Power Frequencies

Dimensions 7 to 11

D374 Test Methods for Thickness of Solid Electrical Insu-

Effect of Push-Back After Heat Aging 73 to 78

lation

Flammability 22 to 28

Hydrolytic Stability 66 to 72

D471 Test Method for Rubber Property—Effect of Liquids

Oil Resistance 34 to 37

D746 Test Method for Brittleness Temperature of Plastics

Selection of Test Material 5

and Elastomers by Impact

Solvent Resistance 60 to 65

Thermal Endurance 38 to 44

D876 Test Methods for Nonrigid Vinyl Chloride Polymer

Tubing Used for Electrical Insulation

1.3 The values stated in inch-pound units, except for °C, are

D1711 Terminology Relating to Electrical Insulation

to be regarded as the standard. The values in parentheses are

D2307 Test Method for Thermal Endurance of Film-

mathematical conversions to SI units that are provided for

Insulated Round Magnet Wire

information only and are not considered standard.

D3487 Specification for Mineral Insulating Oil Used in

1.4 This is a fire-test-response standard. See Sections 22

Electrical Apparatus

through 28, which are the procedures for flammability tests.

D3636 Practice for Sampling and Judging Quality of Solid

1.5 This standard measures and describes the response of

Electrical Insulating Materials

materials, products, or assemblies to heat and flame under

D5423 Specification for Forced-Convection Laboratory

controlled conditions, but does not by itself incorporate all

Ovens for Evaluation of Electrical Insulation

factors required for fire hazard or fire risk assessment of the

D6054 Practice for Conditioning Electrical Insulating Ma-

materials, products or assemblies under actual fire conditions.

terials for Testing

1.6 This standard does not purport to address all of the

E145 Specification for Gravity-Convection and Forced-

safety concerns, if any, associated with its use. It is the

Ventilation Ovens

responsibility of the user of this standard to establish appro-

E176 Terminology of Fire Standards

2.2 IEEE Standard:

1

These test methods are under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and are the direct responsibility of

2

Subcommittee D09.07 on Flexible and Rigid Insulating Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2008. Published June 2008. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1932. Last previous edition approved in 2001 as D350 – 01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0350-08. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D350–08

IEEE 101 Guide for the StatisticalAnalysis ofThermal Life 3.2.2 wall thickness, n—one half the difference between the

3

Test Data outside diameter of the sleeving mounted on a loosely fitting

2.3 IEC Standard: gage rod and the d

...

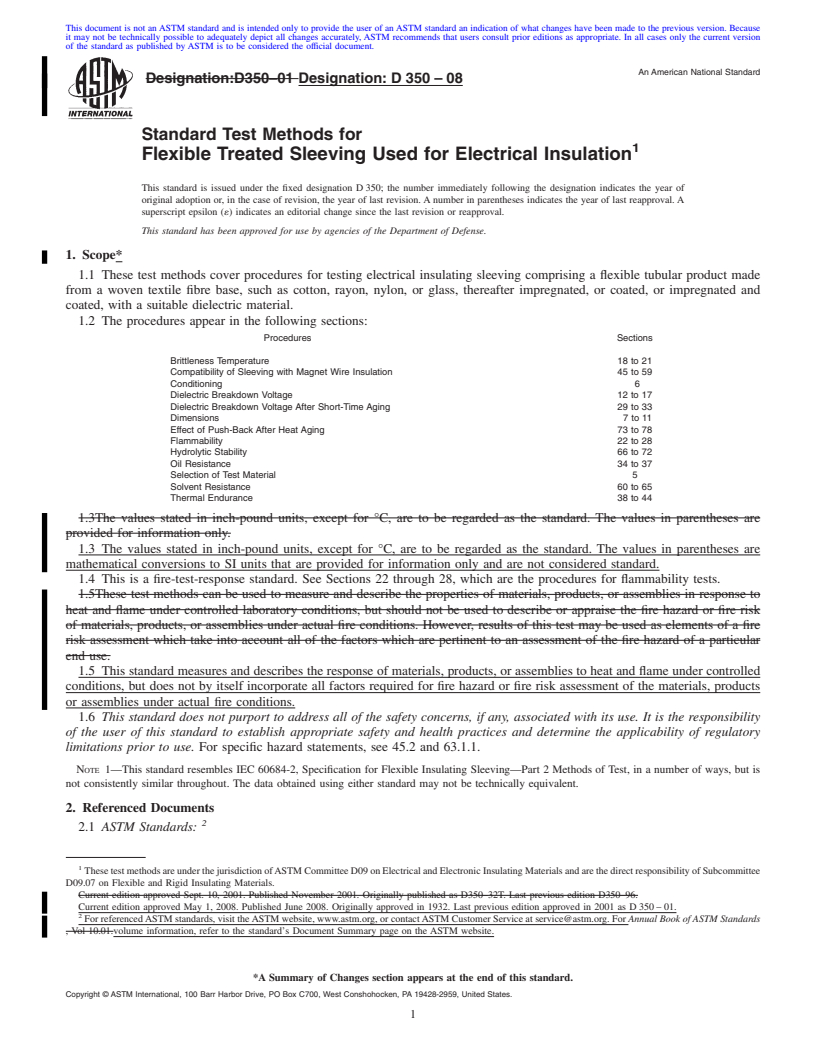

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D350–01 Designation:D350–08

Standard Test Methods for

1

Flexible Treated Sleeving Used for Electrical Insulation

This standard is issued under the fixed designation D 350; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 These test methods cover procedures for testing electrical insulating sleeving comprising a flexible tubular product made

from a woven textile fibre base, such as cotton, rayon, nylon, or glass, thereafter impregnated, or coated, or impregnated and

coated, with a suitable dielectric material.

1.2 The procedures appear in the following sections:

Procedures Sections

Brittleness Temperature 18 to 21

Compatibility of Sleeving with Magnet Wire Insulation 45 to 59

Conditioning 6

Dielectric Breakdown Voltage 12 to 17

Dielectric Breakdown Voltage After Short-Time Aging 29 to 33

Dimensions 7to11

Effect of Push-Back After Heat Aging 73 to 78

Flammability 22 to 28

Hydrolytic Stability 66 to 72

Oil Resistance 34 to 37

Selection of Test Material 5

Solvent Resistance 60 to 65

Thermal Endurance 38 to 44

1.3The values stated in inch-pound units, except for °C, are to be regarded as the standard. The values in parentheses are

provided for information only.

1.3 The values stated in inch-pound units, except for °C, are to be regarded as the standard. The values in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This is a fire-test-response standard. See Sections 22 through 28, which are the procedures for flammability tests.

1.5These test methods can be used to measure and describe the properties of materials, products, or assemblies in response to

heat and flame under controlled laboratory conditions, but should not be used to describe or appraise the fire hazard or fire risk

of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire

risk assessment which take into account all of the factors which are pertinent to an assessment of the fire hazard of a particular

end use.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled

conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products

or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see 45.2 and 63.1.1.

NOTE 1—This standard resembles IEC 60684-2, Specification for Flexible Insulating Sleeving—Part 2 Methods of Test, in a number of ways, but is

not consistently similar throughout. The data obtained using either standard may not be technically equivalent.

2. Referenced Documents

2

2.1 ASTM Standards:

1

ThesetestmethodsareunderthejurisdictionofASTMCommitteeD09onElectricalandElectronicInsulatingMaterialsandarethedirectresponsibilityofSubcommittee

D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved Sept. 10, 2001. Published November 2001. Originally published as D350–32T. Last previous edition D350–96.

Current edition approved May 1, 2008. Published June 2008. Originally approved in 1932. Last previous edition approved in 2001 as D 350 – 01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 10.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D350–08

D 149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D 374 Test Methods for Thickness of Solid Electrical Ins

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.